Document 197632

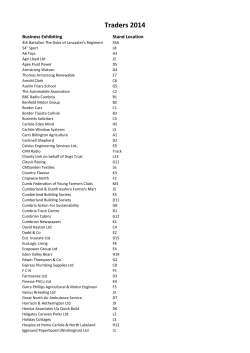

20 years on and still growing Benefit by Pre-Registration! Remember that by Pre-Registering for North West Manufacturing 2007 you’ll receive: I Your Entry Badge ten days ahead of the Show I A voucher to exchange for the Exhibition Catalogue (worth £5) I The ability to book seminar sessions – on-line, by post or by ‘phone I A copy of the preview magazine All in all, it means that you’ll arrive at the Show fully informed and will have hassle free entry through a special badge holders channel. And, don’t forget that parking at the easy to reach Reebok Stadium is absolutely free. Visit www.industry.co.uk/northwest now or complete the form below. How to get there Access to the Reebok Stadium couldn't be easier; it’s just 500 yards from Junction 6 of the M61. Once on-site, there is ample free parking for over 3,000 cars. From The North: Follow signs on the M61 towards Manchester/Bolton and leave at Junction 6. Take the first exit off sliproad roundabout onto the A6027 Mansell Way. From The South East or West: Join the M60 Manchester ring road then follow the signs for the M61, which is Junction 15 on the M60. Head north towards Preston (DO NOT TAKE THE A666 TOWARDS BOLTON). Turn off the M61 at Junction 6 and take the 3rd right exit from the sliproad onto the A6027 Mansell Way. This is a hectic year for Yamazaki Mazak, as June marks the 20th year of manufacturing machine tools in the UK. This will officially be celebrated by the opening of a new 4,000 m² extension, which brings the total up to 29,000 m². The new extension will house the fabrication shop, which will contain the most advanced laser cutting facilities ever seen in the UK. This features a sheetmetal robot load/unload system that incorporates 7,200 mini-vacuum manipulators. This eliminates the need for ‘nibs’ and finished parts can just be automatically lifted out. Currently machine output is running at well in excess of 1,200 machines a year and now there is capacity to significantly increase this. At the plant there is a Cyber production offices that oversees the three FMS systems that are at the heart of component manufacture. The plant is a showcase for the latest in production technology. Any visitor who wants to attend the “20th Anniversary Open Week” that starts Monday 18th June should log their interest on the stand. As part of the overall expansion plan, the Northern office of Yamazaki Mazak has just relocated to larger premises at Haydock. That’s why attending the show, in spite of all the current turmoil of activities, was considered important. It provides an ideal platform to meet senior engineers from potential customers in the region. At the show Mazak will be advocating the benefits of “One-hit” machining or “Done in One” as it prefers to call it. The Integrex, multi-function turning centre features twin 6,000 rev/min spindles combined with an upper rotary tool spindle incorporating an automatic tool changer. There is also a lower, nine station, drum turret to dramatically reduce cycle times. Originally such machines really only appealed to manufacturers of very complex parts. Today, things have changed. Many SME’s who produce more Creating the right image A label shouts about your company. But, is it saying the right thing? That's where a company like Diametric Technical comes in. It can advise on the right approach for your product taking into account all circumstances. Has anyone ever seen a hydraulic cylinder where the label starts slowly sliding south as soon as there's the slightest leak or spillage that causes the label adhesive to dissolve? That's not the image you want for your product. The company has the advantage in that it is not tied to any one label production process; seven different formats are available. When making recommendations, the company takes into account the environment, product life span, budget and product place in the market. After all you don't want a tuppence halfpenny label on a hundred thousand pound machine. available include Options electroformed labels. These are recommended for premium brands, which need an unobtrusive label, that still reflects precision imagery. As an alternative, Injection mouldings can achieve strong visual images with 3D effects. Domed labels can impart a 3D effect even on semi-rigid surfaces. Various print processes are also offered. Check this stand out to make sure your labels project the rightimagefor you. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 514 Assembly on a large scale devices predominate. Glass reinforced mouldings are an area of speciality as is insert moulding. USE THE COUPON BELOW TO... G G G Request information on any of the exhibitors featured in this Preview. Reserve seats on the Free Engineering Seminar Programmes, see page 3, (NB. whilst places are free, seats are allocated on a first- come, first-served basis, so you are advised to book early). Order extra tickets for your colleagues. Website Ticket Hotline Fax Postal Address FREEPOST SEA 0907 ETES Ltd 9-11 High Street, Staines Middlesex TW18 4BR Name:_________________________________________________________________________ Position:_______________________________________________________________________ As would be expected of a company located in the middle of the beautiful Pembroke National Park, it has the highest grade of environmental credentials. For bought in items, it uses its massive purchasing power to guarantee competitive prices. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 515 Second-op turning, with its associated manual loading, can often account for 7080% of the total production time and only add 20% to the component value. Factor in the additional time saved by incorporating third-op milling, then the economic justification for one-hit machining on even simpler work becomes overwhelming. This trend is only accelerated by subcontractors’ customers who, more and more, are demanding the tight, flexible delivery schedules that are made possible with one hit machining. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 513 Robot welding workholding New on the AMF stand will be the first workholding kit for robot welding, although the company has extensive experience in workholding applications for machining. The starter kit contains more than 1,250 system components. Water-cooling within the basic fixture ensure consistent quality during extended periods of use. Within the kit can be found different size clamps, location stops and the base, which has a 50 mm grid for fixture building. The kit comes on a convenient trolley and can be expanded with options such as pneumatic clamping For machining applications visitors will see the Zero Point positioning system. This enables pallets to be removed from the machine table and replaced to within 5 micron. The system has a number of applications. In the aerospace industry it permits components to be removed, without unclamping, from the fixture, moved to an inspection machine, then returned to the same datum for final machining. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 516 The common denominator is the strength Company:______________________________________________________________________ Address:_______________________________________________________________________ ______________________________________________________________________________ conversational programming control system. All machines are fitted with this Hurco-developed control. ______________________________________________________________________________ Postcode : __________________________________________________________________ Tel: _____________________________________Fax: __________________________________ e-mail:_________________________________________________________________________ Website________________________________________________________________________ Please send Please reserve extra free tickets place(s) on Engineering Seminar Session/s , Please send additional information on the following Preview articles on exhibitors (enter the article ref No or session No. in the boxes) Fax to 01784 880892 Ê Ê www.industry.co.uk/northwest 01784 880890 01784 880892 Every week St David’s Assemblies manufacture over two and a half million components that are used to produce over half a million assemblies. It’s no surprise that with such volumes the automotive and domestic appliance markets feature heavily in its order book. Precision pressings plus injection mouldings are produced and high speed contact welding is a significant resource; this means that electro-mechanical Lean manufacturing techniques ensure globally competitive prices. Also, a totally inclusive service starts with concept design or optimising an existing design for the most economic production processes. Producing prototypes includes the design and manufacture of prototype tooling. Depending on production rates, manual or fully automated assembly is employed. prosaic parts have realised they too can reap the benefits. Hurco will be showing a CNC lathe and a machining centre from its extensive range. The common denominator linking the two machines is the great strength of the range. What’s that? It’s the It is ideally suited for one off’s and small batch production. Minimal training is needed for this ‘intuitive programming’ system. Many common features are shared between the turning and the milling versions. Programs can be generated at the machine or downloaded from a CAM system. If necessary, downloaded programs can be tweaked on the shopfloor then the modified version uploaded when the batch is completed. The vertical machining centre on show is the smallest in the range with 660mm of travel on the X-axis and a spindle speed of 8,000 rev/min. A high spindle speed version with speeds up to 30,000 rev/min is available specifically for machining graphite. Other models offer X-axis travel up to 1,625 mm. The CNC lathe has 305 mm turning diameter and length of 478 mm. The 14.2 kW motor provides a maximum spindle speed of 4,800 rev/min. There is a heavyduty lathe in the range with an 18.7 kW spindle motor. Fo r Fu r t h e r I n fo r m a t i o n e n t e r Note: all sessions may be subject to change without notice. The organisers accept no responsibility for the statements made in this preview, nor for any errors or omissions which may have occurred. 517 OFFICIAL 2007 SHOW PREVIEW NORTH WEST ENGINEERING EXCELLENCE! Premier Suite, Reebok Stadium, Bolton G 9-10 May G 9.00am – 4.30pm YOUR EVENT ON YOUR DOORSTEP Whether you’re in the plant, warehouse, workshop or boardroom you’ll find something at the North West Manufacturing Show for you. With over 150 companies expected to be there to greet you, the Exhibition is the region’s largest event dedicated to manufacturing. If your company is involved in design, production, subcontracting or distribution, a visit will transform your approach to innovation, production and supply chain management. As a means of evaluating and improving your manufacturing efficiency it’s second to none. Not only will you be able to see new products galore – with dozens in action – but you can also take in a whole host of topical, free to attend, Manufacturing Seminars presented by some of the leading names in the business. RKING A P E FRE ll visitors for a North West Manufacturing 2007 is packed full of exhibitors and features, is easy to reach and, best of all, whether you want to attend the Show, the seminars - or both – it’s completely Free of Charge! Read on to see how to register for your free ticket and for a glimpse of what’s on display from just a fraction of the companies taking stands. Secure Your Free Ticket Now See The Best In Machine Tools Factory & Process Automation Packaging & Handling Design & Rapid Prototyping Test & Measurement Labelling & Marking Electronics Fastenings Pressings & Mouldings Process Engineering ...and much more! See Who’s Here Over 150 exhibitors are due to make this year’s Exhibition the largest ever event in the North West. Turn to page 3 and you’ll find a listing of who’s due to be there and the vast range of products and services they will have on display. Some of the suppliers you may already know but there are bound to be dozens that perhaps you should know about. What’s certain is that, whatever you’re looking for, you’ll find it at North West Manufacturing 2007. Trail Not Trawl To make visiting easy for you we’ve created several Technology Supplier Trails – Autosport/ Automotive, Aerospace/Defence, Electronics and Processing. Identified in your Exhibition Catalogue (free as a pre-registered visitor) will be the exhibitors who have identified themselves as suppliers to these industries. To help you further these companies will also be carrying special logos on their stand name boards. Inside You’ll find The machine tool company that in 20 years has grown to become the UK’s largest manufacturer. Bolton company that achieves 25% year on year growth. A New approach to process heating that combines precise temperature control with energy saving performance With such a large event on offer it would be wise to plan your visit in advance. The exhibitor list on the centre pages of this preview will provide a taster of what’s on Show but, if you visit our web-site, you can find out much more about the companies involved – www.industry .co.uk/northwest. Finally, if you register for your Free Entry Badge now, you’ll receive a free Exhibition Catalogue (worth £5) on arrival. Fixture system that introduces modular building to robot welding. What you need to know about WEEE, CE marking, Lean Manufacturing, How to crack the MoD and much more Easy to Reach Plan Your Visit Now Video measuring system that’s accurate, simple to operate and doesn’t cost the earth Ever wished you could visit a major exhibition without having to take a whole day (or more) out? With North West Manufacturing 2007 you can! Its Reebok Stadium, Bolton location means that, by road, you are just 500 yards away from J.6 of the M61 and free parking is plentiful. And, if you arrive by train, the Stadium is just 400 yards away from Horwich Parkway. You’ll be back at home before you know it. (See back page). Tickets to visit North West Manufacturing 2007 (or to attend the concurrent seminars) are absolutely free so long as you are an Industry professional. If you pre-register now, there are extra benefits to be had. Not only will you be making sure that you avoid any queues at the entrance but you’ll also receive advance exhibition news, be able to book your place on seminar sessions and will be guaranteed a free copy of the Exhibition Catalogue (otherwise £5) on arrival. Simply complete the form on the back page or visit www.industry.co.uk/northwest. When doing so, remember to book tickets for your colleagues – with so much to do and see at the Show it may make sense! Learn from the Experts Want to learn more about Six Sigma, Lean Tools, Continuous Improvement, How to Succeed at Exporting or WEEE Legislation? Then book into one of the Exhibition’s FREE hour long seminar sessions because these subjects and many more will be covered over the two Show days. Turn to page 3 for the full list now and reserve your seat by visiting www.industry.co.uk/northwest or by completing the form on the back page. Remember, places are limited and allocated on a first come, first served basis – Act Now! Book your Free ticket on-line Now - www.industry.co.uk/northwest Wraps come off new low cost vision system A low cost two-axis video measuring machine will be making its debut on the Vision Engineering stand. One of its redeeming features is ease of operation using touch screen technology. This, coupled with a high degree of repeatability, ensures that consistent results can be obtained between different operators, even with minimal training. Its high performance is accounted for by the use of a dedicated Quadrachek 300 video microprocessor, which offers Video Edge Detection - VED – for high throughput of measurements. It is ideal for batch routines or measurement of form features. There is a unique contrast teach facility that enables the operator to easily determine the component edge. Also, the processor is capable of automated point data capture with full PC connectivity. The free moving table has a 150 by 100mm measuring area. Give it a try and see if it’s as easy as they say!! Fo r Fu r t h e r I n fo r m a t i o n e n t e r 500 Contract cleaning components Pumps, filters, valves, paint spray fixtures are just a few of the many components and assemblies that are cleaned by B & M Longworth Process Technology. In markets like the chemical process and polymer industries, where downtime can cost of the order £100,000 a day, replacement rather than refur-bishment used to be the order of the day. Environmental pressures are forcing companies to re-assess such policies, especially if they can be reassured that the cost benefits of refurbishment can be achieved without any adverse impact on performance. Refurbishment brings its own questions; what process to use, what cleaning agents and probably the biggest question of all what are the legislative disposal issues? These are all issues that Longworth has resolved. customers go the Many subcontract route because it gives them access to a wide range of different cleaning processes that would be difficult to justify installing. A 24 hour service is operated and there is lifting capacity up to 10 tonne. When the decision is to go the in-house route, a design and build service enables them to tap into the wealth of available experience. Fo r Fu r t h e r I n fo r m a t i o n e n t e r If you want it: it’s probably here 501 Over 65,000 different products are available from first-time exhibitor FWB Products, an industrial distributor that guarantees next day delivery throughout the North West. With such a stock range it’s difficult to know where to start. Tools, fasteners, pipeline products process controls, electrical products, heating and ventilation equipment, that’s just the start. Then there is the workwear, safety boots, fire safely equipment, well you get the picture. At the core of the product range are branded products from international suppliers such as Siemens, Dormer, 3M, Bosch and Mitutoyo. These are supported by technical back-up services, which includes sales engineers to make site visits. Orders may be placed over the internet and there is a trade counter for same day collection. 504 Fo r Fu r t h e r I n fo r m a t i o n e n te r Try before you buy Tooling for aerospace Materials such as composites, Kelvar, carbon fibre and graphite can be machined with a new series of two flute PCD end mills from Industrial Tooling Corporation (ITC). These feature a solid carbide shank with PCD brazed tips and a cutting length equal to the cutter diameter. The solid shank delivers maximum rigidity for cutting under difficult conditions. Ball nosed versions are also available. For machining aluminium at extremely high speeds and feeds, there is a two-flute solid carbide cutter with a 50º right hand helix. These can also be used for machining plastics and brass. To reduce machine noise, and hence improve surface finish, a four-flute cutter incorporates unequal flute spacing. This reduces the noise by eliminating the harmonic effects. The right hand helix provides excellent swarf removal from the cutting zone. Exploiting the latest in cutting tool technology is probably the most costeffective way of improving productivity. Often the tooling costs are similar and the only difference is the productivity. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 502 Catalogue offers nearly 70% more The choice of workstation and storage systems from Bott has always been extensive. Now it’s even more extensive. The latest catalogue for 2007 is nearly 70% bigger; for the first time it also includes all the product range from European sister companies in Germany and Hungary as well as the UK factory. New for 2007 are six-man workbenches. Modular design allows the layout to be optimised to suit the job in hand. There is a choice of accessories including shelving, tool storage, light assemblies and back panels & ducting with power sockets and PC stands. The benches can also be fitted with suspended cabinets that can be located anywhere along the bench. Also there is a “ Tool Store” system that uses dividers to create over 3m² of storage space. There are four extending slides, each having a 25kg capacity. Heavy duty versions of the Tool Store increase this figure to100kg. Visitors will also see a selection of louver panels, bin sets and mobile maintenance trolleys. The latter can accommodate a tool board, shelf kit and louver back panel. The modular design enables the company to offer a bespoke design service based on standards elements from the range Fo r Fu r t h e r I n fo r m a t i o n e n t e r 503 Precise temperature control for pipes All the benefits of a unique process heating system, already available for tanks and bulk storage, can now be applied to pipes with the introduction of pre-prepared pipe lengths by Inditherm. The heating technology is based on a carbon-filled polymer that can be used for temperatures up to 120º C. An electrical current, in the range 6 to 48V, is passed through the material and uniformly heats it. Temperature can be controlled to within ±1º C without localised hotspots. The material can be cut and joined to any shape. For the pipes, the heating polymer is fixed to the pipe work along with insulation and cladding. As this is carried out in a factory environment there is enhanced levels of quality control. In addition, on-site work and health and safety issues are minimised. The outer cladding has special features that ensure high levels of hygiene, important in food and pharmaceutical environments. Associated valves, pumps and metering equipment can all be fitted with jackets made from the original carbon-filled polymer. The pipes have already been fitted in several major confectionary plants; one installation involved 85m of pipework used to transport sweetener material. The system uses significantly less energy, which with the focus on environmental Other impact cannot be ignored. applications range from patient warming to under soil heating at football stadia and process heating to accelerated concrete curing, particularly in cold weather. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 506 Where there’s muck there’s brass Dust is something every one who lives the bachelor life understands: it’s everywhere!! Couple that with the sentiments of the headline and you get a feel for what Particle Technology does as a business. It makes and sells dust. Not just any dust, it offers nearly 40 different grades where the size of particles and the constituent mix are carefully controlled. Fatuous comments aside, it doesn’t take long to identify the serious value of such a service. Think Desert Storm and the problems of filter systems and tank engines immediately spring to mind. In fact the automotive and aerospace industries are two major market sectors. Using various types of mills, including hammer, ball and pin mills, together with multi-deck sieving systems, particle sizes from sub-micron to several millimetres can be produced. As with any test system, there has to be a valid method of measuring and comparing results. At the show a new development will be seen. This is a Component Part Cleanliness Verification device. It can be used in the validation of test results on a wide range of products including filters, engines, gearboxes and other machinery. Fo r Fu r t h e r I n fo r m a t i o n e n t e r 507 All the fun of the fair fun, the demonstration graphically illustrates another more serious benefit; the operator can position himself to best see what's going on rather than as dictated by the position of the control. Rösler manufactures a wide range of surface finishing and shot blasting systems. Also, it has extensive facilities for providing a subcontract service. Put these two together and it brings customers two significant advantages. First, the customer who is intent on making a purchase can carry out extensive trials before making a final decision. This means not just a few components, but several complete production batches to confirm beyond doubt that the required standards are being achieved. Secondly, those who want to limit capital investment can plug into the subcontract service on a permanent basis. The subcontract service includes full pre and post-process inspection. Also, the customer has full access to the in-house expertise. This includes fixturing and all the necessary masking and plugging that may be required prior to processing. One finishing process that appeals to the subcontract sector is superfinishing of engine components for Formula 1 racing teams1. Also all the health and safety issues, labour costs and disposal of used media are taken care of. In fact, the subcontracting looks quite an attractive proposition. Fo r Fu r t h e r I n fo r m a t i o n e n te r 505 Wireless means no cables. Cables mean dodgy joints and pinched cables or to put it another way, wireless means enhanced reliability. And, as Schmersal will be demonstrating, it also means all the fun of the fair. A wireless funfair crane on the stand will be picking up soft toys. As well as being wireless, you don't have to put any money in so you can have as many goes as you like. Apart from being a bit of The system meets the requirements of control category EN 9541. This means it can be used for safety stop controls on machinery and 3-phase enabling switches. When a machine is being upgraded or a new machine produced, there are cost savings to be made by eliminating cables and other mechanical transmission devices such as slip rings. Check it out you might win a bear!! Fo r Fu r t h e r I n fo r m a t i o n e n t e r 508 One-stop-shop fabricator As a subcontractor, Maledon Engineering has its roots in the manufacture of steel fabrications for the industrial battery market. To this end it has all the resources in-house starting from 3D CAD design to a range of metal finishing processes. To produce profile shapes from plate, there is high definition plasma cutting capability that can handle 4 by 2m plate up to 20mm thick. Larger plates up to 100mm thick can be cut with conventional plasma. Plates can be formed using roll formers and CNC press brakes. Coded welders are on hand for MIG and TIG welding of both mild steel and stainless steel. Not surprisingly with its battery industry background, finishing services that can be drawn on include shot blasting, corrosion resistant coatings and plastic lining as well as standard and textured finish conventional spraying. The company also offers a mobile, onsite welding service using its fully certified welding engineers. This means that the mobile units can undertake emergency safety critical repairs. The company is accredited to ISO 9001 quality standards Fo r Fu r t h e r I n fo r m a t i o n e n t e r 509 Keeping up to date is not an option For manufacturing industry, the pace of today’s fast-moving technology means that keeping up to date is not an option; it’s an absolute necessity. The best opportunity to do just that in 2007 is right on your own doorstep at the Technical Seminar that runs alongside the show. The seminar comprises 11 one hour long, individually bookable sessions. Topics are carefully selected to address the most pressing concerns that industry must focus on to achieve global competitiveness. They cover technical issues such as rapid prototyping. This technology is progressing in leaps and bounds. Where will it go in the future? Here’s a chance to find out. Other presentations cover legal obligations such as CE Marking and WEEE regulations, the latter cover amongst other things the disposal of electronic products. These regulations are no longer in the future. They are operative here and now. Get it wrong and you could be facing punitive fines. Yet other presentations concentrate on improving performance in the marketplace. For example, would you like to identify new export markets? Or, how would you like to grab a share of a £15 billion, yes billion, market in the UK? This is the MoD. It’s not all Eurofighter and Trident. The MoD buys machine tools, fencing, packaging, logistics, even dog kennels. The secret is, knowing what’s wanted and where it’s wanted. Anyone can find out at the seminar session. Looking to improve productivity? Lean Manufacturing techniques can demonstrate dramatic results 30% plus improvements are not unusual. Similarly Six Sigma is transforming even small companies. No one would suggest that an hour long seminar will resolve all your problems, but if it points you in the right direction towards achieving your goal then it’s got to be time well spent. All the sessions are free, but places are limited and allocated on a first-come, first served basis. So the advice is simple; book early by calling 01784 880 890, completing and returning the coupon on the back page or visiting the website www.industry.co.uk/northwest. Wednesday 9th May SESSION 1 “Rapid Manufacturing in the future” 9.30am Looking at the development of Rapid Prototyping and Rapid Tooling Technologies and their impact on manufacturing in the future. Graham Tromans, Rapid Manufacturing Research Group, Loughborough University. SESSION 2 – 10.45am “CE Marking – A legal requirement or just more red tape?” Nearly all products must conform to CE Marking Legislation, if manufactured or sold within the EU. Ignorance of the law is NOT an excuse. The seminar will demonstrate how to prove compliance, removing the fear and ignorance at minimum cost. Mike Foster, CE Marking Association. SESSION 3 12.00pm “Continuous Improvement - How it can impact your company” Learn about the skills needed to support change and improvement, how the multi-national approach can be transposed to smaller organisations and the success and failure factors for sustainable improvement. John Grieves, Continuous Improvement Services. Thursday 10th May SESSION 4 1.15pm “Six Sigma - An innovative approach for both large and small companies” Why Six Sigma is the next generation approach for Process Improvement across your company. Can it be adopted by SMEs? How does it differ from other techniques? Brian Butler, Operations Director, Accelerate Ltd. SESSION 5 2.30pm “Lean Manufacturing - delivering Maximum Benefits for your company” Find out how the implementation of Lean Manufacturing techniques can deliver rapid, sustainable, bottom line benefits to all types of company, whatever the size. Carl Tomlinson, MAS North West. SESSION 6 3.30pm “How to succeed at exporting and identifying new markets” Key steps to take, how to avoid pitfalls, identifying opportunities for your product and an overview of support available. North West International Trade Team, UKTI. The other string to the bow is the design, build and on-site installation of integrated systems. These can be a one off such as a test fixture for London Underground. This was required to fatigue test escalator steps at 20 Hz frequency. Another unusual project was a rig to test the recoil of a 155mm UFH or Ultra lightweight Field Howitzer. On-site installation projects have been completed as far a field as China, Iceland. Belgium and Ireland. For machine builders, once completed, a design can be supplied in line with production demands, as a packaged kit of parts right down to the last pipefitting. With such an embracive service, whatever you are looking for in automation or power systems, it’s likely you’ll find it on the Hyquip stand. Fo r Fu r t h e r I n fo r m a t i o n e n t e r SESSION 10 “Selling to the Ministry of Defence” 9.30am 1.15pm How embracing Lean Thinking can increase your competitiveness, reduce waste, shorten lead times, reduce inventory and add real value for your customers. The MoD spends £15billion on goods and services annually. This seminar gives a unique insight into their purchasing process and offers valuable advice on how to sell to the MoD. Stuart Mitton, MAS North West. Defence Suppliers Service. SESSION 8 10.45am “Winning with Six Sigma - An innovative approach for both large and small companies” SESSION 11 2.30pm “Implications on design & manufacture of WEEE and RoHS legislation” Why Six Sigma is the next generation approach for Process Improvement across your company. Case studies from Food & Drink and Processing sectors. WEEE regulations are now a reality! Some deadlines have already passed and, in less than two months, the regulations will be fully implemented. This session is your chance to be updated on the legislation, ask questions and make sure you are operating legally. Paul Glossop, MAS North West. SESSION 9 “Succeeding at New Product Development” Leigh Holloway, Envirowise. 12.00pm With an estimated 96% of new products failing, it is a business imperative that you sort 'winners' from 'losers' at an early stage. Techniques for new product development and strategy and branding covered. Mark Stone, MAS North West. Correct as at 17 04 07 Automation – the building blocks 25% growth a year and still growing Any company that’s has hit an annual growth rate of 25% over the last couple of years must be doing something right. A couple of factors contribute to the success of Hyquip, a company that supplies hydraulic and pneumatic equipment. First, it is a distributor for some of the most respected names in the industry. Its portfolio includes such household names as Rexroth, Hilma, Roemheld and Hydac, Second it supplies a wide range of industries. These range from nuclear to petro-chemical, machine builders to utilities. Again, there is diversity in the type of service. At this point in time it splits about 50/50 between ‘shipping boxes’ and design and build of integrated systems. To successfully ‘ship boxes’ demands investment in significant stock levels coupled with a next day delivery service. SESSION 7 “Lean Tools and Techniques” A soundbite from the Thatcher era that lodged in the collective memory of manufacturers is “Automate or Liquidate”. It did so because it precisely encapsulated the stark options that face companies in the competitive global marketplace. Hopefully most embrace the first option, which means a visit to the Automation Supplies stand is in order. On show will be a selection from a wide range of modular automation equipment, which enables the user to design and construct assembly machines and automated handling lines. Valuframe is a system of aluminium extruded sections, which can be used to construct machine elements. These can range from a single workstation to a multi-station line linked by a conveying system. Conveyor belt widths from 30 mm to 1.5m can be specified. In addition, corner units and elevating systems can thread the line through the constraints of an existing building or production facility. Also part of the portfolio is the myriad of minor components such as door latches, hinges, levelling feet, and connectors that are needed to complete a line Fo r Fu r t h e r I n fo r m a t i o n e n t e r Maintenance software for SME's Tb be seen in action on the Xetec stand will be MicroMaint a maintenance software package costing under £700. It is claimed to be the sort of software investment that recoups its costs in a matter of weeks by helping keep a process plant at the peak of operating efficiency by minimising any downtime. Easy software navigation and simple menus are the key to its simplicity. Intuitive operation enables any maintenance engineer, working on his own, to have the system up and running in under two days. The first step is to create an asset tree structure using a cut, copy and paste facility. Each asset is located geographically and is quickly found using a simplified search routine. A simple menu offers fast access to all program areas that may be required to 510 maintain and manage typical small to medium sized maintenance operations. Within the system will be found a complete asset register, planned maintenance schedules, works orders, spare parts stock management and details of appropriate suppliers and geographic reporting. All data can be imported and modules are available for working on the web. Fo r Fu r t h e r I n fo r m a t i o n e n t e r LIST OF EXHIBITORS Stand No. B16 G10 D20 G2 F42 F2 C16 D28 A20 F17 F6 D32 D40 F1 D6 D42 A6 H6 F24 E12 C12 D30 A6 G20 A14 F7 D22 E14 D38 D12 C2 F10 B22 A6 F50 C9 G14 F3 B15 G22 Company Will be Showing Abrasives For Industry Ltd Abrasive Products - Specialising in Metalworking Abtest Limited Environmental Testing, ATE Equipment/Calibration Alliance Design & Manufacture Ltd Toolmaking for Plastic Injection Moulding Industries AM Technical Services Plastic Injection Moulding AMF Andreas Maier GmbH & Co KG Mechanical, Pneumatic & Hydraulic Clamping & Fixture Systems Ansmann Energy (UK) Limited Batteries, Chargers, Power Supplies & Mobile Lights Applied Coating Technologies Coatings For Plastic & Metal Components Arcom Solutions for Embedded, Communication & Control Technology Assembly Solutions Ltd Cable Assemblies/Wire Harnesses/Electronic Coils Associated Spring SPEC Springs, Clips, Washers, Pins, Mechanical & Gas Struts Automated Packaging Systems Bagging Machinery Automation Direct Automation and Industrial Control Products Automation Supplies Ltd Modular Assembly/Conveyor Systems Autoy Ltd Subcontract Precision Engineers B&M Longworth (Edgworth) Ltd Chemical and Thermal Processing Bespoke Machines Ltd Special Purpose Industrial Machines & Equipment BioCat Cleaning Solutions Bolton Council Bolton Business Support Bott Ltd Heavy Duty Workshop & Storage Equipment The Bradley Group Bespoke Precision Engineered Products Bradshaw Industrial & Welding ServicesWelding Equipment & Accessories-Sales,Service,Repair,Calibration Brady Corporation Ltd Identification Products, Labels, Signs, Printers Carr Lane Standard/Tooling Components CCSL SolidWorks CAD Solutions Clean Air Group Heating, Ventilation & Air Conditioning Engineers Conception Marketing Ltd Strategic Marketing Consultancy CRDM Ltd Rapid Prototyping & Tooling Services Dawson Precision Components Ltd Precision Subcontract Machining DBO Services Ltd RightStock« Inventory Forecasting & Replenishment Software Diametric Technical Ltd Industrial Nameplates & Labelling Products Diamond Point International Embedded Computer Products DSG-Canusa GmbH & Co KG Heat Shrink Solutions for Industrial Applications Electrox Laser Marking Systems Enerpac Hydraulic Components & Tools-High Force Applications Envirowise Free Independent Environmental Advice ETES - Regional Sales Office Exhibition Organisers Faro UK Portable 3D Measurement Solutions & Systems Finishing Techniques Ltd Deburring & Polishing Solutions Focus CNC Ltd CNC Milling & Turning Functional Safety Engineering Ltd Machinery Safety & Control Products Stand No. A12 E6 C28 C22 A16 A6 B13 C10/C8 C24 A6 A6 A4 B20 G18 C18 E8 E1 F32 G9 A17 B10 A8 C9 E8 G30 A18 C9 E24 A6 F13 C9 G12 C9 C9 G32 D34 E34 E22 D2 C13 511 Company FWB Products Ltd GGB Goodfellow Cambridge Ltd GSM Graphic Arts Ltd Hexagon Metrology Heypac HPC Gears Ltd HRS Hurco Europe Ltd Hydac Ltd Hyquip Ltd ILME UK Ltd Inditherm Plc Industrial Tooling Corporation Ltd Ingersoll Rand Kabelschlepp Metool Laser Process Ltd LC Automation Ltd Macdermid PLC Machinery Market Machinery Safety Solutions Maledon Ltd Manufacturing Technology - Ireland Metool Products Limited MHH Engineering Co Ltd Middle Carr Consultants Ltd Midlands Manufacturing Exhibition Mil-Tek Express Minibooster Network China Ltd North West Manufacturing Exhibition Northern Industrial Electronics Northern Manufacturing Exhibition Organisers Office Panasonic Electric Works UK Ltd Particle Technology Ltd Plastic Parts Centre Pneumatic Services Ltd Pneumax Ltd Polish Embassy-Trade Promotion Dept Will be Showing Engineering & Safety Products - Distributor Bearings Metals & Materials for Research, Development & Manufacturing Industrial Labels & Nameplates Co-Ordinate Measuring Equipment Double Acting Air/Oil Intensifiers Gear Transmission Products Manufacturing Software & Related Services CNC Machining Centres & Lathes - Sales/Service Hydraulic Engineers Production, Automation, Workholding, Hydraulics Multipole Connectors, Plugs & Socket Outlets Low Voltage Heating for Process Control/Storage Applications Prec Cutting Tools - Manufacturer, Reconditioner, Modification & Distribution Air Compressors and solutions for your specific industry or application. Flexible Cable & Hose Handling Systems Laser Cutting & Marking Motion Control, Automation & Machinery Safety Product Distribution Speciality Chemicals Trade Publication - Engineering & Manufacturing CE Marking, Risk Assessment, Electrical Safety Product Solutions Fabrication Engineers - Services/Solutions Organisers Office/Sales Stand Flexible Cable & Hose Handling Systems Torque Wrenches, Screwdrivers & Calibration Equipment Sourcing & Out Sourcing Solutions Organisers Office/Sales Stand Waste Management, Baling Oil Intensifiers Subcontract Manufacturing Services in China Organisers Office/Sales Stand Industrial Electronic & Automation Repair & Design Organisers Office/Sales Stand Exhibition Organisers Factory Automation Products Cleanliness Equipment & Services, Particle Sizing Analysers/Test Dusts Plastic Protection & Finishing Parts Compressed Air Equipment/Servicing Pneumatic Control Equipment Promotion of Trade & Investments with Poland Stand No. C20 K27 K1 G31 F56 A6 A6 F28 A6 F8 F12 E2 D14 D10 K25 F34 E4 C9 C9 F44 B18 E30 F15 B24 F40 B26 B12 F46 F38 H4 G4 F4 F30 C14 F56 C4 TBA Company Will be Showing Preactor International Production Planning & Scheduling Software Press Office Press Office Proetch Services Ltd Metal Components Profil UK Ltd Mechanically Attached Fasteners & Installation Equipment PW Circuits Ltd Manufacturer of Printed Circuit Boards Ram Power Ltd Specialist Hydraulic Manufacturers & Designers Rexroth Bosch Industrial Hydraulic Products Rewinds & J Windsor & Sons Ltd Electrical, Mechanical & Electronic Engineers Roemheld UK Ltd Innovative Solutions for Workholding Rosler UK Surface Finishing Techniques, Shot Blasting, Vibratory Finishing Rubbertech 2000 Ltd Silicone Keypads, Gaskets, Seals & Protective Mouldings Scaglia Indeva Ltd Electronic/Pneumatic Manipulators Schmersal Ltd Machine Safety Components Manufacturer Seaborne Plastics Thermoform Plastics Seminar Theatre/Registration Free Seminars/Registration Desk Soabar Labels, Tags & Electronic Printers Solutions 2 Enterprise Ltd Computer Aided Design & Manufacture Software & Services Southern Electronics Exhibition Organisers/Sales/Press Office Southern Manufacturing Exhibition Organisers Office/Sales Stand Specialised Polymer Engineering Ltd Polymer Products - Design & Manufacture Springmasters Ltd Spring & Wireform Manufacturers St Davids Assemblies Ltd Pressings, Mouldings & Assemblies Star Tubes Ltd Tube Stockholders/Lasertube Processors Steel Service Centre Ltd Subcontract Laser Cutting Stowan Health & Safety Consultants Tapeswitch Ltd Safety Mats, Sensing Edges, Ribbon Switches, Panic Strips Telesis Eagle Marking Equipment Telsonic UK Ltd Ultrasonic Equipment-Manufacture & Supply TeslaTest Systems Temperature & Humidity Test Chambers The Manufacturing Institute & MAS NW Productivity & Skills Improvement Support The University Of Liverpool World Class Research, Knowledge & Expertise Velden Engineering UK Ltd Sub-Contract Engineering Service Vesterbro Of Denmark Product decoration, Nameplates, Badges & Labels Vision Engineering Optical Inspection, QC & Non Contact Measuring Systems Xetec Ltd Computerised Maintenance Management Software (CMMS) Yamazaki Mazak UK Ltd Machine Tools & Manufacturing Systems YTS Manufacturing Ltd Subcontract Component/Machine Tool Mfrs Correct at time of going to print 512

© Copyright 2026