Titanium Alloys – How to Capitalize on the Performance in

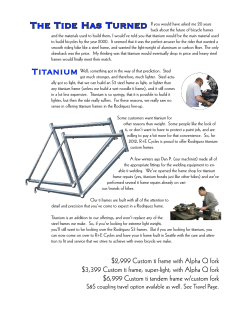

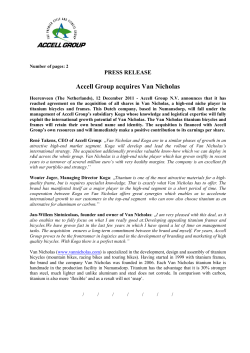

Titanium Alloys – How to Capitalize on the Performance in Demanding Corrosive Applications While Assuring Against Failure Richard A. Clapp Senior Consultant – Materials Engineering DuPont Engineering Technology John A. Mountford Jr. Director of Marketing Tico Titanium, Inc. Presented at: 2001 Chem Show the 49th CPI Expo - Javits Convention Center, New York City October 23 - 25, 2001 Introduction: Titanium alloys along with their reactive metal brethren can provide significant advantages over the more historically specified nickel base and high alloy stainless steels in corrosive chemical process environments. The downside of titanium is that misapplication, faulty design or operation of equipment outside the anticipated process conditions can lead to unacceptable equipment failure. This risk can be inconsequential when a structured approach is applied to the selection process, when proper equipment design practices are employed and cooperation between the process and operations communities assures that process conditions stay within prescribed limits of safe alloy performance. This paper is complementary to the 2001 Chem Show Conference Program presentation, that focuses on some of the key considerations that one needs to take with respect to specification, equipment design, and maintenance of titanium process equipment to assure long-term trouble free performance. In the oral presentation the focus is on the structured approach to be applied for alloy selection, from a corrosion standpoint, and the required operational control that history has shown can translate into decades of trouble and maintenance free service. TITANIUM SPECIFICATIONS FOR ALLOYS USED IN THE CPI Fortunately for the consumer, the titanium industry has wisely chosen to produce to ASTM specifications and not create a dearth of company specific specialty alloys. Where new alloys have been developed, as has been the case with the recent addition of the lean Palladium and Ruthenium doped alloys, the company developing the alloy quickly moved for inclusion into the ASTM product specifications. Appendix I provides details of the different ASTM designated grades that have application in the CPI along with a brief thumbnail sketch of the typical applications and their chemical compositions. [Fig. 1 contains the actual chemistry compositions of the grades.] This write-up is very beneficial in understanding the different alloy grades, that are essentially identical in mechanical properties, but which differ only by the small quantities of Palladium and Ruthenium added for improved corrosion resistance. Appendix II racks up the various product specifications and related specifications [listed in Fig. 2] for titanium alloys used in the CPI. It also provides a listing of sizes available in industry for the various product forms. It is included to provide a handy reference for the reader. Appendix III provides the details regarding the Welding and Other Fabrication Processes utilized for titanium. ASTM and the associated ASME product standards are quite complete and don’t require supplemental company specifications for the bulk of CPI applications. Some of the standards have supplemental requirements that can be specified, but these should only be selected when a real benefit can be identified. The ASTM specification for condenser and heat exchanger tubing, B 338 is a case in point. It is a very comprehensive specification. The required nondestructive testing is often only available as supplemental requirements for nickel and stainless alloys or it requires independent specification. For example, welded titanium is subjected to an electromagnetic (eddy current) and an ultrasonic test. In addition, a hydrostatic or pneumatic test is also required. Except for high-pressure applications, practice is to conduct a pneumatic test, which provides high sensitivity to very small defects that aren’t picked up by the electromagnetic (EC) or ultrasonic (UT) techniques. DESIGN CONSIDERATIONS The successful design of process equipment using titanium alloys is a mature science. Titanium equipment has been utilized in the chemical industry in significant quantities for well over 30 years. Key properties of titanium, however, influence the specifics of the design. Outlined below are some experience-based considerations when designing with titanium. Thermal Expansion The significantly lower thermal expansion of titanium versus competitor nickel and stainless alloys doesn’t pose a problem in initial design if recognized, but historically it has caused problems because it was not considered during component or equipment replacement. Key areas where thermal expansion considerations need to be taken into account are: • Shell and Tube Heat Exchangers – In new design typically no problems are encountered if proper expansion calculations are conducted as part of the design process. For re-tubed exchangers, analysis should be conducted to assure that the existing expansion joint is adequate for the new shell and tube material combination. Special care needs to be taken when re-tubing exchangers with tubes and shells of the same material, as changing to titanium can result in tube end loads that exceed the pullout strength of the expanded joint. 2 • Vessel Replacement – Piping stress analysis should be conducted on mating piping to assure that no excessive nozzle loads are applied due to piping moments, or due to differential thermal growth between the vessel and piping • Use of titanium for vessel internals, such as distillation trays and packing supports in nickel and stainless steel alloy vessels, mandates the need to take into account the significant difference in thermal growth between titanium and the shell materials. Locking of components to the shell, and not providing points where relative motion can occur has resulted in failures of titanium internals and failures of vessel shells at the attachment points. Modulus of Elasticity Shell and Tube Heat Exchangers – One common reason for the failure of titanium tubed exchangers is vibration damage. This typically manifests itself as tubing wear at the baffles but also can result in wear due to tube collision and in rare cases, local hydriding of tubes in the contact areas. This problem is often encountered when titanium exchangers are ordered as replacements of existing units without an experienced design review. • Thermal rating programs such as “HTRI” (Heat Transfer Research Institute) have built in analysis routines to determine if vibration is a concern when designing new equipment. It should also be considered as an assessment tool when replacing “in kind”, except for materials. • Very conservative practice is to minimize the free span of titanium tubing to no greater than 30”. Note that this is NOT BAFFLE SPACING, as tubes in the area of the baffle that don’t overlap adjacent baffles are supported only be every other baffle. • Double and triple segmental baffles have often been utilized to reduce potential titanium tube vibration problems when conventional single pass designs are shown to be inadequate owing to the high shell-side flow rate. • Increased baffle thickness reduces contact loads under vibration conditions, reducing the wear on the tube. Baffle thickness should not be skimped on. • Where process is on the tubeside, it is good practice to standardize on 304 baffles, tie-rods and spacers in cooling water and steam applications. This assures that the baffle to tube fit doesn’t increase with corrosion of the baffle hole, which can lead to vibration. It also provides protection against local hydriding that has infrequently occurred when a process leak into the shell has caused rapid corrosion of carbon steel baffles. • In some exchanger layouts, the edge of the baffles can be scalloped and not fully confine a tube on all sides. This can lead to the tubing being supported in only one direction. Under the proper excitation, these tubes on the scalloped edge can fail by baffle wear, even though the free span of the tubing is within correct limits. Thermal Conductivity Thermal conductivity of titanium is significantly lower than copper and copper-nickel alloys, but 50% greater than 304 SS. On the other hand, titanium has excellent antifouling characteristics in the full range of industrial cooling waters, from fresh potable water to seawater. Thin tube gauges can be specified with titanium because no corrosion allowance needs to be specified. Also, titanium has excellent erosion-corrosion resistance in cooling waters versus competitor alloys such that cooling water velocities can be much higher than competitor alloys. All these, combined, lead to titanium often being significantly more thermally efficient than the other alloys. 3 • Take advantage of titanium’s antifouling behavior when selecting the fouling coefficients for exchanger design. Proper selection can result in significant exchanger area reductions and lower exchanger cost versus other alloys. • Take advantage of titanium’s resistance to erosion /corrosion by maximizing cooling water velocities consistent with pressure drop constraints and potential for tube vibration. Rules such as 3 to 6 feet per second for cooling water on the tube-side need not apply. • Often, in the design process for new facilities, heat exchanger sizing will be done for cost estimating purposes prior to final materials selection; or sizing will be based on a base material and the design will be sent out for pricing with titanium as one of the material options. To assure the most cost effective design is achieved, exchangers should be thermally rated and sized with titanium taking credit for the low fouling, thinner tube gauges and higher permissible velocity characteristics. Material Strength Design stresses for the CP alloys drop significantly with temperature. This, combined with the low elastic modulus (see “Vacuum Design”), will often require a thicker vessel than that of an alternate material. Design allowable stresses for titanium per the ASME code are shown in Table 1. • Decisions should be based on fabricated cost! To the uninitiated, the greater required thickness for titanium indicates higher cost. In reality, titanium is very competitive versus other alloys in first time costs. Table 2 provides some cost comparisons to provide a sense of the relative costs. As alloy prices are constantly changing, pricing of titanium and other candidate alloys should be obtained for comparison by requesting budget quotations from fabricators and suppliers. A key mistake seen in past projects is to estimate the equipment thicknesses for another candidate alloy, take the calculated weight, and then price the vessel on a “per lb” cost 3 3 for titanium. With titanium’s low density of 0.163 lbs./in versus 0.294 lbs./in for stainless steel, the use of this method greatly overestimates titanium material costs. • Process people often don’t appreciate the impact of selecting a high design temperature for equipment. They routinely set vessel design temperatures equivalent to the supply pressure for steam used in steam-out. In reality, these temperatures are not reached as the steam supply is small and the vessels are typically at atmospheric temperature during the process. Significant savings in fabricated cost can often be achieved by mechanical and process interaction to set the vessel design temperature as low as practical. Vacuum Design In most critical vessel applications, full vacuum is a design criteria. This allows for the ability to handle product draining and steam out conditions without the use of vacuum breakers or other elaborate (and often failure prone) systems to minimize negative pressure in the equipment. With titanium’s low elastic modulus, vacuum can be controlled at lower pressures than can competitor alloys. • Where vacuum is controlling in design, resistance can be improved by increasing the thickness or the use of external stiffeners on equipment. In most cases the more economical choice is to use more stiffeners. Typical practice is to use plate ring stiffeners and not complex shapes such as tees or angles. This will typically result in the stiffeners projecting through the insulation. Titanium is immune to stress corrosion cracking under thermal insulation so that elaborate “boxing in” with insulation of the stiffeners is only required where significant concerns for heat losses due to wet insulation exist. 4 • Temperature has a strong effect on vacuum resistance. As noted above for positive pressures, the selection of the design temperature under full vacuum should be specified as low as possible. If the conditions where vacuum can occur are at a distinctly lower temperature than for positive pressure, two design conditions can be specified to capitalize on the differences. Flange Design Details of flange types used in titanium equipment are covered below in the piping section. One consideration that should be addressed in flange design is the potential for crevice corrosion. Gasket surfaces on titanium equipment can suffer crevice corrosion in high temperature brines and halogenated high temperature organic acid environments. Where crevice corrosion has been identified or, in new processes where the risks of crevice attack are not fully assessed, gasket surfaces have been produced from the more crevice resistant materials such as Grade 7. They have been produced for stub-ends by welding a crevice corrosion resistant titanium grade to a Grade 2 barrel or by making the complete stubend from the crevice corrosion resistant grade. For clad equipment a similar process has been used for producing nozzle and nozzle liners. Internal Vessel Attachments Titanium internals such as baffles, agitator paddles and feed and dip pipes have experienced failures in operation due to fatigue. Titanium has the advantage over other alloys in that its fatigue strength is not materially effected in most corrosive environments. Its very low corrosion rate allows for successful weld contouring and blending that can provide benefits over the life of the equipment. Care should be taken to properly support piping inside the vessel. A good practice is to mechanically restrict piping and baffles against vibration by craddling them in supports with guides, without directly welding them to the supports, where vibration is a serious concern. Most titanium agitators are of bolted construction with the paddles attached to the shaft by bolting to allow for removal through manways and agitator openings. Typically the paddle and agitator are mated together with a flange type arrangement, with bolting going through the paddle and paddle flange. It is very important that the mating surfaces of the flange be flat and that the back of the flanges be spot faced or machined to assure that those surfaces are parallel to the mating surfaces. This should be checked as part of any critical titanium agitator final inspection after fabrication. If these surfaces are not parallel then the proper bolt pre-load can be lost in service leading to premature failure of the bolting. This is an item that can also be overlooked when repairs are done to paddles due to cracking of attachment welds in the vicinity of the flange. Piping Design Considerations Titanium piping offers a very cost effective and reliable solution in many corrosion applications. Key considerations with piping systems are: • Grade 2 titanium is the most common piping used in chemical processing. Grades 3 and 12 have also been specified for specialized applications to a limited degree. Piping and components, such as elbows and tees, are readily available. One area that can impact the cost of titanium piping systems is in the specification of titanium cast valves. Cast Titanium valves can be expensive versus competitive alloys (see Table 3). Use of valves fabricated completely from wrought components and ‘Wafer” style valves should be considered as options to cast style valves. Fully lined Teflon valves have also been used quite successfully as a lower cost option to cast titanium. 5 • Welded pipe is readily available and of high quality. Applications are limited where the benefits of seamless product out-weigh the additional cost. In some borderline services such as hot pure nitric acid, titanium welds can corrode faster than the base metal. Specification of seamless product can increase the life to some extent in these services. • Schedule 10 is typically specified in the chemical process industry. Owing to the very low corrosion rate exhibited by titanium, the use of schedule 40 for additional corrosion allowance is not required. Certain specific cases where erosion plays a role or in high-pressure applications, schedule 40 is specified. Schedule 5 has also been specified in applications owing to the cost advantage of the thinner wall thicknesses. It should be noted that irrespective of material, Schedule 5, especially in the smaller diameters, requires skilled welders to successfully weld. • Standard flange design for titanium equipment is lap joint stub-ends or studding pads of solid titanium. Stub-ends are typically fabricated from plate versus being forged. Fatigue of titanium stub-ends has occurred around pumps, compressors and centrifuges and areas of flashing two phase flow, where significant piping vibration has existed. For areas where fatigue may be anticipated, Type A stub-ends with fully finished welds between lap and barrel can provide significant added benefit with respect to fatigue. Owing to the strength and elastic modulus of titanium, titanium slip-on flanges and solid weld neck construction are seldom used. (If this style flange is considered, remember that detailed flange design is required using the ASME rules to determine required design thicknesses.) In industry, backer flanges from carbon steel to high alloy have been specified. Often, the impact of the selection of the backer flange material is overlooked. With a flange leak, carbon steel can corrode quite rapidly resulting in having to cut off the stub-end to replace the flange or, in some cases, reinforcing with a split ring back-up flange is possible. Galvanized steel is not recommended for the same reason. In addition, if galvanized material is smeared onto the titanium by the flange, it can potentially lead to hydrogen embrittlement. The most cost-effective selection from a life cycle basis is typically 304 or 316 SS. In the overall cost of a titanium vessel, back-up flanges are typically a very small cost and, considering the maintenance costs associated with repair, should not be selected strictly on a first cost basis. • When changing piping in a system from another alloy to titanium the following should be considered: Titanium being of lower elastic modulus can have piping strain focused on it from the higher modulus piping. A qualified individual should conduct a piping flexibility analysis when piping is changed to titanium. Two phase, flashing flow and high process circulation rates that didn’t excite the original piping may excite titanium when installed. Always have a knowledgeable piping engineer inspect the line after it is put into service. FABRICATION Titanium fabrication of chemical process equipment is a mature industry. The bulk of fabrication is of solid construction. Explosion bonded titanium to carbon steel for clad construction is a proven technology used in high pressure applications where the significantly lower cost of the carbon steel results in lower asfabricated costs. Although carbon steel is by far the most common backer material, titanium clad on stainless steel is sometimes used for tubesheets to protect against backer corrosion in very aggressive environments should a failure of the titanium occur. 6 Welding Welding is the most commonly raised concern for titanium fabrications. It is true that special attention to joint cleanliness and proper gas shielding techniques are required to assure that welds are not embrittled or reduced in corrosion resistance. The major manufacturers, however, have long perfected these shielding techniques. Welding both in an open shop environment and for field welding repairs is routine. In reality, titanium welds very easily with good flowability and wetting of joint surfaces. From the welder’s perspective it is much easier to weld than many of the nickel based and stainless alloys. Detailed considerations for welding are included in Appendix III. MAINTENANCE CONSIDERATIONS Clad Equipment – Purge Holes In clad vessels, batten straps of titanium are used to bridge the welded joints of the backer steel. Typically, the backer steel is welded out and ground smooth, a filler compatible with titanium is inserted in the joint to bring the surface flush with the surrounding clad surface and then a piece of titanium that bridges the joint is added and fillet welded to the clad surface on each side of the joint. To assure against oxidation of the back side of the batten strap welds, purge holes are added. These are drilled through the backer to allow the flow of purge gas through the joint, typically with a _ coupling welded to the outside over the hole to allow for attachment of the purge fitting. Care and feeding of these purge holes is critical to assure that if a leak does occur through the cladding repairs are minimized. Once put into service, these purge holes can be very effective tell-tale holes to let one quickly know whether the batten straps have either been breached by corrosion or fatigue. Always add piping extensions on the nipples and extend them outside of the insulation. Also include, as part of a normal patrol of the equipment, having operations inspect the purge holes for leakage. When extending them outside of the insulation, be sure to have a screen on the end of the pipe to assure that inspectors don’t get in and plug the hole. If you leave them buried in the insulation, leaks can go on for an extended period. Considering that in many services the corrosion rate of bare carbon steel in the process can exceed 5 inches per year or more!, early detection can be critical. Don’t try and get fancy with these purge holes. Several large pieces of equipment suffered life-long reliability problems with batten strap failures because they initially ganged all the purge holes together and pulled a vacuum through a detector trying to identify the first onset of leakage. Unfortunately, when a leak occurred, the process material migrated from purge hole to purge hole contaminating behind all the batten straps in the vessels. If the purge holes had not been interconnected, only one local area would have had to be addressed. • A historical concern in some companies and in specific processes has been that of iron being smeared onto titanium during maintenance activities, leading to pitting in various chemical services. This has lead to practices such as only allowing aluminum scaffolding in vessels, requiring disposable boot coverings when entering vessels, lining vessel floors to assure against tools contacting the titanium, and ferroxyl or other test methods to assure no surface iron contamination is present after completion of maintenance. In laboratory tests it has not been possible to produce pitting without embedding iron in the titanium and having a cap of titanium over top to make a very tight crevice. This is very difficult and the very low number of failures that can be attributed to embedded iron in industrial practice supports this. The requirement for the extent of required precautions is debated in the industry. The actual practices employed should be selected with analysis of the process chemistry and the risk of attack. For example, many services are inventoried with cold acid that will effectively pickle the iron from the surface prior to raising equipment temperatures, while in oxidizing non-halide environments the risk of embedded iron causing damage to the titanium is extremely remote. 7 Painting Near Titanium Equipment Titanium requires no external painting for protection. Titanium is not subject to corrosion under wet insulation. Caution should be taken when spraying structural steel or other equipment in the vicinity of titanium equipment. Failures have occurred when inorganic zinc primer has been inadvertently sprayed on to titanium surfaces. With the inorganic zinc present, corrosion of the paint can occur with acid leakage on to the painted surface resulting in hydrogen generation and hydrogen embrittlement of the titanium. Titanium Cleaning Heat Exchangers – High Pressure Water Cleaning Tubeside cleaning of titanium exchangers with high-pressure water is done routinely. Titanium or Ni-CrMo nozzle tips are specified in some cases where iron contamination of tubing is a concern. Titanium is resistant to high-pressure water erosion, but the minimum required pressure for cleaning should always be specified. Some specifications limit the pressure in critical, severely plugged tubes. Where ultra-high pressure cleaning is the only viable method, it is good practice to determine the dwell time to cause damage. This is done using the proposed cleaning procedure and equipment, and running trials by holding the lance in a trial tube at one location and recording the time to perforation. The test is then conducted at fractions of the perforation time and the tube is split open to see what dwell time causes damage to the tube. This gives a good indication of the relative dwell time that can be tolerated during cleaning without damage. Heat Exchangers - Chemical Cleaning Typical practice in some facilities is to chemically clean the cooling water side of all heat exchangers on a set frequency independent of the specific exchangers’ heat transfer performance. Titanium exchangers with their low fouling characteristics often will not require cleaning at the same frequency as others, if at all. Good practice is to not require chemical cleaning of titanium exchangers unless clear thermal performance degradation is documented and other cleaning methods are not suitable. It is critical that when chemical cleaning will be conducted on titanium exchangers that the chemical cleaning contractor has demonstrated experience with cleaning titanium equipment and that information is clearly transmitted to the contractor that titanium will be cleaned. This is more of a concern when a large number of exchangers are to be cleaned on a shutdown and include an individual titanium exchanger. Major failures of titanium equipment have occurred due to cleaning operations where HCl was utilized without sufficient oxidizing inhibitors. Ammonium bifluoride (ABF) which when added to HCL promotes silica scale removal, has been responsible for severe attack due to the generation on hydrofluoric acid. TABLE 1 8 Allowable Stress Values Per Section VIII of the ASME Boiler and Pressure Vessel Code Material ASTM Form and Grade Spec. No. Sheet Strip Plate SB-265 1 2 3 7 12 9 Specified Tensile Strength For Metal Temperature Not Exceeding Deg. F (Design Stress in KSI) Min. Yield 0.2% Offset 100 35.0 50.0 65.0 50.0 70.0 90.0 25.0 40.0 55.0 40.0 50.0 70.0 150 200 250 300 350 400 450 500 550 600 8.8 12.5 16.3 12.5 17.5 22.5 8.1 12.0 15.6 12.0 17.5 22.5 7.3 10.9 14.3 10.9 16.4 21.7 6.5 9.9 13.0 9.9 15.2 20.8 5.8 9.0 11.7 9.0 14.2 19.8 5.2 8.4 10.4 8.4 13.3 8.6 4.8 7.7 9.3 7.7 12.5 17.6 4.5 7.2 8.3 7.2 11.9 16.8 4.1 6.6 7.5 6.6 11.4 15.8 3.6 6.2 6.7 6.2 --15.3 Source: 1998 ASME Boiler & Pressure Vessel Code, Section II – Part D TABLE 2 Cost Comparisons for CPI Equipment Fabricated from Titanium and Other Corrosion Resistant Grades Material Cost Comparison Vessels Heat Exchangers Ti Grade 2 1.0 1.0 Ti Grade 7 1.3 1.3 Ti Grade 12 1.05 1.1 Incoloy 825* 1.1 1.1 Zr Grade 702 1.3 1.4 Hastelloy B-2** 1.6 1.6 Hastelloy C-276** 1.5 1.6 *Registered Trademark of INCO **Registered Trademark of Haynes International Source: International Titanium Association [ITA] website www.titanium.org (Ti Information Section) TABLE 3 9 3.1 5.7 6.0 5.7 --15.1 Relative Cost of Titanium Versus Other Corrosion Resistant Cast Plug Valves Valve Size Titanium CD-4Mcu Alloy 20 Hastelloy C 2” 10.7 1.3 1.3 5.7 4” 7.9 1 1.2 5.5 6” 9.1 1.1 1.2 6.1 *Registered Trademark of Haynes International 10 * APPENDIX I TITANIUM GRADES AND TYPICAL APPLICATIONS This section provides a thumbnail synopsis of available grades of titanium that are utilized in chemical process environments. Commercially Pure Grades Grades 1, 2, 3 (and 4) represent the original Commercially Pure (CP) grades. Residuals - Oxygen, Iron, Carbon, Nitrogen & Hydrogen impart the strength levels. • • Carbon, Oxygen and Nitrogen act as interstitial strengtheners, maintaining a single-phase hexagonal close packed “alpha” microstructure. Iron & Hydrogen act as second phase body-centered cubic “beta” grain refiners - offering moderate strengthening capabilities. Grade 1: The CP grade with the lowest residual content makes it the lowest strength CP grade with the highest ductility & excellent cold formability. (Typically 99.8% Ti) Applications: “Deep pressing” and intricate forming of sheet strip and plate for Plate & Frame Heat Exchangers (PFHE). It is also used as the corrosion resistant titanium layer of “explosive – bonded” Clad plates for liners in tubesheets, pressure vessels, columns, tanks and chemical process equipment, for transition joints and parts or equipment not requiring high strength but of a more complex shape. Grade 2: The “workhorse” of the CP grades and most widely used in industrial service, it has a good balance of strength and ductility with strength levels very similar to those of common stainless steels and with ductility that allows for good cold formability. (Typically 99.6% Ti) Applications: Pressure Vessels, Columns, Pipe (welded & seamless), Tubing (primarily welded & seamless) in Shell & Tube Heat Exchangers & Utility Steam Condensers, Tubesheets, Fittings, Fasteners, Flanges, Valve Bodies, Rod, Wire, etc. Grade 3: A slightly higher strength grade due to its higher oxygen & nitrogen residual contents, with somewhat lower ductility. (Typically 99.4% Ti) Applications: Tube Sheets (for stronger joints) and for Pressure Vessels, etc., where thinner walls can be accommodated, due to its higher intrinsic strength. Grade 4: Highest strength CP grade used mainly in the aerospace/aircraft industry, which because of its high strength levels and lower ductility is not commonly seen in the CPI. Applications: Anodizing Racks and Baskets for a variety of industrial metal anodizing applications. Grade 12 Developed (slightly alloyed) for moderately higher crevice corrosion resistance at high temperatures (500º - 550º F, 260º - 288º C) and lower pH levels (to as low as 2.5 – 3) having the benefit of higher strength but with a moderate reduction in ductility. Applications: Pressure Vessels and other Chemical Process Equipment that can be designed with thinner walls in lower pH and/or higher temperature service and where crevice corrosion is 11 a factor. Used in Salt Evaporators in the production of salt, in Brine Condensers, Refinery Crude Overhead Condensers and as Heat Exchangers using salt water cooling at elevated temperature levels. Grade 9: An alloy grade 3 Al – 2.5 V (also referred to as half 6Al–4V) is significantly stronger with an approximate 75% increase in yield strength above that of Grade 2, harder, with good erosion resistance, finding a fair amount of use in CPI applications. Applications: Pressure Vessels (allowing thinner gauges), Autoclaves, Shafts & Impellers. Grade 5 A very high strength alloy (6Al – 4V), 3 times that of Grade 2 with very high erosion resistance and hardness. Applications: Shafts & Impellers (in Autoclaves), Rotating parts, Centrifuges and Turbine components. Grade 23 An alloy (6Al – 4V ELI [extra low interstitials]) with very high strength levels, slightly lower than that of Grade 5, developed for use where strength levels close to those of Grade 5 would be required but where Stress Corrosion Cracking (SCC) would be a factor. Palladium & Ruthenium Doped Alloys These alloys have small amounts of palladium or ruthenium added, which dramatically improves titanium’s resistance to reducing acid conditions and crevice corrosion. Elemental Ruthenium is considerably less expensive than elemental Palladium which is why it is used as a substitute (for economic reasons). Grade 26 is cheaper than Grade 7, but can be lower, equivalent or slightly higher than Grade 16 in cost, dependent upon Ru and Pd prices which continue to fluctuate. This is true for all the grades with a Ru addition. Grade 1 Mechanical Property Equivalents Grades 11 & 17 [Palladium] These alloys correspond to Grade 1 in mechanical properties. They were developed for their resistance 0 0 0 to severe crevice corrosion areas in brine/chloride solutions for temperatures to 500 – 550 F (260 – 0 288 C) and pH levels to as low as 1 (or under) at these higher temperatures. They also allow for the use of titanium in more reducing acid conditions. Grade 17 is the leaner Pd version, more economical, but with the same resistance as Grade 11, except for some specific applications. Grade 27 [Ruthenium] This alloy was developed to replace Pd for lower cost and added availability. The same parameters apply as those for Grades 11 & 17. Applications: These grades have the identical physical & mechanical properties as Grade 1 and are used in similar applications where high temperature and/or low pH crevice corrosion situations exist or where reducing conditions warrant their use. 12 Grade 2 Mechanical Property Equivalents Grades 7 & 16 [Palladium] These alloys correspond to Grade 2 in mechanical properties. They were developed for their resistance 0 0 0 to severe crevice corrosion areas in brine/chloride solutions for temperatures to 500 – 550 F (260 – 0 288 C) and pH levels to as low as 1 (or under) at these higher temperatures. They also allow for the use of titanium in more reducing acid conditions. Grade 16 is the leaner Pd version, more economical, but with the same resistance as Grade 7, except for some specific applications. Grade 26 [Ruthenium] This alloy was developed to replace Pd for lower cost and added availability. The same parameters apply as those for Grades 7 & 16. Applications: These grades have the identical physical & mechanical properties as Grade 2 and are used in similar applications where high temperature and/or low pH crevice corrosion situations exist. Grade 9 Mechanical Property Equivalents Grade 18 [Palladium] The equivalent of Grade 9 in physical & mechanical properties but with Pd to impart a high level of corrosion resistance at higher temperatures and/or very low pH levels. Also, it significantly reduces the potential for stress corrosion cracking in specific environments. Grade 28 [Ruthenium] The equivalent of Grade 9 in physical & mechanical properties but with Ru to impart a high level of corrosion resistance at higher temperature and/or very low pH levels. Grade 5 Mechanical Property Equivalents Grade 24 [Palladium] The equivalent of Grade 5 in physical & mechanical properties but with Pd to impart a high level of corrosion resistance at higher temperatures and/or very low pH levels. Grade 29 [Ruthenium] The equivalent of Grade 23 in physical & mechanical properties but with Ru to impart a high level of corrosion resistance at high temperatures and/or very low pH levels. 13 Chemical Compositions of Titanium Grades Used in the CPI ASTM UNS N C H Fe O Grade Number max max max max max Al V Mo Ni Pd Ru each max 1 R50250 0.03 0.08 0.015 0.20 0.18 0.10 0.40 Bal 11 R52550 0.03 0.08 0.015 0.20 0.18 0.12 - 0.25 0.10 0.40 Bal 17 R52252 0.03 0.08 0.015 0.20 0.18 0.04 - 0.08 0.10 0.40 Bal 27 R52254 0.03 0.08 0.015 0.20 0.18 0.10 0.40 Bal 2 R50400 0.03 0.08 0.015 0.30 0.25 0.10 0.40 Bal 7 R52400 0.03 0.08 0.015 0.30 0.25 0.12 - 0.25 0.10 0.40 Bal 16 R52402 0.03 0.08 0.015 0.30 0.25 0.04 - 0.08 0.10 0.40 Bal 26 R52404 0.03 0.08 0.015 0.30 0.25 0.10 0.40 Bal 3 R50550 0.05 0.08 0.015 0.30 0.35 0.10 0.40 Bal 12 R53400 0.03 0.08 0.015 0.30 0.25 0.10 0.40 Bal 9 R56320 0.03 0.08 0.015 0.25 0.15 2.5 - 3.5 2.0 - 3.0 0.10 0.40 Bal 18 R56322 0.03 0.08 0.015 0.25 0.15 2.5 - 3.5 2.0 - 3.0 0.10 0.40 Bal 28 R56323 0.03 0.08 0.015 0.25 0.15 2.5 - 3.5 2.0 - 3.0 0.10 0.40 Bal 5 R56400 0.05 0.08 0.015 0.40 0.20 5.5 - 6.5 3.5 - 4.5 0.10 0.40 Bal 23 R56402 0.03 0.08 0.013 0.25 0.13 5.5 - 6.5 3.5 - 4.5 0.10 0.40 Bal 24 R56405 0.05 0.08 0.015 0.40 0.20 5.5 - 6.75 3.5 - 4.5 0.10 0.40 Bal 29 R56404 0.03 0.08 0.015 0.25 0.13 5.5 - 6.75 3.5 - 4.5 0.10 0.40 Bal 0.08 - 0.14 0.08 - 0.14 0.2 - 0.4 FIGURE 1 0.6 - 0.9 0.04 - 0.08 0.08 - 0.14 0.04 - 0.08 0.08 - 0.14 Other Other Ti APPENDIX II Titanium Product Specifications BAR / BILLET / FORGINGS ASTM ASME Titanium and Titanium Alloy Bars and Billets B 348 SB 348 Titanium and Titanium Alloy Forgings B 381 SB 381 PIPE ASTM ASME Titanium and Titanium Alloy Welded Pipe B 862 Code Case Replaced ASTM B 337 Titanium and Titanium Alloy Seamless Pipe B 861 Code Case (Now Discontinued) B 36.10M Dimensions only Welded and Seamless Wrought Steel Pipe Stainless Steel Pipe MSS COMMENTS ASME / ANSI MSS COMMENTS B36.19M TUBING Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers ASTM ASME B 338 SB 338 FLANGES / FITTINGS ASTM ASME Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings B 363 SB 363 Pipe Flanges & Flanged Fittings Dimensions only ASME / ANSI MSS COMMENTS ASME / ANSI MSS COMMENTS B 16.5 Steel Pipeline Flanges Factory - Made Wrought Steel Buttwelding Fittings ASME / ANSI Dimensions only SP - 44 B 16.9 Wrought Stainless Steel Butt - Welding Fittings Dimensions only Dimensions only SP - 43 Dimensions only Forged Fittings, Socket Welding and Threaded B 16.11 Dimensions only Ferrous Pipe Plugs, Bushings, and Locknuts with Pipe Threads B 16.14 Dimensions only Wrought Steel Buttwelding Short Radius Elbows and Returns B 16.28 Dimensions only Steel Line Blanks B 16.48 Dimensions only 15 Titanium Product Specifications cont'd STRIP / SHEET / PLATE ASTM ASME Titanium and Titanium Alloy Strip / Sheet / Plate B 265 SB 265 CASTINGS ASTM ASME Titanium and Titanium Alloy Castings B 367 SB 367 WIRE ASTM ASME Titanium and Titanium Alloy Wire B 863 SB 863 TESTING & CLEANING ASTM ASME Ultrasonic Examination of Metal Pipe and Tubing E 213 Electromagnetic (Eddy Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Sinilar Alloys B 426 Descaling and Cleaning Titanium and Titanium Alloy Surfaces B 600 ASME / ANSI MSS COMMENTS ASME / ANSI MSS COMMENTS ASME / ANSI MSS COMMENTS ASME / ANSI MSS COMMENTS ASTM - American Society for Testing & Materials ASME - American Society of Mechanical Engineers ANSI - American National Standards Institute [a Division of ASME] MSS - Manufacturers Standardization Society FIGURE 2 16 PRODUCTS (Sizes, Descriptions & Comments) Plate: • Thickness - 3/16” [0.1875”] through 10” Most common sizes 3/16” through 1-1/4”. Heavy sizes in the range of 2” – 3-1/2’’ are common for Tube Sheets (high-pressure) applications. • Width - 96” as produced (most common); can be made to 170” wide. Outside USA 60” wide (1.5 meters) is the most common. • Length - 240” standard but can be made to 400” (depending on thickness) Sheet: • Thickness - 0.016” min., generally, 0.020” to under 3/16” (0.1875”). Most common to 0.120” • Width - 48” standard. Outside USA 39.4” (1 meter) is common. Can be cut to any width above 24” (the minimum to be defined as sheet). • Length - To 20 ‘ (240”). Most common is 120” Strip: • Thickness - 0.016” min. generally, 0.020” to under 3/16” (0.1875”). Common to 0.100” • Width - to 24” max. Outside USA 39.4” (1 meter) is common. Can be cut to any width below 24” (the maximum to be defined as strip). • Length - To 20’ (240”) cut lengths. In coils - to hundreds (thousands) of ft (based on gauge). Pipe: • All standard diameter Nominal Pipe Sizes (NPS) and Schedule sizes (thickness) are available. • Diameters from 1/8” through 30” (welded & seamless) Sch 5 & Sch 10 to 12” diameter for Sch 40 & Sch 80. Most common are the Sch 10 walls. • Due to its high strength/weight ratio Sch 5 can be used for economy and weight reduction. • Welded pipe is more economical and much more common than seamless pipe in industrial applications, as in the CPI. • Titanium is highly erosion/corrosion resistant and ideal for salt water cooling. • Weight savings of 34% to over 85% (versus stainless steels, copper nickel and other Nickel Base Alloys [NBA]) can be attained since its density is 56% of steel and 50% of Cu and Ni alloys. The Sch wall thickness and Nominal OD’s can also be reduced in many applications using higher flow rates. Tube: • Most common for Industrial applications (i.e. heat exchangers) are the “Process Tube” sizes – 20 gauge - 3/4” x .035” and 1” x .035” and 18 gauge - 3/4” x .049” and 1” x .049” [OD x Wall] • Very high erosion/corrosion resistance, elimination of corrosion allowance in saltwater, brines, polluted waters, etc. make savings possible by using reduced wall thicknesses. • Millions of feet of welded process tubing are produced annually and it is significantly less expensive than seamless tube by a factor of 2 to 2-1/2 times (sometimes more, depending on the actual tube size). These sizes are very common and are stocked. • For condenser heat exchangers, particularly for the Utility industry, 25 gauge - .020” is generally the thinnest wall, with 22 gauge .028” the heaviest. Diameters of 1” are generally the largest and most common. Multi millions of feet are produced annually for this service. • There are 3 NDT tests performed on welded tubes – Ultrasonic, Eddy Current, Hydrostatic or Pneumatic that assure the intrinsic high quality standards of the product. Fasteners: [Screws, Nuts, Bolts, Washers, etc.] Fittings: [Elbows, Tees, Stub Ends, Reducers, Couplings, Weld-O-Lets, Soc-O-Lets, Thread-O-Lets] Flanges: [Slip-On, Weld Neck, Blind, Threaded, Figure 8 Blanks, Spectacle Blinds, etc.] Specialty parts are also available. 17 APPENDIX III WELDING & OTHER FABRICATION PROCESSES CP & 6Al – 4V are the most common grades of titanium that are welded. Most welding is done outside of a chamber and it is relatively easy to get very good welds. By Cladding (Explosive welding) titanium can be joined to other metals. Tungsten Inert Gas (TIG) / Gas Tungsten Arc Welding (GTAW) is the most common method of welding titanium. However, all methods can be successfully used, including all of the following: Gas Metal Arc Welding (GMAW) / Metal Inert Gas (MIG); Plasma Arc Welding (PAW); Electron Beam Welding (EBW); Laser Beam Welding (LBW); Resistance Spot / Seam Welding (SPOT); Flash Welding (FW); Explosion Welding (EW); Submerged Arc Welding (SAW); Diffusion Bonding (DB) and Brazing. TIG/GTAW fusion welding is a mature technology, extremely common and performed by thousands of welders. Trained welders have no problems welding complex equipment. Typically, A TIG welder (of other metals) can be qualified on titanium within 2 weeks (within a week, in many cases). 0 Trailing shield of Argon is required to allow Ti to cool below 700 F to prevent oxidation. For CP titanium, due to its purity, the weld pools are very fluid, are much easier to weld and preferred by trained TIG/ GTAW welders over many alloys (i.e. stainless and nickel base). MIG / GMAW is generally used to weld material > 1/8” (The thicker the metal the more economical) Weld gas required is Grade 4.5 [99.995% pure …50 ppm impurities] Filler metal to AWS specification A5.16 SHOP PRACTICES Cleaning 0 Titanium must be Free of dirt, oil, moisture and dust (heat to 160 F to remove moisture) Use non-chlorinated solvents such as acetone, MEK or alcohols (No Methanol) Wipe joint area then Brush with new stainless steel wire brush 1/2” to 1” back from the joint Wipe again with acetone and wipe the filler rod Use (no lint) white cotton gloves Area should be clean and free of drafts Tight joint fit up (to minimize air) and overlap starts Purging Torch should contain a large diameter cup with a diffuser and a trailing shield Use non-permeable gas hoses Trailing shield should have a separate gas line 0 Back side purge tooling used if back is above 500 F Pre-purge setup before striking arc 0 Post-purge until Ti is below approx. 700 F Verify weld color & parameters on a scrap piece (for comparisons) Testing Liquid Dye Penetrant (Easier for Ti due to the fluidity of the weld) Radiographic Visual Hardness / Scratch Color – an additional check (see below) 18 Color & Weld Quality Weld color is an indication something was not 100% correct but may not mean the weld is bad. It may only be that the trailing shield was not kept above the weld long enough and some oxidation occurred and may only be a surface condition. Straw and light blue is generally acceptable in many applications. Once past the Light Blue stage, in most cases, the weld should be ground out / checked to determine if it is throughout the weld or a surface condition and appropriate corrections in weld technique should be made. Coloration is an indicator of the thickness of the oxide layer. The table [Edison Welding Institute] below indicates the progression of oxidation and its effect on Elongation. The fact that titanium shows different colors is a plus, in that it presents an addition visual process control test. Base Glossy Silver Light Straw Dark Straw Light Blue Purple Dark Blue Dull Yellow Dull Gray Powder White 30 % Tensile Elongation 20 % Elongation “ 12 % Elongation “ “ < 12% Elongation “ “ “ OTHER FABRICATION PROCESSES Titanium is not an exotic material and is most often fabricated on the same equipment as other materials such as stainless steels and nickel base alloys. Taking into account the differences in its metal properties such as a lower density and much lower modulus of elasticity, higher melting point, lower ductility, etc. and compensating for them is the key to successful fabrication. Some items with respect to titanium fabrication are shown below: Shearing Capacity standards similar to type 300 stainless steel Cutting – Practically all methods Oxy-Acetylene Torch – same gas, smaller tips, higher speeds Plasma Torch - option Abrasive Saw – Rubber bonded 60 grit silicon carbide wheels are common Hacksawing – coarse blades (3,4, or 6), lots of coolant to minimize heat, heavy feeds Band Sawing – coarse pitch teeth (6 per in. recommended); high-speed steel blades I” wide are typical; 2 cutting rates about 1 in /min; water soluble or sulfo-chlorinated coolant & rigid setup. Grinding Hand Abrasive Grinding – Use Large grain, open type, and clean wheels; avoid heat buildup; Do Not use sandpaper or steel wool; protect areas from sparks; avoid collecting grinding dust. Wheel Grinding – hard wheel, vitrified bonded is best; Al2O3 good below 2000 surface ft/min; SiC @ 4000 to 6000 surface ft/min; feeds of 0.001” per pass common; grit of 60 to 80 and hardness of J to L are common; complete flooding best. Belt Grinding – 5 to 10 micro inches are possible; SiC resin bonded cloth generally best; 50 grit for coarse & 120 grit for fine grinds; lots of fluids, 1000 to 2000 sf/min and 100 psi load generally best. 19 Machining Not difficult, similar to Austenitic stainless steels. Use Low speeds, maintain high feed rates, lots of coolant, sharp tools, do not stop feeding while tool and work are in contact and use rigid setups. Machinability Index for CP Titanium is 40 [302 Stainless = 35; 1020 Steel = 70; 2017 Al = 300] Turning Milling Boring Tapping Reaming Gear Hobbing Drilling Broaching Shaving Planing Shaping Forming Readily formable @ RT using same equipment, etc. as for steel. Ductility being less, more generous Bend Radii are needed. Hot forming may be necessary for severe bends (there is more spring-back due to the modulus of elasticity being half that of steel). Lubrication is very important. Source; Information in Appendix III – International Titanium Association [ITA] (Broomfield, CO) “The Fundamentals of Titanium:101” and Hi-Tech Welding Service, Inc. (El Cajon, CA) 20

© Copyright 2026