Paperless Manufacturing Solutions With MES PAS-X and OSIsoft's

Paperless Manufacturing Solutions With MES PAS-X and OSIsoft's PI System For Bio Manufacturing Presented by Barry Higgins, Janssen Biologics Robert Welter, Werum Software & Systems © Copyri g h t 2013 OSIso f t , LLC. Barry Higgins [email protected] Manufacturing Systems Engineer Janssen Biologics, Ireland Robert Welter [email protected] Head of Department PAS-X Product Management Werum Software & Systems AG © Copyri g h t 2013 OSIso f t , LLC. 2 About Janssen 3 key business sectors: Consumer Medical Devices & Diagnostics Prescription Products JSC API Supply Chain Chemicals – 6 sites Biologics – 5 sites Worldwide Pharmaceutical sales of $24.5 billion in 2012 © Copyri g h t 2013 OSIso f t , LLC. 3 Who we are © Copyri g h t 2013 OSIso f t , LLC. 4 What we do Software Services Content © Copyri g h t 2013 OSIso f t , LLC. 5 Overview ERP CAPA PAS|X Deviations DMS Material Master Overall Inventory Production Orders LIMS SOP’s Drawings Instructions Master Batch Records Production Resource Management Electronic Batch Recording Material Management in Production From Weigh & Dispense to Packaging Review by Exception LDAP / AD Users Synchronization Set values Samples Process Control System(s) PI System Process data Alarm & Events Process data Building Automation System(s) IPC instruments Scales & Printers © Copyri g h t 2013 OSIso f t , LLC. 6 Electronic Batch Recording with PAS|X Master Batch Records Electronic Batch Recording Approval Process Review by Exception © Copyri g h t 2013 OSIso f t , LLC. 7 Integrated Approach • • • • PAS|X Commands & Set Points to Process Control System Process Data, Alarm & Events collected in the OSIsoft PI System OSIsoft PI System data referenced in the PAS|X EBR PAS|X EBR batch execution data referenced in the PI System PI System PAS|X Process Control System(s) Werum's PAS-X User Group Meeting 2012 © Cop yri g h t 2013 OSIso f t , LLC. 8 The Details PAS-X MBR Attributes of Equipment Classes & Equipment Tag 1: Tag 2: Tag 3: Value-Type Value-Type Value-Type PI AF Tag ID Tag ID Tag ID PAS-X EBR Actual values Alarms Events Tag 1: 39.25 C° Tag 2: 47 RPM Tag 3: 1.37 Bar PI System Batch Interface BO: St 09:00 am BF: St 12:00 pm BF: Fi 01:00 pm • Trend data • Events • Batch data © Copyri g h t 2013 OSIso f t , LLC. 9 Integrated Solution - Benefits PAS|X PI System Seamless integration of process data into Master Batch Record definition and Electronic Batch Recording Using industry standard MES and Historian Handling of Alarm & Events according regulatory requirements Pro-active development of new features & functionality Batch analysis at the EBR level Long-term archiving of process data Predefined, configured and reliable integration © Copyri g h t 2013 OSIso f t , LLC. 10 PAS|X to PI Event Frames • OSIsoft and Werum collaborated to develop the Werum PAS-X Batch Interface which will become standard OSIsoft product. • This enables us to perform batch analysis at the EBR level from a Basic Operation (BO) or Basic Function (BF) perspective. • The capability to store basic function activities as batch events is similar to current DCS batch events. • Material and equipment usage data can be captured. Livepoint from Mirabo Systems © Copyri g h t 2013 OSIso f t , LLC. 11 PI Asset Framework – From PI AF to eBR PI AF Element Templates Upload from PI AF MBR Generation •Class based template. •Unit Elements created from template. •Class based PCS MBR elements •Building blocks for MBR modellers •Class based MBR EBR Execution •Unit resolved at run-time. •Data retrieved from PI AF Unit Element © Copyri g h t 2013 OSIso f t , LLC. 12 Removing Paper • pH testing before PAS|X & OSISoft PI: Paper Batch Record instructs technician to take pH sample. Technician manually checks Paper equipment logbooks. Technician takes sample and performs test and prints out result on paper. Technician copies result and attaches it to Batch Record and records result. Result in batch record, printout and copy are reviewed before batch release. © Copyri g h t 2013 OSIso f t , LLC. 13 Removing Paper • pH testing after PAS|X & OSIsoft PI System: EBR prompts Technician to. Take pH sample. Technician scans pH meter for status Technician performs pH test and result is sent to the PI System PAS|X requests result from PI AF Result is evaluated, during EBR execution. © Copyri g h t 2013 OSIso f t , LLC. 14 Benefits of PAS|X and PI AF • One Screen, multiple sources of live data. • Visual Equipment status © Copyri g h t 2013 OSIso f t , LLC. 15 Benefits of PAS|X and PI AF One location for multiple data sources: • MES data • SAP data • OSIsoft PI System data • QA information © Copyri g h t 2013 OSIso f t , LLC. 16 Benefits Removal of over 1000 paper documents (to date) from Manufacturing • Interface of Scales to the PI System and PAS-X eliminates manual entries • Automated pH/Cond/Osmo/Filter integrity testing. Result retrieval directly from the instrument to the PI System Greater Visibility on Status of Orders • Process is tracked from Warehouse to Manufacturing to Warehouse Exception Free Manufacturing • Mistake proofing in area of GDP errors and partially completed ‘Paperwork’ eliminated • No more searching for Docs / SOPs; automatically linked to Master Batch Record © Copyri g h t 2013 OSIso f t , LLC. 17 Brought to you by © Copyri g h t 2013 OSIso f t , LLC.

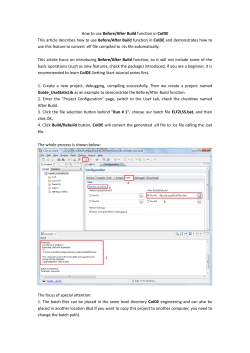

© Copyright 2026