Cd How to understand and deal with overloading in GC The Chrom

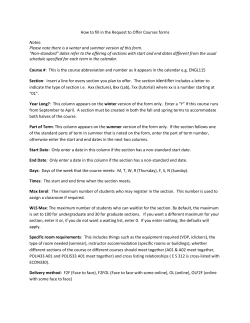

Cd The Chrom Doctor How to understand and deal with overloading in GC When operating capillary columns, we must run at optimal conditions of linear gas velocity to maximize separation power. However, when the amount injected into the column is too high, peaks become nonsymmetrical – this effect is referred to as overloading. An overloaded peak is generally not a problem for quantification, but when it starts to affect the separation of a neighbouring component, corrective action is required. In addition, overloading can change the retention time of the component. As the stationary phase is saturated, the component itself will also act as a stationary phase resulting in ‘strange’ chromatograms. Overloading mainly occurs in stationary phases for which there are several parameters for manipulation. For appropriate corrective action, it is important is to understand the type of stationary phase being used; that is, a solid or a liquid. Overloading in gas-liquid vs gas-solid 1. The polarity of the stationary phase: chromatography Polar components will dissolve better in a In gas-liquid chromatography (GLC), in which polar stationary phase than in a non-polar we use polysiloxane (liquid)-type stationary stationary phase. Figure 2 shows the elution phases an overloaded peak will show itself of an acidic component, 2-ethylhexanoic with a slow-raise and a sharp end. This is also acid from two different columns. On the known as fronting. non-polar column (a) the peak is strongly In gas-solid chromatography (GSC), overloaded, while on the polar column (b), in which the stationary phases used are the peak is high and symmetrical. Also on adsorbents such as alumina, molecular this phase, the acid peak elutes after the sieves and porous polymers, an overloaded methyl dodecanoate peak. component will show a fast rise but slow tail. This is also known as tailing (Figure 1). Figure 1 To deal with these phenomena, it is vital to know whether we are dealing with GLC or GSC. Gas-liquid chromatography Ideally, a component that is separated in a capillary should elute with a symmetrical, Gaussian peak shape. However, this will only occur if with sufficient loadability. The g l g s b (s maximum amount that can be injected onto a particular capillary column depends mainly on: 38 Figure 1: Peak shape of overloaded peak in gas-solid and gas-liquid chromatography. chrom doctor www.sepscience.com 2. The amount of stationary phase present identification. Injecting less sample, as within the column: The main parameter here shown in Figure 4(b), improves the peak is film thickness. Thicker films allow more shape considerably. sample to be while keeping symmetrical If injection of less sample is not possible, peaks. Also, if we use wider diameter, because of GC setup restrictions (for longer columns, we will benefit from example, when a fixed sample loop is used higher loadability. However, be aware that with direct injection), or for detecting a trace with increased film thickness and column analyte, consideration should be given to a length, retention times and column bleed 0.53 mm type PLOT column, perhaps even a will increase proportionally. Figure 3 shows longer one. the impact of increased film thickness on Another approach is running at a higher loadability. For comparison reasons, the test temperature as this will improve peak shape mixture on the thicker film was analysed at a significantly using PLOT columns. Figure 5 higher temperature for which the retention factors are similar. Figure 2 3. The retention (factor) of the component on that particular column: Components (a) with a higher retention will often show (b) quicker overloading phenomena than early eluting components. Note that we can influence retention factor with the oven temperature. If a late-eluting peak shows sign of overloading, run the analysis at a higher temperature and/or increase the temperature program rate. Gas-solid chromatography In gas-solid chromatography there is Time (min) Time (min) Figure 2: Effect of solubility on loadability. Columns: (a) Rtx-1, (b) Stabilwax-DA; dimensions = both 30 m x 0.53 mm with 0.5 μm film. generally little flexibility in the amount of stationary phase in porous layer open tubular (PLOT) columns – the layers are Figure 3 already very thick to generate maximum retention for volatiles. Overloading in gassolid chromatography is visualized by a strong tailing of the component. As the capacity of adsorbents is usually lower than liquids, the overloading phenomena is observed much faster. When peaks start to tail using a PLOT column, try to inject less sample. Figure 4(a) shows hydrocarbon overload on a PLOT column, in which the polar hydrocarbons, methyl-acetylene and 1,3 butadiene, tail Time (min) Time (min) significantly. The overloaded hydrocarbons also elute earlier, which can result in a false separation science — volume 1 issue 4 Figure 3: Effect of liquid stationary phase film thickness on loadability. Column: Rtx-1, 30 m x 0.25 mm i.d. chrom doctor 39 Figure 4 (a) (b) Time (min) Figure 4: Impact of absolute sample load on solid stationary phase/PLOT column. Column: 30 m x 0.32 mm Rt-Alumina BOND/KCl: (a) overloaded injecting 50 ng per component, (b) injecting 5 ng/component. Peaks: 1 = pentane; 2 = methylacetyene; 3 = pentane; 4 = 1,3-butadiene. Figure 5 (polar) hydrocarbons will elute faster relative to saturated (non-polar) hydrocarbons. This is why, in the example, both peaks elute closer to the pentane peaks. 150 In practice 100 To solve an overloading issue that impacts 50 0 0 1 2 3 4 5 6 7 on quantification a new column with more 8 capacity or solubility can always be applied. 125 Initially, it is preferable to overcome the 100 challenge using the existing column by 75 reducing the absolute amount of sample 50 25 0 0.0 compound injected on to the column. This 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 Figure 5: Impact of temperature on peak shape of 1,3-butadiene and methyl acetylene. Column: 30 m x 0.53 mm Rt-Alumina BOND/Na2SO4. Peaks: 1 = 1,3-butadiene, 2 = methyl acetylene. can be done via: • Injectingless,smallersamplevolume, higher split ratio (Figure 6). • Dilutingofthesamplepriortoinjection. shows the separation of C1-C5 hydrocarbons using Al2O3, but operated at different By doing this a higher sensitivity setting of temperatures. The peak shapes for both the detector must be used. However, if this 1,3-butadiene and methyl acetylene improve does not solve the problem, a column with at higher temperatures. It should also be more capacity/solubility is required. noted that changing temperature will initiate 40 chrom doctor another effect – the alumina will become Acknowledgements less ‘polar.’ The result being that unsaturated SpecialthankstoBillBromps,RestekR&D www.sepscience.com Figure 6 20 ng/component on the column Split ratio was increased by a factor of 2 10 ng/component on the column Figure 6: Example of practically improving the separation by decreasing the injected amount on the column by a factor 2. Column: 30 m x 0.25 mm Rxi-5Sil MS, film = 0.25 μm. and Tom Vezza, Restek PLOT specialist for supplying chromatograms. Jaap de Zeeuw is a specialist in gas chromatography working for Restek Corp. 21 - 24 September 2009 Grand Hotel Malahide Dublin, Ireland CASSS AN INTERNATIONAL SEPARATION SCIENCE SOCIETY separation science — volume 1 issue 4 chrom doctor 41

© Copyright 2026