FACTS WEMA GmbH: Airbus: How to construct

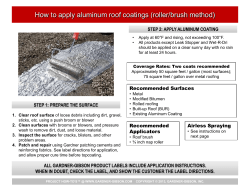

Customer magazine No. 30 September 2007 FACTS for coating technology How to construct a high-performance coating on my tool? Page 14 WEMA GmbH: Increasing cutting Photo: Airbus S.A.S. Airbus: Taking off Pages 8-9 N TE T Photo: WEMA GmbH AE PALT D E I ING ER C T N A H SCTO UENCGO ES P D N IS NTC TE E E S A M R RRL EUW O 4 T H O F E R e6-17 TEF M g E H n a P IC E HN eiPte G CH G S I N S I BAR H BE Pages 6-7 Increasing performance is not rocket science In this edition n Editorial 2 n “Thick” PVD-coatings Coating thicknesses up to 12 µm lead to longer tool life 3 n In-house coating with small capacities The CC800®/9 JET brings PVD-technology to every company economically 4 n With smooth coatings drilling becomes easier Longer machining of high-tempered steels 5 n High-quality tools from Bavaria Solutions adapted to all tasks in machining 6-7 n That’s how the super bird takes off Diamond-coated tools optimize the production of the Airbus A380 8-9 n For special applications – the adapted milling tools Smooth coatings and high reproducibility without chip congestion but with long tool lives 10-11 n Qualified manpower recruited Twelve young adults are trained in Würselen 12 n Who said fishing is relaxing? 13 CemeCon-team successful in „The Great Fish Race“ n Imprint 14 n Four steps to the optimum coating CemeCon presents its new internet site and offers the easy way to high-performance coatings 14-15 n Powder metallurgy in focus The experts of the branch meet at the Hagener Symposium 15 n Product surfaces with an added value Whether colored or wear resistant: coatings refine jewelry and more 16 Dr.-Ing. Toni Leyendecker, CEO CemeCon AG „How do I design a high-performance coating for my tool?“ We intend to look at this question in detail on our internet site as well as at this year’s EMO in Hannover. For almost all modern precision tools are now coated with extremely high-performance coatings. Material, grinding technology, geometry and coating are carefully coordinated with one another to achieve the extremely high performance required by the user. When designing a tool, tool designers know every detail of the application, basic materials, grinding techniques, geometries and microgeometries and combine this knowledge with their expertise. However, it is usually only major manufacturers that approach the layout and design of the coating systematically. Yet a coating is not rocket science – it was viewed as such only in the early stages. However, a great deal of time and consideration goes into creating the optimum specifications. This is because even the most painstakingly planned tool will fail to deliver if the designer does take pretreatment, coating material, coating thickness and tolerances as well as color and post treatment into account. But how do I do that? This is a question we aim to answer in our article on page 14 by explaining to you the system involved in structuring and designing a high-performance coating. From September 14, you will also find this information by clicking on our new internet site at the familiar address www.cemecon.de. Even better, you can visit us at the EMO, Booth B15, Hall 4. I know that this is not the usual way of looking at things. And that is precisely why my colleagues and I are looking forward to some very interesting talks with you. Have fun reading the FACTS! Dr.-Ing. Toni Leyendecker 2 3 Numerous benefits with the PVD method “Thick” coatings on cutting inserts In order to be able to react quickly to new machining requirements and not be left behind, it is essential to recognize trends at an early stage. This also applies to the coating industry. To achieve this, it is essential to cooperate closely with tool manufacturers and users. It is almost ten years since the first attempt to create PVD coatings with thicker coatings. They were used particularly successfully on indexable inserts. The “thick” PVD coatings from CemeCon are coating specifications, where customers adapt coating materials such as ALOX SN² and ALOX SN² gold to their particular insert types and/or requirements, and successfully use them. Just how thick is “thick”? What does a coating specialist consider to be a “thick” coating? After all, we’re only talking about a few thousandths of a millimeter. Most coatings with high thicknesses are nowadays produced using the CVD method. The average coating thicknesses are between 10 and 12 µm. The coating compositions are primarily TiN, TiCN and aluminum oxide in combination with one another. However, a significantly wider range of materials is now being demanded. Tool manufacturers want the option of combining elements such as aluminum, chrome and silicon in order to adapt the properties of the coating materials even more precisely, thus equipping themselves in the best possible way for new challenges and materials. At present, the only way to achieve this goal is through using PVD technology. This enables the user to benefit from additional advantages such as ultra-smooth coating surfaces and low process temperatures. Accordingly, oxidic coatings are no longer beyond the limits of PVD technol- the machining process such as high temperature. Secondly, by doubling the coating thickness, the user gains in excess 100% tool life in some applications. Both already the existing coatings as well as future developments are suitable for turning and rough milling applications in all common steels and grey cast irons. n ogy. Using elements such as aluminum, chrome, zircon and others, innovative coating materials are set to open up completely new possibilities in the coming years. These coating materials can be produced in combination with supernitrides, for example, in PVD-typical 3 µm coatings as well as 8 µm and even higher coating thicknesses – depending on the conditions of the cutting edge and the application. Longer tool life with thick coatings The advantages of thicker coatings are clear: on the one hand, the substrate is protected against effects resulting from Coatings up to 12 µm are already possible with PVD technology. A technology for (almost) every purpose In the past, manufacturers of indexable inserts in particular had to come to terms with various technologies in order to cater for all the requirements. With the new PVD developments it will soon be possible to meet a much wider range of requirements using a single technology. From coatings for milling to burring and turning – in future it will be possible to process all this and more using a single system. Because, in addition to modern high-tech nano coatings, PVD technology also allows the deposition of oxidic coatings, the coating of non-conductive cutting ma- terials and the creation of greater coating thicknesses in combination with the advantages of PVD sputter technology. In addition, the PVD method is environmentally friendly and does not result in any toxic waste products! Your contact at CemeCon Inka Harrand Product Manager Cutting Inserts Phone: +49 (0) 24 05 / 44 70 105 [email protected] In-house coatings even with small capacities PVD coating technology for the price of high-quality grinding technology Working together with a tool coating company is one way of gaining access to state-of-the-art coating solutions. An alternative is to integrate coating technology directly into in-house production. There are fewer obstacles than commonly perceived. Compact dimensions for coating systems requiring only a small amount of space which are easy to operate thanks to fully automatic process control make it easier to take the first steps and enable tool manufacturers to react more flexibly to customer requirements. The advantages to tool manufacturers of integrating high-quality PVD technology into in-house production are obvious: the reaction time to customer wishes is substantially reduced, the logistics are noticeably reduced and no transport costs between in-house production and the tool coating company. Small, but what a performance What happens if only smaller coating volumes are required? Does it make sense economically to use an in-house PVD system? The CC800®/9 JET makes it easier for small and medium-sized companies to take the first steps towards in-house coating with tried-and-tested technol- ogy. Despite its compact design, the “little one” is capable of precisely the same performance as its big “brothers and sisters”. The CC800®/9 JET supplies exactly the same coatings, which tool manufacturers and recoaters can design for their applications using the same broad range of various coating materials of the Würselen-based systems engineers. The high-precision coatings created by PVD sputter technology are distinguished by extreme wear protection, excellent oxidation resistance as well as hardness and hot hardness. They also create extremely smooth surfaces, no cutting edge roundings, with outstanding adhesion qualities. In this way, tool manufacturers can produce hard and super hard coatings with the CC800 ® /9 JET successfully and economically within their own companies. Excellent service It is not especially difficult to integrate production of this Taking the first steps towards inhouse coating: CC800®/9 JET. 4 kind into one’s own company. For this purpose, CemeCon has experienced employees who assist tool manufacturers at all stages including first draft, installation, production start-up and beyond. Moreover, training is provided for the in-house personnel to ensure safe operation of the technology. In this way, the Würselen-based company passes on its many years of experience in systems engineering and coating services to the user, experience that was gained in its own coating center. This coating center provides the best opportunities for this. It is, after all, one of the world’s largest. In addition, CemeCon offers a guaranteed long-term spare part and delivery service for consumables. Should the coating volume increase, the coating system can be expanded accordingly, since all CC800®/9 systems are based on the same concept and identical process technology. As a result, tool manufacturers remain flexible even if batches increase in size and, thanks to the simple operation of the systems, are able to drastically shorten the time they need to react to market requirements. n Your contact at CemeCon Dr. Peter Ballhause Product Manager Technology Transfer Phone: +49 (0) 24 05 / 44 70 110 [email protected] 5 JEL: Drilling in hard materials Sharp increase in tool lives Innovative technologies and high-performance precision tools are in great demand not only in the automotive industry. JEL Precision Tools GmbH & Co. KG is finding increasing numbers of solutions for special applications in a number of markets. For example, a famous car manufacturer has contacted the tool experts. Longer tool lives when drilling in highstrength steels with an Rm tensile strength of 800 to 1,200 N/mm2 and steels with hardnesses of up to 58 HRC were the goal that JEL set itself in accordance with customer wishes. The varioius solid carbide step drills and countersinks for the automotive industry which are used in these application are sometimes used with minimal lubrication. In order to adapt the precision tools to the requirements, the experts based in Swabia designed a tool solution with coating materials from CemeCon that was customized to this special application and which not only creates particularly smooth surfaces but also increases tool life by 35% from 2,000 drillings to 2,700 (cutting parameters vc=110 m/min; fp=0.24 mm/U). JEL also sought an optimum solution with CemeCon for the regrinding process including recoating. The Stuttgartbased tool manufacturer combined the individual work steps in such a way that the same performance is achieved after regrinding and recoating as with a new tool. n Easier drilling with smooth coating Of particular importance when drilling is the smooth removal of the chips from the drilled hole as the chips otherwise block the drilled hole and the tool jams. This applies even more with materials that tend to form long chips when being cut. An extremely smooth drill surface, especially in the flute, ensures that the chips are removed and creates high surface qualities thanks to the low friction of the Tland. A coating should not only be smooth but also match the contour. This is made possible by means of a coating specially designed by JEL. The company uses this successfully on carbide drills with margins. Photos: JEL At JEL, modern systems technology and expertise ensure tools with optimum performance. JEL Precision Tools GmbH & Co. KG JEL Precision Tools GmbH & Co. KG, a company of the Komet Group, was founded in 1931 in Stuttgart and traditionally produces threaded tools. In recent years, the Swabian company increasingly specialized in solid carbide drilling tools as well as all kinds of carbide and PCD special tools. Today, JEL has 75 employees. JEL Precision Tools GmbH & Co. KG Ruppmannstraße 32 70565 Stuttgart Germany Tel. +49 (0) 711 / 78891-0 Fax +49 (0) 711 / 78891-11 E-Mail: [email protected] Internet: www.jel.de Your contact at CemeCon Marc Semder Sales Manager Phone: +49 (0) 171 / 9700 736 [email protected] WEMA: High-quality Bavarian tools Longer tool life – faster cutting Whether for mechanical engineering or the automotive industry, for basic tools or a special solution – WEMA GmbH, based in Pfaffenhofen, offers quality and technology of the highest degree. Thanks to a well-equipped machine park, the company is able to produce tools for milling, drilling and reaming at short notice. This includes not only new tools but also a comprehensive regrinding service. fit chuck and a coating specification based on an extremely tough coating material. The tools work with a cutting speed of 230 m/min and a feed of 0.05 mm per tooth. Removal of material residues on flat contours as well as long cantilevers show that the tools have a high running smoothness and good surface qualities. Moreover, WEMA increased tool life three to fourfold. The full-radius milling During the product development stage, WEMA, the development and marketing partner, meta-cut, and CemeCon work closely together to ensure that the coatings used are perfectly customized to the applications. This tried-and-tested hand-in-hand procedure allows WEMA to adjust the tools designed by meta-cut and coated with CemeCon technology to the customer requirements at short notice: The solution for every machining problem For example, KBW GmbH was looking for an optimum solution for the production of body prototypes (using the ST52 material). WEMA provided it: a Q-Cut carbide full-radius milling tool for highperformance machining with a CAD-optimized cutting edge, tension in the shrink- Power packages in a row: Coated WEMA milling tools stand out thanks to excellent cutting speeds and tool lives. Sale via the world wide web WEMA cutting tools achieve maximum performance in numerous materials. 6 Based in Pfaffenhofen, meta-cut GmbH sells carbide machining tools from WEMA via the internet. The company places particular value on providing products that are made in Germany and on ensuring that tools always conform to the highest technological standards. The symbiosis of hard metal quality, cutting geometry and coating ensure optimum performance in various applications. You will find further information at www.meta-cut.com 7 tools also deal excellently with pocket milling and aluminum processing. Process safety in GFP and CFP Process safety was the concern of Thoun carbon fiber design GmbH when processing special products using GFP and CFP for industrial systems manufacturing and carbon-fiber products for the sports industry. WEMA supplied a special solution that was perfectly tailored to these applications: with the coated single-tooth milling tools in various diameters, which have a similar geometry to that of A-Cut carbide aluminum milling tools, the tool life was increased thanks to excellent c h i p flow and the tendency towards cutting edge breakages was minimized. During processing of the very abrasive materials, the tools – coated with a coating based on the coating material CC plus D – also achieved a 15% increase in cutn ting speed. WEMA GmbH produces milling, drilling and reaming tools for mechanical and mould engineering as well as for the automotive industry. The Pfaffenhofen-based company works closely with dealers and distributers and offers both new products and a regrinding service. WEMA GmbH Fräs-, Bohr-, Reibwerkzeuge Fertigung und Instandsetzung Raiffeisenstraße 9 85276 Pfaffenhofen an der Ilm Germany Tel.: +49 (0) 8441 / 85 916 0 Fax: +49 (0) 8441 / 85 916 20 E-Mail: [email protected] Internet: www.wema-online.de WEMA managing director Max Prem. Catalog tool or special tool: WEMA products meet the highest requirements. Your contact at CemeCon Frank Schönberner Sales Manager Phone: +49 (0) 170 / 6310 718 [email protected] The WEMA team in Pfaffenhofen is constantly working on adapting high-quality tools precisely to the applications in question. Photos: WEMA GmbH Airbus Deutschland GmbH: Take-off with lightweight Substrate, geometry, coating – the fantastic trio Photos: Airbus S.A.S. From summer 2009, the new super airliner – the Airbus A380 – will fly 555 passengers to their holiday or business destinations with previously unheard of comfort and economy. The super bird is produced using hi-tech materials and designed in line with state-of-theart knowledge to enable it to withstand the enormous stresses connected with take-off, landing and flight. Production is also state-of-the-art: thanks to optimized tools, the Airbus workshops have increased the lifetime for drilling carbon-fiber reinforced plastic-metal composites by more than 500% – with fantastically low drilling tolerances. This development is continued with the production of the CFRP airfoils for the new A400M military transporter in Stade. The European aircraft manufacturer, Airbus, has been distinguished in recent years by consistently high quality and innovative strength, thus reinforcing its position on the international market. Such successes are based on close cooperation between specialists: during the processing of fiber composites, Airbus in Stade and Hamburg have made dramatic savings in terms of time and money thanks to individual diamond-coated solid carbide drills developed in cooperation with several companies. 8 Economic effectiveness through expertise weight of the new A380 – a figure which is currently unique. These savings are important as good production costs for aircraft construction are a high priority – as important as a high level of safety and longevity as well as reduced fuel consumption. For this purpose, designers are turning to hi-tech lightweight such as advanced aluminum alloys (AlSi) and carbon-fiber reinforced plastics (CFRP). CFRP now constitutes some 22% of the structural However, this material is very demanding in terms of machining, particularly with regard to tool wear when drilling blends of CFRP, aluminum and titanium in the Hamburg A380 assembly plant. In order to fulfill this machining task with acceptable lifetimes and optimum qualities, the most suitable tools must be acquired: one reason for Airbus to use the expertise of leading tool experts. 9 Specialists cooperate for optimum results In cooperation with the Swiss carbide manufacturer, Extramet, the tool manufacturer Klenk based in Balzheim, Baden-Württemberg and the coating expert, CemeCon, Airbus have received products customized to their special requirements. In the joint project overseen by Hamburg Harburg Technical University, substrate, geometry and coating were precisely designed to the areas of application. Taking off with diamond The 555 passenger capacity can only be achieved by having two levels, which has been achieved for the first time with this aircraft cabin. The upper deck floor beams are made of CFRP and must be connected with the bearing structure, in this case aluminum ribs. The diamond coating used in the machining of this material combination is in its element: using uncoated drills, the tool life quantity was only 90 drillings. After coating with an individually adjusted variant of the coating material CCDia®Fiberspeed, 500 holes were achieved in the first drilling tests – without a drill or coating failure. Bruno Süess, Managing Director of Extramet AG in Plaffeien: “By using diamond-coated tools, we increased the tool life by more than 500% for this application. This was based on a substantial reduction in the drill’s circumferential wear. Reduced replacement times and considerable savings potential in tool procurement costs also ensure drastically increased economic effectiveness in the production while at the same time guaranteeing optimum surface quality.” Diamond masters CFRP For the wing of the new A400M military transporter, it is necessary to produce rivet holes with diameters of 10 mm for connecting the stringers and wing skin. Stringers are longitudinal lightweight reinforcements which increase the rigidity of large-surface components. Stringers and wing skin are made of innovative CFRP materials and should be drilled together in one step of the process. the coated drills can totally withstand the severely abrasive wear caused by CFRP. Moreover, diamond offers the greatest possible resistance towards chemical influences, thus preventing adhesion of the workpiece material. n Horst Klenk, Managing Director of Klenk GmbH & Co. KG in Balzheim: “When drilling CFRP, it is important to avoid delaminations, i.e. separation of the external material layers. The high tolerance H8 class precision required by Airbus could only be achieved economically with the diamond-coated tool. Uncoated drills were not suited to this material combination and the high level of abrasive wear.” The most competitive coating solutions were diamond multilayers in the CCDia® series: due to their extreme hardness Kontakt: Klenk GmbH & Co. KG Mühlstraße 17 88481 Balzheim Germany Tel.: +49 (0)7347 950-0 Fax: +49 (0)7347 950 128 E-Mail: [email protected] www.klenk-tools.de Extramet AG Hartmetallfabrik Rüttistraße 9 1716 Plaffeien Switzerland Tel.: +41 26 419 91 00 Fax: +41 26 419 91 29 E-Mail: [email protected] www.extramet.ch mimatic Zettl: The road to optimum design Circular milling tools for special applications „mimatic Zettl“ – a global synonym for quality and perfect customer-specific solutions for CNC precision and special tools. Since 1974, mimatic Zettl GmbH, based in Betzigau, has been a first-class address for the automotive, mechanical engineering, aircraft manufacturing and timber processing industry with respect to circular milling tools for contour and thread manufacturing as well as grooving and burring tools for interior, exterior and axial processing. Using tools specially developed for this, the Allgau-based experts offer their customers greater productivity. The broader the product range, the more successful the Betzigau-based company is in solving tricky application cases with specially designed tools, in addition to the tried-and-tested standard products. No wonder the corporate philosophy is based on the synergy of highly motivated, expert staff with an excellent standard in the field of technology and development. As a result, mimatic Zettl is able to implement every special solution perfectly. 10 the South of Germany approached CemeCon in Würselen, Aachen. The coating specialists offer a wide range of coating materials and production methods that enabled mimatic Zettl to design the optimum coating specifications for their application. In this particular case, an extremely smooth surface and reproducibility were of utmost importance, especially with respect to the coating thicknesses. The tool that was thus designed and produced enjoyed resounding success: dimensionally accurate free-form contours, passes and threads true to gauge size can now be produced without chip congestion with long tool lives, short processing times and without expensive special tools, particularly in the application case described. Threads in blind holes that reach almost to the base are possible without undercuts. Difficult task – smooth solution As a globally active medium-sized production company, mimatic Zettl GmbH manufactures driven tool units for CNC machines and processing centers. Founded in 1974, the company currently employs 140 people and has a subsidiary in the USA in addition to its production site in Betzigau, Allgau. This is where the wheat is separated from the chaff. After all, every parameter must be perfectly coordinated to match the application. For example, when using circular milling tools for contour and thread production in a difficult application case for which mimatic Zettl had to find a solution: In addition to the tools specially developed for this case, an adapted coating also helped to solve this particular problem. To do so, the company based in mimatic Zettl GmbH Tool Systems – Präzisions- und Sonderwerkzeuge Westendstraße 3 87488 Betzigau Germany Tel. +49 (0) 831 / 57 444 – 0 Fax. +49 (0) 831 / 57 444 –90 E-Mail: [email protected] Internet: www.mimatic-zettl.de Thoste Tel.: +4 11 Consistent performance for carbide inserts This success spurred the company on to further projects: the range offered by the Würselen company allows mimatic Zettl to compose an individual coating on their carbide inserts for dry and wet processing of steel, cast and stainless steels. The desired effect: long tool lives and shortened processing times thanks to higher cutting speeds. A homogeneous and reproducible coating thickness ensures a consistent performance. Triangular inserts, multitooth thread inserts, three-edged and six-edged inserts with a polygonal plate fit as well as grooving inserts are part of the program. perfect-fit coating necessary for the application in question. For example, the new generation of circular milling tools in conjunction with carbide inserts makes it possible to integrate security ring grooves, metric ISO internal and external threads as well as Whitworth pipe threads into components with great precision. The polygonal connection of cutting insert and milling body impro- Since then, the close cooperation between the specialists has continued producing new synergies leading to innovative tool solutions as evidenced by the new mimatic Zettl circular milling tools with polygonal plate fit and six cutting edges for maximum machining volumes. On the basis of existing requirements, mimatic Zettl is contributing its own very specific ideas for ves the economic effectiveness of the machining process thanks to longer tool lives, higher machining volumes and feeds as well as shorter processing times. n Circular milling inserts with six cutting edges from mimatic Zettl supply consistent machining performances thanks to even coating thicknesses. Your contact at CemeCon Frank Schönberner Sales Manager Phone: +49 (0) 170 / 6310 718 Fotos: mimatic Zettl [email protected] CemeCon in the world of sport: Trainers unpacked! That CemeCon is not just a team in the professional sense of the word but also works together in completely different areas is proven by our representatives from CemeCon at the annual Lousberg race, a spectacular sporting event organized by RWTH Aachen University. Around 2,000 runners took to their heels on July 11, 2007, and navigated their way up the Lousberg in Aachen. CemeCon did not let this event pass it by. Seventeen coating expert employees in peak condition showed their fighting spirit on the 5,555 meter-long CemeCon-sportsmen in peak condition fought for the route. And they were best places on the 5,555 meter long route. not alone: Numerous en Rübben, Mohamed Boubrik, Aydin Yildirim 49 (0) 2405 4470 113; -513; -543 From “walking-preferrer” to “speedfreak”: all types of sportsmen joined the race. colleagues lined the route in order to cheer them on and shout words of encouragement. And their efforts were not in vain: After only 22 minutes and 14 seconds, Christoph Schiffers was the first CemeCon representative to pass the finishing line. Ewa Bienk was the first of the women to finish. After 30 minutes and 23 seconds, her colleagues were able to greet her as she crossed the finishing line. Reason enough to celebrate at the CemeCon stand! n Training in Würselen Equipped for the future The youth of today are the specialists of tomorrow: CemeCon adheres to this motto and offers training in various fields. By doing so, the coating expert ensures that it will have qualified staff in the future. CemeCon provides training in six professions and at the moment the Würselenbased company is training twelve young adults: Andreas Janoschka, René Unkart and Waldemar Triller as machine/systems operators, Nina Burhof as a technical draughtsperson, Sebastian Jung as a mechatronist, Timo Gossen as a computer scientist and Claus Binz and Kathrin Knipprath in commercial professions. At the start of August 2007, a prospective machine and systems operator, Sven Zielinski, an industrial sales representative, Jennifer Dahmen, and Heiko Fazlic, who is retraining as an industrial sales representative, and industrial mechanic, Michael Beumers, started their training. In order to allow trainees and apprentices to get to know one another and to promote teamwork, the Human Resources department organizes a trainee day every August, this year with the focus on sport in Kletterwald-Niederrhein. Moreover, 12 during the training period, CemeCon offers further training in „Communications and Holding Discussions for Trainees“ and „A Business Manual for Trainees“ as well as other courses such as „Making Presentations in the Final Examinations“. Gaining an insight into all departments Kathrin Knipprath (22), an industrial sales representative trainee, reports on her experience of training up to now: “During the training as an industrial representative, I have worked in all departments of the company. To begin with, I became familiar with Production and the processes involved there and learned about the coating process. Then, I went to Sales Support. I was involved in all areas of activity and worked independently following appropriate instruction. Purchasing was the next department on the list. My activities there began in the A team with future (from the left): Nina Burhof, trainer Claus Binz, Kathrin Knipprath, Michael Schulteis, René Unkart, Waldemar Triller, Timo Gossen, Hayrettin Kursat and Andreas Janoschka. warehouse where I became familiar with the products required for the process. After a short time, I was working independently and often had contact with the creditors. I am currently working in Information Technology where I am learning about the company network structure and picking up the basics of data processing. It is particularly good that as a trainee I am integrated into the team and, wherever possible, am able to carry out the same activities. Another good thing is that CemeCon offers apprentices the opportunity to take part in vocational seminars.” From training to a permanent job Hayrettin Kursat (machine and systems operator) and Michael Schulteis (industrial sales representative) prove that the end of training is not the end of the road at Würselen. After passing their final examinations, they were given permanent jobs. Michael Schulteis took up his job in the Service, Purchasing & Logistics department and Hayrettin Kursat in the Coating Service Production Diamond department. n 13 A successful fishing expedition in „The Great Fish Race“ Fishing fresh fish ... Fishing can help you to relax, or so they say ... That this sport can also be wildly exciting, however, was proven by the CemeCon English regional sales manager, Darren Cox, and his team in the „Great Fish Race“ in Poole near the English Channel in the South of England. Even the most powerful of men in the world do it. Discussing politics, they sit there with their rod and net, waiting for a fish to bite. However, the contemplative nature of a state visit of this type is completely absent from a fishing competition. Because no matter what fish is being hunted down, every team member must remain on the ball at all times. After all, they have to get more fish to bite within a specified time than their competitors in order to claim the coveted cup, the winner’s prize or even just some fame and renown for themselves. Stiff competition A mere two fish made all the difference in deciding who won and who came seventh – this is what Darren Cox found out at the “Great Fish Race” in Poole, near his home town in Dorset, in the South of England. That was where, in early-June, the task was for each team of four to get as many fish as possible to bite within an eight-hour time span. To this end, two teams started by boat in order to “fish” for the first prize of £1,200 as well as other prizes. Darren Cox: “Even though the competition between the teams is absolutely fierce, there is no end of fun when we’re out there fishing.” At this time of year, the waters around Dorset are home to perches, mackerels, rays, codfish, gurnards, plaice, dogfish and sea eels. Each one receives two points, whether it is only a few centimeters or one meter long. Points are only awarded for fish that are actually caught. By contrast, some smaller species only receive one point. As soon as a team member has a fish on his hook, the fish is identified by both team captains and the skipper and thrown back into the water, still alive. This species can then be struck off the catch list. The right equipment for every fish “The unique thing about this competition is that we always have to get used to new species of fish. To do this, we constantly change our fishing equipment and the baits in order to catch the fish we’re still missing,” says Darren Cox. Even when the competition itself is over, The CemeCon team came seventh in the “Great Fish Race” (from left): Terry Fuggle and Paul Hollyoake (Suisse Autoturn), Darren Cox and Eddie Taylor (Trucut Tools). Two fishing teams in a boat. Off the coast of the south of England, the CemeCon team went looking for fish such as mackerel, cod, dogfish and rays. the fun continues over a luxurious meal with refreshing drinks – providing ample time for the participants to exchange their fishing tales. In 2007, a total of 38 teams on 19 charter boats took part – and all participants were very close together in the results. A mere nine points separated the best eight teams from the winner, who had 36 points. With a score of 27 points, the CemeCon team came seventh, and the sponsor rewarded each team member for their achievement with a brand-new fishing rod. Darren Cox: “To be beaten by the England International Team, world champion in 2006, and to come seventh in 38 teams is a wonderful achievement for us. We are very proud of ourselves. Maybe next year, we’ll do even better!” n Coating experts unveil their new look Extensive information about innovative technology „Greater efficiency“ is the motto under which the online editorial department at CemeCon is currently presenting the company’s new internet site after a thorough preparatory phase. Not only does the website now look attractive and modern, but users can also quickly find the information they require about coating solutions. Coating technology continues to be a topic shrouded in mystery: what kind of coating will provide me with the most economical solution to my machining task? What size system is the right one for my coating volumes? What kind of preparation do my tools need in order to achieve the quickest possible coating? You will find answers to these and other questions on the new CemeCon internet sites, in which the company provides full and clear information about coatings and systems technology. Imprint Published by: CemeCon AG Adenauerstr. 20 A4 52146 Würselen, Germany Tel.:+49 (0) 24 05 / 44 70 100 Fax:+49 (0) 24 05 / 44 70 199 www.cemecon.de [email protected] Editor: KSKOMM • Pleurtuitstr. 8 56235 Ransbach-Baumbach, Germany Tel.:+49 (0) 26 23 / 900 780 Fax:+49 (0) 26 23 / 900 778 www.kskomm.de • [email protected] All rights reserved. Reprints, even extracts only with permission of CemeCon. 14 Four steps to the goal Achieve your own coating in four steps – no problem thanks to the modular system at CemeCon. If you’re interested, you can obtain even more quickly all the information you need about the methods of designing a coating as the basis of your own excellent coating solutions. The user’s tool and coating requirements are defined using checklists. After joint assessment of the test results and comparison with the requirements profile, the final coating specifications are compiled and the question of whether to use diamond or PVD in the production of the coating is addressed. The individual production process for every customer is saved in a bar code. That makes the unique combination of coating How is a modern high-performance coating designed? CemeCon designs and produces individual coatings for various machining applications and tools as commissioned by customers. The specifications are designed 100% in keeping with customer objectives and adapted precisely to the tool and the application. As a result, the user achieves considerably higher performance than with traditional standard coatings. The formula for (coating) success: Coating = pretreatment + coating material + coating thickness + tolerance + colour + post treatment. CemeCon has developed a number of modules for each of these individual components of a high-performance coating. In conjunction with CemeCon, tool designers use these modules to “construct” coatings that correspond to the exact purposes of the tool. This is not as complicated as it sounds. On the contrary, since this design produces extremely highperformance precision tools that can always be (re)produced at a later stage thanks to the systematic procedure involved. … the following four steps to your own coating: n definition of the objective n determining of coating specifications n production of sample tools and tests n finalization of the specifications Of course, this procedure may be executed more than once for complex applications. The important thing is to record all details of the elements for constructing the coating with regard to their effect when the product is used. If this is the case, this procedure will result in extremely efficient user-specific high-performance coatings. 15 specification for the particular application even clearer and offers reproducibility for many years. System technology and periphery out of one hand But the new internet sites don‘t only offer helpful information about how to accurately construct an individual coating, also in the field of coating systems the visitor will find his way. of a turn-key PVD coating line, as well. Also the customer services took a center stage in the design of the internet site. Hyperlinks to these sections deliver the appropriate information – so no question will be left unanswered. n With one click he can reach sectoral information and can see several coating systems from the compact CC800®/9 JET to a second hand system. Because pre- and posttreatment play also a important role for the success of a coated tool, a huge product range from adapted periphery to coating technology is presented, too. The internet site shows the possibilities and advantages Right from the homepage of the new internet sites the visitors gets basic information concerning coating technology by CemeCon. 26th Hagener Symposium: Professional expertise for powder metallurgy The Hagener Symposium is among the leading events in the powder metallurgy industry in the German-speaking countries of Europe. For 25 years, the various topics that have formed the focus of the symposium, the expert speakers, the accompanying exhibition and the evening entertainment have been ensuring the success of the symposium. The highlight of the annual symposium is the award of the Skaupy prize to scien- tists who have made a major contribution to powder metallurgy. Celebrating the 25th anniversary of the symposium in 2006, Prof. Dr. Herbert Danninger from the Vienna University of Technology was awarded the prize by the Chairperson of the Committee, Prof. Dr.-Ing. Bernd Kieback from TU Dresden, and the head of the working group for hard metal in the powder metallurgy industrial association in Hagen, Hans Kolaska. Prof. Dr.-Ing. Bernd Kieback and Hans Kolaska presenting Prof. Dr. Herbert Danninger from the Vienna Institute of Technology with the Skaupy Certificate. On November 29 and 30, 2007, the 26th Hagener Symposium will again be held in the city hall of Hagen. This year’s theme is “Powder metallurgy for high-precision components and dense high-performance materials”. Fifteen talks will be given by representatives from the world of research and industry about new materials produced using powder metallurgy and production procedures. The talks are aimed at designers, production engineers, plant engineers and materials scientists. However, the various materials such as aluminum, hard metal and ceramics as well as biomedical materials will also feature in the talks. CemeCon frequently contributes to the event in Hagen in the form of talks and exhibitions as well. For example, Dr. Oliver Lemmer, COO at CemeCon AG, spoke about new trends in the development of hard material coatings at last year’s event. The program and the registration documents for the 26th Hagener Symposium (November 29/30, 2007) can be found in the attachment. Ara-Coatings: Impressive impressive products! KBS: Koreanischer Marktconcepts, in guten Händen Clocks tick in glowing colors here Winning the Central Franconia Founder Prize and the 2007 Bavarian Founder Prize in the „Concept“ category speaks for itself: Ara-Coatings GmbH & Co. KG is one of the upand-coming companies in Germany – and it uses technology from CemeCon. On the winner’s podium thanks to coating solutions: Dr. Ralph Domnick (bottom right) and his team receiving the Bavarian Founder Prize. With its globally unique range of services, Ara-Coatings impressed the judges and secured itself the top-most position: The company develops, produces and markets surface refinements which are manufactured using nanotechnology. This procedure allows product surfaces to be treated so that their properties such as scratch resistance, temperature resistance and wear-and-tear characteristics can be improved while still allowing the product to blaze forth in the most dazzling of colors. Ara-Coatings GmbH & Co. KG was founded in October 2006 and has specialized in the development and production of decorative and functional coatings. Using these coatings, the company refines jewelry, clocks, n cutlery, cosmetic utensils, writing implements, cell phones and ceramic products. The success of the young company reflects the very good cooperation between Ara-Coatings and CemeCon. The system technology from Würselen was adjusted to meet the requirements of the decorative, functional coatings from Central Franconia. The two companies worked hand in hand from the development phase onwards, thereby creating the special solution for the colorful layers. Ara-Coatings GmbH & Co. KG Managing Director: Dr. Ralph Domnick Gundstr. 13 91056 Erlangen Germany Tel.: +49 (0) 9131 / 932150 Fax: +49 (0) 9131 / 932155 Mobil: +49 (0) 176 / 20388051 E-Mail: [email protected] Internet: www.ara-coatings.de Events Calendar CemeCon will be represented at the following trade fairs and events this year: EMO in Hannover: 17. to 22. September 2007. Hall 4, Booth B15. AEPSE in Nagasaki (Japan): 24. to 28. September Medica ComPaMED in Düsseldorf: 14. to 16. November Hagener Symposium in Hagen: 29. to 30. November EuroMold in Frankfurt: 5. to 8. December 16

© Copyright 2026