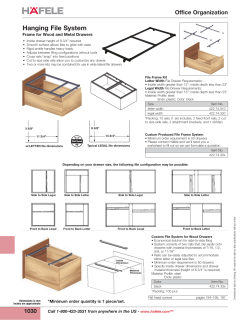

M F