Document 92474

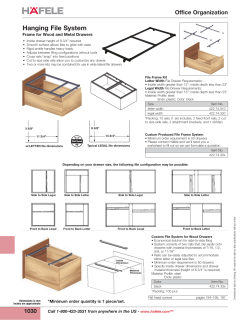

W TAUNTON’S Build a Pie Safe Aproject plan for a 19thcentury cook’s companion For more FREE project plans from Fine Woodworking CLICK HERE NOW! Build an Oak Bookcase h ch enbcen rkobrk urdyoW , St letu rdy W Simp S , le Y Simp From Getting Started in Woodworking, Season 2 From son 2 B y A s 2C h r i s t i A n A ing, ASea orkas Se on in Woodw rted ou can thank Mike Pekovich, rking, ting Sta Fine Woodworking’s odwoart direcA Wo t i A n From Get ted in tor, for designing thishsimple r i sbut s AtookC a straightforbookcase. He B y A n Adado g Star stylish i Awith ward form--an oak bookcase i s t Gettin h r and rabbet C joints--and added nice proA Lies LisT A s and elegant curves. portions B y anD supp ware We agreed that screws would reinforce LisT er, harD eds pLie LuMb the joints nicely, and that gave us a de-sup kiln-dri ng 2x4s, ensive be 8-ft.-lo ed re anD inexp sign option on the sides. Choose oak 4Dwa jaw can easy and 4x4s, kiln-dri be ng ried wide. Front , har tile and align plugs, grain ench is 8-ft.-lo by 3 in.jaw canthick. 2 carefully, berthe , kiln-d and MDF and versathe plugs his workb 2x4sthem in. Front LuM ofa 71/2 in. long Make from ried sheet long wide. jaw is 3/4 8-ft.-long 1 4x8 vise jaws, by 3 in. yet is sturdypensive kiln-d base is disappear. by 6 in. the rear thick. 4 wood, wide 4x4s, andodthe pieces for in. long long to build, like walnut, orker. The contrasting thick and is 3/4 in. d, 46in. inex , joined by in. woodw 8-ft.-long 2 Hardwo jaw ick plywoo 71/2 and 11/2 any and 2 add rear3/4-in.-th rows of plugs a nicet design of MDF feature 1 in.jaws, foreasy n vise h is in. wide atile and 2x4s) thevise, shee betwee enoug Thesides, anding od, 4 r (4x4s s forconbench mount to the s. broad at the and vers thick 1 4x8 hintingpiece dowel n lumbe is k plywo blockin.for oodcraft.com) sturdy his workconstisructio Filler and short struction 3/4-in.-thic and 11/2 (www.w ) in a2subtle way.11 in. The base Hardwood glue vise, , yet with long joined nsity yellow rker.bolts orking Visedcraft.com of ting een (medium-de bottle .woo to build simply By design the betw bookcase moun a 2x4s), 1 contains woodwo s and ction Woodw (www MDF for The , with Vise ed rod blocklessonsGroz layers of for any is two els.sheet number of fundamental forRapid-A ing (4x4 . thread 7-in. gh Filler glue er dow 1 w single 3 work t 1 -in.-dia a top 8 ⁄ enou of shor and likelengths the Wood shelf. furniture-makers, e of yello cut sitywould-be tion lumb and from 6-ft.d-Action oard), -denhandy ded rod 4 Rapi 1 bottlvideo bolts construc fiberb make a other projects the ia.sthrea todium jaw of vise Groz series, (me this benchin this over 3 ⁄ 8-in. 3 washer -in.-d withwhole with long hofleft ng front MDF vise ofa ⁄ 8few 16 hs thing can1be7-in. built with just dt,to make for attachi enoug rs simply jaw of le shee handlengt 3 ⁄ 8-in. nuts washers front ng rear jaw f. portable singneede and a power tools: two laye only atools 4 6-ft.a circular 16 erssaw, a bolts, nuts, attaching y shel ar saw, Thefrom for attachi top is circul jaw benchtop ng 1/4-20 d screws drill,hand a router 3 ⁄ 8-in. wash ers for e a ahand d), cut drill/d river, 2 2-in.-lo flathea hing rear ting 16 this benc a to mak 1/4-20wash table. attac for laminahtop attaching vise fiberboar areover , nuts, The- shelves attach 3to thenuts sides with -long, make casts forscrews benc s, for vise ⁄ 8-in. router bolts 11/2-in. or a to left a hand a small drywall ating 16 the back 2and -longscrew hing router needed simple dadoes,tial and back, and end for lamin and washer long 1/4-20 enough held attac flathead one of 11/4-in. s forscrews tools Box essen laratsaw 1/4-20 2 2-in.-Screws 1 g, room ers, for screw -long lag and hardware List is an drop into rabbets. allLumber wash 21/2-in. aiscircu The only There .,dryw n.-lon 3 reinwhichsplash - dadoisjoints2and -in.-dia 11/2-i s and rs driver, fastene 4 ⁄ 8n.-lon thevise also attach the g pPart ll cast table.vise, smaforce orking The drill/ woodw er lag screw QtY size of 11/4-i ype gtableto l are a iron 3 in. long a rout Box plugs the for a shop. lower stretcher, and 1wood S-clip-t ntia 16ia.,cover endorking 21/2-in.-lon er or any one , roughly ners jaws, and dowels an esse in at woodw h is woode 3 ⁄ wood thenscrew holes. Smaller 8-in.-d screws 3 ⁄ 8-in.-dia top. faste held rout tool long 4 in. room arring sized table 16 is 3 is 2 3/4 in. x 11 in. x 52 in. ly sides , whic non-m holes, -type vise to attach the plywood back. with dogused There fitted g vise ls, rough . Thee are . 16 S-clip pieces receiv the shop sories add life to rectangular dworkin bench ia. dowe gtop and ,Curves acces 3 ⁄ 8-in.-d and jaws bench dworkin handy iron woo jaws 16 d and Pekovich of furniture, worked in wooden y of 5 3/4 in. x 10 5/8 in. x 27 in. sheLVes any wooa variet s, size three types, each irregular and organic marring tool in to fit dog hole 62 in. ies. with non(asssor opposed to radius curves that can receive acce fitted htop in. 11/2 in. bench seem mechanical). At the top are genin. 1 3/4 in. x 3 1/4 in. x 27 1/24in. back 62 sPLash and benc handy jaws ty of tle curves that speed up as they move a varie 35 ⁄16 in. forward, each taken from a section of to fit T T 24 in. 11/2 in. curve. At the bottom are two a French arched stretcher long curves formed with a flexible wood batten, one extending end to end on the 27 ⁄8 in.and the other a short lower stretcher, graceful arch at the bottom in. the sides, 10 of 13 ⁄16 in. ending at a straight step at each end to 8 in. 27 ⁄legs. suggest 24 in. Side stretchers VideOs 13 ⁄16 in. 17 in.in. 13 ⁄16 in. 31/2 in.17 ViDeOs 31/2 in. ViDeOs us Oak Oak Oak in.3 4 Oak veneer 5 ⁄8 in. 1/4 in. x 27 1/2 in. x 45 3/4 in. 5 in.plywood 33 ⁄8 33 3 ⁄4 in. 3 ⁄4 in.1 #12 x 2 in. flat head screws 1 Steel 24 #6 x 3/4 in. flat head screws Steel 93 ⁄16 in. 93 ⁄16 in. Go to Finewoodworking.com/start to watch a multi-part video detailing how to build this bookcase from start to finish. 41 in. 9 in. 95 ⁄8 in. 9 in. 95 ⁄8 in. Finewo online at Visit us Visit screws FOr back materiaL 4 in. 13 ⁄4 in. 3/4 in. x 3 in. x 26 1/2 1 ⁄ in. Oak 1 1ers back Long stretch stretchers screws Long FOr 30 sheLVes 10 in. Side ers 16 in. 13 ⁄stretch --Asa Christiana, editor, Fine Woodworking 35 ⁄16 in. odwork oodw at Finew online orkin ing.com g.com /start /start 41 in.48 in. . to finish. start to finish 48 in. start nch from workbeh from build this benc g how to this work detailin t video to build a two-par ling how to watch detai art video a two-p to watch See how our magazine makes you a better woodworker SUBSCRIBE TODAY! Build a Pie Safe A 19th-century cook’s companion adapts well to modern storage B Y M I K E D U N B A R W hen my wife and I decided recently that we needed more room for her holiday dishes and large servingware, we agreed that an attractive way to store them would be in a hardwood pie safe. Although the first pie safes were built to protect cheese and baked goods in 19th-century kitchens, their simple design adapts comfortably to today’s more modern and more formal surroundings. Being pieces of utilitarian kitchen furniture, most of the early pie safes were quite simple, sometimes downright crude. The average piece was made at home from local softwoods such as pine or yellow poplar and finished with paint. Still, some very sophisticated and elegant hardwood pie safes were made in cabinet shops for those families who could afford the very best. This pie safe was inspired by the more formal examples. I kept the simple design of the originals but made it more of a showpiece by using figured hardwood— yellow birch with a flame figure. The carcase is a large frame Most of the joinery for the case can be tackled on the mortiser and tablesaw. The challenge is in staying organized while cutting the 48 mortise-and-tenon joints the piece requires. Make the mortises in the 32 FINE WOODWORKING Photos: Steve Scott A S T U DY I N F R A M E A N D PA N E L Mortise This 19th-century pie safe is made of flame birch, with tin door panels. Eastern white pine is used as a secondary wood for the back panels, shelves, and shelf cleats. Cleat, glued to case and screwed to top POST DETAIL Panel Panel groove is aligned with mortise. Top, ⁄ in. thick 34 Front top rail, ⁄ in. thick by 51 ⁄4 in. wide Filler strip, 1⁄8 in. thick 34 Rails are inset 1 ⁄8 in. Cornice, see p. 35 Rear and side top rail, 3⁄4 in. thick by 71 ⁄4 in. wide Panels, 1 ⁄2 in. thick, with 1 ⁄ 2-in. rabbet on all edges Cleats, 3⁄4 in. sq., support shelves, including bottom. All rails unless noted, 3⁄4 in. thick by 2 in. wide Rail, 3⁄4 in. thick by 4 in. wide Drawer front, 7⁄8 in. thick DOOR DETAIL Drawer sides and back, 3⁄4 in. thick Outside molding is rabbeted. Drawer guide, 7⁄8 in. thick Inside molding secures the tin panel. Door rails and stiles, 3⁄4 in. thick by 2 in. wide Rabbet, 1⁄8 in. deep by 1⁄4 in. tall Tin panel Offset tenons, 1 ⁄4 in. thick by 1 in. wide; 1 in. long on front side of rail, 1 ⁄2 in. long on back side Drawings: Bob La Pointe CROSS SECTION All case tenons, 1 ⁄4 in. thick by 1 in. long Posts, 13⁄4 in. sq. by 59 1 ⁄4 in. long, taper on two inside faces to 1 1 ⁄2 in. sq. at the floor. Moldings, 3⁄8 in. sq., chamfered JANUARY/FEBRUARY 2006 33 S TA R T W I T H T H E E N D S WHEN GLUING THE CASE Slide the rabbeted panels into position and clamp everything. Then join the case together. Glue up the stretchers and back, and put the whole assembly under clamps. 71 ⁄4 in. 9 in. 2 in. 35 in. 11 in. 9 in. 2 in. 9 in. 121 ⁄2 in. 4 in. 2 in. 81 ⁄2 in. 61 ⁄2 in. 61 ⁄2 in. 2 in. 2 in. 93⁄4 in. 81 ⁄2 in. 34 34 in. 13 in. 371 ⁄2 in. 171 ⁄2 in. FINE WOODWORKING 81 ⁄2 in. posts first. Because all the posts are identical, confusing them is a real possibility. Mark each with its location in the frame. Then identify the surfaces to be mortised. Finally, lay out the mortises. Check your work one last time before cutting. With the mortises cut, it is possible to cut and fit test tenons on a piece of scrapwood until you reach a setup that gives you a smooth, easy fit. Cut the rail tenons and dry-fit the frame under clamps so that you can check it for square. For the side panels, I chose a birch board with a pattern of circles that resembled a string of pearls running up the center. It is a pattern I do not recall seeing before. Lay out the order of your panels in the board you choose and cut them to dimension. Identify the front surfaces and cut the rabbets. At the same time, cut the rabbets on the large pine panels for the back. Groove the posts and rails to receive the rabbeted panels. In the posts, the groove’s lower end is blind (stopped) to prevent it from showing in the legs. I did this by starting the router cut in the lowest mortise. Some pie safes had punched-tin panels on the sides as well as the doors. If you choose this approach, you will have Crown molding that you can make on the tablesaw A series of angled cuts yields a rabbeted cornice that accepts the top of the case and creates a flat surface for displaying items on top. Case top ⁄ in. 12 ⁄ 7 16 ⁄ in. 12 in. ⁄ in. 14 Tack the cornice into place. The molding’s angular profile accentuates the square corners of the piece. Fillet, ⁄ in. by 1⁄8 in. 18 FULL-SIZE TEMPLATE Post C O R N I C E CUTTIN G SEQUEN CE This simple, angular profile can be milled from a piece of stock 3⁄4 in. thick by 2 in. wide. It requires a series of eight cuts, all but one made with the blade tilted to 45°. Cutting in the sequence shown ensures a flat reference face for each cut. 1 5 6 to rabbet the rails and glue vertical support strips to the posts. Take apart the carcase. This is a good time to taper the posts. Dry-fit again with the side and back panels in place, and pull the frame together with clamps. When satisfied, disassemble the parts and remove any machine marks and other blemishes that would show through the finish. I handplaned each surface, but sanding or scraping also would work. When the glue is dry, secure the shelf cleats and fit the 2 7 shelves, including the bottom panel. You can secure the shelves in place, but I let gravity do the job. A cornice that doesn’t hide the top The cornice figures prominently in this pie safe. My wife wanted to use the top of the pie safe as a display shelf. For that reason, I made the cornice sit flush with the top, cutting a rabbet into the back of the cornice to accept the edge of the top. This way, objects placed there will be entirely 3 4 8 visible. The pie safe is square and flat. I wanted to use a cornice that continued that theme but added some visual interest. What I like about this one is that it is made completely on the tablesaw (see drawings, above). Fit the cornice and top to the frame. When satisfied with the fit, screw the top in place through the interior cleats and nail the cornice in place with finish brads. Because the rails are recessed 1⁄ 8 in. from the front of the posts, I used a 1⁄ 8-in.-thick JANUARY/FEBRUARY 2006 35 RABBET THE DOOR FRAMES BEFORE A S S E M B LY spacer behind the cornice that matched the width of the cornice and the length of the rails. Assemble and fit the doors To make the doors, begin by cutting a rabbet on the rear inside edges of the stiles and rails. Next, mortise the stiles. The mortises are cut into the rabbets’ shoulders and are of necessity only 1⁄4 in. wide. The tenons on the rail ends have offset shoulders to accommodate the rabbets in the stiles. Cut the tenon shoulders in all the rails first, taking care to ensure that each tenon’s short side is cut on the back side of the rail. Use a tenoning jig to cut the cheeks, raising the blade to cut the longer surfaces. Dry-fit the doors under clamps and check for square. Scrape, sand, or plane all visible surfaces, and glue and assemble the two doors. Fit the doors to the carcase and mount them on their hinges. With the hinges fitted, mount the tin panels. As an accent to the light-colored birch, I chose to hold the tins in place with walnut molding inside and out that also acts as a shadow frame. The outside molding is rabbeted in the back Rabbet all the rails and stiles at once. This means fewer setups on the tablesaw. Cut mortises before tenons. The tenons then can be sized for a precise fit. Rail tenons look lopsided. The joinery needs shoulders of different heights to seat properly in the rabbeted stiles. 36 FINE WOODWORKING Assemble the door frames. Dry-fit the doors, check them for square, and prepare surfaces for finishing before breaking out the glue bottle. Punching tin Tack the tin onto an MDF backer board and tape the pattern in place. Punch the tin through the pattern using consistent force to ensure an even result. so that it fits over the edges of the doors and overlaps the stiles and rails. I glue the outside molding into place, but secure the inside molding with brads. Apply the finishing touches The drawer construction contains no surprises. I hand-dovetailed mine. You can use any drawer-construction techniques that you prefer. The drawer will be used to store linens, which are lightweight. For that reason, I felt perfectly comfortable with the traditional solution of gluing in hardwood The punched-tin door panels for this pie safe were easy and fun to make, requiring a few simple tools and some inexpensive materials. Punches can be found online for as little as $4.95 (www.piercedtin.com). A basic pointed tool and a chisel-type punch should be enough to make an attractive design. A 10-in. by 14-in. sheet of tin costs $3 at Van Dykes Restorers (www.vandykes.com). Patterns are available from craft stores, or you can make your own by tracing or photocopying images that appeal to you. Be sure to choose a design that isn’t too busy and that lends itself to making a clear silhouette. Consider wearing some support for your wrists. After a lengthy punching session, the hammer may leave the upper arm and wrist sore, and keeping a tight grip on the punch also can cause an aching thumb and forefinger. —Priscilla Chellis runners instead of installing heavy-duty drawer slides. The final touch is the hardware. Because pie safes come from a particular period, I chose to remain within the flavor of that time. Rather than plain butt hinges, I selected distinctive late-Victorian hinges with removable pins. The green glass pulls evoke the same period. There is a lot of contrast between yellow birch’s tan-colored heartwood and its creamy sapwood. I wanted to tone down this contrast while making sure the flame remained visible, so I stained the piece with a strong brew of ordinary tea. I boiled a couple of cups of water and tossed in 10 tea bags, letting it brew for about 15 minutes. When the brew had cooled, I brushed it onto the piece. After the first coat had dried, I sanded with 330-grit paper. Not happy with the amount the wood had darkened, I applied a second coat and sanded again. Finally, I applied two coats of polyurethane, sanding each with 330 grit. Mike Dunbar is a contributing editor. His assistant, Fred Chellis, and his wife, Priscilla, helped in the construction of this project. Secure the tin panels from the rear. A strip of molding, mitered and tacked into place behind the tin sheet, holds the panel in the frame created by the rabbets in the rails and stiles. JANUARY/FEBRUARY 2006 37

© Copyright 2026