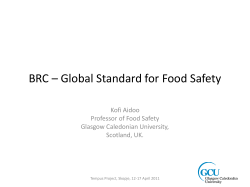

IFS – International Food Standard Kofi Aidoo Professor of Food Safety

IFS – International Food Standard Kofi Aidoo Professor of Food Safety Glasgow Caledonian University, Scotland, UK. Tempus Project, University of Zagreb, 24-25 Feb '11 Introduction • Associated members of German retail federation (HDE) and its French counterpart (FCD) drew up quality & food safety standard for retail branded food products • IFS allow assessment of suppliers’ food safety & quality systems. • The standard applies to post-farm gate stages of food processing. • After 01/01/2008, only audits to version 5 of the Standard is acceptable. Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Food & IFS Logistics • IFS Foods concerns: (i) processing foods (cat. 1 to 17), (ii) handling of loose food products/ingredients (cat. 18) & (iii) primary packing activities (cat. 18). IFS Foods doesn’t not apply to company that deals with already pre-packed products. • IFS Logistics concerns auditing all logistic activities for food and non-food products – transport, storage, distribution, loading/unloading. If a food Co has its own logistics then it will audited under Foods. Tempus Project, University of Zagreb, 24-25 Feb '11 Product Category No. Product category 1 Product category 2 Name of Product Category Product category 3 Product category 4 Product category 5 Poultry – Chilled and Frozen Fish – Chilled and Frozen Fruits and vegetables (produce) Product category 6 Product category 7 Product category 8 Product category 9 Dairy Meat products and preparations Fish products and preparations Ambient stable hermetically sealed (cans) Egg Red meat – Chilled and Frozen Tempus Project, University of Zagreb, 24-25 Feb '11 Product Category Name of Product Category No. Product category 10 Ready-to-eat (RTE) Product category 11 Beverages Product category 12 Bakery and baked products Product category 13 Dried goods Product category 14 Confectionery Product category 15 Product category 16 Product category 17 Product category 18 Snacks and breakfast cereals Oils and fats Food ingredients Co-packers (Co-packing & Handling) Tempus Project, University of Zagreb, 24-25 Feb '11 SCOPE • IFS is a Standard for auditing Retailers & Wholesalers and concerns food processing companies (Co) & those that pack loose foods. • Scope is defined & validated between the Company & Certification Body before audit • Scope stated clearly and unambiguously in audit report and on certificate • Audit is site-specific • Audit shall include the complete activity of the Co • Scope shall make ref. to product category. Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Preparation for audit – Company (Co) should study all requirements of IFS • Certification body selection – Co appoint approved certification body (CB) which shall be accredited EN45011 for scope of IFS. • The CB shall carry out IFS audits and issue certificates. • A contract shall exist between the Co and CB. Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Duration of an audit Typically an audit may take 1.5 days; preparation of audit report may require additional 0.5 days. Duration will depend on several factors (size of site; number of personnel; production/process type, etc). Above is based on <100 employees; 2 products; <10,000 m2 and 2 production lines. Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Audit Plan - Certification Body drawn up the plan. Auditing should take place when the company is producing the product (s). Five elements for audit are: • opening meeting • evaluation of quality & food safety systems (HACCP, etc) • on-site inspection • final preparation and conclusions from audit • closing meeting Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Evaluation of requirements - Scoring a requirement in the Standard, there are 4 possibilities: A – Full compliance = 20 points B – Almost full compliance/small deviation = 15 C – Small part of requirement implemented = 5 D –Requirement not implemented = 0 Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Evaluation of requirements - There are 2 types of non-conformities during scoring: (a)Major = substantial failure to meet requirement; can lead to serious health hazard a major will subtract 15% of total points. (b)Knock out (KO) = there are specific requirements designated as KO and will result in non-certification. Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process - 10 requirements defined as KO Responsibility of the senior management Monitoring system of each CCP Personal Hygiene Raw material specification Finished product (recipe) specifications Foreign bodies management Traceability system Internal audits Procedure for withdrawal and recall Corrective actions Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process – Scoring for KO requirements Results Explanation Awarded scores A Full compliance 20 points B (deviation) Almost full compliance 15 points C (deviation) Small part of requirement implemented No “C” scoring possible D = KO The requirement is not implemented 50% of total points deducted therefore no certificate awarded Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Scoring requirement with N/A (not applicable) – the auditor will use N/A with explanation where the auditor decides the requirement is not applicable. • Audit frequency – Audit frequency for all levels of certification whether Foundation level or Higher level for all products is 12 months Tempus Project, University of Zagreb, 24-25 Feb '11 IFS Certification Process • Audit report - The audit report is divided in (a)audit summary in a tabular form (b) observations on KO requirements & Majors (c) summary of deviations and non-conformities (d) a list with explanations of all requirements evaluated and N/As. Company has to produce corrective action plan for all deviations (B,C,D) + KOs all scored with B. Tempus Project, University of Zagreb, 24-25 Feb '11 Auditors - Scoring and awarding certificates Audit requirements Status Company action Certificate At least 1 KO Unapproved New audit No >1 Major & <75% fulfilled Unapproved New audit No Max 1 Maj & >75% fulfilled Unapproved Action plan sent further then follow-up action audit in 6 months Yes but depends on follow-up audit Total score >75% & <95% Approved at Foundation level Action plan sent within 2 weeks Yes, at Foundation level, 1 yr validity Total score >95% Approved at Higher level Action plan sent within 2 weeks Yes, Higher level, 1 yr val. Tempus Project, University of Zagreb, 24-25 Feb '11 International Food Standard (IFS) – Requirements (Technical) Senior Management Responsibility (A) • shall draw up and implement Corporate Policy to take into account • customer focus • environmental, ethics & personnel responsibilities • product safety, legality, quality. •the policy shall be communicated to all employees. • quality objectives shall be communicated to employees, implemented, reviewed at least annually. • relevant information communicated effectively to all. Tempus Project, University of Zagreb, 24-25 Feb '11 International Food Standard (IFS) – Requirements (Technical) Senior Management Responsibility (B) Corporate structure • organizational chart to show Co. structure • senior management to ensure employees are aware of their responsibilities and effective monitoring of their operation (This is a KO). • senior management to provide resources. et al. Tempus Project, University of Zagreb, 24-25 Feb '11 International Food Standard (IFS) – Requirements (Technical) Senior Management Responsibility (C) Customer focus • procedure in place to identify customers’ needs and expectations. • results of this procedure shall be evaluated to determine quality objectives Tempus Project, University of Zagreb, 24-25 Feb '11 International Food Standard (IFS) – Requirements (Technical) 1. Senior Management Responsibility (D) Management review • Review quality man. system at fixed period and should include measures to control the system and for continuous improvement. • Identification and regular review of internal audits and on-site inspection eg. Buildings, supplies, equipment, transport, staff facilities, hygienic conditions, safety and security. Tempus Project, University of Zagreb, 24-25 Feb '11 2. Quality Management System (a) HACCP System • based on Codex Alimentarius principles • to cover all raw materials, products, etc and process from goods-in to dispatch including product development and packaging. • based on scientific literature or technical verified specification. Tempus Project, University of Zagreb, 24-25 Feb '11 HACCP - requirements REQUIREMENTS 12 CODEX STEPS 7 PRINCIPLES HACCP FOOD SAFETY TEAM 1 DESCRIBE THE PRODUCT 2 IDENTIFY INTENDED USE 3 CONSTRUCT FLOW DIAGRAM 4 VERIFY FLOW DIAGRAM 5 LIST POTENTIAL HAZARDS - HAZARD ANALYSIS 6 1 DETERMINE CRITICAL CONTROL POINTS (CCPs) 7 2 ESTABLISH CRITICAL LIMITS FOR EACH CCP 8 3 ESTABLISH MONITORING SYSTEM FOR EACH CCP 9 4 ESTABLISH CORRECTIVE ACTION PLAN 10 5 ESTABLISH VERIFICATION PROCEDURES 11 6 HACCP DOCUMENTATION AND RECORD KEEPING 12 7 R E V I E W HACCP Plan, eg change in law, recipe equipment Tempus Project, University of Zagreb, 24-25 Feb '11 Supplier, etc. Quality Management System (b) Documentation requirements • quality system shall be documented, implemented & retained in one location. • all documents & their amendments shall be (i) comprehensive, legible, unambiguous (ii) up to date with latest version, (iii) available to relevant personnel (iv) controlled. • any amendments to documents shall be recorded. Tempus Project, University of Zagreb, 24-25 Feb '11 Quality Management System (c) Record keeping • all records shall be complete, maintained and available on request; any amendments be done by authorised person. • records shall be legible and genuine • all records shall be kept in accordance with legal requirements – for products with very short or no shelf life, record-keeping shall be based on risk analysis Tempus Project, University of Zagreb, 24-25 Feb '11 3. Resource Management (a) Human resource management all personnel whose duties may affect product safety, legality an quality shall be competent, experienced and with appropriate training. Tempus Project, University of Zagreb, 24-25 Feb '11 3. Resource Management (b) Personal hygiene To include hand washing, smoking, eating, jewellery, hair, fingernails, boils, cuts. Requirement for personal hygiene shall be in place and applied by all staff, contractors an visitors. Compliance with the requirement shall be checked regularly (This is a KO) Tempus Project, University of Zagreb, 24-25 Feb '11 3. Resource Management (c) Protective clothing • Company to ensure all personnel, contractors an visitors are aware of the rules regarding management of wearing and changing protective clothing • Suitability of protective clothing; cleaning, etc. • There shall be written procedures for staff, contractors, visitors regarding infectious diseases. Tempus Project, University of Zagreb, 24-25 Feb '11 3. Resource Management (d) Training • all staff to be trained to commensurate with their work. • Co shall put in place documented training programme. • training records should be kept • contents of training shall be reviewed and updated regularly and in accordance with legal requirements. Tempus Project, University of Zagreb, 24-25 Feb '11 3. Resource Management (e) Staff facilities • Company shall provide facilities which shall be kept clean and in good condition • Suitable changing rooms for staff, contractors, visitors • Where necessary outdoor clothing and protective clothing shall be stored separately • Toilets with no direct access to food preparation area • Adequate hand washing facilities (running hot/cold water; liquid soap; single use towels Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (a) Product specification • Specification shall be available for all products all raw materials, ingredients, additives, in agreement customer and shall be unambiguous, up to date and in conformance with legal requirements (This is a KO) • Recipe in customer finished product specification shall be complied with (This is a KO). • Provision of specifications and/or their contents shall be accessible to all relevant personnel. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (b) Purchasing • Purchased products/services shall conform to specification and contractual agreements. There shall be: • Records to show which product is sourced from which supplier. • Procedure for approval and monitoring of suppliers • Clear assessment criteria for supplier, eg. audits, certificates; assessments shall be review regularly • Purchased products checked in accordance with specification Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (c) Product packaging • All packaging shall comply with current relevant legislation and suitable for intended use • Detailed specifications for all packaging materials. • Certificate of conformity for packages in direct contact with food (raw material, semi-processed, finished products) • Conformity of product with its labelling shall be reviewed when new label is issued for use. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (d) Factory environment • Choice of location – eg ground, air. • Exteriors – outdoor storage area; clean tidy • Plant layout & process flow – to minimise risk of cross contamination (eg, Linear work flow, clean room technology) • Work flow should reduce or minimise potential physical, chemical or microbiological contamination. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (e) Housekeeping and hygiene • Cleaning and disinfection schedule • Qualified, trained personnel for cleaning and disinfection • Effectiveness of cleaning. • Current material safety data sheets (MSDS) and instructions for use shall be available • Cleaning utensils clearly marked and stored in segregated area to avoid risk of contamination. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (f) Pest control/monitoring • There shall be pest control in place – site plan, responsibilities in-house/external, inspection and frequency, etc. • All recommendations after inspection shall be documented. Any infestation shall be documented and control measures taken • Where external provider is used, activities required shall be documented in a written contract. • Incoming materials to be checked Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (g) Waste/waste disposal • All current legal requirements for waste disposal shall be met. Removal; type of waste collection container; frequency; pest-proof, etc. (h) Traceability (including allergens & GMOs) - KO • A traceability system shall be in place to enable identification of product lots & relation to batches of raw materials, packaging in contact or intended to be in direct contact with food. Traceability system shall incorporate all relevant processing & distrib. records. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (i) Receipt of goods and storage • All raw materials, semi-processed of finished products shall be checked against specifications, etc. (j) Transport • Condition of vehicles; prevention of contamination during transportation, etc. (k) Maintenance and repair • All materials for maintenance & repair shall be fit for purpose or intended use (eg food grade). • All maintenance & repairs documented. Tempus Project, University of Zagreb, 24-25 Feb '11 4. Production Process (l) Equipment • Designed for intended use; easily cleanble, etc. (m) Process validation •Change in product reformulation, processing methods, equipment, packaging shall require reviewing to assure product requirements are complied with. (k) Maintenance and repair • All materials for maintenance & repair shall be fit for purpose or intended use (eg food grade). • All maintenance & repairs documented. Tempus Project, University of Zagreb, 24-25 Feb '11 5. Measurements, analysis, improvements (a) Internal audits • Internal audits shall be conducted according to agreed plan. Scope and frequency shall be determined by risk analysis (This is a KO). Conducted at least once a year (b) Site factory inspection – Regular inspection (c) Quantity checking – Legal requirements for nominal quantity should be met through frequency/methodology of quantity checking. Tempus Project, University of Zagreb, 24-25 Feb '11 5. Measurements, analysis, improvements (d) Product analysis • Ensure all specified product requirements and specifications (including legal) are met. • Product analysis shall be performed by an accredited laboratory (accredited to ISO 17025), • Organoleptic tests shall be considered when validating shelf life of a product. Tempus Project, University of Zagreb, 24-25 Feb '11 5. Measurements, analysis, improvements (e) Product withdrawal and recall • There shall be an effective procedure for the withdrawal and recall of all products, which ensure that involved customers are informed, as soon as possible. This procedure shall include a clear assignment of responsibilities (This is a KO). • There shall be an updated emergency contact details of suppliers, customers and competent authorities. Tempus Project, University of Zagreb, 24-25 Feb '11 5. Measurements, analysis, improvements (f) Corrective actions • Corrective actions shall be clearly formulated, documented and undertaken as soon as possible to prevent further occurrence of nonconformity. The responsibilities and the timescales for corrective actions shall be clearly defined. The documentation shall be securely stored and easily accessible. (This is a KO). Tempus Project, University of Zagreb, 24-25 Feb '11 5. Measurements, analysis, improvements (g) Management of complaints from customers and authorities. • A system shall be in place for the management of product complaints • All complaints shall be assessed and analysed with a view of implementing preventative action. Tempus Project, University of Zagreb, 24-25 Feb '11 6. Requirements for accreditation bodies, certification bodies & Auditors • Requirements for Accreditation bodies • Requirements for Certification bodies • Requirements for IFS Auditors Tempus Project, University of Zagreb, 24-25 Feb '11 Process for accreditation of certification International Accreditation Forum (IAF), European Accreditation (EA) Accreditation Bodies (ISO/IEC 17011) Certification Bodies (EN 45011 ISO/IEC Guide 65) Supplier Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Accreditation Bodies General requirements Fulfil requirements of ISO/IEC 17011 conformity assessment & sign Multilateral agreement of EA or IAF Training of Accreditation Committee (AC) A committee member shall take part in ‘Train the Trainer’ course Competences of assessor Assessor of AC to accompany & of the accreditation body witness IFS auditing. Assessor to meet EN45011 & IFS requ’ments Frequency of assessment For accreditation cycle, ≥1 Head Office assessment/yr & ≥ 1 of certification bodies witness asses/yr Accreditation of internationally-active certification body Witness assessment shall cover typical activities ( + international) of the certification body Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Certification Bodies Certification bodies (CB) intending to perform IFS audits shall comply with the following: (a) EN 45011 IFS accreditation • shall be accredited to IFS according to EN45011 by a IAF or EA recognised accreditation body (b) Signing contract with proprietors of IFS commitment to meet all IFS requirements. When accreditation gained to EN45011, CB is not allowed to audit (except 1st witness assessment) until a final contract is signed with proprietors of IFS. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Certification Bodies Certification bodies (CB) intending to perform IFS audits shall comply with the following: (c) Certification decision Decision on certification only taken by Certification committee or competent person an approved IFS auditor or an IFS trainer and shall be independent of the person who performed the audit. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Certification Bodies (d) Certification body’s (CB) responsibilities for IFS trainers & IFS auditors CB’s responsibilities: • at least 1 member of staff is an IFS trainer (taken part in “Train the Trainer”) • auditor is competent for scope • maintain record of auditor competence • no auditor acted against IFS rules • no auditor performs >3 IFS audits of same company • training session for IFS auditor once a year • perform on-site observation of an auditor under EN45011 before IFS exams • cognisant of exam IFS regs. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Certification Bodies (e) Specific requirements for IFS trainers • audit experience to EN 45011 standards + IFS audits • knowledge in (i) food sector & (ii) in food legislation • teaching skill • participated in “Train the Trainer” course by IFS • fluent in written and spoken language used in training Also participate in IFS training seminars once every 2 yr. It’s recommended that IFS trainer take part in IFS exam. IFS is responsible for selecting the relevant trainer. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for Certification Bodies (f) “Train the trainer” course • Course provided by IFS • In case of publication of new doctrine, all IFS auditors shall be trained before doctrine comes into force. • Trainer receives certificate of attendance of course. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for IFS Auditors (a) Requirements before applying for IFS exams • signed a contract with Certification Body (CB). • confirm they will perform audit for at least 12 months; may work for other CBs • Submit relevant information about competence • CB shall observe & confirm professional qualification and competence of auditor. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for IFS Auditors (b) General requirements for auditors when applying for IFS exams • Degree in food related area or ≥ 5 yr experience in food industry or equivalent • ≥ complete audits • Food Hygiene + HACCP; QA and Quality management knowledge • specific knowledge in product scope • Language • taken part in IFS in-house. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for IFS Auditors (b) General requirements for auditors when applying for IFS exams • Degree in food related area or ≥ 5 yr experience in food industry or equivalent • ≥ complete audits • Food Hygiene + HACCP; QA and Quality management knowledge • specific knowledge in product scope • Language • shall have taken part in IFS in-house training. Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for IFS Auditors Requirements (pre- IFS application Auditor Explanation/remarks requirements) Contract ✔ Comply with EN45011; signed contract with Certification Body Certification body ✔ Perform IFS audits for only 1 certification Body Competence ✔ Supply CB with all relevant information relating to competence Observation audit ✔ Pass observation audit to confirm professional qualification and competence Tempus Project, University of Zagreb, 24-25 Feb '11 Requirements for IFS Auditors Education & minimum experience ✔ Food related degree + ≥ 2yr experience in food industry or equivalent General audit experience ✔ ≥ 10 complete audits in food processing industry Food Hygiene/HACCP ✔ Qualified training on basis of Codex principles for Food Hygiene QA & Quality Man knowledge ✔ Practical experience/recognised training as part of Uni. degree. Specific & practical knowledge ✔ ≥ 10 audits under EN 45011 & ≥ 2yr professional experience in product scope Language ✔ Native & other language, training. In-house traing ✔ Participation in IFS in-house training Tempus Project, University of Zagreb, 24-25 Feb '11 7. Reporting • Audit overview • Audit details – name and address & logo of CB, date, etc • Audit report – results, date, summary, KOs and Majors, detailed report • Action plan – any KOs, Majors. • Minimum requirements for IFS certificate – name and address of CB, IFS logo, name and address of audited company, level achieved, date of audit, date issued, place, etc. Tempus Project, University of Zagreb, 24-25 Feb '11

© Copyright 2026