International Research Journal of Applied and Basic Sciences www.irjabs.com

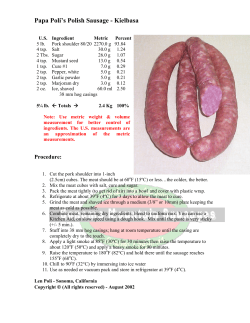

International Research Journal of Applied and Basic Sciences © 2013 Available online at www.irjabs.com ISSN 2251-838X / Vol, 5 (11): 1388-1393 Science Explorer Publications Maximum Current Tracking in Switched Reluctance Motor Converters Alireza, Siadatan1, Mehran, Rafiee2, Rana, Moeini3, Ebrahim, Afjei4 1. Department of Electrical Engineering, West Tehran Branch, Islamic Azad University, Tehran, IRAN, 2. Department of Electrical Engineering, West Tehran Branch, Islamic Azad University, Tehran, IRAN, 3. Department of Electrical Engineering, West Tehran Branch, Islamic Azad University, Tehran, IRAN, 4. Department of Electrical Eng., Faculty of Electrical & Computer Eng., Shahid Beheshti University G.C., Tehran, IRAN, Corresponding Author email: [email protected], [email protected], moeini.rana @gmail.com, [email protected] ABSTRACT: In this paper, two types of converters are used in order to drive a 12 by 8 and 6 by 4 three-phase Switched Reluctance Motor (SRM). One of them is a Two-Switch per Phase (TSP) converter which has two transistor and two schottky diodes in each phase. The other on is N Switches in N Phases (NSNP) converter in which one switch is used in each phase. The SRMs are then tested in laboratory with the both converters and the current-speed curves of them are obtained for different values of speed. The current-speed curves are then compared. Because of using schottky diodes in TSP converter, the energy stored in the phase is turned back to the voltage supply during switching which increases the efficiency of the converter. But in NSNP converter, the stored energy is not able to turn back to the voltage supply and loses in the phase as ohmic losses which decreases the efficiency of the motor and increases the motor current consumption. INTRODUCTION The stator and rotor poles in SRM are salient. SRM has many advantages. The rotor has no winding which means the motor structure is so simple and low cost. Lighter rotor also allows the motor to achieve higher speed and efficiency. This family of motors is able to work in harsh environment with a low less maintenance. SRM was invented about two century ago. Since its driver circuit required power electronic devices and transistors it was not implemented for many of years till last decades when power electronics improved and power switches were built. The rotor pole position information is needed in SRM drive. Lots of direct and indirect techniques are presented in order to rotor position detection and SRM drive (Moraveji; et al, 2007), (Najafi et al, 2007), (Acarnley, 1982), (Ehsani; et al, 1994), (E. Afjei 2010). After position estimation, desired command pulses are produced which have to be transferred to the phase windings of the motor. Converters are used in this transition. Many converter topologies are presented so far. TSP converter and a converter with N+1 switches in N phases SRM and bifilar converter are presented in (Krishnan. 2001), (Krishnan. 2001) Different types of Cdump converters are studied in (Miller. 1988). A converter with voltage-boosting capacitors is proposed in (Dessouky et al, 1998). In all of the converters power switches are used. In this paper the current behaviour of TSP and NSNP converters is studied and compared on two types of three-phase 6 by 4 and 12 by 8 SRM. This paper is organized as follows: Section II introduces the three-phase 6 by 4 and 12 by 8 SRMs and their specification. The motors are also simulated in order to obtain their electromagnetic parameters. In section III the TSP and NSNP converters and their details are studied. The SRMs are then tested in laboratory driven by the TSP and NSNP converters and the current-speed curves are obtained for different values of speed in section IV. At the end Section V presents the conclution. The specification of the SRMs Both of the 12 by 8 and 6 by 4 three-phase SRMs are built in a same motor housing with a same volume which is shown in Fig.1. Intl. Res. J. Appl. Basic. Sci. Vol., 5 (11), 1388-1393, 2013 Figure1. The housing of 12 by 8 and 6 by 4 three-phase SRMs The rotor position is required in SRM driving which is usually obtained by a plate coupled to the motor shaft and position sensors on the back of the motor as it's illustrated in Fig.2. Fig.2.a shows the back of the 12 by 8 and Fig.2.b shows the back of the 6 by 4 three-phase SRM. (a) (b) Figure2. The plate and position sensors at the back of the motor, (a): 12 by 8 SRM. (b): 6 by 4 SRM 12 by 8 Three-Phase SRM The specification of the 12 by 8 three-phase SRM is presented in table1. The rotor pole arc is 16 while the stator pole arc is 14. The stator has the diameter of 60 mm and the rotor has the diameter of about 35 mm. There is 0.25 mm air gap between the rotor and stator pole. Each coil in this motor includes 150 turns winding. The motor has about 50 watts power. Table1. The specification of 12 by 8 Stator core outer diameter Stator core inner diameter Stator pole arc Air gap Rotor core outer diameter Rotor shaft diameter Rotor pole arc Number of turns per pole 60mm 52mm 14 0.25mm 35mm 8mm 16 150 Three-Phase SRM 6 by 4 Three-Phase SRM The specification of the 6 by 4 three-phase SRM is presented in table 2. The rotor pole arc is 32 while the stator pole arc is 30. The stator has the diameter of 60 mm and the rotor has the diameter of about 35 mm. There is 0.25 mm air gap between the rotor and stator pole. Each coil in this motor includes 200 turns winding. The motor has about 75 watts power. Table2. The specification of 6 by 4 Three-Phase SRM Stator core outer diameter Stator core inner diameter Stator pole arc Air gap Rotor core outer diameter Rotor shaft diameter Rotor pole arc Number of turns per pole 60mm 52mm 30 0.25mm 35mm 8mm 32 200 Different Parameters of the SRMs The parameters of the SRMs can be obtained in simulation. Magnet CAD package (Package. 2006) uses Finite Element Method (FEM) which is performed to find solution for partial differential and integral equations. 1389 Intl. Res. J. Appl. Basic. Sci. Vol., 5 (11), 1388-1393, 2013 Two common methods are implemented to solve magnetic field problems. One of them uses electric vector potential and the other uses magnetic vector potential. In Magnet CAD package electric vector potential (T) is used. The three-phase 12 by 8 and 6 by 4 SRMs are simulated in Magnet for 3A phase winding current. The flux density throughout the SRM is obtained for different values of rotor position. Fig.3 illustrates the flux density in unaligned, half aligned and fully aligned position of the rotor in 6 by 4 SRM. The maximum value of flux density is about 1.0043 Tesla in fully aligned position. Fig.4 illustrates the flux density in unaligned, half aligned and fully aligned position of the rotor in 12 by 8 SRM. The maximum value of flux density is about 1.4023 Tesla in fully aligned position. (a) (b) (c) Figure3. Flux path throughout the 6 by 4 SRM in (a): unaligned, (b): half aligned, and (c) fully aligned rotor position (a) (b) (c) Figure4. Flux path throughout the 12 by 8 SRM in (a): unaligned, (b): half aligned, and (c) fully aligned rotor position TSP and NSNP Converters The TSP converter is shown in Fig.5. In this converter two Mosfets are used in each phase. When the phase is energized, the Mosfets (IRF490S and IRF540) of the phase lead the current to the phase winding. When the phase is switched off, the Mosfets are off and the energy of the phase winding is turned back to the voltage supply by schottky diodes (40CPQ035) Figure5. TSP converter The NSNP converter structure is shown in Fig.6. In this converter only one Mosfet is used in each phase. When the phase is energized, the Mosfet (IRF540) of the phase leads the current to the phase winding. When the phase is switched off, the Mosfet is off but the energy of the phase winding is not able to turn back to the voltage supply by schottky diodes (40CPQ035) and loses in the winding as ohmic losses. This decreases the efficiency of the converter. 1390 Intl. Res. J. Appl. Basic. Sci. Vol., 5 (11), 1388-1393, 2013 Figure6. NSNP converter Operational Test Both SRMs are tested in laboratory with TSP and NSNP converters in different speed and the current of the motors is measured. Fig.7 illustrates the current of the three-phase 6 by 4 SRM in different operational speed when it is driven with TSP converter. In nominal speed (about 3000 rpm) the current of the motor is about 0.3A and it increases as the speed decreases. The motor current is about 1.1A in 450 rpm. Figure7. Current versus speed in 6 by 4 SRM driven by TSP converter The 6 by 4 SRM is then driven with NSNP converter and the current is measured shown in Fig.8. In nominal speed (about 3000 rpm) the current of the motor is about 0.96A. In 450 rpm speed, the motor current is about 3.28A. Figure8. Current versus speed in 6 by 4 SRM driven by NSNP converter The 6 by 4 SRM current-speed curve for both TSP and NSNP converters are compared in Fig.9. As it's illustrated the current of the NSNP converter is about three times more than TSP converter. 1391 Intl. Res. J. Appl. Basic. Sci. Vol., 5 (11), 1388-1393, 2013 Figure9. Comparison of Current-speed curve of TSP and NSNP converters in 6 by 4 SRM Fig.10 shows the current-speed curve of the 12 by 8 SRM when it's driven with TSP converter. In nominal speed (about 2500 rpm) the current of the motor is about 0.45A. It increases as the speed decreases and is about 1.6A in 150 rpm. Figure10. Current versus speed in 12 by 8 SRM driven by TSP converter The 12 by 8 SRM is then driven with NSNP converter and the current is again measured. The currentspeed curve in this test is shown in Fig.11. In nominal speed (about 2500 rpm) the current of the motor is about 1.4A. In 150 rpm speed, the motor current is about 4.75A. Figure11. Current versus speed in 12 by 8 SRM driven by NSNP converter The current-speed curve of the 12 by 8 SRM for both TSP and NSNP converters are compared in Fig.12. As it's illustrated the current of the NSNP converter is again about three times more than TSP converter. 1392 Intl. Res. J. Appl. Basic. Sci. Vol., 5 (11), 1388-1393, 2013 Figure12. Comparison of Current-speed curve of TSP and NSNP converters in 12 by 8 SRM CONCLUSION In this paper, two types of SRM (12 by 8 and 6 by 4 three-phase SRM) were driven with two types of converter. One of the converters was TSP converter which had two switches and schottky diodes in each phase. The other on was NSNP converter in which one switch was used in each phase. The SRMs were tested in laboratory with the both converters and the current of the motors was measured in different speed and shown in curves. In TSP converter the phase winding energy is turned back to the voltage supply after phase switching off by schottky diodes which causes the current of the motor be lower and the efficiency be higher. In NSNP converter the energy of the phase winding is not turned back to the voltage supply after phase switching off and loses in the phase winding. It appears as ohmic losses in the motor which decreases the efficiency of the motor on one hand and make the motor hotter on the other hand. REFERENCES Acarnley PP. 1982. Stepping Motors: A Guide to Modern Theory and Practice. Peter Peregrinus Ltd. Afjei E, Moradi Cheshmeh Baygi H, Nour H.2010. Detecting the Rotor Position by Employing Pulse Injection Technique And Digital Pulse Width Modulation Decoder in Switched Reluctance Motor. IEEE Ind. 44-47. Dessouky YG, Williams BW. 1998. A novel power converter with voltage-boosting capacitors for a four-phase SRM drive. IEEE Transactions on industrial electronic. 45(5): 815 – 823. Ehsani M, Hosein I. 1994. Rotor Position Sensing In Switched Reluctance Motor Drivers By Measuring Mutually Induced Voltages. IEEE Trans Ind.App. 30(3): 665-672. Krishnan R. 2001. Switched Reluctance Motor Drivers: Modeling, Simulation, Analysis, Design and Application. CRC Press. Krishnan R.2001. Electric Motor Drives, Modeling, Analysis and Control. Printice Hall. 2001. Miller TJ.1988. Switch Reluctance Motor Drive. CA Intertec Communications Inc. Ventura. Moraveji A, Siadatan A, Afjei E, Rafiee M, Zarei Ali Abadi E. 2007. DSP Sensorless Controller of Switched Reluctance Motor-Generator Approaching to AM Modulation. Sensors & Transducers Journal. 17: 1-5. Najafi A, Afjei E, Khalili H. 2007. Rotor Position Detection in SRM Drive Utilizing Phase Shift Variations in a Formed Resonant Circuit. ieee ind. 1-5. Package Magnet CAD.2006. User Manual. Montreal, Canada.: Infolytica Corporation Ltd. 1393

© Copyright 2026