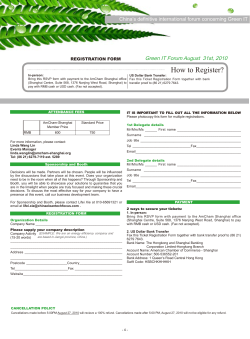

FriedlNet.com 泛德国际信息咨询有限公司