Sample Cleaner SLN malting, feed etc.

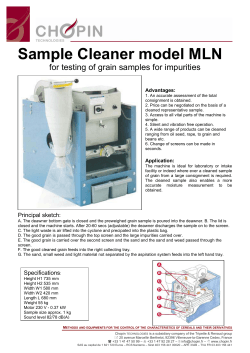

Sample Cleaner SLN for cleaning and grading by size as means of selecting grain for seed, malting, feed etc. Advantages: Selection by sample gives an accurate assessment of the total consignment. Selection based on sample makes it possible to accept quality grain or alternatively reject that which does not meet the specified standards at intake. The sample cleaner is very versatile and can be used on a wide range of products ranging from oil seed rape to maize and beans. Fully automatic cleaning - no maintenance. The screens are self cleaning being equipped with the well proven ball cleaning systern. New locking system for sieves secure quick change of sieves. Silent and vibration free operation. Below 82 dB. Sample Cleaner SLN for cleaning and grading by size as means of selecting grain for seed, malting, feed etc. Application: The identification of quality and type of impurities in a consignment and the actual grain size is important when selecting suitable grain for seed, malting barley, intervention etc. A similar standard of cleaning as that on cereals can be achieved on peas, beans and more difficult products such as sunflower seeds etc. A large feed hopper can be supplied to enable the cleaner to be used for the separation of pedigree seed from experimental yields. Standard Accessories: 5 plastic trays of uniform weight. 2 metres cable. 3 screens. Extra Equipment Screen plates. Electronic weighing scales with percent caiculation. DATAPRINT will calculate percent, print a ticket and has the ability to transfer the results directly to main computer. Extension hopper, run through trays and sack holder for continuos cleaning. Guarantee: The cleaner is guaranteed for one year in respect of manufacturing failure. During the guarantee period defective parts will be replaced free of charge subject to those parts being returned for examination. Dimension Sketches: Principal sketch: A) The deawner bottom gate is closed and the preweighed grain sample fed into the deawner. B) The lid is closed and the machine starts. After 2060 secs (adjustable) the deawner discharges the sample on to the screen. C) The light waste is air lifted into the cyclone and precipated into the plastic bag. D) The good grain is passed through the top screen and the large impurities carried over. E) The good grain is carried over the second screen and the sand and small seeds passed through the screen. F) The good grain is then returned back to the lower grading screen. G) The prime material (good grain) feeds into the right collecting tray. H) The undersized grain feeds into the left hand tray. I) The sand, small seeds and light material not separated by the aspiration system feeds into the tray in the left hand side of the sample cleaner. 1) Switch for start and manual release of deawner. 2) Filling cover. 3) Deawner outlet. 4) Outlet regulation. 5) Tray for small grains. 6) Tray for prime grains (good). 7) Fan. 8) Deawner. 9) Cyclone. 10) Air regulation. 11) Electro magnet for automatic discharge of deawner. 12) Top screen. 13) Lower screen. 14) Grading screen. 15) Tray for sand and non aspirated waste. 16) Plastic bag for aspirated waste 17) Potmeter debearder time 18) Springs

© Copyright 2026