Purpose: 2.0 Scope:

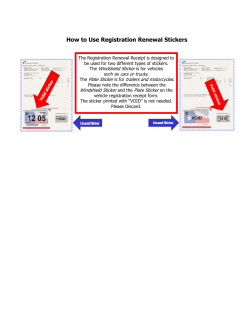

Sample Approval Procedure P7-31 Rev D Page 1 of 3 Purpose: 1 2.0 Scope: 2.01 3.0 3.03 3.04 Sample- Production run piece indicative of final result. Prototype- Initial run of a piece used to give customer idea of what part will look like. May be different material or color. Art work- Either Accutech or customer designed picture or graphic for use on finished product. Proof- Printer supplied copy of what artwork will look like on final product sent for approval before production is run. References: 4.01 4.02 4.03 4.04 4.05 4.06 5.0 This procedure applies to the Thermoforming and Paper Converting/Print Finishing departments at Accutech Packaging as well as material manufactured off site at an approved vendors location. Terms/Abbreviations: 3.01 3.02 4.0 To provide a method for gaining approval of sample parts and art work QM-1 Quality Manual P4-24 Control of Quality Records P7-5 Control of Production and Service Provision P7-4 Purchasing P7-3 Design Control P7-2 Customer Related Processes Responsibility: 5.01 5.02 5.03 5.04 Engineering is responsible for completing the drawing, sample approval sheet and collecting the samples for shipment. They are also responsible for attaching the identification stickers to the parts. Upon return of the approved sample, engineering is responsible for completing the final draft of the drawing and the specifications and distributing them to the appropriate people. The print finish manager is responsible for obtaining the printed proof, produced internally or externally, and submitting it to Quality. Quality Assurance is responsible for checking the Sample Approval Form for completeness, documenting the sample approval form on the Sample Log and delivering it to the proper sales associate. Upon return of the signed, approved sheet and proof/part, Quality Assurance is responsible for noting the return on the Sample Log and communicating to the organization that the approval has been received. The sales representatives are responsible for communicating with customers and delivering the sample parts to them, either in person or by a delivery service. 6.0 Procedure: 6.01 6.02 6.03 6.04 6.05 6.06 6.07 6.08 6.09 6.010 6.011 FOR THERMOFORMING: If a prototype is made, the following steps will be completed: Upon completion of the drawings, a sample mold will be made and a prototype part will be formed on the hand former. The part will be given to the design engineer who will inspect it to ensure it closely resembles the expected finished part. A Sample Approval Sheet (F7-31-02) will be completed by the engineer containing all the pertinent information necessary for the customer to approve the part. Due to the limitations of the hand former, any discrepancies between the hand formed part and the expected finished product should be explained on F7-31-02 The completed F7-31-02 and the prototype will be given to the Quality Manager. The Quality Manager will log the sample on the Sample Log, F7-31-01 and give the sample to the appropriate sales person. The sales person will deliver the part to the customer and request the part and F7-31-02 be completely filled out and signed. The completed F7-31-02 and signed part will then be returned to the Quality Manager. If a prototype is not made, the following steps will be followed. Upon completion of the final mold, a sample part will be run on a production machine. The project manager will inspect the part to ensure it is indicative of the parts to be produced and that it matches the drawing. Once it is determined that the parts are correct, the project manager will attach a Sample Sticker (F7-31-06) to each part with the pertinent information filled out. 6.011.1 Part/Project Number 6.011.2 Date 6.011.3 Material 6.011.4 Revision Number 6.012 Whenever possible, the parts and sample approval form will be brought to the customer for approval. If this is not possible, or the customer requests otherwise, the parts will be brought to an officer of the company or their designee for approval. If the parts are acceptable to them, they will sign the Sample Sticker and Approval Sheet. 6.013 Once the approval is received, the Quality Manager will note it on the Sample Approval log and place the parts and F7-31-02 in the job bag. An email will be sent out to design, the salesperson, and the production team notifying them of the approval. 6.014 Engineering will turn the part from Red to Green on the schedule indicating it is ok to run. 6.015 The signed, approved part and sample approval form will be placed in the job bag 6.016 6.017 FOR PRINT FINISHING, A sample sticker will be placed on the back of the proof or prototype with all the pertinent information filled out. The completed Sample Approval form and stickered proof will be delivered to Quality Assurance. Quality Assurance will document the sample on the Sample Log with the following information: 6.018.1 Part/Project number 6.018.2 Customer 6.018.3 Date out 6.018.4 Date in 6.019 Quality will email the appropriate sales person and customer service representative to notify them that the parts/proof are ready for delivery to the customer. 6.020 Whenever possible, the parts or proof and sample approval form will be brought to the customer for approval. If this is not possible, or the customer requests otherwise, the parts will be brought to an officer of the company or their designee for approval. If the parts are acceptable to them, they will sign the Sample Sticker and Approval Sheet. 6.021 Once the approval is received, the Quality Manager will note it on the Sample Approval log and deliver the form and the signed part/proof to the production supervisor, who will place them in the job bag. 6.022 An email will be sent out to design, the salesperson, and the production team notifying them of the approval. 6.023 Quality will complete the sample log to indicate the approval form has returned and 6.018 7.0 Records: 7.01 7.02 7.03 7.04 8.0 F7-31-01 Sample Log F7-31-02 TF Sample Approval Form F7-31-03 PC Sample Approval Form F7-31-06 Sample Sticker Revision History Date Rev Page 3/24/2009 A NA 6/22/2009 B 1,2 10/14/2009 9/30/2010 C D all 1,2 Comments Initial Issue Changed approval to allow some customers to approve prototypes Major rewrite of sample approval procedure Changed approval requirements Approval R D’Amico R D’Amico R D’Amico R D’Amico

© Copyright 2026