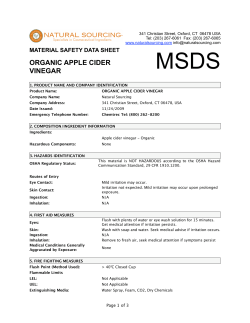

CHEMICAL HYGIENE PLAN AND HAZARDOUS MATERIALS SAFETY MANUAL