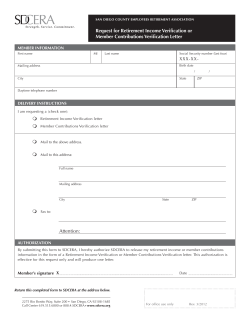

A u t o