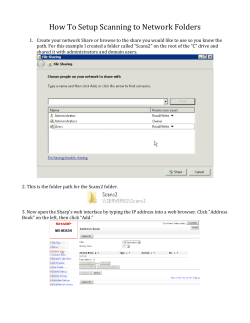

Programmable controller Installation manual EN