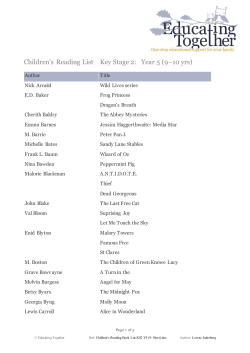

NIBTS