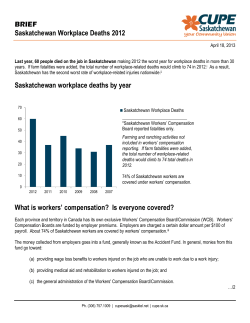

UNIVERSITY OF SASKATCHEWAN DESIGN MANUAL FACILITIES MANAGEMENT DIVISION