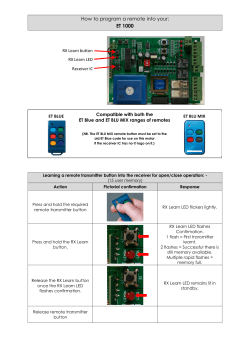

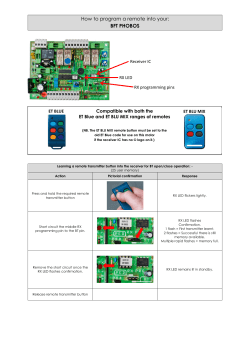

RADIO REMOTE CONTROL M550 User’s Manual