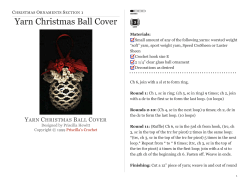

Mini8 ENG oller Eight loop contr