LinkTech Quick Couplings Inc. QUALITY MANUAL Based on ISO 9001:2008

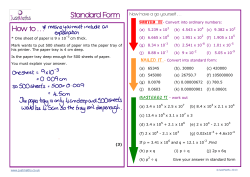

QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 1 of 13 QUALITY MANUAL LinkTech Quick Couplings Inc. 3000 Bunsen Ave. #A Ventura, CA 93003 Based on ISO 9001:2008 Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 2 of 13 INTRODUCTION: This Quality Manual establishes the quality system and related practices used by LinkTech to manage its Quick Couplings business, to continually improve both its operations and the quality management system and to meet its customer’s requirements. Additional procedures have been established and implemented for certain processes to establish additional process control. These procedures are referenced within this document where appropriate. The quality management system described within this Quality Manual, combined with all other documents and/or processes identified by LinkTech has been developed to meet LinkTech’s needs as well as those established by the ISO 9001:2008 International Standard. This Quality Manual is controlled through the LinkTech procedure for establishing and controlling changes within the systems documentation. The history of changes to this document is retained in accordance with the LinkTech documented quality records procedure. 1.0 SCOPE The scope of this document is to demonstrate the capability of LinkTech to develop, supply, and maintain their products and services through the compliance and application of the requirements outlined in the ISO 9001:2008 standard. 1.1 COMPANY BACKGROUND LinkTech established operations in 2005 from its newly constructed facility in Ventura, CA. All engineering, product development, customer service and quality assurance are based at its California headquarters. LinkTech maintains a worldwide distribution network to support its rapidly growing customer base which spans from a single user to fortune 100 world class manufacturers. LinkTech’s management team has over 26 years’ experience in producing and marketing plastic couplings, valves and fittings to the world market. It is LinkTech’s mission to provide customers the best product available, with on-time delivery and excellent customer service, at the best possible cost. Because of its dedication to excellence, LinkTech is rapidly becoming the number one choice for quick coupling solutions. Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL 1.2 Revision Document Number Pages E LT-422-001 Page 3 of 13 EXCLUSIONS The following clauses and/or sub-clauses have been identified for exclusion from the scope of LinkTech quality management system. All production and service processes are capable of verification through monitoring and measurement systems. Therefore, LinkTech has identified Clause 7.5.2 Validation of processes for production and service provision for exclusion from its Quality Management System. 4.2 DOCUMENTATION REQUIREMENTS LinkTech has documented, established and maintains six procedures as required by the ISO 9001:2008 International Standard as: Control of Documents Control of Records Internal Audit Control of Nonconforming Product Corrective Action Preventive Action Other documents established by LinkTech are identified through the Master Revision List and controlled through the Control of Documents procedure. Some, but not all, of these documents may be referenced within this Quality Manual as well as the Process Interaction and Planning flowcharts that appears in the Appendices of this Quality Manual. 5.0 MANAGEMENT RESPONSIBILITY Top management of LinkTech is committed to establishing, maintaining and continually improving the effectiveness of a quality management system that fully complies with all of the requirements outlined in the ISO 9001:2008 International Standard. Through the totality of the processes that comprise the LinkTech quality management system customer, regulatory and/or statutory requirements are identified and met. The top management of LinkTech with regard to quality is identified through the organization chart shown in Appendix 1 of this Quality Manual. Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 4 of 13 5.4.1 QUALITY OBJECTIVES Top management of LinkTech establishes and communicates its quality objectives through a documented process. These objectives are designed to support the activities and quality policy of LinkTech. All quality objectives shall be measurable and pertinent with regard to meeting customer requirements as well as fostering an atmosphere of continual improvement throughout the organization. 5.4.2 QUALITY MANAGEMENT SYSTEM PLANNING LinkTech embraces a “process approach” while planning, developing and improving its quality management system. In addition LinkTech uses the process interaction and quality planning flowchart shown in Appendix 2 of this quality manual as a quality system planning tool. Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 5 of 13 Appendix 1 Operations Manager Accounting President Manager Eastern Sales Customer Service Manager Customer Service Representative Shipping Clerk Manager Vice President Receiving Clerk Western Sales Manager International Sales Manager Assembly Technician Assembly Technician Design Engineer Manufacturing Engineer Procurement Date Printed: February 19, 2014 This document only valid on date printed Marketing Coordinator QUALITY MANUAL Appendix 2: Revision Document Number Pages E LT-422-001 Page 6 of 13 Process Interaction Chart Quality Management System Planning Chart 4.0 Quality management System General Requirements Doc. Requirements Quality Manual (LT-422-001) Control of Documents (LT-423-001) Control of Records (LT-424-001) 5.0 Management Responsibility 6.0 Management Commitment Customer Focus Quality Policy (LT-530-001) Quality Objectives (LT-541-001) Management Review (LT-560-001) Resource Management Provision of Resources Human Resources Competence Awareness/Training (LT-622-001) Infrastructure Work Environment 7.0 Product Realization Management Team Purchasing Product Requirements (LT-722-001) Customer Communication (LT-722-001) Purchasing Process (LT-742-001) Supplier Evaluation (LT-741-001) Quality Control of Production Identification & Traceability Preservation of Product Design & Development (LT-730-001) Verification of Product (LT-743-001) Monitoring & Measurement (LT-760-001) Planning of Product CUSTOMER Operations 8.0 Measurement, Analysis & Improvement Management Team Operations Quality Customer Satisfaction Nonconforming Product (LT-830-001) Analysis of Data (LT-840-001) Internal Audit (LT-822-001) Monitoring & Measuring Continual Improvement Corrective Action (LT-852-001) Preventive Action (LT-853-001) Date Printed: February 19, 2014 This document only valid on date printed SUPPLIER Customer Requirements QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 7 of 13 CLAUSE 6.0 RESOURCE MANAGEMENT LinkTech is committed to identifying training needs and providing training for personnel whose activities within the quality management system can affect product quality. LinkTech identifies those competencies required for personnel to perform their jobs at the highest possible efficiency and effectiveness. Job descriptions, outlining requirements such as education, experience and training, are documented for positions affecting product quality. LinkTech provides and maintains the work environment and infrastructure in a manner that consistently ensures product conformity. 6.1 Provision of Resources 7.0 Product Realization 6.2 Human Resources 6.2.1 General 6.2.2 Competence, Awareness & Training Training Process (LT-622-001) Training Sign In Sheet Job Descriptions Employee Training Log (LT-622-002) 6.3 Infrastructure 6.4 Work Environment Maintenance Log Maintenance Log Records Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL CLAUSE 7.0 Revision Document Number Pages E LT-422-001 Page 8 of 13 PRODUCT REALIZATION LinkTech ensures product quality throughout the product realization phase by identifying and planning the processes required to produce quality product. This includes the documentation of processes, inspection steps and records identified by LinkTech as critical to the organization. The planning and linkages of these processes is outlined in the Product Realization Planning Flowchart located in this quality manual. Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 9 of 13 Appendix 3: Product Realization Planning 7.1 Planning of Product Realization CUSTOMER 7.2 Customer Related Processes 7.2.1 Determination of Requirements (LT-722-001) 7.2.2 Review of Requirements (LT-722-001) 7.2.3 Customer Communication Customer Complaints Corrective Action (LT-852-001) 7.4 Purchasing 7.4.2 Purchasing Information Approved Supplier List 7.4.3 Verification of Purchased Product Receiving/Inspection (LT-743-001) 7.5.1 Control of Production & Service 7.5.3 Identification & Traceability 7.5.4 Customer Property 7.5.5 Preservation of Property 7.6 Control of Monitoring and Measuring Equipment Calibration (LT-760-001) Records Date Printed: February 19, 2014 This document only valid on date printed 7.6 Control of Monitoring & Measuring Devices 7.3 DESIGN & DEVELOPMENT (LT-741-002) SUPPLIER 7.4.1 Purchasing Process Supplier Evaluation(LT-741-001) Supplier Evaluation Form QUALITY MANUAL CLAUSE 7.3 Revision Document Number Pages E LT-422-001 Page 10 of 13 DESIGN AND DEVELOPMENT Design and Development activities are planned based upon the requirements of the ISO 9001:2008 international standard and the fundamentals of project management. All requirements, verification and validation activities and changes are controlled in accordance with planned arrangements. All records of reviews, design changes, and acceptance criteria are stored in the Design Notebooks for each project. Appendix 4: Design and Development Planning 7.3.4 7.3.2 Design & Development Inputs (LT-730-001) 7.3.3 Design & Development Outputs (LT-730-001) Product Characteristics Acceptance Criteria Performance Requirements 7.3.5 Design & Development Verification (LT-730-001) 7.3.6 Design & Development Validation (LT-730-001) Meets Product & Customer Requirements Records Design Project File Date Printed: February 19, 2014 This document only valid on date printed SUPPLIER & CUSTOMER REQUIREMENTS Design & Development Review 7.3.7 Control of Design & Development Changes 7.3.1 Design & Development Planning QUALITY MANUAL CLAUSE 8.0 Revision Document Number Pages E LT-422-001 Page 11 of 13 MEASUREMENT, ANALYSIS & IMPROVEMENT LinkTech plans and conducts monitoring and measurement activities as a tool for improving the effectiveness of the quality management system. LinkTech determines applicable measurement systems and the extent of their use to measure and analyze areas important to the success of our business such as customer satisfaction, product quality and process capability. LinkTech uses quality tools such as internal audits, corrective actions and preventive actions to perform an evaluation of the quality management system. Corrections, corrective actions and preventive actions are used to continually improve the effectiveness of the quality management system. Date Printed: February 19, 2014 This document only valid on date printed QUALITY MANUAL Appendix 5: Revision Document Number Pages E LT-422-001 Page 12 of 13 Measuring and Monitoring Planning 8.1 General 8.2.1 Customer Satisfaction 8.2.2 Internal Audit Customer Complaints Internal Audit Procedure (LT-822-001) Corrective Action (LT-852-001) 8.2.3 Monitoring & Measurement of Processes 8.2.4 Monitoring & Measurement of Product Control of Non-Conforming Product Procedure (LT-830-001) Nonconforming Product Tag (LT-830-002) 8.5 Improvement 8.5.1 Continual Improvement 8.5.2 Corrective Action Management Review (LT-560-001) Corrective Action (LT-852-001) CAR/PAR Form (LT-852-002) Product Characteristics Acceptance Criteria 8.5.3 Preventive Action Performance Requirements Preventive Action (LT-853-001) CAR/PAR Form (LT-852-002) Records Date Printed: February 19, 2014 This document only valid on date printed 8.3 Control of Nonconforming Product 8.4 Analysis of Data (LT-840-001) 8.2 Monitoring & Measurement QUALITY MANUAL Revision Document Number Pages E LT-422-001 Page 13 of 13 DOCUMENT RELEASE HISTORY Revision A B C D E Rev. Date 05/09/2011 12/12/11 3/20/12 8/24/12 1/23/13 Change Description IR Updated organization chart Updated Header Logo Updated organization chart: added Materials Manager, Sales Manager etc.. Updated organization chart: removed Materials Manager, added operations manager; changed company name. Date Printed: February 19, 2014 This document only valid on date printed

© Copyright 2026