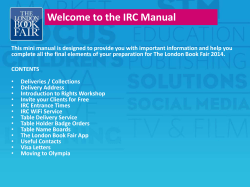

Document 322182