Module: 4 Lecture: 21 SODIUM BROMIDE

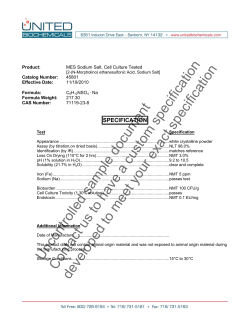

Module:4 Lecture:21 Sodium bromide Dr. N. K. Patel Module: 4 Lecture: 21 SODIUM BROMIDE INTRODUCTION Sodium bromide (NaBr) was discovered by Carl lowig in 1826. Sodium bromide was first registered as a pesticide in USA in 1975. Now a days the number of pesticides products containing sodium bromide are available in the market. Sodium bromide is used as an anti-epileptic drug and has anti-seizure properties. Bromide is considered the second drug of choice when it comes to controlling seizures Phenobarbital being the first. Bromide was used to treat gynecologic seizures in women since 1857. Bromide therapy is still considered for dogs whose seizures are considered refractory which is not controlled by another anti-epileptic drug. Other important reasons for considering bromide therapy are: Effective in controlling cluster seizures Bromide is not processed by the liver It is an inorganic compound. It is a high-melting white, crystalline solid that resembles sodium chloride. It is a widely used source of the bromide ion and has many applications. Sodium bromide is the one of the most utilized alkali bromide and salt of hydrobromic acid. It is available in the form of crystals or powder. From aqueous solution sodium bromide crystallizes as a dihydrate and monohydrate NaBr2.H2O at below 510C, while above it crystallizes as the anhydrous compound. NaBr crystallizes in the same cubic motif as NaCl, NaF and NaI. The anhydrous salt crystallizes above 50.70C. It is produced by treating sodium hydroxide with hydrogen bromide. NPTEL 1 Module:4 Lecture:21 Sodium bromide Dr. N. K. Patel MANUFACTURE 1. By neutralization of sodium hydroxide Raw materials Basis: 1000kg sodium bromide by neutralization of sodium hydroxide Sodium hydroxide 380kg Hydrobromic acid 760kg Reaction Manufacture process Sodium bromide can be produced by neutralization method, in which solution of sodium hydroxide or sodium carbonate was neutralized using hydrobromic acid which should be free from bromine. For neutralization process, solution of sodium hydroxide was introduced into the reactor having stirrer where it was treated with hydrobromic acid at ambient temperature. Mother liquor Water vapor Steam out Reactor Evaporator Steam in Crystallizer Filter Hydrobromic acid NaOH solution Cold air out Hot air Dryer Sodium bromide Figure: Manufacture of sodium bromide by neutralization Block diagram of manufacturing process Diagram with process equipment NPTEL 2 Module:4 Lecture:21 Sodium bromide Dr. N. K. Patel Animation As the neutralization reaction proceed amount of water in system was increased. After neutralization steps reaction mass was transferred to evaporating tank where water vapour was removed. Concentrated sodium bromide solution was sent to the crystallizer tank where sodium bromide was crystallized. The temperature of the crystallizing system should be kept below 510C. So, a hydrated sodium bromide crystal was obtained. While anhydrous sodium bromide crystals were obtained above 510C temperature. Mother liquor was separated out via filtration and recycled to the reactor. While a crystal of sodium bromide was sent to a dryer and dried product was then sent for packaging section. 2. By using excess of bromine Raw materials Basis: 1000kg sodium bromide by using excess bromine Excess bromine 1553kg Sodium hydroxide 380kg Reaction Manufacture process Generally this process is used for preparing commercial quantity of sodium bromide. Excess of bromine was added into a reaction kettle containing sodium hydroxide solution under continuous stirring at ambient temperature. Then the excessive bromine-NaOH solution was transferred to evaporating tank where it was evaporated to dryness. After that it was treated with reducing agent in reducing tank. Generally activated carbon or formic acid was used as reducing agent which converts the sodium bromate into sodium bromide. NPTEL 3 Module:4 Lecture:21 Sodium bromide Activated carbon or formic acid Water vapor Filter Excess bromine NaOH solution Dr. N. K. Patel Steam out Reactor Evaporator Steam in Reducing agent for purification Reducing tank Cold air out Hot air Dryer Sodium bromide Figure: Manufacture of sodium bromide using excess bromine Block diagram of manufacturing process Diagram with process equipment Animation Health and safety factors The LD50 for this compound taken orally by rats is 3.5gm/kg body weight. The gastrointestinal and central nervous system of human can be affected by sodium bromide. Gastrointestinal effects include nausea and vomiting, foul breath, anorexia, weight loss, constipation and dehydration. Due to exposure of large amounts of sodium bromide, immediate abdominal pain may occur in a single dose. Neurological effects include the headache, slurred speech, impaired memory and intellectual capacity and drowsiness. PROPERTIES NPTEL Molecular formula Molecular weight Appearance Odour Boiling point Flashpoint : NaBr :102.89gm/mole : White powder : Odourless : 13960C : 8000C 4 Module:4 Lecture:21 Sodium bromide Melting point Density Refractive index Solubility Dr. N. K. Patel : 7470C (anhydrous) 360C (dihydrate) : 3.20gm/cm3 (anhydrous) 2.18gm/cm3 (dihydrate) : 1.6459 : Soluble in water, methanol USES Sodium bromide is useful inorganic bromide in industry As a hypnotic, anticonvulsant and sedative in medicine Used in conjunction with chlorine as disinfectant for swimming pools Used to prepare dense fluids used in oil wells It can be used as a source of the chemical element bromine this can be done by treating an aqueous solution of NaBr with chlorine gas Used widely as a hypnotic, anticonvulsant and sedative in medicine Its action is due to the bromide ion, and for this reason potassium bromide is equally effective NPTEL 5

© Copyright 2026