SRT 251 Construction and Structure 2 Project 1 : Construction Research

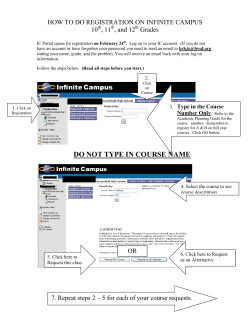

SRT 251 Construction and Structure 2 Project 1 : Construction Research TEAM members: Hideto Chijiwa Makiko Ikeda Phil Rogers Shaun Ely Yenny Kusuma PORTAL FRAME PORTAL FRAME definition; Portal frames are single storey, single( or multi-bay) frames with pitched or flat roof. Fabricated from universal beams, it is an ideal structural solution in many circumstances, regarding its economic and structural efficiency. The system is specially ideal for industrial buildings due to its ability to span large areas of unobstructed open space within its building envelope. This is made possible through the design and use of refabricated steel sections. Technological advance in the footing system also cooperate for the large span achieved due to their ability to carry greater loads (or its efficiency to transfer and distribute the loads to the foundation). Three major elements are; cladding for both roof and walls; secondary steel to support the cladding and form framing for doors, windows and the like; and the main framework of the structure, including all necessary bracing. In addition, the building requires appropriate footings designed to transmit all the load to the foundations( supporting soil). The design is essentially to provide a structure which is without, or has a limited number of internal columns, in principle the requirement is for the construction of four walls and a roof for a single or multi-bay structure. Light latticed portal frame structure for the roof of an industrial buildings provide a neat efficient structure which is simple to design, economic to execute and frequently satisfies architectural requirements. Portal frame structure 26m-span located in the breakwater st. Industrial area in Geelong. FOOTINGS Due to the point loads applied to the foundation, Pad footings are respectably the most suitable in long-span portal frame construction. Also in achieving a workable surface and the distribution of loads to the foundation, combined concrete slab would be used along with the Pad footing. The reinforcements and metal dowels also play a big part in the sufficient footings behaviour. Concrete Pad Footing Strip or combined column footing There are 3 types of connection systems for a Portal Frame structure. • Rigid base • 2 pin • 3 pin The 3 types mentioned above are of purely how rigid or flexible the connections are at the apex, knee, and the base. This however relates greatly to the load transfer of the structure, as the bending moment becomes a big issue. Rigid bases are used much commonly in the current construction due to its ability to carry the bending moment and axial loads, thus giving the framework a much lighter finish. (Max bending moment at the knee, apex and base) Pinned bases however transmit the bending moment straight through to the foundation. (max bending moment at the apex and knees for the 2 pin, max bending moment at the knee for the 3 pin.) FIXED BASE CONNECTION PINNED BASE TO PORTAL Diagram- shows the difference in the base, rigid and pin. Georgiou, Jim. Construction & Structures 2 READER, DEAKIN University. The advantage of using steel as the material is due to the ability to design relatively light, long-span, durable, and is easy to erect safely and quickly. A primary requirement is flexibility of planning which results in a demand for as few columns as possible. The ability to provide spans up to 60m (most commonly around 30m), using steel has proved very popular for commercial and leisure buildings. The lightness and flexibility of this kind of steel structure reduces the sizes and the costs of foundations and make them less sensitive to the geotechnical characteristics of the soil. The structural envelope are simple, it is essential to ascertain correctly the load applied to the structure and to predict the load paths from the load applied through to the foundations. (e.g. Sheeting to the purlins and side rails, through the roof girder to the column and finally to the foundation and supporting soil. THE BENDING MOMENTSPURLINS and RAFTERS; Purlins and Rafters are the essential beams that make up the portal frame structure. Purlins are the beams that run the length of the frame connected to the rafters, the purlins are bolt connected by the cleat that is welded to the rafter. The purlins are directed towards the apex with a pitch to achieve the best possible performance. The size of the sections of these beams is specified by the engineer, along with the size of the web and flange, depending on the spans and load derived from the design. EAVES connection; The eaves connections are in many different forms and changed forms through history of construction. Originally the diagonal connection plane was considered, however there was a major stability problem at the inside corner. •Tapered portal frames fabricated by automatic welding can be utilised to create aesthetic and economical industrial buildings. •The behaviour of fabricated sections with slender webs is more complex than that of rolled sections; the resistance checks must take account of local buckling, cross-section distortion and the interaction between the primary and secondary structure through the stays. LONG SPAN TIMBER STRUCTURES: Long-span structures( span 30m or greater) can also be constructed using timber (mainly plywood) as the material. Long-span structures require a level of technical sophistication that indicates a confidence in timber as a structural and aesthetic medium on the part of the designers. The spanning potential of timber portal frame structure can reach around 50 metres, and provides an extremely economic solution. The Plywood Gusset The Steel Plate and Dowel Knee Joint Bracket; although this is not a timber product, it is used in conjunction with timber columns and rafters to provide a steady connection system. The various timber products used in those of Timber Portal Frame structures are; diagram- a typical plywood gusset (solid section). P.J. Yttrup & Associates Pty. Ltd. Australia. diagram – Timber portal frame structure@Mt Gambia, SA. Accessed April 2004. http://oak.arch.utas.edu.au/projects/aus/207/istos.html By collaborating steel knee joints with glue-laminated Timber products, Timber portal frame structures to form large-span structure can be produced. The economical aspect of this material can not be surpassed. TIMBER PORTAL FRAME construction process: DURING CRANE LIFTING THE STRUCTURE; the rafters, purlins and roof bracing are fabricated on the site, the roof is then lifted on and joined to the columns (this process can be done as a whole, or by sections). Elements such as the gussets and purlins are then installed. All purlins should have all connections installed, including joist brackets, tension straps and fly braces. The rest of the major connection joints such as the knee gussets must also be fixed along with required bracings. Temporary bracing is also fitted, due to the support the structure needs when the support from the crane is released. AFTER CRANE DETACHED; After the cranes are detached, the remainder of the fixing/nailing takes place, this is when the detailed installations are carried out, such as; girts, eaves, mullions, remaining purlins and additional roof wind bracings. Though Timber being a highly economic solution in structural frames, it is also highly flammable and prone to elemental attacks, and due to the natural property of the material, it needs to be tested before any type of work is done to check the performance of the timber. The tests include trial fabrication and treatments (paints and chemical protection coating must be applied before the erection). Yttrup, Peter. Ham, Jeremy, Deakin University Construction and Structures 2 SRT251 LECTURE powerpoint slides. Spatial requirements of the client: The selected system provide the client with adequate space to utilise the floor space according to their business needs. As buildings will often change hands throughout their working life, a re-fit of the warehouse and/or office space may be necessary. Structural members with significant spanning capacity allow the occupant to carry-out such activities without the expense of making structural alterations. Appropriateness of steel portals in this issue. Steel has extremely high material strength in both compression and tension. With a Young’s Modulus of 200,000Mpa, it is by far the stiffest of all conventional building materials. These two characteristics of steel are most exemplified in the design of universal beams and columns. Universal beams have excellent spanning capacity, making their application in portal frame construction the most desired framing option for medium-sized industrial construction. (Mcleod, 2003) Appropriateness of saw-tooth construction in addressing issue. Saw-tooth trusses were used in close span construction, which was prevalent prior to the mid 1970’s. Unlike portal frames, buildings with saw-tooth trusses had to be designed in a series of bays, supported by loadbearing columns. Such design is far more restrictive than portal framing in allowing spatial freedom to the end user. Adaptability of the structural system to a variety of site conditions. Structural systems that can be constructed in extreme conditions are likely to be popular with building designers. On sites with high, extreme or abnormal moisture conditions, differential movement may cause excess structural deflection. This can adversely affect the aesthetic quality of the building, leading to costly repair work. CONCRETE CONSTRUCTION Tilt-up and On-site Casting Economy: Very economic as it provides a larger amount of building, operating and investment for your dollar. Design Freedom: The beauty of tilt-up designed buildings, is that they create a structure that suits and is sufficient for any purpose or taste. System characteristics The most common characteristics of tilt-up construction include: Building Quality: Tilt-up construction structures require the latest technology, experienced design and construction professionals. Speed Of Construction: Due to the systems engineering and assembly lie involved in tilt-up construction, productivity then provides savings in time and labour. •Versatility: Tilt-up wall panels also make it very simple to create a building that is easily repositioned in order to provide new openings or other building additions. •Financing: Tilt-up-built structures have proven to be a more attractive investment to lending institutes due to their lasting value. •Resale: Concrete buildings much easily retain their appearance, structural integrity and, most importantly, their value. •Infiltration Factor: Tilt-up constructed buildings are air-tight. This enables the building to save on heating and cooling loads, and the size of mechanical units. •Reduced Maintenance: Building maintenance costs are reduced because of the rugged durability of concrete, and its practical construction detailing. •Floor Utilisation: Because tilt-up construction requires no columns inside the building, there is unrestricted space for door locations and rack spacing. •Security: The steel reinforcements in the concrete provide a deterrent for potential illegal entry. •Noise Abatement: The sound abatement properties of concrete make an efficient sound proofing. •Thermal Economy: Energy costs can be minimised due to the natural heat-sink properties of concrete. System application Prepare for castings: When producing tilt-up panels, factors that need to be considered include, most importantly, providing a suitable casting bed/ slab for the panels. The surface must be a sound, dense, smooth concrete surface. Then follows the essential elements such as; creating an effective mix design (concerning the use of fly ash and water, if needed), the use of moisture barriers, considering the temperature at the time of placing, vibration of the concrete, and being sure of sufficient proper finishing and curing techniques. (Tilt-Up Construction,1989) Form work: Formwork is a temporary structure, that acts as a stencil, to form a sand bed,for the pouring of the concrete, in order to create the panels. Basically, timber planks are temporarily positioned outlining the perimeter of the desired structure, then used to hold the poured concrete in position as it dries, forming the panel. Bondbreaker: A vital part of the panel construction, is selecting a sufficient curing compound and bondbreaker. Factors to be considered when choosing an appropriate bondbreaker include; a product that performs both the curing and the bondbreaker (to ensure compatibility between the materials), weather conditions (rain and heat can effect the bondbreaker), durability of the bondbreaker, whether or not the panels will be painted (in this case, bondbreakers that leave a paintable surface are available), whether or not the panels will be exposed (because bondbreakers leave stains), and, will floor treatments be needed. Lifting- Inserts: The location of lifting inserts should be used in instances where strongbacks are used, where the panel is of a large size. These are positioned in accordance to where the rigging equipment is needed in order to lift the panel safely off the ground without damaging the panels. The inserts are required so as the crane can then be connected to the panel easily when it is time for lifting. Bracing and Bracing Inserts: Braces are needed to help resist wind and construction loads. Where an applied load is apparent, three bracing inserts are essential, and generally, a minimum of two braces are needed for a single panel. These are usually placed on the same side as lifting inserts. (Code Of Practice Tilt-Up Construction, 1985) ISOLATION JOINT Joining: There are usually two types of construction joints; those that allow relative movement, and those that do not. Joints are required where a break in concrete pouring occurs, at planned joint locations, they are to coincide with expansion joints, remembering that faulty joints can lead to rusting on the reinforcement. Vertical joints include: mechanical key, dowel bar, reinforcement mesh and wirebrush joint/ scabble back concrete. Horizontal joints are to be placed between columns, slabs or beams. SAW CUT CONTRACTION JOINT Control joints are used to create a plane of weakness, and cause the concrete to crack in the desired area. Other joints include: Expansion joints, Isolation joints and Watertight joints. A contraction joint is used so as two concrete surfaces are able to move away from each other as a result of shrinkage etc. FACE SEALED JOINTS COMPRESSION SEAL Benefit of cast on-site •No transport costs •Limits useability of floor •Easier liftings •Can be load bearing •No columns Benefits of Tilt-up •Cost effective •Speed construction - Reduced labour cost •Ease of construction- factory process on site •Durability-compare with metal system failures and accidental damage •Security- used for prisons •Fire resistance Plus Sound reduction 50db v,30 metal skin Architectural expression new and versatile Energy conservation: thermal mass Low maintenance and cost Building Applications Step 1 "Parameter Formwork": The desired panel thickness is fixed to the casting surface, this is done including any openings or features. A coating of bondbreaker is applied, in a spray form, to the concrete and formwork. Step 2 "Reinforcement": Reinforcement is fixed within the forms, also using the required lifting and bracing inserts. The concrete is then poured, followed by being vibrated, screeded and then bull floated. Step 3 The concrete is then trowelled finished, by hand and power. Followed by a spray-applied cure coat. Step 4 This process is then repeated once more for all panel casting, using climbing framework. Step 5 All concrete is then cured, the formwork is stripped, the building's slab is prepared, and the lifting equipment is organised to arrive. The first panel is lifted, set, and temporarily braced. Step 6 The rest of the panels are then tilted from their stacks, transferred, set and braced. Step 7 The crane, then, is placed in a single position and working limits,where it can lift and set all panels. Step 8 All panels are lifted within one day, and the structure is now ready for intermediate floors, roofing system and final wall decoration to be fixed for completion. METAL CLADDING • Advantages: – Lightweight. – Offer pre-finished options. – Provided a range of materials option, finishes, appearance options and maintenance requirements. – Prefabricated – Rigid finishes • Disadvantages: – Just suitable for regular rain washed area or unless needs regularly clean. – Not be able to composite with other materials- contact between dissimilar metal can lead to galvanic corrosion. – Transmit roof noise from heavy rain or hail- unless sound insulation material is installed under the roofing. – Provided little or no thermal insulation benefit- the roof spaces will heat up and cool down rapidly Cladding Materials 1.1Zinc Aluminium Alloy-Coated Mild Steel ; manufactured by dipping the mild steel in a hot solution of 45% zinc and 55% aluminium alloy followed by a chromate wash to protect the steel form corrosion Advantages: – – – – Offers a wide range of profile (e.g.: curve) and finish options. Fast fabrication as it can be supplies in long lengths It’s nature color , silver-grey , dulls slowly when exposed to the weather. Provided the corrosion protection, best durability. Disadvantages: Fig 1 Zinc Aluminium Cladding – – Not suitable to use as a walking surface on the roof High cost materials. 1.3 Zinc Formed by melting of ores which contain the zinc blend followed by rolling to form a sheet material. Zinc is described as either commercial (pure) zinc or as alloy containing small amounts of copper and titanium to improve tensile strength and creep strength. Advantages: • Better durability on steeper pitched roofs, because of better rain washing • Recyclable • Suitable use to form roof accessories and ornaments • corrosion-resistance • can be pressed to form a tile shape 1.2 Lead 99% pre metal which may contain very small amounts of copper, silver and tellurium to stabilize the movement properties of the lead. Sheet lead roofing is manufactured by milling, hand casting, and machine casting. Advantages: – Easily worked into shaped (complex and curve) and for forming joints – Recyclable – Excellent corrosion resistance in most environments. – Excellent performance at high wind loads area. Disadvantages: – Very low maintenance. – Requires specialized installation skills and Disadvantages: procedures- cost and time considerate. • Limited range of profile and finish options – Low fatigue resistance ( can crack where not • Reform at cold temperatures; become brittle free to expand or contract). • Impurities in the zinc can cause the – Heavyweight . formation of localized small holes. – No thermal insulation. 1.4 Aluminium • Advantages: – – – – – • Offers a wide range of roof slope and profile options. Lighter and more durable Ductile, malleable and corrosionresistance. Fast fabrication. Excellent performance in different tempers. Disadvantages: – – – Sensitive with acids and strong alkalis materials Easily damage by poor storage prior to installation, severe hail storms, being walked on during and after installation. Impurities lead to perforation. 1.5 Stainless Steel ; are iron alloys which contain at least 12% chromium and have controlled concentrations of other elements. • Advantages: - offer a wide range of profiles and finished options, including factory coated - Fully supported sheets, where it can be jointed by welding or with specially designed edges incorporating a selfdraining joint. - Great corrosion-resistance • Fig 7 Aluminium Cladding Disadvantages: - Low maintenance - More difficult to form on-site than copper, lead, aluminium or zinc Roof Cladding Selection: According to the Design considerations( the environment issue and performance), aluminium cladding became the best solution of roofing for the warehouse and showroom design. – The roof geometry for the warehouse and showroom are quiet simple; 2° pitch roof surrounded by gutter (roof drainage). In this case, Aluminium would be able to cover up the design requirement. It is much cost effective than others steel-based cladding ( lead, copper ), more durable, and available in a wide range of forms ( such as; guttering, downpipes ). The nature color of aluminium; light grey with either a smooth or orange peel surface, is suitable for the industrial environment. Properties of aluminium cladding are lightweight than the others, approx. 2.3 kg/m² with typical thermal movement 0.023mm/m/ºC. Specification product of Roof and Wall cladding: Lysaght”, KLIP-LOK 406 “ Materials specification: ; Metal base with 0.60 mm BMT thickness ; contain 2.82 kg/m masses ; available with the COLORBOND pre-painted steel complies with AS/NZS 2728-1997. Maximum support spacing: ; 3600 mm c/c span ; based on testing in accordance with AS1562.1-1992, AS4040.0-1992 and AS4040.1-1192 Fig 9 KILP-LOK 406 Wind pressure capacities: ; 1.67 kPa ; Testing was conducted in accordance with AS 1562.1-1992 Design and Installation of Sheet Roof and Wall Cladding- Metal, and AS4040.2-1992 Resistance to Wind Pressure for Non-cyclonic Regions. The rigid shape of an inflated airbag does not apply pressure to the ribs of secret - fixed cladding or adjacent to support It’s direct pressure rig uses no air bags and applies pressure uniformly over the entire profile- including the ribs. “Uniform pressure distribution of our direct pressure rig which accurately reproduces the wind conditions experiences in the field.” INSTALLATION: STEP 1 STEP 2 The first sheet set longitudinally in relation to gutter When lifting sheets lengths onto the roof frame ready for installation, make sure all sheets have the overlapping ribs facing towards the side where fastenings to commence. Fasten clips to the purlins at each of the sheet, having positioned so that the first sheet will be in correct relation to other building elements. Align and fasten the remainder of the first run of clips using a string line or the first sheet as a straight edge overhang and locates it over the fastened run of clips, positioning the centre rib first, and engages the centre and overlapping ribs onto all clips by foot pressure STEP 3 STEP 4 Position and fasten the next run of clips, one Place the second sheet over the second run of clips, to each support, with the short return leg of again positioning the centre rib first. A string line the clip over the underlapping rib of the stretched across the bottom alignment of the sheets can installed sheet. The spur can be flattened with a blow from a rubber mallet to seat down over the ribs, if the clip fouls one of be used to check that the ends of the sheets are in line. Fully engage the interlocking ribs and the centre rib over each clip. Apply foot pressure to the top of the centre rib over each clip. For complete interlocking, along the the spurs spaces along the outer free edge of underlapping rib must be fully engaged in the shoulder the underlapping rib. of the overlapping rib. When engaging the interlocking ribs, stand only on the sheet being installed, that is the overlapping sheet, and not on the preceding sheets. Make periodical checks that the installed sheets are aligned with the roof perimeter. STEP 5 a) If the space left between the last full sheet and the fascia or parapet is more than a half sheet width, a sheet can be cut longitudinally, leaving the centre rib complete. This particular sheet can be fully clipped onto a row of clips as for a full sheet, before installing the capping or flashing. b) Otherwise, it can be covered by the capping or flashing if the space left between the last full sheet less than a half sheet width . In this case,the last sheet should be secured by cutting clips in halves and fastening the underlapping rib at each purlin with a half clip. CRITICAL KEY-POINTS: The selection/choice in choosing the right members in the structure (beams, columns, and connection details) depends largely on cost. Economic approach towards the construction of the building is an important aspect but keep within the functional constraints. The factors that needs to be considered when working out the width or the span of the warehouse are: Amount of load capabilities of the purlins and girts used, this is determined by the beam-size and the material. Footings and foundation capability, the soil-condition plays a large part as it must be able to accommodate the column loads. The size and the material of the cladding/envelope system. BRACING; Bracing is an important issue within a portal frame structure, as long-span structures need considerable amount of bracings in response to the wind loads applied. Angle bracings and rod bracing can be considered, however angle bracings would be a much economical solution, and as rod-bracings have tendencies to sag, cross bracings therefore provide a much practical bracing system for this type of structure. In designing warehouse structures of long-span characteristic, the main factor considered is to fulfill the functional(/structural) requirements with regards to the economical view( cost). This can be solved by the standardization of the frame by incorporating beams and columns of similar characteristics (size, mass, density). Design proposal : Warehouse The warehouse building is approximately 45m x 35m of concrete pad footing with concrete slab,fitted with a metal sheet cladding with clip-lock roof system.The main access to showroom and office building is via a side pedestrian access door. The long-span warehouse; span 40m was designed on the site provided, the warehouse provides an automobile showcase area and a maintenance facility included within the warehouse. [include diagram of schematic design of the warehouse along with the site plan] SHOWROOM/OFFICE STRUCTURAL MEMBER SIZE: Type of members Size (mm) Max span / size Weight Location 460 UB ( BHP) 450 x 190 9520mm 74.6kg/m Portal frame 360 UB ( BHP) 350 x 170 6470mm 50.7kg/m Column in office building 250 PFC ( BHP) 250 x 90 4520mm 35.5kg/m Roof purlins in both buildings 16 UA ( BHP) 150 x 90 3550mm 27.9kg/m Eaves strut in office building Metal sheet ( Lysaght) Zincalume 0.6 mm thickness 3600mm 2.82kg/m Minimum roof pitch 1 degree Concrete panel 150mm thickness 7000mm x 6000mm 0.36t/m2 Cladding in office building RIGID BASE CONNECION BASE PLATE BOLTS HAUNCHING DETAIL STIFFENED RIDGE CONNECTION OFFICE STRUCTURE Construction Process Concrete Flooring systems TILT-UP SLABS: The tilt up wall system is a site precast method of building construction. Slab dimensions are approximately 10 metres high, 10 metres wide and 190 mm in thickness. These slabs weigh upwards of 15 tonnes. Tilt-up slabs are held at their base in a trench at or below floor level and secured at their base by no other means. The upper section of the slabs are attached by metal bolts to a metal plate, welded to rolled steel joists (RSJ), forming the roof support structure of the building. PRE-CAST PANEL AND SLAB FLOORING FIXINGS RAFT FOOTING with CONCRETE FLOORING BEHAVIOUR OF ‘TILT-UP’ SLABS IN A FIRE SITUATION: Structural steel will rapidly loose strength when subjected to heat (A 56% loss of strength will occurs at 593° Celsius); As this happens, collapse can occur within 5 to 10 minutes. Further, Steel roof beams when heated will expand and may push walls outward. The direction of slab fall may also be governed by the performance of the roof, subjected to heat and fuel loads from within the building. CASE STUDY Critical review of structures: The purpose of the following section is to critically analyse the alternative structural systems that may be deemed as suitable for the design of medium-scale warehouse and office spaces. In the course of conducting research for this review, advise was sought from a reputable local building professional with extensive experience in this area of construction. Information drawn from interviews with this professional, along with various textual sources, will form the basis of this review. The content of the review will centre on the following incomplete structure, which have been observed over the last month. Another two types of structural systems will be reviewed, these are; Timber portal framing and steel construction with saw-tooth trusses. STRUCTURE ONE Leopold Primary School: Multi-Purpose Facility. Address: 1 Kensington Rd, Leopold. Builder: Lyons Construction, Fyans St, South Geelong. Structural details: Super-structure: Steel portal frame on pad footings. Footings in main hall are concrete pads supporting a timber-framed sub-structure. Non-load bearing timber-framed walls divide up the office space. Stiffened raft slab footing used in performance and office areas. Building Envelope: Corrugated iron roofing throughout structure. Corrugated iron wall cladding enclosing main hall. Masonry cladding enclosing office space and performance area. Steel portals. (1) Steel has extremely high material strength in both compression and tension. With a Young’s Modulus of 200,000Mpa, it is by far the stiffest of all conventional building materials. These two characteristics of steel are most exemplified in the design of universal beams and columns. Universal beams have excellent spanning capacity, making their application in portal frame construction the most desired framing option for medium-sized industrial construction. (Mcleod, 2003) (2) Portal frames- footings systems. Reference to pads in hall. Good for athletic facilities not for warehouses. Pad footings, such as those used for the hall in Structure 1 are prone to differential movement. The pad footings and strip flooring used in this case will provide greater comfort to the facilities users, than would the harder surfaces of raft slabs. Such issues are not of concern in the design of warehouses. Of more importance, is providing support to the immense live loads that will be imposed on the structure, such loads would only compound the problems caused by differential movement. Saw-tooth trusses were used in close span construction, which was prevalent prior to the mid 1970’s. Unlike portal frames, buildings with sawtooth trusses had to be designed in a series of bays, supported by load-bearing columns. Such design is far more restrictive than portal framing in allowing spatial freedom to the end user. Issues critical to the selection of structural systems for warehouse and office spaces Spatial requirements of the client The selected system provide the client with adequate space to utilise the floor space according to their business needs. As buildings will often change hands throughout their working life, a re-fit of the warehouse and/or office space may be necessary. Structural members with significant spanning capacity allow the occupant to carry-out such activities without the expense of making structural alterations. Pre-cast/Insitu Structural systems with pre-cast insitu wall panels as load-bearing members are in wide spread use in industrial construction. Rafters are bolt-connected to fixing plates, which are connected to the reinforcement and cast into the panel. The spanning capacity of such systems is comparable to portal framing, with the size of wall members increasing in accordance with the roof loading. Saw tooth construction Saw-tooth trusses were used in close span construction, which was prevalent prior to the mid 1970’s. Unlike portal frames, buildings with saw-tooth trusses had to be designed in a series of bays, supported by load-bearing columns at close span. Such design is far more restrictive than portal framing in allowing spatial freedom to the end user. Timber Portals Timber Portal frame construction may be designed span the same distances as steel portals. The nailing pattern that is used in timber portal connection systems is far more complex than the rigid bolting system used in steel portal connection. Durability of the structural material throughout the building’s life-span Of paramount importance to building designers and clients, is the likely cost of maintenance works throughout the working life of the building. Materials used in modern construction, such as steel, timber and concrete, have diverse compositional properties and differ in how they are affected when sustaining prolonged load actions. Weather resistance also varies among the type of structures, which can be critical if the conditions in which they exist are extreme. (Creep etc) Steel Portals The hot-rolled, mild steel used in portal framed construction s renowned for its durability. The material maintains it’s stiffness over long periods of time, making it the least susceptible to time dependent creep deflection. This allows steel structural members to be recycled after building demolition. (Ham, 2003) Pre-Cast/Insitu. Reinforced concrete wall panels, like all concrete products, must be carefully manufactured to ensure that durability can be maintained over long periods. All reinforced concrete panels must undergo surface treatments to guard against chemical attack and to water proof the material. Steel, however is a naturally occurring material and its manufacturing process is far more simplistic than that far concrete. Saw-tooth truss construction. One major disadvantage of using saw-tooth truss systems, was the need for a box gutter drainage system in the truss troughs. The box gutters were prone to leakage, which would often occur within the main work area, and thus required frequent maintenance. In portal frame construction, storm water drains to gutters that run parallel to the external walls perpendicular to the rafters, reducing the likelihood of leakage. Cost of the Building Materials and Construction Process Budgetary concerns will often be the most important factor in the choice of design for a building client. In these situations, the building design that is the most cost-efficient, in terms of materials costs and constructability will be chosen. Steel portal framing is the most cost-effective form of industrial steel construction. It is for this reason that saw-tooth truss construction was superseded as the preferred structural system for industrial applications in the 1970’s, when the cost of labour began increasing, in relative terms, to the cost of steel, as a result of labour market pressure. (Page, 2004) What about constructability comparison b/w Pre-cast timber and steel portals. References: Code Of Practice Tilt-Up Construction, F.D. Atkinson Government Printer, Melbourne, 1985. Economical Structural steelwork – fourth edition, Australian Institute of Steel Construction, 1996. Ham, Jeremy, SRT251 Construction and Structures 2, LECTURE, School of Architecture and Building, Deakin University, 2004. Mortlock M., Tatham C.,Selecting Roof Cladding, Branz, (Porirua City)New Zealand,1998. Oehlers D. J., Bradford, M. A., Composite Steel and Concrete Structural members , Pergamon, New York, 1995 STEEL CONSTRUCTION – Journal of the Australian Steel Institute, volume 32 Number 4 Dec 1998, Australian Steel Institute, 1998. Tilt-Up Construction, Seminar Course Manual, American Concrete Institute, United States Of America, 1989. Tilt-Up Construction, Concrete International: Design and Construction, American Concrete Institute,1982-6. Tilt-Up Digest, Architectural Details, Steel Reinforcement Institute Of Australia, Mathieson and Mackay, 1991. SRT251 Construction & Structures 2, Reader, School of Architecture and Building, Deakin University,1997. Page, D, 2003: Structural Engineer, Page & Green & Associates, Information obtained through interview conducted on the 1st April 2004. LYSAGHT pamphlets, BlueScope Steel Limited, 2003. Internet Sources- Websites: * BLUESCOPE webpage; http://www.bluescopesteel.com.au/index.cfm * LYSAGHT info webpage; http://www.lysaght.com * TIMBER BUILDINGS in AUSTRALIA; http://oak.arch.utas.edu.au/tbia/default.asp * http://www.claycorp.com/tiltup.html * http://www.tilt-up.co.uk/ * http://www.consteel.com/consteel/cshome.nsf/fsshowcase

© Copyright 2026