Case Study of BPR

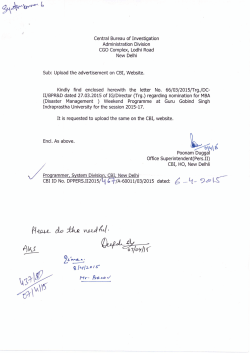

Case Study of BPR What is it (the topic history and evolution)? What are the basic concepts or principles, techniques, deliverables behind it? Where will it be applicable? Why do we have to care? When should someone use it? What are the similar approaches available in this field and make a comparison? How one should go about in implementing it (advantages and potential disadvantages)? Case study of Toyota (Kanban and E-Kanban) What is BPR? A management approach aiming at improvements by means of elevating efficiency and effectiveness of the processes that exist within and across organizations. The use of information technology (IT) is conceived as a major contributing factor to accelerate benefits. What is BPR? In 1990, Michael Hammer, published an article in the Harvard Business Review which management should improve nonvalue adding processes. This idea was rapidly adopted and by 1993, 65% of the Fortune 500 companies had plans to adopt BPR concepts or already applied BPR. What are the basic concepts or principles, techniques, deliverables behind it? Hammer's claim (1990): Most of the work being done does not add any value for customers, and this work should be removed, not accelerated through automation. Instead, companies should reconsider their processes in order to maximize customer value, while minimizing the consumption of resources required for delivering their product or service. What are the basic concepts or principles, techniques, deliverables behind it? Hammer's claim (1990): Most of the work being done does not add any value for customers, and this work should be removed, not accelerated through automation. Instead, companies should reconsider their processes in order to maximize customer value, while minimizing the consumption of resources required for delivering their product or service. What are the basic concepts or principles, techniques, deliverables behind it? Methodology 1. Envision new processes 2. Initiating change 3. Process diagnosis 4. Process redesign 5. Reconstruction 6. Process monitoring Where is it applicable? A firm which - Emphasizing on organizational efficiency - Having repetitive operations - Functional departments becoming barriers to change. - Spending too much time and money in ineffective coordination and communication. - Doing work that really benefits customers with a little time. - Spending a lot of overheads - Business processes’ design not handling changing business environments or not taking advantages of emerging technologies. Why do we have to care? Some managers focusing on the wrong issues. - Even though they consider significance of information technology - Applying unnecessary automation to processes - Instead of managing non-value adding processes Due to high competitions in business, organizations need improvements. Rapid developments in IT fields. When should someone use it? Even it is difficult to define specific answers, some factors can be concerned. Is the competitive outperforming the company by factors? Are there many conflicts in the organization? Is there an extremely high frequency of meetings? Are there excessive uses of non-structured communication? (memos, emails, etc.) Is a more continuous approach of incremental improvements not possible? (such as Kaizen) What are the similar approaches available in this field? Kaizen refers to a workplace 'quality' strategy and is often associated with the Toyota Production System and related to various quality-control systems. English - Continuous Improvement - Continual Improvement Japanese - Change for the better - Improvement What are the similar approaches available in this field and make a comparison? Comparison between BPR and Kaizen Topic Implemen- Style tation BPR Harder Kaizen Easier Main Requirement Technology- Requires longoriented term discipline Peopleoriented Enables radical changes, but requires major change management skills How one should go about in implementing it (advantages & potential disadvantages)? Advantages - Increase of efficiency productivity (such as higher performance, cost and cycle time reduction) Disadvantages - The disregard of people in an organization (such as layoffs, work environment, employee satisfaction) - Investments, update, and maintenance of systems Case study of BPR Advantages - Increase of efficiency productivity (such as higher performance, cost and cycle time reduction) Disadvantages - The disregard of people in an organization (such as layoffs, work environment, employee satisfaction) - Investments, update, and maintenance of systems Case study of Toyota (Kanban and E-Kanban) Kanban (Before BPR) Toyota Kanban Supplier Unloading Part arranging Delivery part to TMT Case study of Toyota (Kanban and E-Kanban) E-Kanban (After BPR) eKanban Toyota SCP system Calculate Order Base on Veh. Sequence Vehicle Plan Supplier Supplier - Kanban Printing - PDS Printing - Skid Label Printing ALC L/ O Part arranging. Delivery part to TMT Case study of Toyota (Kanban and E-Kanban) Cycle time reduction - Faster operations (internet transfer information immediately) Performance increase - More accuracy by internet tracking (Kanban can be lost and difficult to tract) - More flexibility of logistics (easily adjust orders) Cost Reduction - Inventory and part stock area reduction (more JIT-Just in time) - Manpower reduction (fewer processes) Reference 1.Professor Chen’s BPR lectures 2.http://en.wikipedia.org/wiki/Business_proc ess_reengineering 3.http://www.valuebasedmanagement.net/m ethods_bpr.html 4.http://en.wikipedia.org/wiki/Kaizen 5.Toyota production system PPT (from Toyota Motor Thailand) 6.An internal document of Toyota Motor Thailand’s logistics section.

© Copyright 2026