Hazard Analysis and Critical Control Points (HACCP) STENUM GmbH www.stenum.at

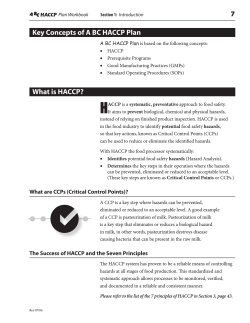

Hazard Analysis and Critical Control Points (HACCP) STENUM GmbH www.stenum.at Slides 12 – HACCP What is HACCP? Problems Foodborne diseases Market access – importance of food safety all along the food-chain Solutions Food safety system that focuses on preventing problems before they occur Industry-led programme used to improve and verify food safety Answer Hazard Danger to health Analysis Investigation of the hazard Critical Crucial for containment Control Handling of conditions Points Position in the process 12 – HACCP Slides What is HACCP? Hazard Analysis and Critical Points Science-based, internationally accepted food safety system Can be applied to all segments of the food chain Focused on hazard identification and prevention Addresses chemical and physical hazards Source: Department of Food Science and Technology, Virginia Tech. Slides 12 – HACCP Why adopt HACCP? A properly functioning HACCP system will result in the production of safer food. Benefits: Improved food safety Increased market access Protection against liability Drive for continuous improvement Enhanced process control 12 – HACCP Slides Where can HACCP be used? HACCP can be used in any food sector from production to retail Production Retail and food service Processing Transport 12 – HACCP Slides The seven principles of HACCP I II III Conduct a hazard analysis Identify critical points Establish critical limits for each critical control point Establish critical control point monitoring requirements Establish procedures for verifying that the HACCP system is working as intended VII Establish record keeping procedures VI Establish corrective actions V IV Slides 12 – HACCP ISO 22000 Requirements for a food safety management system 4 elements Interactive communication System management Prerequisite programmes HACCP principles Source: Van Voorst Consult Slides 12 – HACCP Implementing HACCP 1. Preliminary Steps for the introduction of a HACCP System Gathering the resources and information needed 2. Seven principles of HACCP in action Completion of all steps will result in a properly functioning HACCP plan Slides 12 – HACCP Preliminary steps 1. Assemble the HACCP team Group of people that will oversee the implementation and maintenance of the HACCP programme Multi-disciplinary (i.e. production, sanitation, management, etc.) Including a HACCP-trained person Slides 12 – HACCP Preliminary steps 2. Description of products and identification of intended use and consumers Full description of the product(s) being manufactured under the programme Product information assists with hazard analysis Which group(s) will be consuming the food product Where will the product be sold How will it be prepared Slides 12 – HACCP Preliminary steps 3. Development and verification of process flow diagram(s) The flow diagram should Outline all processing steps Include all processing steps The plant schematic should Outline where all of the processing steps occur Display the movement of products, people and waste Slides 12 – HACCP Preliminary steps 4. Grouping of products Decide whether products can be grouped using process categories Slaughter – all species Raw product – ground/not ground Thermally processed – commercially sterile Heat/not heat treated – shelf stable Fully cooked – not shelf stable Heat treated but not fully cooked – not shelf stable Product with secondary inhibitors Further categories for grouping can be commodity group, hazards, etc. Products in the same process category may be covered by the same HACCP plan Slides 12 – HACCP Principle I Conduct a hazard analysis Evaluate information regarding potential hazards associated with the manufacturing process and ingredients Determine which hazards are significant to food safety Consider: • Probability of occurrence • Severity of consequences Slides 12 – HACCP What are hazards? There are 3 types of hazards Biological Chemical Physical Do not forget cross-contamination Microbiological, allergens Slides 12 – HACCP Biological hazards Biological hazards can cause illness and include: Bacteria: E.coli, Salmonella, Listeria, Campylobacter, Shigella Viruses: cold viruses, Hepatitis A, Norwalk virus Parasites: Giardia, Cryptosporidium, Trichinella, tapeworms Yeasts and moulds Any toxin produced by microbiological organisms is also a biological hazard Slides Chemical hazards Chemical hazards can cause injury or poisoning and include: Naturally occurring substances (e.g. allergens, plant specific toxins) Excessive, intentionally added chemicals: antibiotics, pesticides, herbicides, fungicides, nitrates Accidentally added chemicals: cleaning chemicals, paint, pest control chemicals 12 – HACCP Slides Physical hazards Physical hazards are foreign objects that can cause injury: Glass Metal grindings, screws, nuts, bolts Stones, pebbles Needles Hard plastic Bones 12 – HACCP Slides 12 – HACCP Principle II Identify Critical Control Points (CCPs): A CCP is a point, step or procedure at which a control measure has to be applied to prevent, eliminate or reduce a food safety hazard CCPs are not: Necessarily located where the hazard occurs, they may be located at a subsequent step Some hazards cannot be controlled by the operator Slides Principle III Establish Critical Limits (CL) What is a critical limit? The maximum and/or minimum value to which a parameter must be controlled at a CCP The critical limit separates acceptability from unacceptability The critical limit must be clearly defined and measurable 12 – HACCP Slides 12 – HACCP Principle IV Establish monitoring procedures Monitoring: Is the process of conducting a planned sequence of measurements to determine if a CCP is under control Monitoring results must be recorded If monitoring shows that critical limits are not met, then the process is out of control and the food may be unsafe. Slides 12 – HACCP Principle V Establish corrective actions Corrective actions are pre-determined measures that have to be implemented when monitoring indicates that a deviation has occurred. Corrective actions must: • Regain control of the process • Locate and segregate affected product • Determine disposal of affected product • Prevent a recurrence Slides 12 – HACCP Principle VI Establish verification procedures Validation Ensures that the HACCP plan is complete and valid Ensures that the plan is effective in achieving expected food safety outcomes Ongoing verification Ensures that the HACCP plan is working effectively Confirms that the plan is operating according to written procedures Auditing Overall review of the HACCP plan To be performed whenever any changes occur that could affect the hazard analysis or alter the HACCP plan Slides 12 – HACCP Principle VII Establish record keeping procedures Record keeping must be complete and accurate and includes: Documentation pertaining to all steps, including the HACCP principles Appropriate record storage procedures A log book to keep track of changes Slides 12 – HACCP HACCP system – Summary HACCP systems consist of two elements Prerequisite programmes • Implemented prior to HACCP plans • Control of the overall plant environment • Control factors not directly related to food (e.g. water quality, transportation and storage, plant sanitation, employee training) HACCP plans • Implemented following pre-requisite programmes • Tailored to a certain product or process • Control factors directly related to food production

© Copyright 2026