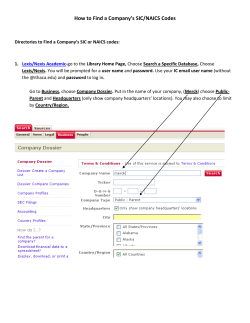

Publisher version