Commercial Refrigeration Scroll Compressors VSC Series Scroll Compressors for Commercial Refrigeration

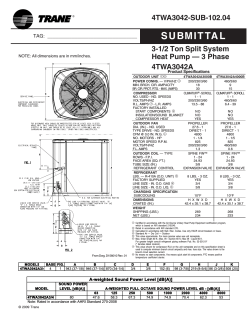

Commercial Refrigeration Scroll Compressors Reference Guide-Wholesale Distribution VSC Series Scroll Compressors for Commercial Refrigeration Scroll Compressors for Commercial Refrigeration CBP and LBP Commercial Refrigeration Applications Tecumseh’s new VSC Series Scroll Compressor has been designed to replace Original Equipment compressors used today on 2 to 10 ton R404A/R507 commercial refrigeration applications. The VSC scroll complements our current offering of 1-1/2 to 5 ton refrigeration reciprocating compressors, giving Tecumseh Authorized Wholesalers a single source for commercial refrigeration replacement compressors. VSC Series Scroll refrigeration compressors are considered “Universal” replacements since they have the standard mounting footprint, overall height, rotolock connections, orientation and performance characteristics of competitive models. FEATURES AND BENEFITS • UNIVERSAL REPLACEMENT FOR ORIGINAL EQUIPMENT COMPRESSORS • High Reliability Built-in reliability due to scroll design and engineered bearings. Thermal fault protection contributes to excellent reliablity. Standard mounting footprint, overall height and rotolock connection size/orientation. Meets or exceeds performance characteristics of competitive models. • Quietest Scroll on the Market Note: VSC compressors are supplied with rotolock connections only. (All images show sweat connections.) 2 Low sound is a result of smooth and continuous compression combined with the absence of suction/discharge valves. • Energy Savings High efficiency motor and optimized scroll design combine to reduce energy consumption and deliver high capacity for commercial refrigeration applications. Vapor injection (LBP models) boosts cooling capacity. Table of Contents Introduction ............................... 2 Product Marketing......................10 Additional Information.................14 Features and Benefits...............................2 Model Nomenclature .............................10 Product Dimensions and Weights..........14 Models Released......................................4 Product Specifications...........................11 FAQs.......................................................15 Competitive Cross....................................6 What’s in a Single Pack?........................12 Installation Instructions .........................16 Ease of Change-Out...............................13 TECH TIPS Tecumseh has developed a number of tools to help you sell, while also helping your customer sell. Website: www.tecumseh.com Tecumseh’s portal to the world, the website offers product information, compressor data sheets, wholesaler location lookup, basic crossreferencing and a library filled with marketing brochures/catalogs, application bulletins and more. Tecumseh Web Applications Tecumseh Web Applications Box Load Program Capillary Tube Sizing Program A suite of online web application tools that eliminates the guess work. Site includes product and component look up, cross reference tools, drawings, along with performance data. Analytical tools are also available for use including, refrigerant line sizing and calculating box (heat) load requirements. Go to the website at, http://boxload.tecumseh.com/ Condensing Unit Data Sheets Evaporator Coil Data Sheets Electrical Service Parts Guidebook Competitive Cross Reference Condensing Unit Fast Reference Compressor Fast Reference Part Number Fast Reference Refrigerant TP - PT Chart Compressor Performance Data Condensing Unit Performance Data System Analyzer Refrigerant Line Sizing Online Literature 3-Phase Voltage Imbalance Calculator Compressor Housing Drawings Tecumseh’s online literature portal, located under the “Library” tab of www.tecumseh.com, provides downloadable and searchable PDF versions of all catalogs, brochures and reference booklets produced. Units of Measurement Converter Mobile Tech to Go These apps are the electronic version of Tecumseh’s Electrical Service Parts & Cross Reference tools. For iPhone®/iPad® and Android® devices. iPhone/ https://itunes.apple.com/us/app/ tecumseh/id502258181?mt=8 Android Device https://play.google.com/store/apps/ details?id=com.logic.tecumseh COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 3 MODELS RELEASED Model BOM Voltage HP Capacity Motor RLA (Btu/h)* Type LRA Oil Type R404A COMMERCIAL TEMPERATURE 4 VSC9515ZNA VS220ET-103-J7 208-230/60/1 2.0 14,622 PSC 12.2 69 PVE VSC9515ZXG VS220TT-103-J7 460/60/3, 380-420/50/3 2.0 14,499 3PH 4.5 30 PVE VSC9515ZXH VS220VT-103-J7 575/60/3, 480-520/50/3 2.0 14,499 3PH 3.5 26 PVE VSC9515ZXT VS220RT-103-J7 200-230/60/3, 200-220/50/3 2.0 14,499 3PH 9.3 60 PVE VSC9519ZNA VS221ET-103-J7 208-230/60/1 2.5 19,501 PSC 16.0 97 PVE VSC9519ZXG VS221TT-103-J7 460/60/3, 380-420/50/3 2.5 19,461 3PH 6.1 45 PVE VSC9519ZXH VS221VT-103-J7 575/60/3, 480-520/50/3 2.5 19,461 3PH 5.0 38 PVE VSC9519ZXT VS221RT-103-J7 200-230/60/3, 200-220/50/3 2.5 19,461 3PH 11.2 95 PVE VSC9521ZNA VS222ET-103-J7 208-230/60/1 3.0 20,690 PSC 16.7 97 PVE VSC9521ZXG VS222TT-103-J7 460/60/3, 380-420/50/3 3.0 20,843 3PH 6.1 45 PVE VSC9521ZXH VS222VT-103-J7 575/60/3, 480-520/50/3 3.0 20,843 3PH 4.5 38 PVE VSC9521ZXT VS222RT-103-J7 200-230/60/3, 200-220/50/3 3.0 20,843 3PH 11.2 95 PVE VSC9526ZNA VS223ET-103-J7 208-230/60/1 3.5 26,033 PSC 21.0 115 PVE VSC9526ZXG VS223TT-103-J7 460/60/3, 380-420/50/3 3.5 25,808 3PH 6.4 45 PVE VSC9526ZXH VS223VT-103-J7 575/60/3, 480-520/50/3 3.5 25,808 3PH 5.1 38 PVE VSC9526ZXT VS223RT-103-J7 200-230/60/3, 200-220/50/3 3.5 25,808 3PH 14.1 95 PVE VSC9530ZNA VS224ET-104-J7 208-230/60/1 4.0 30,328 PSC 24.4 150 PVE VSC9530ZXG VS224TT-104-J7 460/60/3, 380-420/50/3 4.0 30,324 3PH 8.3 60 PVE VSC9530ZXH VS224VT-104-J7 575/60/3, 480-520/50/3 4.0 30,324 3PH 5.1 42 PVE VSC9530ZXT VS224RT-104-J7 200-230/60/3, 200-220/50/3 4.0 30,324 3PH 16.7 120 PVE VSC9538ZNA VS225ET-104-J7 208-230/60/1 5.0 35,870 PSC 28.9 160 PVE VSC9538ZXG VS225TT-104-J7 460/60/3, 380-420/50/3 5.0 36,497 3PH 9.6 70 PVE VSC9538ZXH VS225VT-104-J7 575/60/3, 480-520/50/3 5.0 36,497 3PH 4.7 53 PVE VSC9538ZXT VS225RT-104-J7 200-230/60/3, 200-220/50/3 5.0 36,497 3PH 16.7 123 PVE VSC9545ZXG VS226TT-104-J7 460/60/3, 380-420/50/3 6.0 44,144 3PH 9.6 82 PVE VSC9545ZXH VS226VT-104-J7 575/60/3, 480-520/50/3 6.0 44,144 3PH 7.7 64 PVE VSC9545ZXT VS226RT-104-J7 200-230/60/3, 200-220/50/3 6.0 44,144 3PH 19.2 170 PVE VSC9548ZXG VS227TT-104-J7 460/60/3, 380-420/50/3 7.0 48,249 3PH 10.3 87 PVE VSC9548ZXH VS227VT-104-J7 575/60/3, 480-520/50/3 7.0 48,249 3PH 8.3 67 PVE VSC9548ZXT VS227RT-104-J7 200-230/60/3200-220/50/3 7.0 48,249 3PH 23.7 190 PVE VSC9558ZXG VS228TT-105-J7 460/60/3, 380-420/50/3 7.5 55,551 3PH 12.8 95 PVE VSC9558ZXH VS228VT-105-J7 575/60/3, 480-520/50/3 7.5 55,551 3PH 9.4 75 PVE VSC9558ZXT VS228RT-105-J7 200-230/60/3, 200-220/50/3 7.5 55,551 3PH 25.6 190 PVE Model BOM Voltage HP Capacity Motor RLA (Btu/h)* Type LRA Oil Type R404A COMMERCIAL TEMPERATURE (continued) VSC9566ZXG VS229TT-105-J7 460/60/3, 380-420/50/3 9.0 65,491 3PH 16.0 110 PVE VSC9566ZXH VS229VT-105-J7 575/60/3, 480-520/50/3 9.0 65,491 3PH 11.5 95 PVE VSC9566ZXT VS229RT-105-J7 200-230/60/3, 200-220/50/3 9.0 65,491 3PH 29.5 235 PVE VSC9576ZXG VS230TT-105-J7 460/60/3, 380-420/50/3 10.0 73,940 3PH 19.2 140 PVE VSC9576ZXH VS230VT-105-J7 575/60/3, 480-520/50/3 10.0 73,940 3PH 14.2 100 PVE VSC9576ZXT VS230RT-105-J7 200-230/60/3, 200-220/50/3 10.0 73,940 3PH 32.0 235 PVE R404A LOW TEMPERATURE VSCF513ZXG VS231TT-106-J7 460/60/3, 380-420/50/3 4.0 13,162 3PH 8.0 62 PVE VSCF513ZXT VS231RT-106-J7 200-230/60/3, 200-220/50/3 4.0 13,162 3PH 17.9 123 PVE VSCF515ZXG VS232TT-106-J7 460/60/3, 380-420/50/3 5.0 16,099 3PH 9.6 88.5 PVE VSCF515ZXT VS232RT-106-J7 200-230/60/3, 200-220/50/3 5.0 16,099 3PH 18.5 180 PVE VSCF518ZXG VS233TT-106-J7 460/60/3, 380-420/50/3 6.0 19,163 3PH 10.0 90 PVE VSCF518ZXT VS233RT-106-J7 200-230/60/3, 200-220/50/3 6.0 19,163 3PH 20.0 184 PVE VSCF524ZXG VS234TT-107-J7 460/60/3, 380-420/50/3 8.0 23,923 3PH 13.5 95 PVE VSCF524ZXT VS234RT-107-J7 200-230/60/3, 200-220/50/3 8.0 23,923 3PH 25.6 190 PVE VSCF534ZXG VS235TT-108-J7 460/60/3, 380-420/50/3 10.0 32,600 3PH 16.0 120 PVE VSCF534ZXT VS235RT-108-J7 200-230/60/3, 200-220/50/3 10.0 32,600 3PH 32.0 240 PVE *ARI Conditions; CBP (Commercial Back Pressure) Evaporating Temp 20°F (-6.7°C), Condensing Temp 120°F (48.9°C), Return Gas 40°F (4.4°C), Liquid Temp 120°F (48.9°C), Ambient Temp 95°F (35°C). LBP (Low Back Pressure) Evaporating Temp -25°F (-31.7°C), Condensing Temp 105°F (40.6°C), Return Gas 65°F (18.3°C), Liquid Temp 105°F (40.6°C), Ambient Temp 95°F (35°C). VSA / VSC FEATURE COMPARISON Feature VSA VSC 7.5” x 7.5” 7.5” x 7.5” Sight Glass X X Schrader Valve X X Braze/Rotolock Rotolock Mounting Footprint Suction/Discharge Connections LBP Liquid Injection X LBP Vapor Injection X Capacity Range (CBP) 1 HP to 6 HP 2 HP to 10 HP Capacity Range (LBP) 2 HP to 6 HP 4 HP to 10 HP Refrigerants (CBP) R404A/R507 R404A/R507, R22, R134a Refrigerants (LBP) R404A/R507 R404A/R507 POE PVE Oil COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 5 COMPETITIVE CROSS REFERENCE Tecumseh commercial refrigeration scrolls are considered “Drop-In” or “Universal” replacements since they have the standard mounting footprint, overall height, rotolock connections and orientation and performance characteristics as competitive models. 5.06 As with any cross reference, please review fit, form and function with your customer and their application. Tecumseh to Competitive Cross R404A COMMERCIAL TEMPERATURE VSA Model VSC Model HP 6 Btu/h Voltage Copeland Model VSA9514ZNA VSC9515ZNA 2 14,622 208-230/60/1 ZS15KAE-PFV VSA9514ZXG VSC9515ZXG 2 14,499 460/60/3 ZS15KAE-TFD N/A VSC9515ZXH 2 14,499 575/60/3 ZS15KAE-TFE VSA9514ZXT VSC9515ZXT 2 14,499 200-230/60/3 ZS15KAE-TF5 N/A VSC9519ZNA 2.5 19,501 208-230/60/1 ZS19KAE-PFV VSA9517ZXG VSC9519ZXG 2.5 19,461 460/60/3 ZS19KAE-TFD N/A VSC9519ZXH 2.5 19,461 575/60/3 ZS19KAE-TFE VSA9517ZXT VSC9519ZXT 2.5 19,461 200-230/60/3 ZS19KAE-TF5 N/A VSC9521ZNA 3 20,690 208-230/60/1 ZS21KAE-PFV VSA9521ZXG VSC9521ZXG 3 20,843 460/60/3 ZS21KAE-TFD N/A VSC9521ZXH 3 20,843 575/60/3 ZS21KAE-TFE VSA9521ZXT VSC9521ZXT 3 20,843 200-230/60/3 ZS21KAE-TF5 VSA9524ZNA VSC9526ZNA 3.5 26,033 208-230/60/1 ZS26KAE-PFV VSA9524ZXG VSC9526ZXG 3.5 25,808 460/60/3 ZS26KAE-TFD N/A VSC9526ZXH 3.5 25,808 575/60/3 ZS26KAE-TFE VSA9524ZXT VSC9526ZXT 3.5 25,808 200-230/60/3 ZS26KAE-TF5 N/A VSC9530ZNA 4 30,328 208-230/60/1 ZS30K4E-PFV VSA9528ZXG VSC9530ZXG 4 30,324 460/60/3 ZS30K4E-TFD N/A VSC9530ZXH 4 30,324 575/60/3 ZS30K4E-TFE VSA9528ZXT VSC9530ZXT 4 30,324 200-230/60/3 ZS30K4E-TF5 N/A VSC9538ZNA 5 35,870 208-230/60/1 ZS38K4E-PFV VSA9536ZXG VSC9538ZXG 5 36,497 460/60/3 ZS38K4E-TFD N/A VSC9538ZXH 5 36,497 575/60/3 ZS38K4E-TFE VSA9536ZXT VSC9538ZXT 5 36,497 200-230/60/3 ZS38K4E-TF5 VSA9544ZXG VSC9545ZXG 6 44,144 460/60/3 ZS45K4E-TFD N/A VSC9545ZXH 6 44,144 575/60/3 ZS45K4E-TFE VSA9544ZXT VSC9545ZXT 6 44,144 200-230/60/3 ZS45K4E-TF5 4.38 34 R404A COMMERCIAL TEMPERATURE VSA Model VSC Model HP Btu/h Voltage Copeland Model N/A VSC9548ZXG 7 48,249 460/60/3 - N/A VSC9548ZXH 7 48,249 575/60/3 - N/A VSC9548ZXT 7 48,249 200-230/60/3 - N/A VSC9558ZXG 7.5 55,551 460/60/3 ZS56K4E-TWD N/A VSC9558ZXH 7.5 55,551 575/60/3 ZS56K4E-TWE N/A VSC9558ZXT 7.5 55,551 200-230/60/3 ZS56K4E-TWC N/A VSC9566ZXG 9 65,491 460/60/3 - N/A VSC9566ZXH 9 65,491 575/60/3 - N/A VSC9566ZXT 9 65,491 200-230/60/3 - N/A VSC9576ZXG 10 73,940 460/60/3 ZS75K4E-TWD N/A VSC9576ZXH 10 73,940 575/60/3 ZS75K4E-TWE N/A VSC9576ZXT 10 73,940 200-230/60/3 ZS75K4E-TWC R404A LOW TEMPERATURE VSA Model VSC Model HP Btu/h Voltage 4.32 Copeland Model VSAG513ZXG VSCF513ZXG 4 13,162 460/60/3 ZF13K4E-TFD VSAG513ZXT VSCF513ZXT 4 13,162 200-230/60/3 ZF13K4E-TF5 VSAG514ZXG VSCF515ZXG 5 16,099 460/60/3 ZF15K4E-TFD VSAG514ZXT VSCF515ZXT 5 16,099 200-230/60/3 ZF15K4E-TF5 VSAG518ZXG VSCF518ZXG 6 19,163 460/60/3 ZF18K4E-TFD VSAG518ZXT VSCF518ZXT 6 19,163 200-230/60/3 ZF18K4E-TF5 VSAG523ZXG VSCF524ZXG 8 23,923 460/60/3 ZF24K4E-TWD VSAG523ZXT VSCF524ZXT 8 23,923 200-230/60/3 ZF24K4E-TWC N/A VSCF534ZXG 10 32,600 460/60/3 ZF33K4E-TWD N/A VSCF534ZXT 10 32,600 200-230/60/3 ZF33K4E-TWC 4° 31° 45° 73° COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 7 COMPETITIVE CROSS REFERENCE Tecumseh commercial refrigeration scrolls are considered “Drop-In” or “Universal” replacements since they have the standard mounting footprint, overall height, rotolock connections and orientation and performance characteristics as competitive models. As with any cross reference, please review fit, form and function with your customer and their application. Competitive Cross to Tecumseh 5.06 R404A COMMERCIAL TEMPERATURE 8 Copeland Model VSC Model VSA Model HP Btu/h Voltage ZS15KAE-PFV VSC9515ZNA VSA9514ZNA 2 14,622 208-230/60/1 ZS15KAE-TFD VSC9515ZXG VSA9514ZXG 2 14,499 460/60/3 ZS15KAE-TFE VSC9515ZXH N/A 2 14,499 575/60/3 ZS15KAE-TF5 VSC9515ZXT VSA9514ZXT 2 14,499 200-230/60/3 ZS19KAE-PFV VSC9519ZNA N/A 2.5 19,501 208-230/60/1 ZS19KAE-TFD VSC9519ZXG VSA9517ZXG 2.5 19,461 460/60/3 ZS19KAE-TFE VSC9519ZXH N/A 2.5 19,461 575/60/3 ZS19KAE-TF5 VSC9519ZXT VSA9517ZXT 2.5 19,461 200-230/60/3 ZS21KAE-PFV VSC9521ZNA N/A 3 20,690 208-230/60/1 ZS21KAE-TFD VSC9521ZXG VSA9521ZXG 3 20,843 460/60/3 ZS21KAE-TFE VSC9521ZXH N/A 3 20,843 575/60/3 ZS21KAE-TF5 VSC9521ZXT VSA9521ZXT 3 20,843 200-230/60/3 ZS26KAE-PFV VSC9526ZNA VSA9524ZNA 3.5 26,033 208-230/60/1 ZS26KAE-TFD VSC9526ZXG VSA9524ZXG 3.5 25,808 460/60/3 ZS26KAE-TFE VSC9526ZXH N/A 3.5 25,808 575/60/3 ZS26KAE-TF5 VSC9526ZXT VSA9524ZXT 3.5 25,808 200-230/60/3 ZS30K4E-PFV VSC9530ZNA N/A 4 30,328 208-230/60/1 ZS30K4E-TFD VSC9530ZXG VSA9528ZXG 4 30,324 460/60/3 ZS30K4E-TFE VSC9530ZXH N/A 4 30,324 575/60/3 ZS30K4E-TF5 VSC9530ZXT VSA9528ZXT 4 30,324 200-230/60/3 ZS38K4E-PFV VSC9538ZNA N/A 5 35,870 208-230/60/1 ZS38K4E-TFD VSC9538ZXG VSA9536ZXG 5 36,497 460/60/3 ZS38K4E-TFE VSC9538ZXH N/A 5 36,497 575/60/3 ZS38K4E-TF5 VSC9538ZXT VSA9536ZXT 5 36,497 200-230/60/3 ZS45K4E-TFD VSC9545ZXG VSA9544ZXG 6 44,144 460/60/3 ZS45K4E-TFE VSC9545ZXH N/A 6 44,144 575/60/3 ZS45K4E-TF5 VSC9545ZXT VSA9544ZXT 6 44,144 200-230/60/3 4.38 3 7.50 R404A COMMERCIAL TEMPERATURE Copeland Model VSC Model VSA Model HP Btu/h Voltage - VSC9548ZXG N/A 7 48,249 460/60/3 - VSC9548ZXH N/A 7 48,249 575/60/3 VSC9548ZXT N/A 7 48,249 200-230/60/3 ZS56K4E-TWD VSC9558ZXG N/A 7.5 55,551 460/60/3 ZS56K4E-TWE VSC9558ZXH N/A 7.5 55,551 575/60/3 ZS56K4E-TWC VSC9558ZXT N/A 7.5 55,551 200-230/60/3 - VSC9566ZXG N/A 9 65,491 460/60/3 - VSC9566ZXH N/A 9 65,491 575/60/3 VSC9566ZXT N/A 9 65,491 200-230/60/3 ZS75K4E-TWD VSC9576ZXG N/A 10 73,940 460/60/3 ZS75K4E-TWE VSC9576ZXH N/A 10 73,940 575/60/3 ZS75K4E-TWC VSC9576ZXT N/A 10 73,940 200-230/60/3 4.32 R404A LOW TEMPERATURE Copeland Model VSC Model VSA Model HP Btu/h Voltage ZF13K4E-TFD VSCF513ZXG VSAG513ZXG 4 13,162 460/60/3 ZF13K4E-TF5 VSCF513ZXT VSAG513ZXT 4 13,162 200-230/60/3 ZF15K4E-TFD VSCF515ZXG VSAG514ZXG 5 16,099 460/60/3 ZF15K4E-TF5 VSCF515ZXT VSAG514ZXT 5 16,099 200-230/60/3 ZF18K4E-TFD VSCF518ZXG VSAG518ZXG 6 19,163 460/60/3 ZF18K4E-TF5 VSCF518ZXT VSAG518ZXT 6 19,163 200-230/60/3 ZF24K4E-TWD VSCF524ZXG VSAG523ZXG 8 23,923 460/60/3 ZF24K4E-TWC VSCF524ZXT VSAG523ZXT 8 23,923 200-230/60/3 ZF33K4E-TWD VSCF534ZXG N/A 10 32,600 460/60/3 ZF33K4E-TWC VSCF534ZXT N/A 10 32,600 200-230/60/3 34° 31° 45° COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 9 PRODUCT MARKETING COMPRESSOR MODEL NOMENCLATURE VS C 9 5 15 Z XT Family 9.40 VS Series 7.50 Approved Voltage 4 x Ø 0.75 Release Generation Application “9” Commercial Temperature 5.06 “F” Low Temperature, Vapor-Injection 208-230/60/1 200-230/60/3, 200-220/50/3 460/60/3, 380-420/50/3 575/60/3, 480-520/50/3 Refrigerant* Z9.40 = R404A, R507 4.32 Capacity 7.50 Number of digits in Rated Btu/h Capacity Capacity Next two digits are the first two digits in Rated Btu/h Capacity. 4.38 * CBP also designed for common refrigerants R22 and R134a 34° NA XT XG XH 31° 45° 73° DIMENSIONS All dimensions are in inches. Discharge port Two Electrical Connection Types 2 1 Vapor port (LBP) Dim. Drawing Suction port Oil sight glass Height Ring Connect Screw Terminal Quick Connect Spade Terminal Suction Rotolock Discharge Rotolock Height (in.) Conn. Types A1 1 1/4 A2 1 1/4 1 16.2 2 1 17.9 1 A3 1 3/4 1 1/4 21.1 1 B1 1 1/4 1 19.1 1 B2 1 3/4 1 1/4 21.3 1 B3 1 3/4 1 1/4 22.2 1 All measurements are in inches. Schrader valve and cap 9.40 7.50 4 x Ø 0.75 5.06 4.32 All dimensions in Inch Discharge port 4.38 Vapor port (LBP) 34° Suction port 31° 45° 73° 10 Oil sight glass Discharge port 9.40 7.50 Vapor port (LBP) PRODUCT SPECIFICATIONS Commercial Scroll (R404A/R507, R134a, R22) Evaporating Ranges: CBP -20°F to +50°F (-30°C to +10°C) LBP -40°F to +14°F (-40°C to -10°C) Refrigerants: CBP R404A/R507, R134a, R22 LBP R404A/R507 Oil: Viscosity 32 cSt Polyvinyl Ether Size: Commercial (CBP) 2 to 10 HP Low (LBP) 4 to 10 HP Connections (in): Suction Rotolock 1 1/4 and 1 3/4 Discharge Rotolock 1 and 1 1/4 Footprint (in): Industry Standard 7.5 x 7.5 Motor Type: PSC, 3 Phase SERIAL LABEL S 03 09 K 12345 Manufacturing Location Sequential Serial Number Production Week Production Year Scroll Compressor Model no: VSC9530ZNA 208-230 V Tech no: XGD290HA07 Serial no: S0114K993414 1 ~ 60 Hz Run Cap: 70 uFd / 370 V LR: 150.0 A Lubricant: PVE - 53 oz / 1.6 L Refrigerant: R404A/R507 Note: Serial label is marked A4, and the Item no: VS224ET-104-A4 Carton label is marked J7. 2014 MADE IN USA C US THERMALLY PROTECTED PROTECTED BY DOMESTIC AND FOREIGN PATENTS COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 11 WHAT’S IN A SINGLE PACK? To facilitate ease of change-out, Tecumseh provides the following packaging, labeling, components and support documentation with scroll compressor purchase: Discharge T CHECKLIS Vapor (LBP only) Suction ssor q Compre ve Cover q Protecti ting Kit ssor Moun P-10070) re p m o C : :L q CBP d Grommets (Spacers an ting Kit ssor Moun otolock Braze re p m o C : dR q LBP rommets an Numbers) (Spacers, G See next page for Kit . Adaptor Kit tions tion Instru5c / TPC#132-10010, a ll ta s In )* 0 q Outer Carton Spacer and Grommet 0011 #TR-3 (CBP: Pub #TR-306 / TPC#132-1 b u LBP: P Quick Connect SpadeTerminal Scroll Terminal Fence Inner Tube Quick Connect l Screw Termina C T1 R T3 R T3 3 S T2 2 AMS S C Run Capacitor Line R CSR 2 Potential Relay 1 S Run Capacitor Start Capacitor Line R 3 PHASE L1 L2 T1 T2 L3 T3 T2 the system. l to evacuate m dehydrationTermina damage. this may cause G WARNIN 5 C Never system. • Scroll Terminal the complete psig. use leak detection 450 • Do not leak detection test on detection. a must not exceedand repeat the leak • Perform side test pressure n repair the leak ed, • The low PinisOrientatio Terminal leak discover • When a as LP & HP sides. to both the of 500 microns Hg. is under vacuum • Never sor while it a vacuum pump vacuum to the compres • Connect the system under a apply power C • Pull T₁down a megohmmeter nor S use ents. T₂ • Do not T1, T2, and spade terminals sor requirem Quick connect box type and compres the terminals are labeled supply. P terminal standards connections ons, the main power as per local Electrical ase applicati (start), and R (run). its from the off and isolate ents must be selected S R For three-ph be used for on• Switch t! (when viewed is not a major must only ons details. labeled C (common), T₃ l compon Importan clockwise compres sor All electrica s are scope of applicati • electrical connecti angles , reverse rotation rotating counterthe terminal The VSC Scroll (s) and within its guideline s Refer to page 4 for g on the phase correct applications only compress gas whilerun in only one direction application • haseterminals screw designed purpose limits). Consult umseh.com single-p connect direction, dependin operates in the sors will T3. ForRing will start and box type terminal compres (refer to operatingavailable at www.tec hase motors will start and run in either that the compressor hCscroll single-p Tecumse t(s) • ensure Since however, top). on to (C type). and datashee compressor Three-phase motors, taken during installati in Inch screw terminal All dimensions be consideration. power. Care must with ring connect connection supplied power and push the 4 the of for s charge (betweenbeen ring terminal d nitrogen has direction. and ¼”push with a pressurize s all pressure - 32 screws type). r is delivered fittings, etc...unleswork gloves. • Use #10 26.6 in. lb torque. compresso terminals (P to ground. and spade with le bolts, plugs, NOTE: The goggles sor Fasten connect not disassemb r. Wear protective must be used. the compres 6 psig). Do tabs for quick requirements the compresso • Use ¼” tapping screw to connect regulation Refrigerant(lb) relieved from offset local safety self • Use apush ces, applicable position (maximum . HP charge limit in the vertical Under all circumstan if possible with caution off. the system 8 charge limits ck by using r must be handled Chargingthe compressor switched the indicated and secured. flood-ba The compresso 15°). 2 - 3.5 cover in place charge below sor against liquid • Keep 12 terminal box refrigerant from the vertical: 4-7 • Keep the limit; protect the compresaccumulator. r without electrical 16 compresso d to the circuit. Above this suction line Never operate 7.5 - 10 wn cycle or nt filling cylinder connecte a pump-do they are ot unless the refrigera (CBP) scroll tions leave s. Ensure that or troublesho repair, Commercial information • Never issioning and mechanical relief ns and safety standard ation Instruc y Never service, h VSC Series these functions. comm to perform regulatio or pressure switch before to the Tecumse They provide necessar General Install are qualified ation applicable safety you ns pertain seriousasinjury lead to such ion systems. Verific can and locally These instructio refrigerat devices servicing for product. generally Settings used or explosion. both Improper of this Use safety ce with the compressors and proper usage Minimum electrical shock, the maximum handles in valvefire,in complianproperly set. death from don’t exceed regarding safety and 7 psig Use the dedicatedappropriate and safe ssure switches operational or with care. R22 and use high-pre n. of lug compress lifting the or the settings component. pressure operatio • Handle 6 psig Use the compress • Check that of any system ended to avoid low position. R134a packaging. ce t. right). 70°C). in an upright service pressureswitch is recomm table to the and in complian lifting equipmen the compressor and 158°F (-35°C and sure atmosphere. 20 psig Setting fastened low-pres corrosive A transport or -30°F • R404A to the Minimum are properly • Store and compressor between the packaging to rain (Please refer electrical connections or and least 24 hours • Store the all the compress energized at • Verify that regulations. re. , it must be shutdown. • Don’t expose e atmosphe less than 7° slope. d with local heater is required istics. with or in a flammabl crankcase and start-up after prolonge l flat surface material. or motor character the compress • When a start-up • Never use compressor on a horizonta nds to the compress and silver alloy brazing 15 ft-lb. befores.initial installed. the nut to 66 ± supply correspoion-grade copper tubes • Mount are open, if vibration the power Tightenor.rotolock charge. service valves conformity and ns to dampen •compress • Verify that and dehydrated refrigeratcomponents. refrigerant discharge 3 dimensio the the proper unless suction and not start, check wiring flexible in supplied with • Use clean and dehydrated system or must be grommets sor does Startup start the compressor without compresor the the rubber to compres • Use clean connected to the compress with ial the l power Never mounted . electrica promptly. If ports. • ambient moisture pressure different should be • The piping or must always be It must start and suction Do not provide from e noise, no A service technician in the removed. compressor. s. the discharge oil contamination• cannot bethe • The compress ena; excessiv to avoid • Energize the compressor terminalby following phenom than immediate cooling.the compressor is rotating charge through where burrs in reverse, that nitrogen holding as soon as possible Never drill holes voltage at ft-lb ±can 15 be detected warming ratherproperly phased and a maximum of 150 hours release the rotation valve. cutting tubes. or to the system ended. For e, and line • Slowly below). 3/4'' = 81 for power is 15 1Reverse the compress into the system while connections (see are recomm recommends to operate the internaland discharg that supply = 66 ft-lb ± • • Connect entering to verify 7/14 for rotolock between suction start-up 15 1 1/4'' if any, is used, remove sors are designed periods, phase monitors ons. Tecumseh ± TR-305 material torque ft-lb compres 59 Publication: Avoid port, • at initial maximum Scroll ns: 1'' = d for longer required for all applicati the schrader Number: 132-10010 exceed the Partpresent . VSC-series are can go unnotice • Do not rotolock connectio devices. When correct direction rotation situation larger, phase monitors g torque of control • Tightenin required safety and 8Z and the but as a reverse models VSC954 • Connect compressor WIRING DIAGR PSC Rotolock Screw sor VacuuRing Connect use the compres Terminal Pin Orientation T1 Quick Connect 73° k Suction Rotoloc S T2 Ring Connect Screw Terminal 45° Discharge 1 Quick connect spade terminals P terminal box type 31° Spade Termina C T1 ONENTS L COMP specific ELECTRICA l components electrica Use only new sor model. for this compres 132-10010 Publication: RT : techni AND SUPPO 27 or Email from QUESTIONS n available rt: 800.211.34 n at any time. other informatiopersonnel in safely Tech Suppo , or replace service n in this publicatio Tecumseh IS THE al service personnel intended to assist any informatio essential. IT PART NO. VS224ET-104-J7 MODEL VSC9530ZNA Discha 1 3 Suction Rotoloc S T2 2 t! Importan The VSC Scro designed purp (refer to oper and datashee S C with a pressurize r is delivered fittings, et compresso le bolts, plugs, NOTE: The not disassemb r. Wear protective gogg 6 psig). Do the compresso reg relieved from local safety ces, applicable in t Under all circumstan with caution r must be handled The compresso 15°). term from the vertical: r without electrical compresso Never operate Run Capacitor R 5 2 Potential Relay Run Capacitor or in the compress • Never use compressor on a the supply • Mount the power • Verify that and dehydrated r • Use clean and dehydrated • Use clean connected to th • The piping or must alw • The compress L1 L2 T1 T2 L3 T3 is profession nts is NEEDS right to change required for n in this documentapplication requireme WHICH MEETS THE nt(s). reserves the the training T to replace rers. The informatio review of current MENT PRODUC compressor replaceme t manufactu is not intended ors. Careful ED A REPLACE nt additional This document air conditioning equipmen Scroll compress PURCHAS e or subseque and VSC Series ASSURE THEY HAVE refrigeration requiring immediat servicing Tecumseh PERSON TO misapplication, installing and Reserved. OF THE SERVICE so may result in . All Rights RESPONSIBILITY ION. Failure to do Products Company OF THE APPLICAT ©2014 Tecumseh Tecumseh electrica Use only new sor model. for this compres 132-10010 Part Number: Model: VSC9530ZNA Item: VSC224ET-104-J7 Scroll Compressor (S) Carton Label SP1.lwl 12 MADE IN USA Carton Label 89X1.lwl nitrog release the or • Slowly the compress • Connect entering • Avoid material the maxi exceed • Do not ro g torque of • Tightenin required s the • Connect ONENTS L COMP specific ELECTRICA l components Use only new electrical components specific for that compressor model. SERIAL NO. 04B101411987456 ion These instructio used for refrigerat of thi compressors and proper usage regarding safety or with car the compress or • Handle Use the compress packaging. t. lifting equipmen the compr transport • Store and compressor between or • Store the the compress • Don’t expose Start Capacitor R TR-305 7/14 DANFOSS MLZ030T1 t ation Instruc to the Tecums General Install ns pertain syste 1 S C Replaces: COPELAND ZS30K4E-PFV VOLTAGE 208-230V ~ 60 PH 1 73° C T1 R T3 Second Wholesale Carton Label - Cross Reference TECUMSEH COMPRESSOR COMPANY 45° k rge Rotoloc ELECTRICAL COMPONENTS Ring connect screw terminals C terminal box type 31° Spade Termina T3 Wholesale Carton Label 7.50 34° l Quick Connect Handling 34° Ring Connect ng on ambient to reset. Dependi sors. 140°F (60°C) al compres it must cool down to n for residenti out, phase protectiooverload protector trips hours. taken at other several ation ns must be • If the internal this may take up to Pin Orient running conditio Terminal temperature, l volts during essor of amps and sor Screw Termina the compres running compr Measurement electrical box. Ring Connect oil return to Check with draw and voltage.in the compressor . to ensure proper • Check currentpower supply, not such as risk of slugging) for about 60 minutes e measures points in the superheat to reduce require correctiv glass (if provided C T1 in (1.5 mm) • Check suctionoil level in the sight 1/16 from the of the in excess far as possible g limits. • Observe . Movements sure side as the operatin R T3 in the low-pres • Respect tubes for abnormal vibration may be added phase • Check all . nt in liquid g during this process. tube brackets additional refrigera leak S T2 be operatin ss, noise and • When needed,The compressor must regarding cleanline n compressor. ge the system. ns. ere. on inspectio overchar to the atmosph out a general installati for future inspectio • Do not refrigerant as a reference site, carry • Never release the installation g conditions G DIAGRAMS well as operatin s andWIRIN • Before leaving nt charge as ance operator burns. of refrigera detection. severe nt injury. Mainten type and amount and can cause cause permane • Record d.PSC 212°F (100°C) us and may ns are performe e ure are dangerotemperature may exceed by local regulatio Maintenanc and surface temperat Tubing as required and tools. ended: reliability and Internal pressure appropriate skills nce is recomm to ensure system installers require periodic maintena inspections s, following Line periodic service sor problem and properly set. Ensure that nal related compres operatio system are ns. To prevent that safety devices ambient conditio is leak tight. • Verify records and draw. that the system maintenance l • Ensure compressor current and electrica with previous consistent shell, tubes • Check the operating limits. g in a way fastened. compressor the is operatin adequately and oxidation on the • Respect ons are still that the system of rust CSR • Confirm all electrical connecti the absence clean and verify • Check that regularly. compressor be checked • Keep the and oil should connections. content in system warranty claim. • Acid / moisture with any product serial number cases: Warranty the model number and Line the following marks. be void in Always provide feet and shock warranty may te/label. The product welding, broken sor namepla of compres in particular, drilling, ge the system. • Absence Do not overchar modifications; returned unsealed. nce. or compressor. h. • External on or maintena inside the sor opened • Compres or leak detection dye approved by Tecumseg to installation, applicati t not • Rust, water or lubrican instructions pertainin refrigerant ended • Use of a from recomm 3 PHASE • Any deviation applications. claim. ent. warranty mobile environm eric with the • Use in its site. e atmosph transmitted company at serial number • Use in explosiv by a suitable number or be recycled • No model sor oil should sors and compres m Disposalrecommends that compres tecumseh.co Tecumseh cal.service@ Sc VSC Series g (CBP) Refri Safety First 4.38 l ation Pin Orient Terminal Commercial pressor for n. fire or explosio Scroll Com llation Instructions could cause VSC Series or dry air. This with oxygen geration Insta Leak tion tion system l detec ze the refrigera (CBP) Refri Spade Termina pressuri Fence dye. 7.50 4.38 Assembly 9.40 4.32 5.06 9.40 4.32 4 x Ø 0.75 7.50 Part Number: Bottom Tray 4 x Ø 0.75 7.50 5.06 9.40 Handling Compressor 9.40 Installation Instructions Safety First Top Pad ll details. 20-23 for fu Assembly Two Electrical Connection Types *See page Note: The Cross Reference information listed on this diagram is for example purposes only. For the most current information refer to the competitive cross reference available at http://boxload.tecumseh.com/ on Tecumseh’s Web Application site. Publication: TR-305 7/14 CREATING VALUE AND EASE OF CHANGE-OUT Tecumseh provides the following: 1. Second Wholesale Carton Label - Cross Reference This label with cross reference (Tecumseh and competitive) has been added to assist wholesalers and their customers. Second Wholesale Carton Label - Cross Reference Model: VSC9530ZNA Item: VSC224ET-104-J7 Scroll Compressor Replaces: COPELAND ZS30K4E-PFV DANFOSS MLZ030T1 Note: The Cross Reference information listed on this diagram is for example purposes only. For the most current information refer to the competitive cross reference available at http://boxload. tecumseh.com/ on Tecumseh’s Web Application site. Carton Label 89X1.lwl 2. Compressor Mounting Kit These have been supplied with each compressor to make the change out quick and easy. Braze rotolock adaptor kits are included with LBP models only. CBP Kit Number: LP-10070 LBP Models Kit Numbers VSCF513Z* LP-10094 VSCF515Z* LP-10094 VSCF518Z* LP-10094 VSCF524Z* LP-10095 VSCF534Z* LP-10095 9.40 4 x Ø 0.75 7.50 9.40 4.32 4 x Ø 0.75 3. Installation Instructions Installation Instructions with wiring diagrams and safety precautions. See pages 16-19. l ation Pin Orient Ring Connect Screw Quick Connect Terminal Spade Termina C T1 1 C T1 R T3 R T3 3 S T2 2 S T2 AMS WIRING DIAGR PSC S C Run Capacitor Line R 2 Potential Relay 1 S C Start Capacitor Line Safety First R L1 L2 T1 T2 L3 T3 Assembly 3 PHASE 73° Handling Run Capacitor 45° Quick Scroll not use leak • Do G WARNIN 5 CSR 31° complete test on the . 450 psig. a leak detection must not exceed repeat the leak detection • Perform and side test pressure n repair the leak ed, • The low PinisOrientatio Rotolock Terminal leak discover Discharge • When a the system. l cause damage. m dehydration sor to evacuateLP & HP sides. Screw Termina as this may VacuuRing Connect the compres the Hg. is under vacuum • Never use vacuum pump to both 500 microns sor while it a vacuum of k to the compres • Connect the system under a apply power C Suction Rotoloc • Pull T₁down a megohmmeter nor S use ents. not T₂ • Do T1, T2, and spade terminals sor requirem Quick connect box type and compres the terminals are labeled supply. P terminal standards connections ons, the main power as per local Electrical ase applicati (start), and R (run). its from the off and isolate ents must be selected S R For three-ph be used for on• Switch t! (when viewed is not a major must only ons details. labeled C (common), T₃ l compon Importan clockwise compres sor All electrica s are scope of applicati • electrical connecti angles , reverse rotation rotating counterthe terminal The VSC Scroll (s) and within its guideline s Refer to page 4 for g on the phase correct applications only compress gas whilerun in only one direction application • haseterminals , dependin the screw designed purpose limits). Consult umseh.com and single-p will connect For start direction sors Ring type T3. operates in will box terminal compres (refer to operatingavailable at www.tec hase motors will start and run in either that the compressor hCscroll t(s) • Tecumse top). Since single-p however, on to ensure (C type). and datashee compressor Three-phase motors, taken during installati in Inch screw terminal All dimensions be connect ation. must consider with ring power. Care push connection 4 and of the supplied s for the power charge (betweenbeen ring terminal d nitrogen has direction. and ¼”push with a pressurize s all pressure - 32 screws type). r is delivered fittings, etc...unleswork gloves. • Use #10 26.6 in. lb torque. compresso terminals (P and le bolts, plugs, NOTE: The Fasten with for quick connect spadethe compressor to ground. not disassemb r. Wear protective goggles must be used. 6 psig). Do requirements to connect Use ¼” tabs the compresso • screw from regulation Refrigerant(lb) relieved offset local safety self tapping • Use apush ces, applicable position (maximum . HP charge limit in the vertical Under all circumstan if possible with caution off. the system 8 charge limits ck by using r must be handled Chargingthe compressor switched the indicated and secured. flood-ba The compresso 15°). 2 - 3.5 cover in place charge below sor against liquid • Keep 12 terminal box refrigerant from the vertical: 4-7 • Keep the limit; protect the compresaccumulator. r without electrical 16 compresso d to the circuit. Above this suction line Never operate 7.5 - 10 wn cycle or nt filling cylinder connecte a pump-do they are ot unless the refrigera (CBP) scroll tions leave s. Ensure that or troublesho repair, Commercial on • Never issioning and mechanical relief ns and safety standard ation Instruc Never service, h VSC Series necessary informati these functions. comm Install switch l Tecumse perform to regulatio the or before to Genera They provide are qualified ation applicable safety pressure you ns pertain serious injury ion systems. Verific can lead to such as and locally These instructio safety devices Settings used for refrigerat of this product. or explosion. both generally Improper Useservicing shock, with compressors and proper usage Minimum in the the maximum fire,inelectrical compliance from handles exceed set. safety valve death don’t safe regarding and properly 7 psig Use the dedicatedappropriate and ssure switches operational or with care. R22 and use n. of high-pre the compress or lifting lug the settings component. pressure operatio • Handle 6 psig Use the compress • Check that of any system ended to avoid low position. R134a packaging. pressure ce t. right). 70°C). in an upright service is recomm table to the and in complian lifting equipmen the compressor and 158°F (-35°C and sure switch atmosphere. 20 psig transport or corrosive -30°F • A low-pres to the Minimum Settingare properly fastened R404A • Store and compressor between the packaging to rain (Please refer electrical connections hours and 24 or least at • Store the all the compress energized • Verify that regulations. re. , it must be shutdown. • Don’t expose e atmosphe less than 7° slope. d with local heater is required istics. with or in a flammabl crankcase and start-up after prolonge l flat surface material. or motor character the compress • When a start-up • Never use compressor on a horizonta nds to the compress and silver alloy brazing 15 ft-lb. befores.initial installed. the nut to 66 ± supply correspoion-grade copper tubes • Mount are open, if vibration the power Tightenor.rotolock charge. service valves conformity and ns to dampen •compress • Verify that and dehydrated refrigeratcomponents. refrigerant discharge 3 dimensio the in and wiring with proper clean the check flexible d system supplied • Use not start, or must be or unless suction grommets and dehydrate Startup start the compressor without the compres If the compressor does the rubber • Use clean connected to the compress l power to Never mounted with . differential be electrica promptly. ports. • ambient moisture • The piping or must always be no pressure technician should not provide It must start and suction ation• Do noise, from sor. e compress in the removed. excessiv A service the discharge oil contamin • The cannot bethe compres sor terminals. phenomena; immediate cooling. compressor is rotatingreverse, to avoid • Energize charge through where burrs compres in by following rather than phased and that the nitrogen holding as soon as possible Never drill holes voltage at the 15 be detected of 150 hours release the ft-lb ±can maximum and line warming rotation cutting tubes. or to the system ended. For • Slowly below). 3/4'' = 81 valve. power is properly to operate for a 15 1Reverse discharge, the compress into the system while connections (see are recomm recommends internaland that supply = 66 ft-lb ± • remove thesuction • Connect entering to verify 7/14 for rotolock sors are designed periods, phase monitors ons. Tecumseh is used, between ± 15 1 1/4'' TR-305 start-up • Avoid material the maximum torque at initialPublication: 1'' = 59 ft-lb schrader port, if any, Scroll compres d for longer required for all applicati Number: 132-10010 exceed connections: Partpresent . VSC-series go unnotice When the are can • Do not rotolock of direction devices. monitors situation correct g torque control phase rotation • Tightenin required safety and 8Z and larger, the but as a reverse models VSC954 • Connect compressor 34° ONENTS L COMP specific ELECTRICA l components electrica Use only new sor model. for this compres Part Number: 132-10010 Publication: RT : techni AND SUPPO 27 or Email from QUESTIONS n available rt: 800.211.34 n at any time. other informatiopersonnel in safely Tech Suppo , or replace service n in this publicatio Tecumseh IS THE al service personnel intended to assist any informatio essential. IT is profession nts is NEEDS required for n in this documentapplication requireme WHICH MEETS THE nt(s). reserves the training T Tecumseh to replace rers. The informatio review of current MENT PRODUC compressor replaceme t manufactu is not intended ors. Careful ED A REPLACE nt additional This document air conditioning equipmen Scroll compress PURCHAS e or subseque and VSC Series ASSURE THEY HAVE refrigeration requiring immediat servicing Tecumseh PERSON TO misapplication, installing and Reserved. OF THE SERVICE so may result in . All Rights RESPONSIBILITY ION. Failure to do Products Company OF THE APPLICAT ©2014 Tecumseh change the right to 4.38 34° Quick Connect 31° 45° Quick 73° l Spade Termina Discharge Scroll Rotolock Terminal Pin Orientation C T1 l Ring Connect 1 R T3 3 C T₁ its be used for on must only compres sor scope of applicati s The VSC Scroll (s) and within its guideline application designed purpose limits). Consult umseh.com (refer to operatingavailable at www.tec t(s) and datashee t! R T₃ All dimensions Run Capacitor 5 Potential 2 (CBP) scroll Start Capacitor R L1 L2 T1 T2 L3 T3 push push ONENTS L COMP ents specific ELECTRICA electrical compon Use only new sor model. for this compres Part Number: G WARNINot unless repair, or troublesho Never service, these functions. to perform injury or are qualified you serious ion can lead to These instructio used for refrigerat of this product. Improper servicing shock, or explosion. the compressors and proper usage fire, electrical handles in death from regarding safety Use the dedicatedappropriate and safe or with care. and use the compress or lifting lug • Handle Use the compress position. packaging. t. 70°C). in an upright lifting equipmen the compressor and 158°F (-35°C and atmosphere. transport or corrosive -30°F • Store and compressor between the packaging to rain or and • Store the the compress expose Don’t re. • e atmosphe less than 7° slope. istics. with or in a flammabl l flat surface material. or motor character the compress • Never use compressor on a horizonta nds to the compress and silver alloy brazing the supply correspoion-grade copper tubes • Mount vibrations. the power ns to dampen compressor. • Verify that and dehydrated refrigeratcomponents. 3 dimensio the flexible in supplied with • Use clean and dehydrated system or must be grommets the rubber • Use clean connected to the compress mounted with ports. moisture. • The piping or must always be and suction from ambient the discharge oil contamination cannot be removed. • The compress to avoid charge through where burrs nitrogen holding as soon as possible Never drill holes release the ft-lb ± 15 cutting tubes. or to the system • Slowly below). 1 3/4'' = 81 valve. the compress into the system while connections (see 66 ft-lb ± 15 remove the internal = • Connect 1/4'' rotolock 1 entering for is used, TR-305 ft-lb ± 15 Publication: port, if any, • Avoid material the maximum torque ns: 1'' = 59 132-10010 the schrader exceed Part Number: • Do not rotolock connectio devices. When g torque of control • Tightenin required safety and the • Connect 1 Run Capacitor in Inch tions Commercial information ation Instruc y h VSC Series to the Tecumse They provide necessar General Install ns pertain systems. Relay S screw terminals Ring connect box type C terminal push 4 and charge (betweenbeen d nitrogen has with a pressurize s all pressure r is delivered fittings, etc...unleswork gloves. compresso and le bolts, plugs, NOTE: The not disassemb r. Wear protective goggles must be used. 6 psig). Do requirements the compresso regulation relieved from offset local safety ces, applicable position (maximum in the vertical Under all circumstan with caution r must be handled and secured. The compresso 15°). cover in place box vertical: terminal from the r without electrical compresso Never operate S R C S T₂ spade terminals Quick connect box type P terminal Importan C Screw Termina k Suction Rotoloc S T2 2 Handling 4.38 Terminal Commercial pressor for n. fire or explosio Scroll Com llation Instructions could cause VSC Series or dry air. This with oxygen geration Insta Leak tion tion system l detec the refrigera Termina (CBP) Refri pressurize system. Connect Spade • Never Terminal Fencedetection dye. 7.50 5.06 ng on ambient to reset. Dependi sors. 140°F (60°C) al compres it must cool down to n for residenti out, phase protectiooverload protector trips hours. taken at other several ation ns must be • If the internal this may take up to Pin Orient running conditio Terminal temperature, l volts during essor of amps and sor Screw Termina the compres running compr Measurement electrical box. Ring Connect oil return to Check with draw and voltage.in the compressor . to ensure proper as • Check currentpower supply, not risk of slugging) for about 60 minutes measures such points in the superheat to reduce corrective glass (if provided (1.5 mm) require C T1 • Check suctionoil level in the sight from the of 1/16 in the nts in excess far as possible • Observe sure side as operating limits. l vibration. Moveme the low-pres R T3 the • Respect tubes for abnorma be added in phase may • Check all . nt in liquid g during this process. tube brackets additional refrigera leak T2 operatin S and be noise • When needed,The compressor must cleanliness, n regarding compressor. ge the system. ns. ere. on inspectio overchar to the atmosph out a general installati for future inspectio • Do not refrigerant as a reference site, carry • Never release the installation g conditions G DIAGRAMS well as operatin s andWIRIN • Before leaving nt charge as ance operator burns. of refrigera detection. severe nt injury. Mainten type and amount and can cause cause permane • Record d.PSC 212°F (100°C) us and may ns are performe e ure are dangerotemperature may exceed by local regulatio Maintenanc and surface temperat Tubing required as and tools. ended: reliability and Internal pressure appropriate skills is recomm to ensure system maintenance installers require inspections following periodic Line periodic service problems, properly set. Ensure that compressor and operational system related ns. To prevent that safety devices are tight. ambient conditio is leak • Verify records and draw. that the system maintenance l • Ensure compressor current and electrica with previous consistent shell, tubes • Check the operating limits. g in a way fastened. compressor the is operatin adequately and oxidation on the • Respect ons are still that the system of rust CSR • Confirm all electrical connecti the absence clean and verify • Check that regularly. compressor checked the be Keep • and oil should connections. content in system warranty claim. • Acid / moisture with any product serial number cases: Warranty the model number and Line the following marks. be void in Always provide feet and shock warranty may te/label. The product welding, broken sor namepla of compres in particular, drilling, ge the system. • Absence Do not overchar modifications; returned unsealed. nce. or compressor. h. • External on or maintena inside the sor opened • Compres or leak detection dye approved by Tecumseg to installation, applicati t not • Rust, water or lubrican instructions pertainin refrigerant ended • Use of a recomm from 3 PHASE • Any deviation applications. claim. ent. with the warranty • Use in mobile e atmospheric environm at its site. transmitted number company serial • Use in explosiv by a suitable number or be recycled • No model sor oil should sors and compres m Disposalrecommends that compres tecumseh.co Tecumseh cal.service@ Safety First 9.40 4.32 Assembly 7.50 Commercial pressor for Scroll Com llation Instructions VSC Series geration Insta Terminal (CBP) Refri Connect Spade Terminal Fence 7.50 5.06 9.40 132-10010 Publication: TR-305 7/14 TR-305 7/14 COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 13 ADDITIONAL INFORMATION Product Dimensions and Weights Model Number Item Number (BOM) Wt. Footprint Height *Dim. (lb) (in) (in) Drawing R404A Commercial Temperature Item Number (BOM) Wt. Footprint Height *Dim. (lb) (in) (in) Drawing R404A Commercial Temperature (continued) VSC9515ZNA VS220ET-103-J7 68 7.5 x 7.5 16.2 A1 VSC9545ZXH VS226VT-104-J7 82 7.5 x 7.5 17.9 A2 VSC9515ZXG VS220TT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9545ZXT VS226RT-104-J7 82 7.5 x 7.5 17.9 A2 VSC9515ZXH VS220VT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9548ZXG VS227TT-104-J7 82 7.5 x 7.5 17.9 A2 VSC9515ZXT VS220RT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9548ZXH VS227VT-104-J7 82 7.5 x 7.5 17.9 A2 VSC9519ZNA VS221ET-103-J7 68 7.5 x 7.5 16.2 A1 VSC9548ZXT VS227RT-104-J7 82 7.5 x 7.5 17.9 A2 VSC9519ZXG VS221TT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9558ZXG VS228TT-105-J7 97 7.5 x 7.5 21.1 A3 VSC9519ZXH VS221VT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9558ZXH VS228VT-105-J7 97 7.5 x 7.5 21.1 A3 VSC9519ZXT VS221RT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9558ZXT VS228RT-105-J7 97 7.5 x 7.5 21.1 A3 VSC9521ZNA VS222ET-103-J7 68 7.5 x 7.5 16.2 A1 VSC9566ZXG VS229TT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9521ZXG VS222TT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9566ZXH VS229VT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9521ZXH VS222VT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9566ZXT VS229RT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9521ZXT VS222RT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9576ZXG VS230TT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9526ZNA VS223ET-103-J7 68 7.5 x 7.5 16.2 A1 VSC9576ZXH VS230VT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9526ZXG VS223TT-103-J7 68 7.5 x 7.5 16.2 A1 VSC9576ZXT VS230RT-105-J7 100 7.5 x 7.5 21.5 A3 VSC9526ZXH VS223VT-103-J7 68 7.5 x 7.5 16.2 A1 R404A Low Temperature VSC9526ZXT VS223RT-103-J7 68 7.5 x 7.5 16.2 A1 VSCF513ZXG VS231TT-106-J7 93 7.5 x 7.5 19.1 B1 VSC9530ZNA VS224ET-104-J7 82 7.5 x 7.5 17.9 A2 VSCF513ZXT VS231RT-106-J7 93 7.5 x 7.5 19.1 B1 VSC9530ZXG VS224TT-104-J7 82 9.40 VS224VT-104-J7 82 7.5 x 7.5 17.9 A2 VSCF515ZXG VS232TT-106-J7 93 7.5 x 7.5 19.1 B1 7.5 x 7.5 17.9 A2 VSCF515ZXT VS232RT-106-J7 93 7.5 x 7.5 19.1 B1 7.5 x 7.5 17.9 95 7.5 x 7.5 19.1 B1 7.5 x 7.5 17.9 VSCF518ZXG A2 4 x Ø 0.75 VSCF518ZXT A2 VS233TT-106-J7 VSC9538ZNA VS224RT-104-J7 7.50 82 VS225ET-104-J7 82 VS233RT-106-J7 95 7.5 x 7.5 19.1 B1 VSC9538ZXG VS225TT-104-J7 82 7.5 x 7.5 17.9 A2 VSCF524ZXG VS234TT-107-J7 102 7.5 x 7.5 21.3 B2 VSC9538ZXH VS225VT-104-J7 82 7.5 x 7.5 17.9 A2 VSCF524ZXT VS234RT-107-J7 102 7.5 x 7.5 21.3 B2 VSC9538ZXT VS225RT-104-J7 82 7.5 x 7.5 17.9 A2 VSCF534ZXG VS235TT-108-J7 105 7.5 x 7.5 22.2 B3 VSC9545ZXG VS226TT-104-J7 82 7.5 x 7.5 17.9 A2 VSCF534ZXT VS235RT-108-J7 105 7.5 x 7.5 22.2 B3 VSC9530ZXH VSC9530ZXT 5.06 Model Number *Dimension Drawings on page 10. 4.32 9.40 7.50 4.38 19'' 34° 31° 45° 14 73° 10.6'' 11.0'' FAQs Q A Is the existing VSA Scroll product line available? No, the current VSA product line is no longer available. No VSA replacement compressors or VSA condensing units are available. Q A Is there any change to the warranty return process? No, the Wholesale Warranty and Return Process remains unchanged. Q A I already stock electrical service parts for the VSA compressor, can I use those service parts on the VSC? No, VSC component and electrical parts are not interchangeable with VSA compressors. Q A Can I get service components and electrical parts for the VSC? Yes, Tecumseh has established new “K” replacement relay, start capacitor kits and run capacitors. Q A Will the VSC be used in Tecumseh Condensing Units? Yes, VSC compressors will be integrated into Tecumseh’s line of indoor air-cooled condensing units and outdoor air-cooled condensing units. We plan to launch the VSC line of CBP and LBP (Vapor injection) Indoor and Outdoor condensing units in Fall 2014. Q A Will I receive a new price list? Yes. An updated price list will be sent to all authorized wholesalers’ designated contact(s). Q A Can I purchase VSC compressors as part of the 2015 pre-season program? Yes, details will be forthcoming. Q A What are the advantages of the VSC compressor? See pages 2 and 5. Q A Will the VSC be available in a pallet pack option? Yes. Models will be available in a pallet pack option. Contact your Tecumseh Sales Rep for details. Q A When will VSC (LBP) Liquid Injection models be available? Liquid injection LBP models are planned to launch in 2015, more details to follow. COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 15 on: TR-305 7/14 16 4.38 5.06 31° 45° Quick connect spade terminals P terminal box type All dimensions in Inch WARNING push Ring connect screw terminals C terminal box type push S T₂ Never service, repair, or troubleshoot unless you are qualified to perform these functions. Improper servicing can lead to serious injury or death from fire, electrical shock, or explosion. Publication: TR-305 7/14 • Slowly release the nitrogen holding charge through the discharge and suction ports. • Connect the compressor to the system as soon as possible to avoid oil contamination from ambient moisture. • Avoid material entering into the system while cutting tubes. Never drill holes where burrs cannot be removed. • Do not exceed the maximum torque for rotolock connections (see below). • Tightening torque of rotolock connections: 1'' = 59 ft-lb ± 15 1 1/4'' = 66 ft-lb ± 15 1 3/4'' = 81 ft-lb ± 15 • Connect the required safety and control devices. When the schrader port, if any, is used, remove the internal valve. Part Number: 132-10010 • Never use the compressor in a flammable atmosphere. • Mount the compressor on a horizontal flat surface with less than 7° slope. • Verify that the power supply corresponds to the compressor motor characteristics. • Use clean and dehydrated refrigeration-grade copper tubes and silver alloy brazing material. • Use clean and dehydrated system components. • The piping connected to the compressor must be flexible in 3 dimensions to dampen vibrations. • The compressor must always be mounted with the rubber grommets supplied with the compressor. • Handle the compressor with care. Use the dedicated handles in the packaging. Use the compressor lifting lug and use appropriate and safe lifting equipment. • Store and transport the compressor in an upright position. • Store the compressor between -30°F and 158°F (-35°C and 70°C). • Don’t expose the compressor and the packaging to rain or corrosive atmosphere. These instructions pertain to the Tecumseh VSC Series Commercial (CBP) scroll compressors used for refrigeration systems. They provide necessary information regarding safety and proper usage of this product. General Installation Instructions Never operate compressor without electrical terminal box cover in place and secured. The compressor must be handled with caution in the vertical position (maximum offset from the vertical: 15°). Under all circumstances, applicable local safety regulation requirements must be used. push R T₃ C T₁ Ring Connect Screw Terminal Terminal Pin Orientation Scroll Terminal Fence Quick Connect Spade Terminal The VSC Scroll compressor must only be used for its designed purpose(s) and within its scope of application (refer to operating limits). Consult application guidelines and datasheet(s) available at www.tecumseh.com Important! Suction Rotolock Discharge Rotolock 73° 9.40 NOTE: The compressor is delivered with a pressurized nitrogen charge (between 4 and 6 psig). Do not disassemble bolts, plugs, fittings, etc...unless all pressure has been relieved from the compressor. Wear protective goggles and work gloves. 34° 7.50 VSC Series Scroll Compressor for Commercial (CBP) Refrigeration Installation Instructions 4.32 CBP Installation Instructions Handling Safety First Assembly Refrigerant charge limit (lb) 2 - 3.5 8 4-7 12 7.5 - 10 16 HP 7 psig 6 psig 20 psig R22 R134a R404A Minimum Settings • Never start the compressor without the proper refrigerant charge. • Do not provide electrical power to the compresor unless suction and discharge service valves are open, if installed. • Energize the compressor. It must start promptly. If the compressor does not start, check wiring conformity and voltage at the compressor terminals. • Reverse rotation can be detected by following phenomena; excessive noise, no pressure differential between suction and discharge, and line warming rather than immediate cooling. A service technician should be present at initial start-up to verify that supply power is properly phased and that the compressor is rotating in the correct direction. VSC-series Scroll compressors are designed to operate for a maximum of 150 hours in reverse, but as a reverse rotation situation can go unnoticed for longer periods, phase monitors are recommended. For compressor models VSC9548Z and larger, phase monitors are required for all applications. Tecumseh recommends Startup • Check that the settings of high-pressure switches don’t exceed the maximum service pressure of any system component. • A low-pressure switch is recommended to avoid low pressure operation. (Please refer to the Minimum Setting table to the right). • Verify that all electrical connections are properly fastened and in compliance with local regulations. • When a crankcase heater is required, it must be energized at least 24 hours before initial start-up and start-up after prolonged shutdown. • Tighten rotolock nut to 66 ± 15 ft-lb. Use safety devices such as safety pressure switch and mechanical relief valve in compliance with both generally and locally applicable regulations and safety standards. Ensure that they are operational and properly set. Verification before commissioning • Keep the compressor switched off. • Keep the refrigerant charge below the indicated charge limits if possible. Above this limit; protect the compressor against liquid flood-back by using a pump-down cycle or suction line accumulator. • Never leave the refrigerant filling cylinder connected to the circuit. Charging the system • Switch off and isolate the main power supply. • All electrical components must be selected as per local standards and compressor requirements. • Refer to page 4 for electrical connections details. For three-phase applications, the terminals are labeled T1, T2, and T3. For single-phase applications the terminals are labeled C (common), S (start), and R (run). • Tecumseh scroll compressors will only compress gas while rotating counter-clockwise (when viewed from the compressor top). Since single-phase motors will start and run in only one direction, reverse rotation is not a major consideration. Three-phase motors, however, will start and run in either direction, depending on the phase angles of the supplied power. Care must be taken during installation to ensure that the compressor operates in the correct direction. • Use #10 - 32 screws and ¼” ring terminals for the power connection with ring connect screw terminal (C type). Fasten with 26.6 in. lb torque. • Use ¼” tabs for quick connect spade terminals (P type). • Use a self tapping screw to connect the compressor to ground. Electrical connections • Never use the compressor to evacuate the system. • Connect a vacuum pump to both the LP & HP sides. • Pull down the system under a vacuum of 500 microns Hg. • Do not use a megohmmeter nor apply power to the compressor while it is under vacuum as this may cause damage. Vacuum dehydration • Never pressurize the refrigeration system with oxygen or dry air. This could cause fire or explosion. • Do not use leak detection dye. • Perform a leak detection test on the complete system. • The low side test pressure must not exceed 450 psig. • When a leak is discovered, repair the leak and repeat the leak detection. Leak detection This docume refrigeration installing and RESPONSIBI OF THE APP Tecumseh re QUESTI Tecums Tecumseh r Disposa Always pro The produc • Abs • Exte • Co • Rust • Use • Any • Use • Use • No Warrant Internal pre installers re Ensure that To prevent • Verif • Ens • Che • Res • Con • Che • Kee con • Acid Mainte • Che poin • Che • Obs • Res • Che tube • Whe com • Do • Nev • Befo dete • Rec Check pha • If th tem ould be ng in the n reverse, d. For ecommends if installed. ty and 0 psig psig psig ettings t they are rant mit (lb) type). m the ot a major se angles the correct T1, T2, and ©2014 Tecumseh Products Company. All Rights Reserved. This document is not intended to replace the training required for professional service personnel, or replace other information available from refrigeration and air conditioning equipment manufacturers. The information in this document is intended to assist service personnel in safely installing and servicing Tecumseh VSC Series Scroll compressors. Careful review of current application requirements is essential. IT IS THE RESPONSIBILITY OF THE SERVICE PERSON TO ASSURE THEY HAVE PURCHASED A REPLACEMENT PRODUCT WHICH MEETS THE NEEDS OF THE APPLICATION. Failure to do so may result in misapplication, requiring immediate or subsequent additional compressor replacement(s). Tecumseh reserves the right to change any information in this publication at any time. QUESTIONS AND SUPPORT Tecumseh Tech Support: 800.211.3427 or Email: [email protected] Tecumseh recommends that compressors and compressor oil should be recycled by a suitable company at its site. Disposal Always provide the model number and serial number with any product warranty claim. The product warranty may be void in the following cases: • Absence of compressor nameplate/label. • External modifications; in particular, drilling, welding, broken feet and shock marks. • Compressor opened or returned unsealed. • Rust, water or leak detection dye inside the compressor. Do not overcharge the system. • Use of a refrigerant or lubricant not approved by Tecumseh. • Any deviation from recommended instructions pertaining to installation, application or maintenance. • Use in mobile applications. • Use in explosive atmospheric environment. • No model number or serial number transmitted with the warranty claim. Warranty Internal pressure and surface temperature are dangerous and may cause permanent injury. Maintenance operators and installers require appropriate skills and tools. Tubing temperature may exceed 212°F (100°C) and can cause severe burns. Ensure that periodic service inspections to ensure system reliability and as required by local regulations are performed. To prevent system related compressor problems, following periodic maintenance is recommended: • Verify that safety devices are operational and properly set. • Ensure that the system is leak tight. • Check the compressor current draw. • Respect the operating limits. • Confirm that the system is operating in a way consistent with previous maintenance records and ambient conditions. • Check that all electrical connections are still adequately fastened. • Keep the compressor clean and verify the absence of rust and oxidation on the compressor shell, tubes and electrical connections. • Acid / moisture content in system and oil should be checked regularly. Maintenance • Check current draw and voltage. Measurement of amps and volts during running conditions must be taken at other points in the power supply, not in the compressor electrical box. • Check suction superheat to reduce risk of slugging. • Observe the oil level in the sight glass (if provided) for about 60 minutes to ensure proper oil return to the compressor • Respect the operating limits. • Check all tubes for abnormal vibration. Movements in excess of 1/16 in (1.5 mm) require corrective measures such as tube brackets. • When needed, additional refrigerant in liquid phase may be added in the low-pressure side as far as possible from the compressor. The compressor must be operating during this process. • Do not overcharge the system. • Never release refrigerant to the atmosphere. • Before leaving the installation site, carry out a general installation inspection regarding cleanliness, noise and leak detection. • Record type and amount of refrigerant charge as well as operating conditions as a reference for future inspections. Check with running compressor phase protection for residential compressors. • If the internal overload protector trips out, it must cool down to 140°F (60°C) to reset. Depending on ambient temperature, this may take up to several hours. 3 PHASE CSR PSC Line Line WIRING DIAGRAMS R T3 C T1 T3 T1 C C R S T2 R S 2 3 2 S T2 L3 L1 L2 1 5 Part Number: 132-10010 Use only new electrical components specific for this compressor model. Publication: TR-305 7/14 Start Capacitor Potential Relay Run Capacitor Run Capacitor R T3 1 C T1 Quick Connect Spade Terminal ELECTRICAL COMPONENTS S T2 Ring Connect Screw Terminal Terminal Pin Orientation 4.38 5.06 34° • Never us • Mount t • Verify th • Use clea • Use clea • The pipi • The com • Slowly r • Connect • Avoid m • Do not e • Tighteni • Connect • Handle t packagi lifting eq • Store an • Store th • Don’t ex These instructio compressors us regarding safety General In Never operate co The compressor from the vertical: Under all circumst NOTE: The compr 6 psig). Do not di relieved from the Handling Safety First Assembly se damage. COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 17 lication: TR-306 7/14 T3 T1 Ring connect screw terminals C terminal box type T2 Ring Connect Screw Terminal push WARNING push push Never service, repair, or troubleshoot unless you are qualified to perform these functions. Improper servicing can lead to serious injury or death from fire, electrical shock, or explosion. Publication: TR-306 7/14 • Slowly release the nitrogen holding charge through the discharge and suction ports. • Connect the compressor to the system as soon as possible to avoid oil contamination from ambient moisture. • Avoid material entering into the system while cutting tubes. Never drill holes where burrs cannot be removed. • Do not exceed the maximum torque for rotolock connections (see below). • Tightening torque of rotolock connections: 1'' = 59 ft-lb ± 15 1 1/4'' = 66 ft-lb ± 15 1 3/4'' = 81 ft-lb ± 15 • Connect the required safety and control devices. When the schrader port, if any, is used, remove the internal valve. Part Number: 132-10011 • Never use the compressor in a flammable atmosphere. • Mount the compressor on a horizontal flat surface with less than 7° slope. • Verify that the power supply corresponds to the compressor motor characteristics. • Use clean and dehydrated refrigeration-grade copper tubes and silver alloy brazing material. • Use clean and dehydrated system components. • The piping connected to the compressor must be flexible in 3 dimensions to dampen vibrations. • The compressor must always be mounted with the rubber grommets supplied with the compressor. • Handle the compressor with care. Use the dedicated handles in the packaging. Use the compressor lifting lug and use appropriate and safe lifting equipment. • Store and transport the compressor in an upright position. • Store the compressor between -30°F and 158°F (-35°C and 70°C). • Don’t expose the compressor and the packaging to rain or corrosive atmosphere. These instructions pertain to the Tecumseh VSC Series Commercial (LBP) scroll compressors used for refrigeration systems. They provide necessary information regarding safety and proper usage of this product. General Installation Instructions Never operate compressor without electrical terminal box cover in place and secured. The compressor must be handled with caution in the vertical position (maximum offset from the vertical: 15°). Under all circumstances, applicable local safety regulation requirements must be used. NOTE: The compressor is delivered with a pressurized nitrogen charge (between 4 and 6 psig). Do not disassemble bolts, plugs, fittings, etc...unless all pressure has been relieved from the compressor. Wear protective goggles and work gloves. The VSC Scroll compressor must only be used for its designed purpose(s) and within its scope of application (refer to operating limits). Consult application guidelines and datasheet(s) available at www.tecumseh.com Important! Suction Rotolock Vapor Injection Rotolock Discharge Rotolock VSC Series Scroll Low (LBP) Compressor for Commercial Refrigeration Installation Instructions LBP Installation Instructions Handling Safety First Assembly 18 Refrigerant charge limit (lb) 4-6 10 8 - 10 16 HP 7 psig 6 psig 20 psig R22 R134a R404A Minimum Settings • Never start the compressor without the proper refrigerant charge. • Do not provide electrical power to the compresor unless suction and discharge service valves are open, if installed. • Energize the compressor. It must start promptly. If the compressor does not start, check wiring conformity and voltage at the compressor terminals. • Reverse rotation can be detected by following phenomena; excessive noise, no pressure differential between suction and discharge, and line warming rather than immediate cooling. A service technician should be present at initial start-up to verify that supply power is properly phased and that the compressor is rotating in the correct direction. Phase monitors are required for all applilcations. • If the internal overload protector trips out, it must cool down to 140°F (60°C) to reset. Depending on ambient temperature, this may take up to several hours. Startup • Check that the settings of high-pressure switches don’t exceed the maximum service pressure of any system component. • A low-pressure switch is recommended to avoid low pressure operation. (Please refer to the Minimum Setting table to the right). • Verify that all electrical connections are properly fastened and in compliance with local regulations. • When a crankcase heater is required, it must be energized at least 24 hours before initial start-up and start-up after prolonged shutdown. Use safety devices such as safety pressure switch and mechanical relief valve in compliance with both generally and locally applicable regulations and safety standards. Ensure that they are operational and properly set. Verification before commissioning • Keep the compressor switched off. • Keep the refrigerant charge below the indicated charge limits if possible. Above this limit; protect the compressor against liquid flood-back by using a pump-down cycle or suction line accumulator. • Never leave the filling refrigerant cylinder connected to the circuit. Charging the system • Switch off and isolate the main power supply. • All electrical components must be selected as per local standards and compressor requirements. • Refer to page 4 for electrical connections details. Three-phase applications, the terminals are labeled T1, T2, and T3. • Tecumseh scroll compressors will only compress gas while rotating counter-clockwise (when viewed from the compressor top). Three-phase motors will start and run in either direction, depending on the phase angles of the supplied power. Care must be taken during installation to ensure that the compressor operates in the correct direction. • Use #10 - 32 screws and ¼” ring terminals for the power connection with ring connect screw terminal (C type). Fasten with 26.6 in. lb torque. • Use a self tapping screw to connect the compressor to ground. Electrical connections • Never use the compressor to evacuate the system. • Connect a vacuum pump to both the LP & HP sides. • Pull down the system under a vacuum of 500 microns Hg. • Do not use a megohmmeter nor apply power to the compressor while it is under vacuum as this may cause damage. Vacuum dehydration • Never pressurize the refrigeration system with oxygen or dry air. This could cause fire or explosion. • Do not use leak detection dye. • Perform a leak detection test on the complete system. • The low side test pressure must not exceed 450 psig. • When a leak is discovered, repair the leak and repeat the leak detection. Leak detection This docu refrigerati installing RESPONS OF THE A Tecumseh QUEST Tecu Tecumse Dispo Always p The prod • A • E • C • R • U • A • U • U • N Warra Internal installers Ensure t To preve • V • E • C • R • C • C • K c • A Maint • C p • C • O • R • C tu • W c • D • N • B d • R Check enerally and gerant limit (lb) 10 16 l (C type). T1, T2, and T3. from the ngles in the correct ambient should be tating in the n, if installed. mity and 20 psig 6 psig 7 psig Settings ©2014 Tecumseh Products Company. All Rights Reserved. This document is not intended to replace the training required for professional service personnel, or replace other information available from refrigeration and air conditioning equipment manufacturers. The information in this document is intended to assist service personnel in safely installing and servicing Tecumseh VSC Series Scroll compressors. Careful review of current application requirements is essential. IT IS THE RESPONSIBILITY OF THE SERVICE PERSON TO ASSURE THEY HAVE PURCHASED A REPLACEMENT PRODUCT WHICH MEETS THE NEEDS OF THE APPLICATION. Failure to do so may result in misapplication, requiring immediate or subsequent additional compressor replacement(s). Tecumseh reserves the right to change any information in this publication at any time. QUESTIONS AND SUPPORT Tecumseh Tech Support: 800.211.3427 or Email: [email protected] Tecumseh recommends that compressors and compressor oil should be recycled by a suitable company at its site. Disposal Always provide the model number and serial number with any product warranty claim The product warranty may be void in the following cases: • Absence of compressor nameplate/label. • External modifications; in particular, drilling, welding, broken feet and shock marks. • Compressor opened or returned unsealed. • Rust, water or leak detection dye inside the compressor. Do not overcharge the system. • Use of a refrigerant or lubricant not approved by Tecumseh. • Any deviation from recommended instructions pertaining to installation, application or maintenance. • Use in mobile applications. • Use in explosive atmospheric environment. • No model number or serial number transmitted with the warranty claim. Warranty Internal pressure and surface temperature are dangerous and may cause permanent injury. Maintenance operators and installers require appropriate skills and tools. Tubing temperature may exceed 212°F (100°C) and can cause severe burns. Ensure that periodic service inspections to ensure system reliability and as required by local regulations are performed. To prevent system related compressor problems, following periodic maintenance is recommended: • Verify that safety devices are operational and properly set. • Ensure that the system is leak tight. • Check the compressor current draw. • Respect the operating limits. • Confirm that the system is operating in a way consistent with previous maintenance records and ambient conditions. • Check that all electrical connections are still adequately fastened. • Keep the compressor clean and verify the absence of rust and oxidation on the compressor shell, tubes and electrical connections. • Acid / moisture content in system and oil should be checked regularly. Maintenance • Check current draw and voltage. Measurement of amps and volts during running conditions must be taken at other points in the power supply, not in the compressor electrical box. • Check suction superheat to reduce risk of slugging. • Observe the oil level in the sight glass (if provided) for about 60 minutes to ensure proper oil return to the compressor • Respect the operating limits. • Check all tubes for abnormal vibration. Movements in excess of 1/16 in (1.5 mm) require corrective measures such as tube brackets. • When needed, additional refrigerant in liquid phase may be added in the low-pressure side as far as possible from the compressor. The compressor must be operating during this process. • Do not overcharge the system. • Never release refrigerant to the atmosphere. • Before leaving the installation site, carry out a general installation inspection regarding cleanliness, noise and leak detection. • Record type and amount of refrigerant charge as well as operating conditions as a reference for future inspections. Check with running compressor 3 PHASE WIRING DIAGRAMS T3 T1 T2 T2 Use only new electrical components specific for this compressor model. ELECTRICAL COMPONENTS T3 T1 Ring Connect Screw Terminal Terminal Pin Orientation Part Number: 132-10011 L3 L1 L2 Publication: TR-306 7/14 • Never • Moun • Verify • Use c • Use c • The pi • The c • Slowl • Conn • Avoid • Do no • Tighte • Conn • Handl packa lifting • Store • Store • Don’t These instruc compressors regarding saf General I Never operate The compresso from the vertic Under all circu NOTE: The co 6 psig). Do not relieved from t Handling Safety First Assembly cause damage. COMPANY CONFIDENTIAL. INTERNAL USE ONLY. 19 Tecumseh North America Sales and MArketing 5683 Hines Drive Ann Arbor, MI 48108 [email protected] Tel. 734.585.9500 TEchnical Services 5683 Hines Drive Ann Arbor, MI 48108 [email protected] Tel. 800.211.3427 For more information on products by Tecumseh, please visit our website www.tecumseh.com ©2014 Tecumseh Products Company. All Rights Reserved. Publication TP-013 Rev 0 07/14

© Copyright 2026