The Standard | Summer 2014 Livestock Trading since 1975 Contents

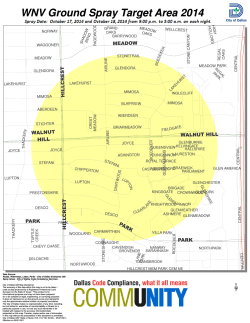

Main Icons Main Icons Livestock Trading since 1975 The Standard | Summer 2014 Secondary Icons Secondary Icons Contents Cattle - Page 2 Jones Bros Calf Rearers The new White Tag health reassurance scheme Sheep - Page 4 A visit to Kilby Grange Organic Conference 2014 Congratulations Robin Pigs - Page 3 Introducing Ryan Noble National Pig Awards Safeguarding your future White Icons are here White Icons are here Photo courtesy of The Hereford Cattle Society Company Update F OLLOWING the sad loss of our long standing Chairman last summer, Vice Chairman, Mike Sheldon was appointed Chairman at the September AGM. We will be looking to recruiting additional farmer Directors onto the Board shortly. More details at September 23rd AGM. The 2013 summer also bought further bad news with the failure of several long established abattoir businesses. We were directly affected by two plant failures which we have supported over many years, Seddons and Preston Meats; and incurred debts in excess of their insured limits. This will result in an overall trading loss for the year, although the ‘day to day trading’ was profitable and the company retains a strong balance sheet. It is also pertinent to say, that in almost 40 years of livestock trading and the inevitable knocks that occur with meat businesses, every MQ producer has been paid 100% of their stock value, 100% of the time! As they were in these cases. Lynda Porter, our Finance Director of many years, left the company last summer and Mike took on direct responsibility for the financial affairs of the company, with the support of a contract Finance Director for a limited number of days. Autumn 2013 saw the appointment of Simon Davies onto the Board as Commercial Director, responsible for managing our Pig Division. Simon had been running the Pig Division successfully for some time, and earned his elevation, thanks to some excellent results. Later in the autumn, Greg Mowbray changed his role to that of Trading Director, taking a more hands –on responsibility for our whole Ruminant Division, made up of our cattle, calf and sheep operations. This division offers us a great opportunity for growth and warrants the extra focus and experience that Greg can bring. Mike Sheldon has taken on further day to day responsibilities as Executive Chairman, with a direction from the Board to support and implement our growth strategy and modernise our central infra-structure. Thanks to the brilliant efforts of the company’s highly committed and skilled staff, and thanks to the continuing commitment of our members, suppliers and customers, this programme of change is well underway and we have made a very encouraging start to 2014. Mike Sheldon, Executive Chairman Meadow Quality Limited 01789 734 100 www.meadowq.co.uk 1 The Standard Summer 2014 Jones Bros – Calf rearers for Meadow Quality W E visited Arfon and Gerallt Jones at their farm high up in the mountains behind Colwyn Bay on a beautiful early spring day to see how they rear calves for Meadow Quality. The Jones family have been farming at Llindir since the 1930’s. The farm is situated at 1,000 feet above sea level and enjoys stunning views across the mountains and down to the coast below. Brothers Arfon and Gerallt started rearing calves a couple of years ago and usually have a total of about 280 calves in rear at any one time. They are keen to expand the rearing operation further and are planning to put up another shed to facilitate this. Calves arrive in batches every fortnight and on arrival are fitted with collars and deep bedded in straw and shown where the milk feeder is. All feeding is computerised via a Holm and Laue system, which recognises each calf via the chip in its collar and can then provide information as to when and how much milk each calf has drunk each day. Once a calf has drunk its predetermined amount of milk in each 24 hour period, the computer does not allow it to drink more. The environment in the rearing sheds is also controlled via a computerised ventilation system which automatically circulates air every 10 minutes. Each batch of calves stays on the farm for about 90 days and, following TB testing, is then moved on to the finisher, allowing the pens to be fully cleaned and disinfected ready for the arrival of the next batch. In addition to calf rearing, the Jones brothers run 600 ewe lambs, mainly Suffolk X mules and Texel X mules, which they buy in, keep for 12 months and then sell on as breeding ewes. They also grow 20 acres Brothers Arfon and Gerallt of swedes for the sheep and the following year plough up and under sow grass to whole crop barley, rotated around the farm acreage to keep the grass growing young. Arfon Jones says “Rearing for Meadow Quality gives us confidence in our calf enterprise, as they have already marketed the calves, which means we are never stuck with unsold calves. We get a consistent supply of healthy calves which haven’t spent all day at market. Robin Bebb, our Meadow Quality fieldsman, is always on hand with his extensive knowledge and experience if we have any problems, and regularly visits us on farm”. Recently arrived British Blues. For more information on becoming a contract calf rearer for Meadow Quality or having your calves professionally reared for you by Meadow Quality, please contact Simon Fryar on 07703 563 787. And, in order to meet the growing demand for our services in North Wales, we have recently appointed agent Catrin Edwards to handle calf sales and enquiries. Please contact her on 07785 972 923. 2 The White Tag Health Scheme J AMES Allcock of Lambert Leonard & May, the veterinary practice which provides the Meadow Quality Calf Rearers Health Plan has some exciting news! After a successful pilot exercise late last year, we are really pleased to announce that Meadow Quality is now able to roll out a fantastic and innovative service that can bring added value to everyone. Calves can now be sampled and tested for BVD virus during the few hours they spend in our accredited centres at Carmarthen, Chippenham and Ash. They are then left with a shiny white tag which gives a clear indication that the animal has been sampled and tested with a negative result for BVD. What does this mean to you? The CheckTAG BVD service can add value to everyone in the supply chain. Rearers and growers can be assured that calves leaving the collection centre have tested negative for BVD themselves or, just as importantly, have not travelled in close contact with an infected calf. This means that calves in the group are considerably less likely to become immuno-suppressed and susceptible to infectious causes of pneumonia after they arrive on your holding. The risk of pneumonia outbreak occurring will be reduced and when cases do occur, they should have less severe consequences. For dairy farmers that choose to bring calves to our collection centres, testing calves reveals two valuable pieces of information. Freedom of infection in the calves sold through Meadow Quality means that BVD is unlikely to be active on your farm. It also means that the mother of the calf must be non-infected and free of BVD. Conversely, when we find the occasional calf – typically just over one in every hundred is persistently infected – then it’s a strong signal that the calf’s mother might be a source of infection in your breeding herd. Meadow Quality can carry out the white tag application for all calf orders, whether they are our contract reared calves, or a baby calf order, at a cost of £8 per head. For more information, please call your fieldsman today. Meadow Quality Limited www.meadowq.co.uk The Standard Summer 2014 Introducing Ryan Noble A WARM welcome to Ryan Noble who joined the Meadow Quality Pig Marketing Team at the beginning of March. Ryan will be looking after our pig producers in the North East and Scotland. Ryan tells us that his passion for pigs started at a very young age when he went out to work with his father at weekends on the grow-out unit which his father ran. As a teenager, Ryan got his own part time job working on a pig unit and then went on to study at Oatridge College where he gained a SVQ3 in Pig Production. Since that time, he has worked his way up through the ranks from Stockman to Unit Manager and, most recently, Production Manager of a major multi-site pig farming business. Ryan says that he is looking forward to the further progression of his career and to bringing the knowledge and experience that he has gained from both indoor and outdoor pig production to Meadow Quality and its customers. Contact Ryan on 07736 056 713. Simon Davies, Commercial Director, says having Ryan join the Pig Team will further strengthen the Meadow Quality business. Safeguarding your future T O ensure we continue to offer detailed, clear and relevant information to your business in as timely a manner as possible, we are investing in and introducing the Hellenics System software at Meadow Quality to improve data reporting to you, our pig customers. Hellenics has theWhite capacity pig returns between Icons to arecompare here several plants to highlight the best returns. Crucially, it will also enable us to deliver the after-slaughter information required by BPEX for a robust, independent price reporting mechanism after the demise of the “DAPP”, continuing our tradition of protecting producer interests within the wider market place. The Hellenic system will provide advanced functionality to manage, analyse and report animal data and is used by most large processors within the meat industry. Taking input from the Farm and Abattoir, this is combined to provide grade, health and price analysis over selected time periods. Some of the benefits: • Web based for local and remote access with analysis tools for graphing • Customer emailing of stats & grade data • Producer analysis reporting • Stats summaries • • • • • Multiple “What if?” pricing comparisons Web based for local and remote access Trends and scatter analysis Grading Analysis reporting Historical analysis for multiple abattoirs Terry Carter, Managing Director of Hellenic Systems comments “We are very proud to be working with Meadow Quality in providing advanced data management tools built on top of our existing technologies. We see this synergy as a progressive evolution of the abattoir, farm and agent relationship.” Nuturing the talent M Ryan Noble, our new Pig Marketing Specialist National Pig Awards T HIS is a new industry initiative to reward and recognise best practice and production in the British Pig industry which we are pleased to support. Meadow Quality will be represented at the awards which are to be held in London on Tuesday 4th November 2014. Winners will be announced across a wide range of categories designed to cover the entire market, from Trainee of the Year and Green Pig Farmer of the Year, to Producer and Retailer of the Year.Pig World’s Simon Lewis and his team have worked hard in putting this event together and Meadow Quality supports the recognition of those individuals and businesses whose efforts will be rewarded. Meadow Quality Limited 01789 734 100 EADOW Quality recently organised a trip for students and staff from Reaseheath Agricultural College, Cheshire to Tulip’s Ashton site, near Manchester. The students were accompanied by Tulip UK’s Jen Waters and Meadow Quality’s new pig marketing specialist, Ryan Noble. Meadow Quality is delighted to be involved with Reaseheath College as it is one of the longest established Agricultural Education facilities in England, dating back to the late 1800’s. There are 200 students currently studying agriculture on full or part -time courses. This is the first of three planned visits. The College has its own pig unit consisting of 130 sows through to bacon, which are all Freedom Foods Accredited. The purpose of the visit to Ashton was to complement the studies already undertaken, giving the students a greater understanding of the process from‘Farm to Fork’. Ryan Noble comments on a successful day. “We had a comprehensive tour of the plant, seeing pigs arrive in the lairage following through to the butchery department and the different cuts of meat, observing how each carcass is utilised.’’ After the tour, Jen Waters gave a presentation on the Tulip business as a whole which was very informative. Tulip has invested considerable amounts of money into its sites and intends to grow its UK volumes further. Meadow Quality would like to wish the students good luck in their chosen career path, as they are a key part of the future of British Agriculture. We look forward to continuing to work with Reaseheath College and Tulip. Our thanks go to Jen Waters for helping make this an interesting and productive day. Ryan Noble (centre back) with staff and students 3 The Standard Summer 2014 A visit to Kilby Grange Organic Conference 2014 S HEEP farmer Bob Adams runs a flock of 550 ewes plus 100 ewe lambs on his 140 acre farm at Kilby in Leicestershire and also runs Meadow Quality’s busy sheep collection centre with Gordon McWhirter between June and December each year. Bob has been farming at Kilby Grange for over 29 years and has been a valued customer of White Icons are here Meadow Quality and our “sheep guru”, Gordon McWhirter, since 1991. Since 2003, Bob has been accompanying Gordon on his annual two day trip to the north of England to buy ewe lambs for himself and to fulfil regular orders from Meadow Quality customers. Over the two days, Gordon and Bob will visit 8 to 9 farms in the Sinderhope and Allendale area, located between 1,000 and 2,000 feet up in the fells – this means that the lambs will do very well once they get down to the lower levels Bob and Gordon of the Midlands. They buy mainly North Country Mules, mostly running lambs which won’t be tupped. Lambs are organised into batches of 100-250 to meet particular orders with the benefit of a single supply source reducing the risk of disease transmission and more consistency of breed type. Local agent Paul Ferris and local farmer Geoff Wilkinson help prepare the viewing farms to ensure the maximum amount of time is saved for stock selection and their excellent hospitality over the years is much appreciated by “the lads from the south”! During this trip, Bob buys Northumberland blackies that have been born that spring for Kilby Grange – usually tupping lambs averaging 45kg. Once they arrive at Bob’s farm in Leicestershire they have a chance to settle in and are then introduced to the Charollais and Lleyn tups on 5th November. Their lambs start to arrive in early April. Meadow Quality Collection centre Stuart Vile 07802 379 126 Congrats Robin - 50 not out! Bob is kind enough to allow Meadow Quality to run a busy Collection Centre from Kilby Grange which starts operating towards end of June each year and runs until Christmas. Local farmers can bring their lambs to the centre so they can be batched up and sent to the processor in artic loads, thus making significant savings in transport costs. Lambs are booked in as soon as possible after weighing on a Monday or Tuesday, with the collection taking place on a Thursday. Capacity in the centre can be increased if local demand for the service required. All lambs from the collection centre go to the state of the art Dunbia processing plant in Llanybydder. If you would like to use the Kilby Grange centre, or would like to set up a similar centre in your own locality, come and chat to Bob or Gordon at the NSA Sheep Show on Wednesday 30th July at the Three Counties Showground in Malvern, Worcestershire or contact Gordon on 07703 563 788. @meadowquality T HE 8th Organic Producers’ Conference started in glorious sunshine (last year we had snow on the ground!) which helped many Organic producers and advisers come together to discuss ‘ways forward for organic farming’. The opening session saw heated discussions on whether there was a need for organic producers as the world could rely on ‘artificial fertilizers’ to get out of trouble. However, it soon became clear that food could only be produced by taking care of the land - a subject which may turn out to be as important as learning to read and write! A group discussion followed on the role of sustainable farming and how it affected our daily businesses. The session concluded that the Organic Industry has to educate the public, showing the role that organic farming plays in our society and the benefits it can deliver. On day two, I presented a paper on “effective marketing of organic livestock.” The Public want an Organic industry - that was clear from a session showing sales UP 2.5% on 2012 - but the producers need confidence and direction which currently is lacking. My thanks go to Nic Lampkin’s Team from The Organic Research Centre for putting on an excellent Conference. Find out more about the event at www.organicresearchcentre.com. Meadow Quality Ltd C ONGRATULATIONS to our fieldsman, Robin Bebb, based at our Ash, Whitchurch Collection Centre who recently reached his half century and celebrated by climbing Ben Nevis. Here he is clinching a deal at the summit for Meadow Quality! The information contained within the Meadow Quality Standard is taken from sources we believe are reliable, but it does not guarantee that it is accurate and should be used for information purposes only. E&OE. © Meadow Quality 2014 Magazine Design by www.katemoby.com 4 Meadow Quality Limited 01789 734 100 www.meadowq.co.uk

© Copyright 2026