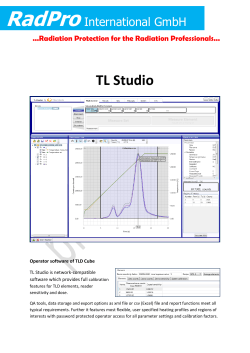

Safe.t Solutions