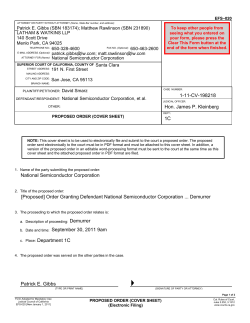

Document 437064