Document 449421

k

High Q*rality

Pip* & Sh*sts

Xnsxrlnftsxn

f.

I

THE PRODUCT

TECHNICAL DATA

APPLICATION RECOMMENDANAN

STANDARD SHEET SIZE

STANDARD TUBE SIZE

PIPE INSULATION

INSULATING FITTINGS

DUCTING INSULATION

I

C H EM ICAL R ES

10

ISTAN C E DATA

dR

Description:

lnsolflex is a flexible and light weight elastomeric nitrite rubber material designed for

thermal insulation. Insolflex insulation is

black in colour, available in tubing and

sheet form. The extruded flexible tubings

are specially designed to fit the standard

diameters of steel and copper pipings.

Sheets are available in standard precut

sizes or in rolls.

Uses,'

Insoflex expanded closed cell structure

provides the ideal and most efficient

vapour barrier for the prevention of condensation or frost formation on cooling systems, chilled water and refrigerant lines.

Insoflex also retards heat loss for

o

hot

water plumbing and heating, dual temperature piping and solar systems. lt protects

pipes by acting as a vibration damper and

giving protection against corrosion

by

atmospheric and industrial environment.

Insoflex inherent flexibility makes it ideally

suited for the insulation of large surface

area such as tanks, irregular shaped vessels, air-ducts and large diameter pipes.

ry

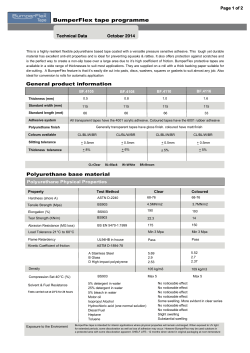

AVERAGE PHYSICAL PROPERTIES

Density

" 0.08,=, 0.,1

.

Thermal Gonductivity at 20"C

mean temp.

Temperature Limits'C

TEST METHODS

RATING

( 5,-

2',gm/Cnfl

I lb/cuft,)

ASTM D 1667

,

::

0 0374:W1mK

"fl

.:

ASTM C 177

(0.26BTU.in/nr.ff

.40"C to +105'C

Water Absorption ( % by weight )

ASTM D 1056

Water Vapour Permeability

Perm - in. Max

ASTM E 96

0.2

Ozone Resistance

Excellent

.:,'

Thermal Stability 7 days

4.5

ASTM C 548

(%shrinkage) 200'F

7 days

?20"F

Average Spread of Flame

Average time of burning

Average extend of buming

Flexibility

Weather and Ultraviolet Rays

Resistance

Chemical Resistance

Odour

Mildew Resistance

u.u

,,

,CLASS,1

,"

BS 476 PART 7

,,,

LesS than S,seconds

., ,,,,,.tr,5,*m' ,.'

. Excell6llt:"'

,,,, Good

ASTMD635-91

::

,,

,:

:::

:, Qq[6[

;

,.,Negligible,

No FUngal Growth

The above average physical properties are values obtained in accordance with accepted test methods.

At-35", insoflex Closed Cell lnsulation becomes hard and as iemperature drops below

- 40' will be increasingly brittle; however this hardening characteristic does not affect

thermal or water vapour permeability.

The Fire Rating standard method of tests conducted under controlled laboratory conditions is a measure of a material to spread flame when compared to a known standard

and is not intended to reflect hazards presented by this or any other material under actual fire conditions.

t"

Thickness Recommendations for lnsulation of Ducting,

Tanks and Equipment of cooling systems

METAL SURFACE TEMPERATURE

DESIGN CONDITIONS

26.7:C {80"F)

50% RH

29.4"C (85'F)

70% RH

32,29C (90"F)

80o/o RH

32.2"C (90"F)

85% RH

ls'c6g"H

12"C (53.6'n

7"C(fr.6"H

2.5"C 86.5"F)

9mm

9mm

13mm

19mm

'25mm

13mm

13mm

19mm

25mm

31mm

13mm

19mm

25mm

3lmm

50mm

25mm

25mm

31mm

38mm

50mm

INSOFLEX

-1g"cfi.H

closed cell rubins & Sheets lnsulation.

Thickness Recommendations to condensation in Pipe lnsulation of Cooling Lines

PIPELINE TEMPERATURE

DESIGN CONDITIONS

14.4'C

70c

2.5"C

-18'C

(58"F)

(u.6"F)

p6"n

(0"fl

MILD,CONDITION

10mm lD to 76mm IPS

9mm,

9mm

9mm

l9mm

26.7"C (80"F)

Above 76mm IPS to 127mm IPS

9mm

lgmm

13mm

25mm

50% RH

Above 127mm IPS to 254mm IPS

13mm

13mm

13mm

25mm

NORMALCONDITION

10mm lD to 76mm IPS

9mm

13mm

13mm

25mm

Above 76mm IPS to 127mm IPS

13mm

13mm

13mm

31mm

l3mm

'l9mm

31mm

29.4"C (85'F)

''

PIPE SIZE

70% RH

Above 127mm IPS to 254mm IPS

SEVERE CONDITION

1Omm lD to 76mm IPS

13mm

'l3mm

19mm

19mm

38mm

25mm

25mm

38mm

32.2"C (90"R

Above 76mm IPS to 127mm IPS

13mm

80% RH

Above 127mm IPS to 254mm IPS

13mm

25mm

31mm

50mm

EXTREMELY SEVERE CONDITION

1Omm lD 76mm IPS

13mm

25mm

25mm

38mm

32.2"C (90"F)

Above 76mm IPS to 127mm IPS

19mm

31mm

3'lmm

50mm

E5% RH

Above 127mm IPS to 254mm IPS

25mm

31mm

38mm

50mm

.

.

.

lnsulation for pipes of 1Omm lD to 76mm IPS are available in tubing form with wall thickness

of up to 25mm.

lnsulation above 76mm IPS are in precut sheets and available up to 38mm thickness.

lnsotlex thickness recommended within the specified temperature ranges will control

condensation on indoor piping under design conditions defined as follows:

MILLD

NORMAL

SEVERE &

EXTREMELY SEVERE

Air-Conditioned and arid areas.

Maximum severity of most indoor conditions seldom exceed

29.4"C and 70% RH.

Conditions of high humidity or poorly ventilated areas where

Temperature may be depressed below the ambient. Under

conditions of high humidity, additional thickness of insulation

STANDARD FLAT SHEETS

1.22 x 0.914

1.22 x 0.914

1.22 x 0.914

1.22 x 0.914

1.22 x 0.914

1.00 x 1.220

1.00 x 1.220

Standard Garfon size ; I 31 Omm x gg0rnm x 320mm (5 1 in x 39in x t 2.5i n)

GONTINUOUS ROLLS

Nominal Thickness

TotalArea Per Foll

Siae Per Roll

mm

ftrch

m

ft

3

1E

1.?2'x9.'14

4x30

6

114

1.22 x 9.14

4x30

I

3/8

1.22 x 9.14

4x30

13

112

1.22 x,9.'14

15

5/8

19

3/4

25

1

m2

Xe

1

1.15

120

1

1.15

120

11.15

120

4x30

11.1s

120

1.82 x 9.14

4x 30

11.15

120

1.2

x 9,14

4x 30

11.15

120

1.22 x 9.14

4x30

11.15

120

1

31

'ilA

1.00 x 9.14

3.281 x 30

9.14

98.43

38

1k

:1.00 x 9.14

3.281 x 30

9.14

98.4i1

ffi

{ry

€h-ogm"*

re.,

p

tlt

ur

lI(o

o

tr

H

IJJ

=

c\

F

(5

t=ll

-l

J

p

cco

xx€

cc

@6

I;

EC^

EEN

OON

oo

O(l)

xxo

EE

83

+$a

o o

o

=

o

5

5l_

ou)

il

'

0

rl

I

cy

OQ

dl>

+P

aa

=

o

6

O

o

6

E

c

6

a

5

l-

P

Lo

N

c

1rl

E

b o

o

N

\

F

x x Ep

--E,F gE

.N

(a

g

NN

@NF

5

=

l-

ll{

g

E EE

6

inSOfleX

tubing insutation is easy and

quick to install. insoflex should only be applied

to pipes that are clean, dry and unheated , The

slip-on method is used to insulate new pipes

before they are installed or connected whereas

Make 90" cut with a sharp knife. the leanl

should be slightly longer then section to be

insulated to avoid stretching when joining the

the snap-on method is used when pipes have

been installed and connected. insoflextubing is

lightly powdered to permit the tubing to be

end.

slipped easily over the pipe. Seal pipe ends with

plugs while installing the tubing insulation to pre-

vent powder from entering the refrigeration system.

It is important not to compress the tubing mate-

rial as the insulation value may be degraded

Slip full lenglh ol insoflex tubing over entire

when compressed and condensation may occur

length of pipe.

on the compressed area. Select the right size

tubing insulation for the pipe to be insulated.

Avoid stretching the material over the pipe. The

length of the insulation tubing should cover the

section of the pipe to be insulated adequately, to

ensure there will be no strain on the surfaces

and joints. Seal all seams and butt joints with

adhesive.

insoflex tubing can be easily slipped over

bent tubing of 45" angle , elbow bend or coupling.

Slip rnsoflex tubing into position and tightly

Brush all joint and seams with even coat o{

againsl the 90" fittings.

adhesive.

*

for(lflex

When adhesive is dry but tacky, joint seame by

pressing the surfaces together firmly.

Cut unslit insoflex tube lengthwise with

a

sharp knife.

Snap the insotlex over the pipe Coat slit

seams evenly wiih adhesive.

Hold the coated seams apart while the adhe

sive dries.

o

with two layers stagger the

When adhesive is dry but facky to touch. press

together surface nearest to pipe first and then

joint outer edges of the two surface.

butt joints.

Snap the slit fitting cover in positing over the

Apply adhesive on the seams. Press the

ioint.

seams frrmly longether when adhesive has

dried. Brush in between overlap surface with

adhesive.

-l

F

1\

Snap fitting cover in place and apply adhesive

to all surlaces to be joined,

press tubrng firmly together when adhesive is

dry but tacky to louch.

w

#r*s€}f,#sx

Fabrication fitting cover

in place and

adhesive to all sudace to be joined.

apply

lnsoflex

Sheets and roll insulation are extremely flexible and

especially adaptable to insulating duct work. Chillers,

tanks, vessels and large pipes. lt is the same high quality, elastomeric closed cell thermal insulation material as

lnsolflex tubing.

Method

Measure the size of sheets required for

insulation.

Cut the material to the measured size with

By using a sharp knife cut ,nsoflex sheet

a sharp knife and straight edge.

accurately and neatly

Ensure that cuts are as accurate as possi-

ble and with smooth edges to ensure full

contact with mating sheets when bonded

together.

Do not stretch sheets and always apply

with smooth skin surface facing out.

be insulated

oil free and

ion.

Place sheet in desired position before adhesive make initial contact as repositioning after

contacl is dilficult.

Join seams after insulation is in place by separating the cut edges and brushing a thin coal

of adhesive on both surfaces.

Seams of ducting joints can be insulated with

strips of insoflex

Half sections

oI insoflex tubing can also

used to insulate seams in ductings

r,O

be

Chemicals

-

Acetone

Ammonia Water

Aniline

Gonc%

100

30

100

Benzene

Boiling Water

100

Butyl Acetate

Butyl Alcohol

100

Caustic Soda

Chloric Acid

Cotton Seed Oil

Ethyl Acetate

Ethyl6ne Glycol

Formaldehyde

Glacial Acetic Acid

Temp

50

6

100

100

100

40

100

'R€sistance

E

room t€mp.

room temp.

E

room temp,

room temp.

100

100

1og1

room t€mp.

room temp.

room temp.

room temp.

room temp.

rooql temp.

room temp.

room tomp,

room temp.

Hydrochloric Acid

Hydrogen Peroxide

Conc%

10

10

P

Kerosine

Lins€ed Oil

100

100

E

MEK

100

n

Methyl Alcohol

Methylene Chloride

100

100

E

N

E

0c

Chemicals

P

itrobenzene

100

(:

Phosphoric Acid

u

Steam

F

Sulfuric Acid

t0

E

Octane

80

G

Toluene

G

Water

85

,T

Tamp

loC)

room temp,

room temp.

toom temp.

room temp.

room temp.

room tomp,

rcom temp.

room t6mp.

room temp.

Rosistance

E

E

P

G

F

E

P

G

E

120 0C

G

room temp.

room temp.

P

room temp.

(0-1 000c)

E

P

E

Remarks:E = Excellent,G = Good, F = Fair, P = Poor.

*insoflex isacotnpoundof speciallynon-polaretastomericmaterht$whichwillbehighlyreststanttothepolarchemicalsuchaswater.

moisture vapour, acid and base, But, it is moderate or poor

in

resistance to non polar chemical such as petrcleum oil,

For lurther informationon chemical resistance, please contaut lnsoflexdistrlbutors in your are€.

-

pepaleum solvent,

l{ici:=::"="''

i,,.i,a+_:_::::

€l_-3:.-j -

.

-

rlr""'-:::l

,in1i,=.il::=:-=:ri.:-:

:!:*.3i::E:::

:

:{irlir.a==

:,4:.8+4.::.:

,

.]jl}:i.i{-!i ::,,':.;::::,

&:i:::,r-:::i

. :*t:.€i:1":r:.

:

...:

:i-::.,

.€;1*3;:::',=-:'

'!:*:i€:::

I

It

.::

i;:::::'

r::r:1i.:t=:i

*gfx *nsa,$*fy

#tp* & #hssf#

Xnssxx*nt$*x*

Marketing by

b

MARIAM TRADING EST.

Makkah

Riyadh

Jeddah

01 4724625

026918666 025384402 012913613

Tel. 02 6978555 Tel. 025361021 Tel.

Fax.026393992 Fax.02 5384402 Fax.01 291361I

T

IrrsS!ffex

Made in Saudi Arabia

Dammam

Tel. 03 8473902

Fax.03 8413897

© Copyright 2026