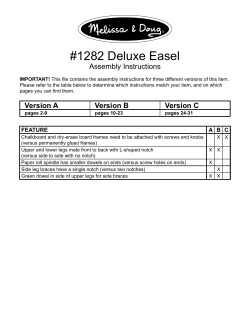

Build a durable and fun playset for your children’s backyard adventures Playset

Playset PROJECT PLAN Build a durable and fun playset for your children’s backyard adventures This playset calls for a slide and 2 swings and features a sturdy frame, 2 ladders, and a crow’s nest peer-out point with a raised platform. A-frame supports, then move on to assembling the main skeleton. After that is raised, you will attach floor joists and install decking, and clad outside walls. BUILD TIME It is an outdoor fixture that will last and have the whole family spending more time outside. Make sure to take proper safety precautions including always wearing gloves, goggles and a dust mask when you’re cutting or sanding. HRS 18 DIFFICULTY You’ll start with the construction of the BuildYella.com Playset WHAT YOU’LL NEED SUPPLIES A A A A 4x4x10’ (8) A A A A G G G G 2x4x10’ (2) M B B B M B B B H 2x4x8’ (1) H 2x4x8’ (1) R R C 2x4x10’ (2) 5/4x6x10’ (1) I C E P 5/4x6x10’ (1) D 5/4x6x10’ (1) E J 5/4x6x10’ (1) F F 5/4x6x10’ (1) L O C 5/4x6x10’ (1) N D Q A-FRAMES 5/4x6x10’ (1) K 4x4x10’ (1) T 4x4x10’ (1) S MAIN BEAM S U U 4x4x8’ (1) 5/4x6x10’ (1) V W X X X X X X X X X X 2x4x8’ (1) LADDERS 5/4x6x10’ (6) X Get more project plans at BuildYella.com 2 Playset WHAT YOU’LL NEED SUPPLIES Y Y Y Y 2x4x8’ (2) FLOOR JOISTS Z 2x4x8’ (1) Z AA 1x4x8’ (1) AA CROWS NEST JOISTS CC DD CC BB BB II EE EE II EE EE 2x4x10’ (1) 5/4x6x10’ (2) KK JJ KK JJ FF LL LL GG HH GG HH HH HH 2x4x8’ (2) CROWS NEST CLADDING 1x4x8’ (2) MM MM MM 5/4x6x8’ (7) MM MM MM MM DECKING NN OO QQ OO 5/4x6x8’ (3) *cut to 4-1/2” width OO PP PP PP PP RR RR RR RR RR RR SS SS SS SS 5/4x6x8’ (2) *cut to 4” width 1x4x8’ (3) REAR CLADDING 5/4x6x8’ (3) SS Get more project plans at BuildYella.com 3 Playset WHAT YOU’LL NEED SUPPLIES TOOLS WOOD STOCK TOTAL 6x1x4x8’ 8x2x4x8’ 5x2x4x10’ Miter saw (or hand or circular saw) Table saw Handsaw Drill / driver 1/8” Countersink drill bit 1/2” Forstner bit Clamps Carpenter’s square Mallet Measuring tape Circular saw 1x4x4x8’ 10x4x4x10’ 15x5/4x6x8’ 16x5/4x6x10’ HARDWARE 1 LB BOX 2-1/2” Star-drive decking screws 3-1/2” Star-drive decking screws 1-5/8” Star-drive decking screws 10x 6” FastenMaster TimberLok 16x 4” FastenMaster TimberLok 8x 2x4 joist hangers BUILD TIME CUTTING 4 HRS ASSEMBLY + 12 HRS Get more project plans at BuildYella.com FINISHING + 2 HRS TOTAL = 18 HRS 4 Playset DIMENSIONS & DIAGRAMS Notes: All measurements are approximate. Cut stock in the sequence of steps because many dimensions are directly measured and will vary based on actual stock and construction. Board dimensions can vary, so be sure to measure your stock. TOP ~210” FRONT RIGHT SIDE ~95” ~94” ~142” Get more project plans at BuildYella.com 5 Playset OVERVIEW OF STEPS 1: A-FRAME SUPPORTS 6: CROW’S NEST CLADDING 2: MAIN BEAM 7: DECKING 3: LADDERS 8: REAR CLADDING 4: FLOOR JOISTS 9: FINISHING 5: CROW’S NEST JOISTS 10: ACCESSORIES Get more project plans at BuildYella.com 6 Playset JIGS CUTLIST & DIAGRAMS FOR JIGS USED A-FRAME MARKING JIG 12” long (scrap 2x4) 18-3/8” 14-1/4” 90˚ 24.6˚ 10-3/4” 15-7/8” A-FRAME TOP BEAM SPACER JIG 12” long (scrap 2x4) 6” tall (scrap 4x4) A-FRAME SIDE CLADDING SPACER JIG 50” long (scrap 5/4x6 cut down to 3-3/4”) 3-3/4” Note: Why are these jigs necessary? To provide accuracy and consistency between parts and make cutting and assembly easier. Using jigs will result in a playset that is safer, stronger, and better looking. Watch the video to see how to make these jigs. Get more project plans at BuildYella.com 7 Playset DIMENSIONS & DIAGRAMS STEP 1: A-FRAMES CUTLIST FOR A-FRAMES: 102-3/4” 3-1/2” 1-3/4” A 99-3/8” 4-5/8” 10-3/16” 46-1/8” B H 13-3/8” 47-3/4” 17” 49-1/2” C I 36-3/8” N 22-1/8” 52” 33-7/8” 25-1/4” 53-5/8” D J 32-1/4” O 30-3/8” 56-3/16” 29-3/4” 33-1/2” 57-3/4” E K 28-1/8” P 38-5/8” 60-3/8” 25-9/16” 41-3/4” 61-7/8” F L Q 46-7/8” 64-1/2” 21-1/2” 50” 24” 66” G M 53-1/4” 67-5/8” 46-1/2” R 3-1/2” 3-1/2” 3-1/2” 1/2” 1/2” R (side view) Get more project plans at BuildYella.com 8 A-FRAME Playset DIMENSIONS & DIAGRAMS STEP 1: A-FRAMES SIDE ASSEMBLY VIEW A-FRAMES B B B H H C D N I O J R G A B B C C D R E P K E F Q L F G B M A Get more project plans at BuildYella.com G M G A A 9 A-FRAME Playset DIMENSIONS & DIAGRAMS 1ST SECTION: THE TWO OUTSIDE SUPPORTS ASSEMBLY VIEW OUTSIDE SUPPORTS Make this Assembly twice. Outside supports are identical. B B C C D D E E F F G G A A A A FRONT BACK (2x) Get more project plans at BuildYella.com 10 A-FRAME Playset DIMENSIONS & DIAGRAMS 2ND SECTION: INSIDE LEFT SUPPORT ASSEMBLY VIEW INSIDE LEFT SUPPORT B H H N N O O R R P P Q G Q M M A A A A FRONT BACK (1x) Get more project plans at BuildYella.com 11 A-FRAME Playset DIMENSIONS & DIAGRAMS 3RD SECTION: INSIDE RIGHT SUPPORT ASSEMBLY VIEW INSIDE RIGHT SUPPORT H H B I I C J J R R K K L L M M G A A A A FRONT BACK (1x) Get more project plans at BuildYella.com 12 A-FRAME Playset BUILDING STEP 1: A-FRAMES A: Prep: Making Jigs and 4x4 Angle Cuts. A1 A2 A3 We’ll begin by making three jigs. See page 7 for the measurements. The first one you’ll make is a Marking Jig for the tops of the 4x4 beams. The second jig is the Top Beam Spacer, used to align the top of the 4x4 beams during assembly of the A-frames. See dimensions on page 7 and make accordingly. The third jig is a Spacer Jig that will be used for spacing the A-Frame side planks and ladder cladding. See dimensions on page 7 and make accordingly. A4 A5 A6 For the Marking Jig, take a 4x4 (part [A]) and measure 102 ¾” on each post. Use the marking jig to inscribe the cut lines. Then flip part (A) over and mark the other side too. You’ll need to do this to all 8 posts, marking both sides with cut lines. Next, cut on the inscribed lines using a circular saw to half depth. Flip the wood and cut through the remainder. If desired, use a belt sander on the cut surfaces to smooth out the faces. Cuts: For each step, you can pre-cut all of the pieces listed in the Cutlist for each section. Tip: Need help, or have questions about how to cut these parts? Watch the video! Get more project plans at BuildYella.com 13 A-FRAME Playset BUILDING STEP 1: A-FRAMES B: Assembling A-Frame Supports B1 B2 B3 All four A-frames share the same basic structure, so you’ll repeat steps B1 - B6 four times. Use the top beam spacer jig and lay out two of the 4x4 posts into the A-frame position. Measure 51 ¼” from the bottom outside corner and mark this on the post. Do this on both posts. Align the top of part (G) to the two points you just marked. This will set the angle of the A-frame. Be sure the top beam spacer is still in place. B4 B5 B6 Countersink part (G) with a half-inch Forstner bit. Make sure the edges of part (G) are flush with the outside of the 4x4 post, and then secure it with 4” TimberLok screws. Finally, attach part (B) to the 4x4 posts using 3 ½” screws. Keep the top beam spacer in place. Repeat steps B1 - B6 three more times to make the remaining A-frames. Get more project plans at BuildYella.com 14 A-FRAME Playset BUILDING STEP 1: A-FRAMES C: Cladding the two Outside A-Frames C1 C2 C3 We’ll focus first on the two outside A-frames. Flip over two of the assembled frames and attach a second part (B) to the tops of them. Keep the top beam spacer jig in place for this. Flip them again and install cladding planks (C) through (F) onto the 4x4 posts. Place the spacer jig between each plank. Use 2 ½” screws. Begin at part (G) and move up toward part (B). Use 2 screws at the end of each board. Make sure the angled edges on the cladding are flush with the 4x4 post. The completed A-frames should look like the photo above. Get more project plans at BuildYella.com 15 A-FRAME Playset BUILDING STEP 1: A-FRAMES D: Cladding and Assembling the Inside Left A-Frame D1 D2 D3 Each of the two inside A-frames are unique. We’ll start by cutting notches into the ends of part (R). These will allow proper positioning of the crow’s nest side walls. Using a handsaw, cut a ½” deep by 3 ½” wide notch at each end of part (R). Next, we will create the crow’s nest walls. This assembly is created separately from the A-frame. D4 D5 D6 Attach parts (H) and (M) to vertical post (R). They should set into the notches at each end. Attach with 2 ½” screws. Be sure the angles at each end of parts (H) and (M) match the angle of the A-frame. Using the spacer jig, lay out the remaining parts (N) through (Q). Align them so that their edges are flush with the edge of part (R), and then attach them with 2 ½” screws. D7 D8 D9 Flip the assembly and position it on the A-frame. Support the overhanging edge with blocking during this step. Align part (M) with part (G), then attach using 4” TimberLok hardware. Next, with the top beam spacer in place, attach part (H) using 3 ½” screws. Attach parts (N) - (Q), starting with (Q). Use the spacer jig for placement. This completes the Inside Left A-frame. Tip: Need help, or have questions about how to cut these parts? Watch the video! Get more project plans at BuildYella.com 16 A-FRAME Playset BUILDING STEP 1: A-FRAMES E: Cladding and Assembling the Inside Right A-Frame E1 E2 E3 Attach parts (H) and (M) to vertical post (R). This is similar to step D4, but reverse the orientation of these parts. Be sure the angles at each end of parts (H) and (M) match the angle of the A-frame. Using the spacer jig, lay out the remaining parts (I) through (L). Align them so that their edges are flush with the edge of part (R), and then attach them with 2 ½” screws. E4 E5 E6 Flip the assembly and position it on the A-frame. Support the overhanging edge with blocking during this step. Align part (M) with part (G), then attach using 4” TimberLok hardware. Next, with the top beam spacer in place, attach part (H) using 3 ½” screws. Attach parts (I) - (L), starting with (L). Use the spacer jig for placement. The angled edges of parts (I) - (L) will be flush with the back edge of the A-frame, creating a walled-in piece. This completes the Inside Right A-frame. CONGRATULATIONS! THE A-FRAMES ARE THE SKELETON OF THE PLAYSET, AND HAVING THEM COMPLETE MAKES THE FOLLOWING STEPS STRAIGHTFORWARD. Get more project plans at BuildYella.com 17 A-FRAME Playset DIMENSIONS & DIAGRAMS STEP 2: MAIN BEAM CUTLIST 90-1/4” 3-1/2” S 120” 3-1/2” T 10-3/8” 3-1/2” U 18-3/8” 90-1/2” 5-1/2” Get more project plans at BuildYella.com V 18 MAIN BEAM Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW MAIN BEAM S T U U V FRONT T U S U V BACK Get more project plans at BuildYella.com 19 MAIN BEAM Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW MAIN BEAM T U V SIDE Get more project plans at BuildYella.com 20 MAIN BEAM Playset BUILDING STEP 2: MAIN BEAM A: Prep and Mark A1 A2 A3 Next we’ll need beams (S) and (T), as well as part (V). This piece will help stabilize the structure during assembly. On the rear posts of the Outside Left A-frame and the two Inside A-frames, make a mark at 50 ½” from the bottom edge of the post. Mark the center of part (V) and the center of the rear post (A) on the Inside Left A-frame as well. These marks will help position part (V) during assembly. A4 A5 Note: The center of part (V) should be attached at the center of the rear post of the Inside Left A-Frame. This step is critical for the dimensions of parts throughout the structure assembly. Measure and double check dimensions as needed. With an assistant or two, lift the Outside Left and Inside Left A-frames up. Get more project plans at BuildYella.com Connect the two frames by installing part (V) using the marks you made to help position the board. Use 3 ½” screws. 21 MAIN BEAM Playset BUILDING STEP 2: MAIN BEAM B: Mount Beams B1 B2 B3 Drop in part (S). Align the end so that it’s flush with the outside edge of part (B) on the Outside Left A-frame. In the center of this beam, drill and countersink using a ½” Forstner bit. Then fasten the parts together using 6” TimberLok screws. Do this on the reverse side of the A-frame as well. The center of the Left Inside A-frame, part (A), should be 46-3/4” from the end of the beam. After confirming this measurement, fasten the pieces together. B4 B5 B6 Raise the Inside Right A-frame into position. Attach part (V) using your reference marks as guides. The outside edge of part (V) should be flush with the outside edge of the A-frame. Top Beam (S) should end at the midpoint of the Inside Right A-frame as shown. Countersink and attach using 6” TimberLok screws. Next, position part (T) vertically with the Outside Right A-frame on the ground. Insert part (T) into the A-frame, then countersink and attach using 6” TimberLok screws. B7 B8 B9 Tip the assembly into position with the end of part (T) butting up against part (S). Countersink and attach with 6” Timberlok screws. Install the additional part (C) to the outside of the Inside Right A-Frame using 2 ½” screws. The angle brace (U) will butt up against this piece. Attach part (U) using 3 ½” screws. There are two of these braces you’ll need to install, one on each side of the swings. Get more project plans at BuildYella.com 22 MAIN BEAM Playset DIMENSIONS & DIAGRAMS STEP 3: LADDERS CUTLIST 40” 3-1/2” W 47” 5-1/2” Get more project plans at BuildYella.com X 23 LADDERS Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW LADDERS X W X X X X X X X X X X FRONT X X X X X X X X X X BACK Get more project plans at BuildYella.com 24 LADDERS Playset BUILDING STEP 3: LADDERS A: Attach to Structure A1 A2 A3 Position and install the bottom rung, part (X). Attach using 2 ½” screws at the end of each board. Using the 3 ¾” spacer jig from before, continue to install parts (X) up the A-frame. The top edge of the top rung should be slightly below the top edge of part (G). Repeat this process for the ladder at the back of the inside A-frames. A4 Finally, install part (W) on the front of the crow’s nest using 3 ½” screws. Get more project plans at BuildYella.com 25 LADDERS Playset DIMENSIONS & DIAGRAMS STEP 4: FLOOR JOISTS CUTLIST 37-1/4” 3-1/2” Y 44-3/8” 3-1/2” Get more project plans at BuildYella.com Z 26 FLOOR JOISTS Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW FLOOR JOISTS Y Y Z Z Y Y Y Y TOP Z Y Z Y BOTTOM Get more project plans at BuildYella.com 27 FLOOR JOISTS Playset BUILDING STEP 4: FLOOR JOISTS A: Attach to Structure A1 A2 A3 The joist hangers will be mounted to the cross frame supports (G) and (M). On part (G), make a mark 2 ½” in from the edge. This is the center of the joist hanger. Also mark this on part (M). Install these joist hangers at the first marks using 1 ½” screws. Use a scrap 2x4 block during this step. The top edge of the 2x4 should be flush with the top of parts (G) and (M). Now mark 45 7/ 8 ” away from the first set of joist hangers (center to center). Do this for each cross frame support and install the second set of joist hangers on parts (G) and (M). A4 A5 A6 Attach part (Z) to parts (Y) to create two “H” shaped assemblies. Part (Z) should be attached to the centers of parts (Y). Attach using 3 ½” screws. Create these assemblies on the ground, separate from the main structure. Drop one “H” shaped assembly into the joist hangers and secure the hangers to the joists using 1 5/ 8” screws. Repeat this on the right side, where the crow’s nest will be. Once complete, the supports for the decking are finished. Tip: Need help with the joist hangers? Watch the video! Get more project plans at BuildYella.com 28 FLOOR JOISTS Playset DIMENSIONS & DIAGRAMS STEP 5: CROW’S NEST JOISTS CUT LIST 38” 3-1/2” AA 18-7/8” 3-1/2” BB 15” 3-1/2” CC 38” 3-1/2” Get more project plans at BuildYella.com DD 29 CROW’S NEST JOISTS Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW CROW’S NEST JOISTS AA BB DD AA TOP DD BB BOTTOM Get more project plans at BuildYella.com 30 CROW’S NEST JOISTS Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW CROW’S NEST JOISTS BB CC CC AA AA BB DD LEFT SIDE Get more project plans at BuildYella.com 31 CROW’S NEST JOISTS Playset BUILDING STEP 5: CROW’S NEST JOISTS A: Attach to Structure A1 A2 A3 We’ll start by adding framing for the crow’s nest. Begin by attaching part (DD) to the back of part (W), creating a double 2x4 beam across the front of the crow’s nest. Use 2 ½” screws. Now, assemble parts (BB) and (CC) using 3 ½” screws to create a center support structure for the crow’s nest decking. Use two screws at the end of each board to make a square structure. Attach part (AA) to the center of the center support structure you just made. The bottom edge of part (AA) should be flush with the bottom edge of part (BB). Use 1 5/ 8” screws. A4 A5 Position the center support structure you just made so that it rests on part (Y) and (DD). It should be centered on these parts. Attach using 3 ½” screws diagonally into parts (Y) and (DD). Also use 1 5/ 8” screws at the edge of part (AA). Finally, position part (AA) so that it is centered on the back of the center support structure. The bottom edge of part (AA) should be flush with the bottom edge of part (BB). Attach using 1 5/ 8” screws. Get more project plans at BuildYella.com 32 CROW’S NEST JOISTS Playset DIMENSIONS & DIAGRAMS STEP 6: CROW’S NEST CLADDING CUTLIST 38” 5-1/2” II 40” 5-1/2” EE 3-1/2” 40” 3-1/2” JJ 3-1/2” FF 14-1/2” 3-1/2” KK 38” 3-1/2” GG 15-1/4” 3-1/2” 20-3/8” LL 3-1/2” Get more project plans at BuildYella.com HH 33 CROW’S NEST CLADDING Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW CROW’S NEST CLADDING FF EE EE EE HH GG HH EE HH HH FRONT II KK KK LL LL JJ JJ FF LEFT SIDE Get more project plans at BuildYella.com 34 CROW’S NEST CLADDING Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW CROW’S NEST CLADDING FF EE EE II LL JJ EE HH GG GG EE II HH KK SIDE Get more project plans at BuildYella.com 35 CROW’S NEST CLADDING Playset BUILDING STEP 6: CROW’S NEST CLADDING A: Install Blocking Supports A1 A2 A3 Install parts (LL) along the back of part (P). The top edge of part (LL) should be flush with the top edge of part (P). Attach using 2 ½” screws from the outside. Repeat on the other side of the crow’s nest, this time making sure the top edge of part (LL) is flush with the top edge of part (K). This will provide support for the decking to come. Next, install parts (KK) vertically, using part (AA) to help position it. Part (KK) should butt up against part (AA) at the bottom, and butt up against part (LL) at the top. Attach using 1 5/ 8” screws from the outside. A4 Attach parts (JJ) to the inside of parts (R). The top edge of part (JJ) should be flush with the top edge of part (LL). Attach with 2 ½” screws from the inside. Get more project plans at BuildYella.com 36 CROW’S NEST CLADDING Playset BUILDING STEP 6: CROW’S NEST CLADDING B: Attach to Structure B1 B2 B3 Attach the lowermost part (EE) to the front of the crow’s nest using 2 ½” screws. Align part (EE) with parts (L) and (Q). Next, attach part (FF) at the top of the crow’s nest using 3 ½” screws. Align part (FF) with parts (H). Then, install the remaining parts (EE) on the front of the crow’s nest, from bottom to top. The remaining parts (II), (GG), and (HH) should fit into the remaining gaps on the crow’s nest. B4 B5 For parts (II) and (HH), the screws should be at the ends of the board and go into the blocking part (KK). Be sure to pre-drill and countersink when screwing this close to the ends of the boards. Get more project plans at BuildYella.com 37 CROW’S NEST CLADDING Playset DIMENSIONS & DIAGRAMS STEP 7: DECKING CUTLIST 83-1/2” MM 5-1/2” 83-1/2” NN 4-1/2” 40” 4-1/2” OO 40” 4” PP 35” 4-1/2” Get more project plans at BuildYella.com QQ 38 DECKING Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW DECKING OO OO NN NN MM MM MM MM MM MM MM MM MM MM MM MM MM MM OO PP PP PP PP QQ TOP QQ PP PP PP OO PP MM MM MM MM MM MM MM MM MM MM MM MM MM MM NN NN OO OO BOTTOM Get more project plans at BuildYella.com 39 DECKING Playset BUILDING STEP 7: DECKING A: Attach to Joists A1 A2 A3 Position the first decking board (MM) against the posts of the A-frame at the front of the structure. Center and attach using 2 ½” screws. Use 2 screws at each floor joist location, for a total of 8 screws per board (MM). Set out the remaining (MM) boards but do not screw them in. The final board of this decking will be board (NN) which should fit up against the rear posts of the A-frames. Now you can attach all these boards with 2 ½” screws into the joists below. A4 A5 Install parts (OO) at the three openings of the structures. They should project slightly beyond the A-frames. Position and install parts (PP) and (QQ) as the decking for the crow’s nest. Part (QQ) will sit between the posts (R). Attach using 2 ½” screws into the blocking you installed below. Get more project plans at BuildYella.com 40 DECKING Playset DIMENSIONS & DIAGRAMS STEP 8: REAR CLADDING CUTLIST 47” 3-1/2” RR 47” 5-1/2” Get more project plans at BuildYella.com SS 41 REAR CLADDING Playset DIMENSIONS & DIAGRAMS ASSEMBLY VIEW REAR CLADDING RR SS SS SS SS SS TOP RR SS RR SS RR SS RR SS RR SS RR BACK Get more project plans at BuildYella.com 42 REAR CLADDING Playset BUILDING STEP 8: REAR CLADDING A: Attach to Structure A1 A2 A3 Position part (RR) on the back of the A-frame posts. Making sure the outer edge is flush with the 4x4 posts behind it, attach part (RR) with 2 ½” screws. Alternate boards (SS) and (RR) up the structure, keeping the outside edges flush with the 4x4 posts behind them. Attach all of the parts (RR) and (SS) with 2 ½” screws into the 4x4 posts behind them. Get more project plans at BuildYella.com 43 REAR CLADDING Playset DIMENSIONS & DIAGRAMS STEP 9: FINISHING YellaWood® brand products provide the best available pressure treated lumber protection against rot, fungal decay and termites. Sanding edges is recommended to reduce snags and splintering. At a minimum, we recommend annual application of a water repellent. You can also paint or stain it if you prefer. A1 Ease any sharp edges with a medium grit sandpaper. Apply a finish to the wood if desired. Get more project plans at BuildYella.com 44 FINISHING Playset DIMENSIONS & DIAGRAMS STEP 10: ACCESSORIES Chose your own playset accessories based on your needs. One or both of the standard swings shown can be replaced by toddler or glider swings if needed. A1 A2 A3 Make a mark on beam (T) 26” from the left edge of beam (T). Make a second mark 18” further in. Drill holes at these points to hold your swing hanger bolts. Follow the swing hanger bolt manufacturer’s instructions for this step. Repeat this step on the right side of beam (T). After installing the swing hanger bolts, follow the swing manufacturer’s instructions for how to attach the swings. Attach the slide to the decking. Follow the slide manufacturer’s instructions for this step. Use approved hardware to attach the slide and swings. CONGRATULATIONS ON COMPLETING YOUR VERY OWN OUTDOOR PLAYSET! TIME TO LET YOUR KIDS ENJOY IT. NEVER LET CHILDREN USE THE PLAYSET WITHOUT PROPER SUPERVISION. Get more project plans at BuildYella.com 45 ACCESSORIES Playset GALLERY Get more project plans at BuildYella.com 46 Playset FASTENER & HARDWARE INFORMATION FOR INTERIOR OR EXTERIOR APPLICATIONS Use fasteners and hardware that are in compliance with the manufacturer’s recommendations and the building codes for their intended use. As with any good design and construction practices, treated wood should not be used in applications where trapped moisture or water can occur. Where design and/or actual conditions allow for constant, repetitive or long periods of wet conditions, only stainless steel fasteners should be used. FOR EXTERIOR APPLICATIONS The following minimum galvanization levels may be used for connectors, joist hangers, fasteners and other hardware that are placed in direct contact with exterior applications of micronized copper treated wood: • Fasteners - nails, screws, etc. ASTM – A 153 (1 oz/ft²) • Hardware - connectors, joist hangers, etc. ASTM – A 653 G90 (0.90 oz/ft²) The effects of other building materials within a given assembly, along with environmental factors, should also be considered when selecting the appropriate hardware and fasteners to use for a given project containing treated wood. Stainless Steel fasteners and hardware are required for Permanent Wood Foundations below grade and are recommended for use with treated wood in other severe exterior applications such as swimming pools, salt water exposure, etc. Type 304 and 316 are recommended grades to use. ALUMINUM Aluminum building products may be placed in direct contact with YellaWood® brand products used for interior uses and above ground exterior applications such as decks, fencing, and landscaping projects. Examples of aluminum products include siding, roofing, gutters, door and window trim, flashing, nails, fasteners and other hardware connectors. However, direct contact of treated products and aluminum building products should be limited to code-compliant construction applications that provide proper water drainage and do not allow the wood to be exposed to standing water or water immersion. YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, systems, and technologies of unrelated third parties. For details regarding the Preservatives, methods, systems, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/ preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Material Safety Data Sheet (MSDS), please visit us at www.yellawood.com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood® and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. Great Southern Wood Preserving, Incorporated makes no warranties expressed or implied as to the fitness for a particular purpose of this plan. We recommend you contact the aluminum building products manufacturer for its recommendations regarding use of its aluminum products in contact with treated wood in ground contact applications or when exposed to salt water, brackish water, or chlorinated water, such as swimming pools or hot tubs. Also check with the aluminum building products manufacturer regarding compatibility with other chemicals and cleaning agents and the use of their aluminum products in commercial, industrial, and specialty applications such as boat construction. Get more project plans at BuildYella.com 47 Playset IMPORTANT INFORMATION • • • • • • • • • • • • • • • Consult the end tag to determine which preservative or preservative system was used in the treatment of that particular product. YellaWood® brand products may be used in direct contact with aluminum building products when limited to codecompliant construction applications that provide proper water drainage and do not allow the wood to be exposed to standing water or water immersion. Use fasteners and other hardware that are in compliance with building codes for the intended use. Do not burn preserved wood. Wear a dust mask and goggles when cutting or sanding wood. Wear gloves when working with wood. Some preservative may migrate from the treated wood into soil/water or may dislodge from the treated wood surface upon contact with skin. Wash exposed skin areas thoroughly. All sawdust and construction debris should be cleaned up and disposed of after construction. Wash work clothes separately from other household clothing before reuse. Preserved wood should not be used where it may come into direct or indirect contact with drinking water, except for uses involving incidental contact such as fresh water docks and bridges. Do not use preserved wood under circumstances when the preservative may become a component of food, animal feed or beehives. Do not use preserved wood as mulch. Only preserved wood that is visibly clean and free of surface residue should be used. If the wood is to be used in an interior application and becomes wet during construction, it should be allowed to dry before being covered or enclosed. Mold growth can and does occur on the surface of many products, including untreated and treated wood, during prolonged surface exposure to excessive moisture conditions. To remove mold from the treated wood surface, wood should be allowed to dry. Typically, mild soap and water can be used to remove remaining surface mold. For more information visit www.epa.gov. Projects should be designed and installed in accordance with federal, state and local building codes and ordinances governing construction in your area, and in accordance with the National Design Specifications (NDS) and the Wood Handbook. Get more project plans at BuildYella.com DISPOSAL RECOMMENDATIONS Preserved wood may be disposed of in landfills or burned in commercial or industrial incinerators or boilers in accordance with federal, state and local regulations. 48

© Copyright 2026