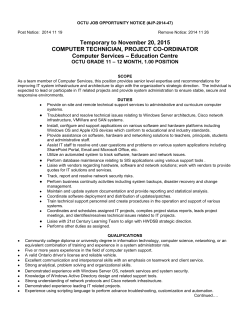

Dr.Friedrich-Wilhelm Wulfert New Product Introduction

Page 1 Dr.Friedrich-Wilhelm Wulfert New Product Introduction Development Support Center MOTOROLA SPS Quality, München ITG FB 8.5 Qualität und Zuverlässigkeit bei kleinen Geometrien Oberammergau, 7.- 8. Mai, 2002 FWW — New Product Introduction Development Support Center — SPS Quality Munich ITG-Oberammergau, May 7-8, '02 Page 2 640& FWW — New Product Introduction Development Support Center — SPS Quality Munich ITG-Oberammergau, May 7-8, '02 Page 3 ,, SURGXFWLRQ ,,, XVH ,9 ZHDURXW )DLOXUH'HQVLW\ , GHYHORSPHQW respectively 3RWHQWLDORI)DLOXUH 5HOLDELOLW\$VSHFWVIURPWKH&UDGGOHWRWKH*UDYH /LIH &\FOH FXVWRPHU UHTXLUHPHQWV SURGXFW UHOHDVH &DXVH FXPXODWLYH ILQDO WHVW HQGRI XVHIXOOLIH (IIHFW IDLOXUHGHQVLW\ F.W.Wulfert - NPI Quality MUC Motorola SPS Page 4 ([DPSOHRI'(/7$$QDO\VLVDQG5LVN2SSRUWXQLW\$VVHVVPHQW 4XDOµHGSURFHVVLQTXDOµHGSDFNDJH'(/7$V F.W.Wulfert - NPI Quality MUC Motorola SPS Page 5 ([DPSOHRI'(/7$$QDO\VLVDQG52$VVHVVPHQW(cont.) DSSOLFDWLRQ window lift standard airbag GHVLJQ IDESURFHVV DVV\SURFHVV manufacturability processability std. library Hyperintegration change during development new cells on product digital + analog + NVM std. HCMOS, 5V + high voltage + mixed signal + large EE or ROM HT HAST interdielectric + analog stability characterization HTOL die size passivation/overcoat interconnects + integrity package 1st and 2nd bond phys. & chem. material match modelling + MSL3/245°C EE ROM JSTD020A + customer + glueability supplier + customer std. SOIC28W leadframe mold compound Page 6 :H.QRZ0DWUL[ /DUJH'LHLQ6PDOO60'xyz( ,1,7,$/ risk & opportunity assessment @ planning ) 3KDVHUHYGDWH 5LVN ,QIRUPDWLRQJDWKHULQJ 0HDVXUHV IRUIXQFWLRQ 2 object parameter 3 4 5 6 target value actual ability stressor load actual reliability 7 8 9 10 11 society 1 PTA Object UHOLDELOLW\VWDELOLW\ organisation nominal value IXQFWLRQ customer functionality characteristic LQIOXHQFLQJSDUDPHWHU type UHTXLUHPHQWV Importance UHOLDELOLW\ 12 13 14 OO DU HY R 15 SODQQH[W VWHSV ZKR ZKHQ 17 18 16 $SSOLFDWLRQFRQGLWLRQV $XWRPRWLYH6DIHW\ ## M AEC + custom M product A Similar product (die + package) does exist and is qualified " AEC baseline + custom confirmation product A Similar product (die + package) does exist and is qualified " AEC baseline + custom confirmation M process B AEC + custom $XWRPRWLYH%RG\ )XQFWLRQDOLW\ digital 0L[HG6LJQDO analog HV ## (PEHGGHG0HPRU\ ROM NVM voltage regulator M M I/O periphery M program array data EE M M A latch-up robustness A array size array size A A program EE array size A program EE program/erase and data retention ## M Vout OK Qualified by similarity Vout +/-5% +/-10% Tj=125C 1008hrs >100mA@hot 100mA@room qualified by identity qualified by similarity Yield of N >> n array ? ? OK OK A ## over 15 yrs 7use/time L L / No action: qualified M L 0 Characterize Vout: HTOL, HTRB + Perform latch-up on first silicon / / No action: qualified, functional parts ready-for-use H H L H L L M M L 0 Model/evaluate yield ? M H L + Get 7use profile from customer ? ? L L M H L L 0 Review assembly rules and l/f design + Review assembly rules and l/f design n array 7use profile L 0DQXIDFWXUDELOLW\3URFHVVDELOLW\ Packaging ## ## Board Assembly SMDxyz M die / flag size length A width A Tambient, Tjunction Tj = Ta + P x ThetaJA X>x Y>y x y TC TC Ta = 125C and Tj < 150C ? H H H + 220C H H H + In-depth MSL/Temp evaluation -40/150C -40/150C Define thermal capabilities of 60'xyz and operating conditions of application(s) Tj=f(Ta, P, ...), Tj < 150C M 245C Reflow M solder temperature resistance package top surface temperature B 245C 245C @ package top M package integrity moisture sensitivity level A MSL3 MSL1 for pre-conditioning per J-STD020A but reflow @ 245C smaller die H H H + In-depth MSL/Temp evaluation 245C @ package top W package integrity moisture sensitivity level A MSL1 MSL1 for pre-conditioning per J-STD020A but reflow @ 245C smaller die M M M 0 In-depth MSL/Temp evaluation SMDxyz A ## Importance: M = Must; W = Want type A: product parameter type B: process parameter Risk-Level: L = low; M = medium; H = high; N = not relevant; U = unacceptable; ? = unknown; ++ = Opportunity FRPSOH WLRQ 19 Page 7 ([DPSOH3URGXFW'HYHORSPHQW This example shows the progress of the incremental product development and inherent qualification from planning through release of a complex large die in a standard package and how the Risk & Opportunity Assessment Process (ROAP) helped to create awareness of existing challenges together with listing and keeping track of achieved items and performance ready for exploitation of these identified opportunities (see in the "We-Know-Matrix" risk logs) in the aimed at automotive market segment with its typical set of AEC (Automotive Engineering Council) defined requirements plus known customer or application specific add-ons (refer to ## in the below shown WKM of the INITIAL ROAP @ Planning, i.e. Fig. A,,.3.1). A cross-functional expert team including customer counterparts was built and contributed to an initial WKM at the begin of the product and qualification planning phase (Fig. A ,,.3.1). The customer had set tough boundary conditions requesting a specific small SMD package for the relatively large die (##). In addition there were some requirements going beyond package and cell design rules of already existing products of the same and already qualified mixed technology (##). Certain product features like the size of the EE Program Array and the stability of the Voltage Regulator needed attention from manufacturing yield point of view respectively for the electrical performance capability. The expected operation at elevated temperatures initiated detailed collection of working conditions for the applications. Customer input of the automotive systems’ mission-profiles was mandatory at this point in time (##). From begin on the main activities, however, resulted from requirements in the area of package manufacturability and processability. Assembly rules and leadframe design needed reassessment for packaging that large die into the customer requested and relatively small plastic body. Related in-depth evaluations were undertaken to confirm compliance with customers’ board soldering process needs of MSL3/245C and to prove market specific board-level processability and reliability requirements are fulfilled (##). F.W.Wulfert - NPI Quality MUC Motorola SPS Page 8 :H.QRZ0DWUL[ /DUJH'LHLQ6PDOO60'xyz(,17(5,0 risk & opportunity assessment during development 3KDVHUHYGDWH 5LVN ,QIRUPDWLRQJDWKHULQJ 0HDVXUHV IRUIXQFWLRQ 2 3 type UHOLDELOLW\VWDELOLW\ PTA Object object parameter 4 5 6 target value actual ability stressor load actual reliability 7 8 9 10 11 society 1 IXQFWLRQ organisation nominal value LQIOXHQFLQJSDUDPHWHU customer functionality characteristic Importance UHOLDELOLW\ UHTXLUHPHQWV 12 13 14 OOD UH Y R 15 SODQQH[W VWHSV 16 ZKR ZKHQ 17 18 FRPSOHW LRQ 19 $SSOLFDWLRQFRQGLWLRQV M M $XWRPRWLYH%RG\ $XWRPRWLYH6DIHW\ A passed AEC & custom / AEC baseline + custom qualification A passed AEC " AEC OK, custom qual ongoing )XQFWLRQDOLW\ 0L[HG6LJQDO digital analog HV (PEHGGHG0HPRU\ ROM NVM ## M process M voltage regulator M I/O periphery M program array data EE M Vout A Vout +/-5% >100mA@hot Vout +/-5% >125mA@hot A array size A Qualified by identity array size A Qualified by similarity Yield of N >> n EE array size A M program EE EE W/E and D/R A functionality A length A width A X>x Y>y B no delamination B > 1mil B no crack x y ? ? ? Tambient, Tjunction Tj = Ta + P x ThetaJA A Ta=125C and Tj < 150C Ta = 85C at limited load package top surface temperature B 245C 245C moisture sensitivity level A MSL3 @ 245C MSL1 @ 245C MSL3 @ 245C MSL3 @ 245C higher shear force too low shear force M Tj=125C product 1008hrs +/- 125mA @ Tj=125C latch-up robustness M program EE Development & NEW ITEM early samples Qualified by similarity B OK L L / No action: qualified OK OK OK OK L L L / Passed requirements L L / Passed requirements / No action: qualified L L L L over 15 yrs reduced customer specification 7use/time ## (ROM + data EE) parts ready-for-use L L L / Meets targets and passes requirements W/E + D/R bake M M L 0 Interim readouts show zero failures, finalize extended D/R bake (OK) L / "Reduced Spec" parts fit-for-use OK OK ? ? ? L L M H H L L M H H L L M L L / Leadframe modifications successful / Leadframe modifications successful 0 Review capabilities, do rel tests + Review capabilities, adjust tools + Review capabilites, adjust tools OK H L L + Specify maximum Tj < 150C and outline thermal limitations ## in application note. M L 0 Successfully processed MSL3/245C. Customer oven profile has to be monitored. L L / Development work finalized @ MSL3/245C. ## ## n array 7use profile / 0DQXIDFWXUDELOLW\3URFHVVDELOLW\ Packaging ## SMDxyz M trim & form lead/plastic adhesion M wire dressing wire-to-edge clearance M 2nd bond heel integrity NEW ITEM NEW ITEM NEW ITEM Tj=f(Ta, P, ...), Tj < 150C Board Assembly ## NEW ITEM M die / flag size M SMDxyz SOIC Reflow M solder profile 245C @ package top M package integrity 245C @ package top W package integrity moisture sensitivity level A Glueability M mold compound surface cleanliness A Importance: M = Must; W = Want type A: product parameter type B: process parameter TC TC -40/150C -40/150C THB, TC, lead pull, etc. bonder capability wire pull pull force operation power dissipation pre-conditioning per J-STD020A but reflow @ 245C pre-conditioning per J-STD020A but reflow @ 245C shear force F Newton ? H U H 8 MSL1/245C needs material and process changes. H M N + Bind mold compound supplier into development work, do experiments. Risk-Level: L = low; M = medium; H = high; N = not relevant; U = unacceptable; ? = unknown; ++ = Opportunity ## Page 9 Another WKM sheet is outlining the situation in course of development (Fig. A ,,.3.2) and includes NEW ITEMS that surfaced during day-to-day progress (##). First functional silicon was successfully characterized and found acceptable per a reduced customer specification (##). That enabled early use of new product taking account of existing and clearly documented limitations. New items of interest and concern surfaced during the development phase and were added to the WKM which is a living document reflecting status and changes all along the new product creation process. The power density issue was clarified together with the customer and limiting the maximum dissipation during device operation and excluding all power stages are ON at the same time. With this boundary condition Tj < 150C could be reliably achieved. The relationship of Tj=Ta + P x ThetaJa was initiated to be detailed in an application note outlining these products’ thermal limitations (##). "Glueability" needs made it necessary to bring the mold compound supplier into the team and have him perform development work to fulfil customer board assembly needs (##). Effort for customer’s WANT of MSL1/245C was abandoned and ranked "8nacceptable" after finding out that the actual material set was capable of only The customer took measures for MSL3 handling and MSL3/245C (##). measured/adjusted/monitored the oven profile of his convection line. Both the solder joint and the package top surface temperature are recorded for components using some volume of similarly populated printed circuit boards (##). F.W.Wulfert - NPI Quality MUC Motorola SPS Page 10 :H.QRZ0DWUL[ /DUJH'LHLQ6PDOO60'xyz( ),1$/ risk & opportunity assessment @ release ) 3KDVHUHYGDWH 5LVN ,QIRUPDWLRQJDWKHULQJ 0HDVXUHV IRUIXQFWLRQ 2 object parameter 3 4 5 6 SODQQH[W society 1 PTA Object OO D U H Y R organisation nominal value IXQFWLRQ customer functionality characteristic LQIOXHQFLQJSDUDPHWHU 12 13 14 15 L L L L L L / product released / product released OK L L / No action: qualified OK OK OK OK L L L / Passes requirements L L L L Passes requirements / No action: qualified L L L / / L L L / (ROM + data EE) in field application Meets targets and passes requirements W/E + D/R bake L L L / OK OK OK OK OK OK L L L L L L L L L L L L L L L / Leadframe modifications successful / Leadframe modifications successful / Monitor during ramp-up / Monitor during ramp-up UHOLDELOLW\VWDELOLW\ type UHTXLUHPHQWV Importance UHOLDELOLW\ target value actual ability stressor load actual reliability 7 8 9 10 11 VWHSV ZKR ZKHQ 17 18 FRPSOHWL ## 16 19 $SSOLFDWLRQFRQGLWLRQV M M $XWRPRWLYH%RG\ $XWRPRWLYH6DIHW\ A passed AEC & custom A passed AEC & custom á á )XQFWLRQDOLW\ 0L[HG6LJQDO digital analog HV (PEHGGHG0HPRU\ ROM NVM Development & early samples M process M voltage regulator Vout B M I/O periphery M program array data EE M latch-up robustness B array size B array size B M program EE EE array size B M program EE EE W/E and D/R B functionality A length B M Qualified by similarity B product Vout +/-5% Vout +/-5% >100mA@hot >125mA@hot Tj=125C 1008hrs +/- 125mA @ Tj=125C Qualified by similarity 85 alified by similar Yield of N >> n n array 7use profile over 15 yrs 7use/time reduced customer specification Passes requirements SMDxyz M die / flag size width M trim & form lead/plastic adhesion M wire dressing wire-to-edge clearance M 2nd bond heel integrity Tj=f(Ta, P, ...), Tj < 150C Board Assembly SOIC Reflow 245C @ package top M SMDxyz M solder profile x y -40/150C no delam THB, TC, lead pull, etc. > 1mil > 1mil bonder capability B no crack no crack B Ta=125C and Tj < 150C Ta = 125C at limited load package top surface temperature B 245C 245C MSL3 @ 245C MSL1 @ 245C MSL3 @ 245C MSL3 @ 245C higher shear force too low shear force M 245C @ package top W package integrity moisture sensitivity level B Glueability M mold compound surface cleanliness B M = Must; W = Want -40/150C no delam Tambient, Tjunction Tj = Ta + P x ThetaJA moisture sensitivity level TC TC B package integrity Importance: X>x Y>y B type A: product parameter type B: process parameter wire pull operation pull force power dissipation OK pre-conditioning per J-STD020A but reflow @ 245C pre-conditioning per J-STD020A but reflow @ 245C shear force F Newton OK / Monitor during ramp-up ## L L L / Maximum Tj < 150C specified and outlined in marking. Application note published and followed. L L / Parts successfully processed with MSL3/245C and passing reliability. / Development work finalized @ MSL3/245C with customer. Development work heading for Pb-free with <260C at package top L L H U H 8 N U = unacceptable; ? = unknown; ++ = Opportunity á á á á á á á á ## Bottom lasering provides glueability. Plastic/mold release system ## in development with supplier. Risk-Level: L = low; M = medium; H = high; N = not relevant; á á á á á á á á Full qual plan completed 0DQXIDFWXUDELOLW\3URFHVVDELOLW\ Packaging RQ á á Page 11 At product release the WKM (Fig. A ,,.3.3) shows all requirements completed (##). Notes indicate what monitoring is committed during ramp-up and what documents explain the proper use of the released product (##). The data sheet and application notes belong together, both reflect the final device specification. The device marking outlines the maximum Tj. An interim solution was established to maintain parts’ glueability for the customers’ SMD processing (##). Actual trend to Pb-free soldering is accounted for by goal setting of package top surface temperature of </= (260 -5/+0)C and plans for looking into necessary assembly material and/or process changes for acceptable MSL as part of future development work (##). F.W.Wulfert - NPI Quality MUC Motorola SPS

© Copyright 2026