(E)-3-(N-oxide-methylimino)indolin-2-one

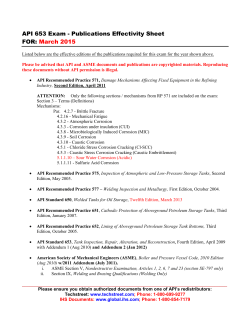

Structure, anticorrosion and antibacterial evaluation of (E)-3-(N-oxide-methylimino)indolin-2-one Hua-rui Hao1 , Cheng-hu Xue1 , Zhi- fang Zhang1 , Gang Chen2 * 1 School of Chemistry and Chemical Engineering, Yulin University, Yulin 719000, People’s Republic of China 2 College of Chemistry and Chemical Engineering, Xi’an Shiyou University, Xi’an 710065, China *Corresponding author: [email protected] Abstract: A nitrone, 3-(4-hydroxyphenylimino)indolin-2-one, was synthesized and analyzed by X-ray single crystal analysis. The inhibition and the mechanism of the title compound on the corrosion of high protective Q235A steel in HCl solution were screened and discussed by weight loss and electrochemical measurements. The results indicated that it can inhibit the corrosion with moderate inhibition efficiency in different conditions, and the inhibition mechanism of the corrosion inhibiting may be mainly contributed to the adsorption. It was screened for antibacterial activity against oilfield water-borne bacteria, and it showed good to moderate activity against sulfate reducing bacteria. Keywords: isatin; nitrone; corrosion inhibition; adsorption; microbiologically influenced corrosion Introduction Nitrone have been largely employed in organic chemistry. The importance of the nitrone functionality has been revealed by the growing number of scientific papers which appeared in the literature over the last years concerning nitrones and related compounds. Nitrones are easily prepared by several methods well-documented in the primary literature. The most used includes condensation reactions between carbonyl compounds and oxidation of amines, imines or hydroxylamines. Isatin is a compound found in Strobilanthes cusia (Nees) Kuntze and many other plants such as genus Isatis, Calanthe discolor LINDL, Couroupita guianensis Aubl. and in mammalian tissue[1]. It has versatile bioactivity and it is used to synthesize a large variety of heterocyclic compounds in preparing drugs[3,4]. Isatin Schiff bases are reported to have antibacterial activity against Bacillus subtilis], Gram(+) and Gram(−) bacterial strains and Magnaporthe grisea[5,6] among others. The compound has been produced industrially and can thus be used for large-scale applications such as treating oilfield water before re- injection. Compounds, containing functional electronegative groups and p and/or π-electron in triple or conjugated double bonds, are found to be efficient as inhibitors against metal corrosion [7,8]. It has been commonly recognized that an organic inhibitor usually promotes formation of a chelate on a metal surface, by transferring p and/or π-electrons from the organic compounds to the metal and forming a coordinate covalent bond during the chemical adsorption[9-11]. Organic compounds, containing heteroatoms, such as sulfur, phosphorus, nitrogen and oxygen, together with aromatic rings in their structure are the major adsorption centers, and the Schiff bases, a condensation product of an amine and a ketone/aldehyde, are such typical molecules [12-14]. Some polydentate Schiff base compounds (PSCs) have been reported as effective corrosion inhibitors for various metals in acid media [13,15-17]. Several isatin derivatives have been reported as inhibitors in HCl solution[18-20], the aim of this work is to screen the inhibition of a nitrone, (E)-3-(N-oxide- methylimino)indolin-2-one, for the corrosion of mild steel both in high concentrated HCl solution and microbiologically influenced corrosion. Experime ntal Synthesis of (E)-3-(N-oxide- methylimino)indolin-2-one (E)-3-(N-oxide- methylimino)indolin-2-one was synthesized according to published methods (as shown in Scheme 1) [21,22]. Isatin (1 mmol) was dissolved in methanol (20 ml), 10 ml methanol solution of 1.2 mmol N- methyl- hydroxylamine was added dropwise. The mixture was refluxed for 1 h, until the disappearance of isatin, as evidenced by thin- layer chromatography. The solvent was removed in vacuo and the residue was separated by column chromatography (silica gel, petroleum ether/ethyl acetate = 1:1 v/v), to give the title compound. Natural evaporation gave yellow single crystals of the title compound suitable for X-ray analysis over a period of 4 d. X-ray Data Collection and Structure Refinement Intensity data for colorless crystals of compound 4 was collected at 150 K on a Bruker SMART 1000 CCD fitted with Mo Ka radiation. The data sets were corrected for absorption based on multiple scans and reduced using standard methods. The structures was solved by direct- methods[13] and refined by a full- matrix leastsquares procedure on F2 with anisotropic displacement parameters for non-hydrogen atoms, carbon-and nitrogen bound hydrogen atoms in their calculated positions and a weighting scheme of the form w = 1/[σ2 (Fo 2 ) + (αP)2 + bP] where P = (Fo 2 + 2Fc2 )/3). All hydrogen atoms were positioned geometrically and allowed to ride on their parent atoms, with d(N—H)=0.86 Å and Uiso(H)=1.2 Ueq(N), d(C—H)=0.93 or 0.96 (CH3) Å and Uiso(H)=1.2 Ueq(C) or 1.5 Ueq(C). Crystal data and refinement details were given in Table 1. Gravimetric measurements The corrosion tests were performed on Q235A with a composition (in wt.%) C: 0.22, P: 0.045, Si: 0.35, S: 0.05, Mn: 1.40, and Fe balance. The electrolyte solution was 2M HCl, prepared from analytical grade 38% HCl and distilled water. The concentration range of 3-(4-hydroxyphenylimino)indolin-2-one was employed as 100 mg/L and 1000 mg/L. All tests have been performed in deaerated solutions and at 60 ± 0.5℃. The gravimetric tests were carried out according to the People's Republic of China Standard of Petroleum and Natural Gas Industry (Evaluation method for behavior of corrosion inhibitor for produced water of oilfield, SY/T5273-2000) with a few modifications. Each test was done with three specimens at the same time to give reproducible results. Electrochemical measurements The electrodes were mechanically abraded with a series of emery papers (800 and 1,200 grades), then rinsed in acetone and double-distilled water before their immersion in the experimental solution. Electrochemical measurements were conducted in a conventional three-electrode thermostated cell. The electrode was inserted into a Teflon tube and isolated with polyester so that only its section (0.5 cm2 ) was allowed to contact the aggressive solutions. A platinum disk as counter electrode and standard calomel electrode (SCE) as the reference electrode have been used in the electrochemical studies. The potentiodynamic curves were recorded using a CS350 system connected to a personal computer. The working electrode was first immersed in the test solution for 60 min to establish a steady state open circuit potential. After measuring the open circuit, potential dynamic polarization curves were obtained with a scan rate of 0.5 mV/s. Corrosion rates (corrosion current densities) were obtained from the polarization curves by linear extrapolation of the anodic and cathodic branches of the Tafel plots at points 100 mV more positive and more negative than the Ecorr. Scanning electron microscopy (SEM) The surface morphology of the sample under study in the absence and presence of inhibitors was investigating using a Digital Microscope Imaging scanning electron microscope (model SU6600, serial no. HI-2102-0003) at accelerating voltage of 20.0 kV. Sampleswere attached on the top of an aluminum stopper by means of carbon conductive adhesive tape. All micrographs of the specimen were taken at 5009 magnification. Microbiological monitoring Viable counts of SRB, TGB and FB were determined with the ―most probable number‖ method, People’s Republic of China Standard of Petroleum and Natural Gas Industry, the national method of the bactericidal agent’s performance, SY/T 5890-1993). The produced water containing the three kinds of bacteria was gathered from Zichang Oilfield Factory, Yanchang Oilfield. Results and discussion Structure The X-ray structural analysis confirmed the assignment of its structure from spectroscopic data. Geometric parameters of (E)-3-(N-oxide- methylimino)indolin- 2-one are in the usual ranges. The atomic coordinates are displayed in Table 2, and the molecular structure is depicted in Fig. 1. The space-group is P-1(2) with a triclinic crystal system. The indol-2-one ring system is substantially planar, the angle of C2–N2–O2 is 121.359(279)°, and the angle of C2–N2–C9 is 123.272(262)°. In the crystal structure, typical intermolecular N—H…O hydrogen bonds are responsible for the formation of dimmers as shown in Fig. 2, and the hydrogen bonds parameters are included in Table 3. The π-π stacking between the planar moities is responsible for the formation of a one-dimensional network, and a packing diagram of (E)-3-(N-oxide- methylimino)indolin-2-one is depicted in Fig. 3. Inhibitor properties and mechanism Corrosion can be defined as the degradation of a material due to a reaction with its environment. Degradation implies deterioration of physical properties of the material. This can be a weakening of the material due to a loss of cross-sectional area, it can be the shattering of a metal due to hydrogen embrittlement, or it can be the cracking of a polymer due to sunlight exposure. The use of corrosion inhibitors has been considered as the most effective method for the protection against such acid attack. Some inhibitors, such as imidazoline, Mannich base, Schiff base and some other heterocyclic compounds, have been employed in this process, but the concentration or the price is too high to be acceptable. In the following work, the performance of the title compound as an inhibitor with the concentration from 100 to 1000 mg/L in 1M and 2M HCl under the temperature from 30 ℃ to 65 ℃, and the results were summarized in Table 4. From the table, it was found that almost all the IE increases along with the concentration of inhibitor, but there is difference in the two concentrations and different temperatures, and it reaches to 83.2% with the concentration of 1000 mg/L in 1M HCl solution, further increase of the inhibitor does not increase the IE. The inhibition mechanism of the corrosion inhibiting may be mainly contributed to the adsorption. The process of adsorption is governed by the chemical structure of these inhibitors. The presence of N, O, S atoms and conjugated bonds in the structures makes the formation of p–d bonds resulting form the overlap of p electrons to the 3d vacant orbital of Fe atoms, which conforms the adsorption of the compounds on the metal surface [23]. The inhibitive performance of (E)-3-(N-oxide- methylimino)indolin-2-one can be explained on the presence of polydentate nitrone and indolin which rises the possibility of transferring the unshared electron of this molecule to iron [24]. The molecules may absorb on the ion surface by the coordinate covalent bonds with the 3d vacant orbital of Fe atoms in the manner described in Figure 1 to form the protective film. The possible reaction centers are unshared electron pair of heteroatoms and/or p-electrons of aromatic ring. The schematic illustration of different modes of adsorption on metal is shown in Fig. 4. Tafel polarisation measurements The anodic and cathodic polarization results were shown in Fig. 5. Table 5 shows the electrochemical corrosion kinetic parameters. As it was expected both anodic and cathodic reactions of mild steel electrode corrosion were inhibited by the increase of the title compound. It means that the addition of the (E)-3-(N-oxide- methylimino)indolin-2-one can reduce anodic dissolution and also retards the hydrogen evolution reaction. With a concentration of 1,000 mg/L, the additive exhibits maximum IE of 80.1%. The extract causes changes in the anodic, cathodic Tafel slopes and the Ecorr values in the presence of different concentrations. Ecorr, βa and βc values do not change appreciably with the addition of the inhibitor, which indicates that the inhibitor is not only interfering with the anodic dissolution or cathodic hydrogen evolution reactions independently but also acts as a mixed-type (anodic/cathodic) of inhibitor. Increasing IE with increasing concentration of the AE shows that the inhibition actions are due to its adsorption on the steel surface [24]. The IEs gotten from potentiodynamic polarization were quite different from that from weight-loss measurements, which is due to the fact that the weight- loss method gives average corrosion rate, whereas electrochemical method gives instantaneous corrosion rates. Scanning electron microscopy To evaluate the conditions of the steel in contact with 2M HCl acid solutions, SEM investigation was carried out as shown in Fig 7. In this figure, a shows the SEM image of the polished steel sample, b shows SEM images of the surface of the steel specimens after immersion in 2M HCl solution without inhibitor for 4 h, which shows the result of cracks caused by acidic corrosion attack. The status in c shows the surface of the steel specimens immersed for 4 h in 2M HCl solutions containing 1000 mg/L inhibitor, and the surface appears smooth, which is much less damaged than that without any inhibitors. This was due to adsorption of (E)-3-(N-oxide- methylimino)indolin-2-one on the steel surface, which accords with the mechanism analysis above. Bioactivity Corrosion is an electrochemical process leading to the deterioration of materials that can be caused or accelerated by microbiological activity, so called Microbiologically Influenced Corrosion (MIC). It is estimated that 30-50% of the corrosion cases are a result of microbial activity. MIC caused by growth of sulfate reducing bacteria (SRB), iron bacteria (IB) and total general bacteria (TGB) in oil pipelines, is considered a major problem for water treatment in the oil industry. MIC can result in different types of attack: pitting, crevices, dealloying and erosion in pipelines [21]. Corrosion products produced by microorganisms are production of hydrogen sulfide, molecular hydrogen, hydrogen ions and destabilization of metal oxide films. In addition, microbial degradation of crude oil can lead to increased acidity in the oil phase, and oil containing acids is a problem concerning corrosion of pipelines. The reported results showed that the interaction of IB, SRB and TGB accelerated the corrosion rate, and the corrosion in the mixture of IB, SRB and TGB was more serious than in a single microbial system. If this is the case, different treatment system to inhibit corrosion should be considered, among which bactericide agent has received the greatest acceptance. Currently, oxidizer, aldehyde, quatemary ammonium salt and heterocycle compounds has been used as bactericide agents, and Cl2 , ClO 2 , formaldehyde, pentane-1,5-dial, trichloroisocyanuric acid (TCCA) [25], but the toxicity tests have been conducted on a limited selection. The antifungal activity of (E)-3-(N-oxide- methylimino)indolin-2-one against oilfield microorganism was tested under the concentration of 0.20g/L and 0.02g/L, and the results were summarized in Table 6. From the table, it can be found that (E)-3-(N-oxide- methylimino)indolin-2-one is antifungal active against SRB and IB, but inactive against TGB under both concentrations. Conclusions (E)-3-(N-oxide- methylimino)indolin-2-one was synthesized and the its inhibition and the mechanism on the corrosion of high protective Q235A steel in HCl solution were investigated by multi- method. It can inhibit the corrosion with moderate inhibition efficiency in different conditions and the highest reaches to 83.2% with the concentration of 1000 mg/L in 1M HCl solution. Besides, it displays potent activity against the oilfield water-borne bacteria, especially for SRB and IB. Acknowledgme nts This work was financially supported by the grants from National Science Foundation of China (21376189), Scientific and Technological Plan Projects of Shaanxi Province (2014TG-09) and Scientific Research Program Funded by Shaanxi Provincial Education Department (2013JK0647). References [1] M. Yoshikawa, T. Murakami, A. Kishi, T. Sakurama, H. Matsuda, M. Nomura, H. Matsuda, M. Kubo, Chem Pharm Bull. 46, 886 (1998) [2] G. Chen, X.J. Hao, Natural Product Research and Development, 22, 356 (2010) [3] G. Chen, X.J. Hao, Q.Y. Sun, J. Ding, Chemical Papers, 64, 673 (2010) [4] G. Chen, H.P. He, J. Ding, X.J. Hao, Heterocyclic Communication, 15, 355 (2009) [5] G. Chen, J. Yang, S. Gao, H.P. He, S.L. Li, Y.T. Di, Y. Chang, Y. Lu, X.J. Hao, Molecular Diversity, 16, 151 (2012) [6] G. Chen, J. Zhang, Y. Tang, X.J. Hao, S.Z. Mu, Letters in Organic Chemistry, 8, 614 (2011) [7] M.A. Quraishi, H.K. Sharma, Materials Chemistry and Physics, 78, 18 (2002) [8] J. Hong, K. Zhen-Peng, L. Yan, Corrosion Science, 50, 865 (2008) [9] K.M. Ismail, Electrochimica Acta, 52, 7811 (2007) [10] M. Benabdellah, R. Touzani, A. Aouniti, A. Dafali, S. El Kadiri, B. Hammouti, M. Benkaddour, Materials Chemistry and Physics, 105, 373 (2007) [11] N. Soltani, M. Behpour, S.M. Ghoreishi, H. Naeimi, Corrosion Science, 52, 1351 (2010) [12] G. Quartarone, T. Bellomi, A. Zingales, Corrosion Science, 45, 715 (2003) [13] S. Issaadi, T. Douadi, A. Zouaoui, S. Chafa, M.A. Khan, G. Bouet, Corrosion Science, 53, 1484 (2011) [14] J. Fang, J. Li, Journal of Molecular Structure: Theochem, 593, 179 (2002) [15] M. Behpour, S.M. Ghoreishi, N. Soltani, M. Salavati-Niasari, Corrosion Science, 51, 1073 (2009) [16] A. Yurt, A. Balaban, S. Ustun Kandemir, G. Bereket, B. Erk, Materials Chemistry and Physics, 85, 420 (2004) [17] K. Stanly Jacob, G. Parameswaran, Corrosion Science, 52, 224 (2010) [18] G. Chen, H. Su, Y. Song, Y. Gao, J. Zhang, X. Hao, J. Zhao, Research Chemical Intermediates, DOI 10.1007/s11164-012-0870-9 [19] M.A. Quraishi, I. Ahamad, A.K. Singh, S.K. Shukla, B. Lal, V. Singh, Materials Chemistry and Physics, 112, 1035 (2008) [20] I. Ahamad, R. Prasad, M.A. Quraishi, Corrosion Science, 52, 1472 (2010) [21] G. Chen, H.J. Su, M. Zhang, F. Huo, J. Zhang, X.J. Hao, J.R. Zhao, Chemistry Central Jounal, 6, 91 (2012) [22] G. Chen, Y. Wang, H.P. He, S.L. Li, L.G. Zhou, X.J. Hao, Acta Botany Yunnan, 29, 712 (2007) [23] F. Kajiyama, K. Okamura, Corrosion, 55(1): 74 (1999) [24] H.T. Liu, L. Huang, T. Li, Y.L. Gu, Journal of Chinese Society for Corrosion and Protection, 29, 154 (2009) [25] K.M. Riedl, A.E. Hagerman, Journal of Agricultural and Food Chemistry, 49, 4917 (2001) - O N+ O + N H O CH3NHOH N H Scheme 1 Synthesis of (E)-3-(N-oxide-methylimino)indolin-2-one O Fig. 1 Molecular structure of (E)-3-(N-oxide-methylimino)indolin-2-one Fig. 2 The inte rmolecular hydrogen bonds of (E)-3-(N-oxide-methylimino)indolin-2-one Fig. 3 The packing diagram of (E)-3-(N-oxide-methylimino)indolin-2-one Fig. 4 Absorption of (E)-3-(N-oxide-methylimino)indolin-2-one molecules on the ion surface Fig. 5 Typical polarization curves for corrosion of the steel in 2M HCl in the absence and presence of different concentrations of (E)-3-(N-oxide-methylimino)indolin-2-one (a) (b) (c) Fig. 6. SEM micrographs of steel samples after 4 h immersion (a) Blank; (b) Immersion in 2M HCl, (c) Immersion in 2M HCl + 1000 mg/L title compound Table 1 Experimental Data of (E)-3-(N-oxide-methylimino)indolin-2-one Crystal parameter data Crystal parameter data a (Ǻ) 6.951(6) Index ranges -4 ≤ h ≤ 5; -13 ≤ k ≤ 12; -11 ≤ l ≤ 12 b (Ǻ) 8.029(7) Reflections collected 3112 c (Ǻ) 8.658(6) Independent reflections 2190 α (º) 103.00(2) Reflections theta (°) 2.26 to 28.27 β (º) 98.46(2) Absorption correction transmission 0.9440 to 0.9861 γ (º) 115.40(1) Reflections with I≥2σ(I) 1427 Volume 408.67(514) Number of parameters 109 Z 2 Goodness-of-fit on F2 1.006 Density (mg/m3 ) 1.510 Final R indices [I﹥2s(I)] R1 = 0.1884; wR2 = 0.1323 0.112 R indices (all data) R1 = 0.0674; wR2 = 0.1027 F (000) 168 Refine different density -0.224 to 0.176 Crystal size (mm3 ) 0.20×0.22×0.30 Theta range for data collection (°) 1.9 to 27.3 Absorption coefficient Table 2 The atomic coordinates (in Å2 ) of (E)-3-(N-oxide-methylimino)indolin-2-one Atom x/a y/b z/c Atom y/b z/c O1 0.5293(4) 0.9571(3) 0.7060(3) O2 0.2534(4) 0.4094(3) 0.8098(3) H7A 0.46280 0.69720 1.03920 N1 0.3609(4) 0.7373(4) 0.4414(3) H7B 0.41060 0.83160 0.95380 0.62480 0.81270 0.94740 H1A 0.39390 0.81930 0.38800 C9 x/a H7C N2 0.3469(4) 0.5782(4) 0.7916(3) C2 0.3293(5) 0.5984(4) 0.6444(4) H5A C8 0.2151(5) 0.4427(4) 0.4873(4) C7 0.2381(5) 0.5349(4) 0.3659(4) H3A -0.06740 C1 0.4224(5) 0.7894(4) 0.6097(4) 0.0352(6) 0.2258(5) 0.1566(4) C3 0.0995(5) 0.2409(5) 0.4423(4) H4A H2A 0.08210 0.17900 0.52200 C6 0.4723(6) 0.7446(5) 0.9466(4) C4 C5 0.1483(5) 0.4288(5) 0.1986(4) 0.16280 0.49000 0.11850 0.0100(6) 0.1333(5) 0.2747(5) -0.02480 -0.00200 0.15070 0.24220 0.04570 Table 3 The intermolecular hydrogen bonds parameters of (E)-3-(N-oxide-methylimino)indolin-2-one D—H···A D—H H···A D···A D—H···A N1(i)—H1A(i)···O1(ii) 0.8593(32) 2.033(3) 2.8845 (46) 170.748(212) N1(ii)—H1A(ii)···O1(i) 0.8593(32) 2.033(3) 2.8845 (46) 170.748(212) *Symmetry codes: (i) −x+1, y+1/2, −z+2; (ii) −x+1, y−1/2, −z+2. Table 4 The corrosion inhibition efficiency of (E)-3-(N-oxide-methylimino)indolin-2-one Concentration HCl Concentration Temperature Inhibition Efficiency (mg/L) (M) (℃) (%) 100 1 30 16.4 100 1 45 25.5 100 1 60 18.9 100 2 30 12.0 100 2 45 13.8 100 2 60 15.6 200 1 30 32.2 200 1 45 20.8 200 1 60 22.1 200 2 30 16.51 200 2 45 17.9 200 2 60 18.9 500 1 30 15.3 500 1 45 79.3 500 1 60 65.9 500 2 30 48.1 500 2 45 35.7 500 2 60 57.8 1000 1 30 83.2 1000 1 45 67.9 1000 1 60 48.6 1000 2 30 68.8 1000 2 45 63.5 1000 2 60 33.3 Table 5 Potentiodynamic polarization parameters for the corrosion of the steel in the 2M HCl solution containing (E)-3-(N-oxide-methylimino)indolin-2-one Concentration (mg/L) −Ecorr (mV) Icorr βa βc 2 (μA/cm ) (mV/dec) (mV/dec) -- 0.4607 151.445 90.435 50 0.4647 141.906 100 0.4552 200 Corrosion rate (mm/a) IE (%) 155.21 1.8022 -- 107.112 166.59 1.3221 26.6 90.512 77.033 146.33 1.0519 41.6 0.4553 31.432 63.162 119.67 0.7986 55.7 500 0.4609 51.930 62.719 81.25 0.5574 69.1 1,000 0.4526 30.781 58.288 135.31 0.35880 80.1 Table 6 The antifungal activity of (E)-3-(N-oxide-methylimino)indolin-2-one against oilfield wate r-borne bacte ria Microbiotic Concentration /mL Concentration SIB IB TGB — 110.0 110.0 110.0 0.20 g/L 0.0 0.0 70.0 0.02 g/L 0.0 1.3 110.0

© Copyright 2026