building code requirements for concrete masonry - NCMA - E-Tek

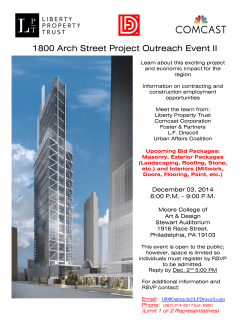

An information series from the national authority on concrete masonry technology BUILDING CODE REQUIREMENTS TEK 1-3D Codes & Specs (2011) FOR CONCRETE MASONRY INTRODUCTION The majority of jurisdictions in the United States adopt a national model code, most commonly the International Building Code (IBC) (refs. 1, 2), as the basis of their building code. The intent of the IBC is to reference and coordinate other standardized documents, rather than to develop design and construction provisions from scratch. With this in mind, the IBC masonry design and construction provisions are based primarily on Building Code Requirements for Masonry Structures (MSJC code) (refs. 3, 4) and Specification for Masonry Structures (MSJC specification) (refs. 5, 6). The code adoption process is shown schematically in Figure 1. In adopting the MSJC code and specification, the IBC can amend or modify some provisions. Similarly, depending on state laws, modifications can be made to the IBC at the state or local level to better suit local building practices or design traditions. However, most state codes require that any modifications to the IBC be more stringent than the corresponding requirement in the IBC. Because significant changes can be introduced into subsequent editions of both the MSJC and IBC, the edition referenced by the local building code can be an important consideration when determining the specific requirements to be met. Note that code officials will often accept more current design and construction standards than those referenced in the code, as they represent more state-of-the-art requirements for a specific material or system. To help determine which code provisions apply and highlight changes of note, this TEK outlines the major modifications to concrete masonry provisions of the 2009 and 2012 IBC, as well as the principal changes to concrete masonry provisions made between the 2008 and 2011 editions of the MSJC code and specification. Note that the scope of the MSJC code and specification covers structural design and construction. Related TEK: 1-2C, 9-2B, 12-6, 14-7C NCMA TEK 1-3D Hence, requirements for items such as fire resistance, sound insulation and energy efficiency are not addressed in the MSJC documents. 2009 INTERNATIONAL BUILDING CODE The 2009 International Building Code (ref. 1) adopts by reference the 2008 editions of the MSJC code and MSJC specification (refs. 3, 5). The MSJC code covers the design of concrete masonry, clay masonry, glass unit masonry, stone masonry, autoclaved aerated concrete (AAC), as well as Consensus process N a t i o n a l MSJC Code and Specification p r o c e s s adoption with modifications and additions International Building Code adoption, possibly with modifications State/ local process State or Local Building Code Figure 1—Masonry Structural Code Development Process Keywords: building codes, construction, masonry design, quality assurance, specifications 1 masonry veneer. The MSJC code requires compliance with the MSJC specification, which governs masonry construction requirements and quality assurance provisions (see also TEK 1-2C, ref. 7). Previous editions of the IBC either contained many of the same provisions as the MSJC, or contained conflicting provisions. The majority of the changes incorporated into the 2009 IBC were made to remove the redundant language and instead directly reference the MSJC. In addition, a reference to TMS 0302, Standard Method for Determining the Sound Transmission Class Rating for Masonry Walls (ref. 8), was included in the 2009 IBC for the first time. The 2008 MSJC Code and Specification Compared to earlier editions of the MSJC code and specification, updates included in the 2008 edition are summarized below. Masonry Design Changes to concrete masonry design provisions included: • For flexurally dominated (M/Vd > 1.0) special reinforced masonry shear walls designed by the allowable stress design method, a limit on the maximum flexural reinforcement used to resist in-plane loads was introduced. This limit does not apply when the axial load is less than or equal to 0.05f'mAn or when checking the reinforcement ratio in the out-of-plane direction. • A moment magnifier approach to determining P-delta effects was introduced for the design of unreinforced masonry using the strength design method. This procedure is presented as an alternative to a more comprehensive second-order analysis for determining bending moments. • Provisions for checking the size and spacing of openings in empirically designed masonry shear walls were added into the 2008 MSJC code. Previous editions were silent on the incorporation of openings in empirically designed masonry shear walls. • With the adoption of a formal strength design procedure into the MSJC code, the pseudo-strength design provisions previously in Chapter 2 (allowable stress design) were deleted. The pseudo-strength design method provided a method that the user could apply to scale the allowable stress design values up to a corresponding strength-level design for application with factored loads. • To help ensure the uniform distribution of prestressing forces, prestressed masonry is required to be laid in running bond unless a bond beam or other technique is used to distribute anchorage forces. Construction and Quality Assurance Specification revisions relative to concrete masonry included: • Tables 3, 4 and 5, outlining quality assurance requirements now include a minimum inspection frequency for each in2 spection task. Inspection frequencies are either: periodic, requiring intermittent observation of masonry work; or continuous, requiring full-time presence in the area while masonry work is underway. The tables were also reformatted for clarity. • The specification now allows bending of foundation dowels, up to 1 in. (25 mm) horizontally for each 6 in. (152 mm) of vertical height. This provision is similar to that used for reinforced concrete construction. • Provisions for the use of self-consolidating grout were incorporated into the 2008 MSJC specification. Self-consolidating grout is a specially-formulated masonry grout which does not require consolidation and reconsolidation by mechanical vibration or puddling. See TEK 9-2B, Self-Consolidating Grout for Concrete Masonry (ref. 9) for more information. • Previous masonry codes have required that grout be placed within 1.5 hours after water is introduced to the mix. The 2008 specification waives this requirement for transit-mixed grout as long as it meets the specified slump requirement. • The 2008 specification requires a grout key when grout is permitted to set between pours (grout keys are not permitted within masonry bond beams or lintels). The grout key helps provide structural continuity between the grout pours. This provision was previously only in the IBC. • A minimum lap length of 6 in. (152 mm) for splicing bed joint reinforcement was introduced. Previous editions were silent on determining minimum lap length of wire reinforcement. Differences Between the 2009 IBC and the 2008 MSJC The 2008 editions of the MSJC code and specification are included in their entirety (by reference) in the 2009 IBC. The IBC modifies several areas of the MSJC code and specification applicable to concrete masonry. The most significant of these are summarized below. In addition, quality assurance provisions are close, but not identical between the IBC and MSJC. Allowable Stress Design For masonry designed using allowable stress design procedures, the IBC: • modifies load combinations to be based on IBC section 1605, rather than those in MSJC code section 2.1.2.1, • modifies minimum inspections required during construction, • modifies the minimum required lap splice length for reinforcing bars. See TEK 12-6, Splices, Development and Standard Hooks for Concrete Masonry (ref. 12), for more detailed information, and • sets a maximum reinforcing bar size based on the size of the cell or collar joint where the reinforcement is placed. Strength Design For masonry designed using strength design procedures, the IBC modifies welded and mechanical splice requirements. Lap splices were modified such that they need not be longer than 72 bar diameters. NCMA TEK 1-3D Empirical Design For empirically designed elements, the IBC includes provisions for empirically-designed surface-bonded masonry walls and for adobe construction. 2012 INTERNATIONAL BUILDING CODE The 2012 International Building Code (ref. 2) adopts by reference the 2011 editions of the MSJC code and MSJC specification (refs. 4, 6). The following section highlights the major changes between the 2008 and 2011 MSJC code and specification. The 2012 IBC revisions to the MSJC remain largely unchanged from the 2009 IBC. In IBC Chapter 17, Structural Tests and Special Inspections, detailed inspection requirements were removed. The chapter now refers the user to the MSJC specification for inspection requirements. The 2011 MSJC Code and Specification The format of the 2011 edition was substantially changed, in that the right-hand side of each page is now reserved for commentary. Hence, commentary appears directly next to the applicable text, rather than in a separate section at the back of the document. Other substantive changes are summarized below. Masonry Design • Allowable stresses (Chapter 2) were recalibrated, resulting in the removal of the 1/3 stress increase for load combinations including wind or seismic loads. Hence, the ongoing conflict between the MSJC allowable stress design loading provisions which permitted the 1/3 stress increase and the ASCE 7-05 (ref. 10) prohibition of the 1/3 stress increase was eliminated. The MSJC committee used both research data and trial designs as a basis for the revisions. The correlation NCMA TEK 1-3D • • • • • • • between the strength predicted by the equations and the values bound by test is much better with the new provisions and this should increase confidence in the design. See TEK 14-7C, Allowable Stress Design of Concrete Masonry Based on the 2012 IBC & 2011 MSJC (ref. 11) for more detailed information. Allowable stress design and strength design shear provisions were harmonized. See TEK 14-7C for more information. A new Appendix B, Design of Masonry Infill, was added. Provisions for the design of deep beams were added. Lap splices are permitted to be reduced where transverse reinforcement is placed within 8 in. (203 mm) of the end of the splice if it is fully developed in grouted masonry. The beneficial effect of larger cover for computation of development length was changed. Strength of reinforcement in compression is permitted when checking the maximum reinforcement requirement but is still ignored when computing nominal strength. Commentary guidance on seismic coefficients for prestressed masonry shear walls was added. Construction and Quality Assurance • Anchor bolt installation requirements were revised. • For walls with laterally restrained or laterally unrestrained unbounded prestressing tendons, a revised equation was incorporated in the document. • Clarification was added to indicate that drips are not permitted in wire anchors and joint reinforcement cross wires and tabs. • Provisions for single pintle anchors were added. • Grout pour heights were increased slightly to 5' 4" (1.63 m) to accommodate modular construction dimensions. • Prism testing provisions for specimens cut from construction were included. 3 REFERENCES 1. International Building Code 2009. International Code Council, 2009. 2. International Building Code 2012. International Code Council, 2012. 3. Building Code Requirements for Masonry Structures, TMS 402-08/ACI 530-08/ASCE 5-08. Reported by the Masonry Standards Joint Committee, 2008. 4. Building Code Requirements for Masonry Structures, TMS 402-11/ACI 530-11/ASCE 5-11. Reported by the Masonry Standards Joint Committee, 2011. 5. Specification for Masonry Structures, TMS 602-08/ACI 530.1-08/ASCE 6-08. Reported by the Masonry Standards Joint Committee, 2008. 6. Specification for Masonry Structures, TMS 602-11/ACI 530.1-11/ASCE 6-11. Reported by the Masonry Standards Joint Committee, 2011. 7. Specification for Masonry Structures, TEK 1-2C. National Concrete Masonry Association, 2010. 8. Standard Method for Determining the Sound Transmission Class Rating for Masonry Walls, TMS 0302-07. The Masonry Society, 2007. 9. Self-Consolidating Grout for Concrete Masonry, TEK 9-2B. National Concrete Masonry Association, 2007. 10.Minimum Design Loads for Buildings and Other Structures, ASCE 7-05. American Society of Civil Engineers, 2005. 11.Allowable Stress Design of Concrete Masonry Based on the 2012 IBC & 2011 MSJC, TEK 14-7C. National Concrete Masonry Association, 2011. 12.Splices, Development and Standard Hooks for Concrete Masonry, TEK 12-6. National Concrete Masonry Association, 2007. NCMA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy and the application of the information contained in this publication. NATIONAL CONCRETE MASONRY ASSOCIATION 13750 Sunrise Valley Drive, Herndon, Virginia 20171 www.ncma.org To order a complete TEK Manual or TEK Index, contact NCMA Publications (703) 713-1900 4 NCMA TEK 1-3D

© Copyright 2026