ISO activity for Motorcycle OBD connector

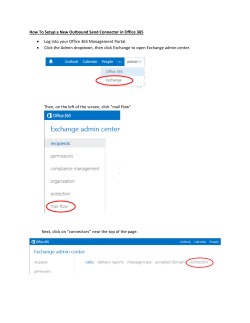

EPPR-09-16e ISO activity for Motorcycle OBD connector ISO/TC22/SC38/WG4 presentation at 9th L-EPPR Geneve, 12 January 2015 ISO/TC22/SC38/WG4 Members of SC38/WG4 Convenor: Koji Yamada (Suzuki) Secretary: Ayako Tsukiyama (JSAE) Active Experts from: JAPAN, ITALY, US Workplan of SC38/WG4 1. In June 2013 (Pontedera, IT) WG17 (Pollution and Energy) agreed to establish an OBD connector standard for motorcycles/mopeds exclusively. 2. In Oct 2013 (Vienna, A) SC38 agreed to organize a new WG dealing with the standardization activity for a Motorcycle dedicated OBD connector. 3. In March 2014 A New Work Item Proposal (NWIP) was officially approved by Pmembers. Workplan of SC38/WG4 4. In May 2014 (Turin, IT) The Kick-of meeting was held, agreeing the following: -- target and timeline of WG4, -- to define "one type of connector with 6 pins" in the standard, -- to go with a faster process (skipping WD stage and FDIS stage), 5. In Nov 2014 (Kyoto, JP) The 2nd meeting of WG4 was held, agreeing to submit the draft as CD. The next 3rd meeting is scheduled in Rome (IT) in May 2015. Target of SC38/WG4 Why we are not using ISO 15031-3 connector The existing OBD standards such as ISO15031 are for passenger cars. ISO 15031-3 is especially not applicable for motorcycles/mopeds since a connector for motorcycle/moped needs to satisfy specific requirements such as water-proofness and smaller size. Target of SC38/WG4 To define the ISO standard for a motorcycle/moped dedicated OBD connector: - meeting specific requirement for motorcycle/mopeds (waterproof, suitable size, optimized contacts, accessibility & anti-chemical fluid) - based on ISO 15031-3 for commonality and productivity Target of SC38/WG4 Target of WG4 is to standardize for; 1. Waterproof 2. Suitable size 3. Optimized contacts 4. Accessibility 5. Anti-chemical fluids Target of SC38/WG4 1. Waterproof Motorcycle does not have a watertight compartment. 5.7.4 Connector system performance requirements Extracted from ISO CD The connector system shall meet the performance requirements given in a) to e) of this sub clause, following performance of each of the environmental exposures according to 5.7.5. Measurements shall be taken at room temperature (23°C ± 5°C). Insulation resistance between adjacent contacts tested in accordance with ISO 8092-2:2005, 4.12:≧ 100 MΩ. Contact retention in housing tested in accordance with ISO 8092-2:2005, 4.7: ≧ 60 N. Connection and disconnection force tested in accordance with ISO 8092-2:2005, 4.3.1, fully equipped with 6 contact pairs: ≦ 75 N. Polarization features shall prevent mismating of connectors when a force of 150 N is applied. Waterproofness tested in accordance with ISO 8092-2:2005, 4.9.1.1.2: leakage current≦ 50μA at 48V and 4.9.1.1.3, Define waterproof toughness according to ISO 8092-2-2005. Target of SC38/WG4 2. Suitable size Car connector is not of a suitable size for compact motorcycles/mopeds Car connector New OBD connector for motorcycle Design new OBD connector 3 times smaller than car connector Target of SC38/WG4 3. Optimized contacts Only 6 pins are necessary/enough for motorcycles/mopeds. Eliminate unnecessary pins for motorcycle from car connector Target of SC38/WG4 4. Accessibility The connector shall meet the requirements for position/ accessibility/protection defined by EU regulation No.44/2014. (3.12) Extracted from EU regulation The preferred installation position is under the seating position. Any other position of the diagnostic connector shall be subject to the approval authority’s agreement and be readily accessible by service personnel but protected from tampering by non- qualified personnel. Smaller connector is necessary for limited space in motorcycle to meet requirement of EU Regulation N. 44/2014 Target of SC38/WG4 5. Anti-chemical fluids The connector for motorcycle could be influenced by chemical fluids such as engine oil, brake fluid, and engine coolant, etc. (4.23) Chemical fluids (4.23.1) Principle and application Extracted from ISO 8092-2-2005 The resistance to chemical fluids is only required for connectors likely to be exposed to such fluids. For this purpose, a list of chemicals and tests common to automotive use has been established (see Table 7). The vehicle manufacturer and supplier should choose the fluids and tests depending on the connector application. Define anti-chemical resistance according to ISO 8092-2-2005 Vehicle Side SCAN TOOL Side Comparison –reference2-wheel 4-wheel (ISO15031-3) Product Sealed 6 Pole Connector Unsealed 16 Pole Connector Terminal Tab Size Inch(mm) 025(0.64) 060(1.50) Area ratio 1 2.10 Cost ratio 1 Unknown Area ratio 1 1.54 Cost ratio 1 2.22 Appearance Appearance Timeline (original) SC22/WG17 in Pisa SC22/WG17 in Vienna Jun/2013 00: Proposal Oct/2013 Proposed Studying Standardization OBD connector May/2014 SC38/WG4 in Turin 10:NP New Working Group Kick Off Discussing for WD We are here Autumn/2015 Spring/2015 30:CD 40:DIS Spring/2016 50:FDIS Autumn/2016 60:IS Nov/2014 in Japan 20:WD NP : WD : CD : DIS : FDIS: IS : New Work Item Proposal Working Draft Committee Draft Draft International Standard Final Draft International Standard International Standard Timeline (revised) SC22/WG17 in Pisa Jun/2013 00: Proposal Proposed Studying Standardization OBD connector SC22/WG17 in Vienna Oct/2013 May/2014 SC38/WG4 in Turin 10:NP New Working Group Kick Off Discussing for WD We are here Autumn/2015 40:DIS Spring/2016 60:IS 6 months advance Spring/2015 Nov/2014 in Japan 30:CD NP : WD : CD : DIS : FDIS: IS : New Work Item Proposal Working Draft Committee Draft Draft International Standard Final Draft International Standard International Standard

© Copyright 2026