here - Smart Textiles and Nanotechnology

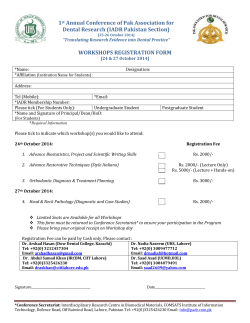

the news service for textile futures Electronic Textiles Ten sensors per fibre with XelfleX XelfleX, developed by the UK’s Cambridge Consultants, is a smart textile that turns garments into active motion sensors. It can be used to make comfortable, washable, robust clothing—and gives users information not available from existing wearables. Until now, smart fabrics have had multiple electronic sensors, making them cumbersome and sensitive to moisture. What makes XelfleX different is its fibre-optic thread which acts as the sensor—making a garment inherently smart. The only addition required is a small electronics pack, which clips on to the fabric – in a pocket, for example – and communicates with a smartphone. The technology could be used for fitness and sports coaching, but also as part of physiotherapy to help patients recover after injury, surgery or neurological problems. It could also be used for motion capture for gaming, film making and virtual reality applications, owing to its ability to make multiple accurate angle measurements. “Our aim was to create wearables that people actually want to wear,” says XelfleX inventor Martin Brock, of Cambridge Consultants. “With XelfleX, the garment itself is the sensor and it allows you to create smart clothing that is low-cost, durable, useful and attractive to wear.” Fibre-optics and radar XelfleX builds on the extensive experience of Cambridge Consultants in industrial fibreoptic sensors and low-cost impulse radar. When a pulse of light is transmitted down an optical fibre, a very well-defined amount of light is scattered continuously along its length. Bending the fibre results in increased scattering and reflection, which can then be measured. By integrating the fibre into a close-fitting garment, the movement of a joint can change the amount of bending at a defined sensor point in the fibre. Up to 10 sensors are possible along each fibre—with the initial light pulse sent by a light-emitting diode (LED) in the electronics pack. Algorithms then turn the results from the sensors into guidance that users can easily understand, giving feedback on their Issue 100 This is the 100th edition of Smart Textiles and Nanotechnogy, which was launched in November 2006. That very first issue revealed, among other things, that over half a million Softswitch textile sensor controls had already been integrated into clothing by brands such as Adidas, Burton, O’Neil and Zegna. It also reported that a Hong-Kong company called U-Right had installed capacity in China to add nanocoatings to ten million garments on a monthly basis. Where are they now? There was not a smartwatch to be seen and no mention of threedimensionally (3D) printed electronics, driverless cars or the internet of things. In this issue, the number of wearable devices at January’s Consumer Electronics Show (CES) in Las Vegas, Nevada, USA, is described as “staggering”. We will continue to serve as a filter for relevant developments at the interface of textiles, nanosciences and electronics in our efforts to provide context and insight into what remains an astonishingly fast-moving field. In another eight years’ time, 2006 will surely seem like a different planet. Adrian Wilson, Editor February 2015 http://www.technical-textiles.net ISSN 1752-2668 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net In this issue ELECTRONIC TEXTILES Ten sensors per fibre with XelfleX First piezoelectric fabrics WEARABLE TECHNOLOgIES Towards a driverless future at CES 2015 New route to reading the body Relieving pain with Quell 1 12 2 4 5 posture and movement, and coaching them on how to improve. It is the latest example of how technology can bring advanced sports technique training within the reach of any athlete. “XelfleX demonstrates the benefits of our ‘cross-fertilization’ of technology between very different sectors—it is at the intersections between industries that innovation often happens,” said Brock. “We’ve combined our extensive experience in wearable technology with our deep knowledge of industrial sensing and control to come up with a smart system design for a new generation of wearables.” Contact: Martin Brock, Cambridge Consultants. Tel: +44 (1223) 420024. [email protected]; http://www. CambridgeConsultants.com Wearable Technologies Towards a driverless future at CES 2015 Stretch electronic ink from DuPont Wearable technology: a materials goldmine 5 6 SMART FABRICS Lung monitoring with smart fabrics £2.8 million for UK smart fabrics development NovaBone promotes new growth Funding for advanced Ebola suit 3 7 9 10 THREE-DIMENSIONAL PRINTINg Three-dimensional metals, stone and wood 6 PRINTED ELECTRONICS Developer’s kit for three-diemensional electronics launched 7 NANOFIBRES Nanofibre media from PGI 8 gRAPHENE Elicarb graphene expansion at Thomas Swan 8 NANOCOATINgS New funding for C3Nano 8 SMART FIBRES Encapsulated infrared fibre from Kelheim 9 SMART MATERIALS Climbing the walls at Stanford 10 EVENTS Diary of Events 11 Wearable devices were everywhere at the 2015 Consumer Electronics Show (CES) held in Las Vegas, Nevada, USA, on 6–9 January. It is clear that the consumer electronics industry wants activity tracking and body monitoring to become the next compulsive displacement activity to follow scrolling through Facebook or checking emails. Despite the buzz and hype around such events, it is still far from clear that there is much consumer enthusiasm for these products beyond specialized sports circles. However, when even the UK tabloid newspaper the Daily Mirror lists its top ten favourite wearable technologies, it is clear the industry and media are opting to prise open a mass-market by brute force. “If there was one product category that was going to thrive at this year’s CES it was always going to be wearable technology,” the Daily Mirror said. “We identified it as a trend before the show and it’s even bigger than we thought.” Quantity “The sheer quantity of wearable tech products on show at this year’s CES is staggering,” Enni Charlton, a Buyer for John Lewis told the paper. “There are lots of weird and wonderful ideas on show, and while we wouldn’t expect every single one to become popular with the British public, one trend that’s clear is that manufacturers are striving to make their wearable products fashionable as well as useful.” Wearables, however, had to share the CES 2015 limelight with a number of other major emerging markets, including three-dimensional (3D) printing and drones. Perhaps most notable was the considerable presence with smart technologies of major car manufacturers including Audi, BMW, Ford and Mercedes—just days before the North American Auto Show in Detroit, Michigan, USA, opened on 12 January. The head of a collaboration between electronics maker LG and Audi used a smartwatch to summon the driverless Audi Prologue on-stage for the company’s press conference. The watch – which will be available in 2016 – started the car’s engine with a single tap. The remote parking of a BMW i3 research vehicle via a smartwatch was also demonstrated. The fully automated Remote Valet Parking Assistant in the car combines information from laser scanners with the digital site plan of a building, such as a multi-storey car park. This allows a driver to leave the vehicle and use a smartwatch to activate the fully automated system to drive it independently through the levels. The Remote Valet Parking Assistant recognizes the structural features of the car park and equally reliably steers around any obstacles that appear unexpectedly—such as incorrectly parked vehicles. Once the BMW i3 has arrived at the parking space, the vehicle locks itself and waits to be called by smartwatch and voice command. The system then calculates the exact time until the driver will arrive at the car park and starts-up the i3 so that it arrives at the car park exit at exactly the right time. 2 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net system brakes automatically. The vehicle is brought to a standstill very precisely with centimetres to spare. If the driver steers away from the obstacle or changes direction, the system releases the brakes. This relieves the burden on the driver in an environment with poor visibility and makes a further contribution to enhanced safety and comfort. Like all BMW assistance systems, this research application can be overridden at any time by the driver. BMW has succeeded in achieving fully automated control of the vehicle by connecting-up vehicle sensor systems and a digital site plan. This avoids dependence on the GPS signal, which is not at all precise in multi-storey car parks. Alongside the laser sensors, the research vehicle also has the processing units and necessary algorithms onboard to determine its exact position in the car park, monitor the environment and carry out independent and fully automated navigation. Contact: Nikolai glies, Business and Finance Communications, BMW. Tel: +49 (89) 382-24544. [email protected]; http://www.bmwgroup.com Collision avoidance BMW’s platform for 360-degree collision avoidance involves secure position and environment recognition. Four advanced laser scanners record the environment and reliably identify impediments such as, for example, columns in a multi-storey car park. If the vehicle approaches a wall or a column too quickly, the Smart Fabrics Lung monitoring with smart fabrics Freudenberg and Swisstom Ag have developed a system that combines electrical impedance tomography (EIT) with an electrode belt, for the real-time monitoring of the human lungs. The SensorBelt is positioned around the patient’s chest and provides what has not previously been possible—a window into the lungs. Every year, almost 50 million patients throughout the world are placed on ventilators, whether in operating rooms or in intensive care units. Around 15% of patients in the intensive care units suffer acute respiratory failure and 39% of these die. In the US, more patients die from acute respiratory failure than from breast cancer. Optimum respiratory therapy saves lives. It is important to monitor the effects of ventilation on the fragile tissue of the lungs. This is where the EIT system with the SensorBelt comes into play. The sensors use the principle of EIT without x-rays. Alternating current flows through the patient’s body creating voltages on the surface of the body. These voltages change rhythmically as the patient breathes. The sensors in the SensorBelt pick up these very small changes in voltage, and a computer uses the measurements to create real-time images of the lungs. To ensure contact between the electronic systems and the patient’s skin at all times – even under the difficult conditions of intensive care units – the electrode belt must fit the patient like a second skin. A tight fit is ensured by the enmech flexible circuit in which the 32 sensors are installed. The skin-friendly outer nonwoven fabric protects both the body and the electronic systems against environmental effects. The nonwoven consists of very fine polyurethane (PU) fibres—a backing material also used for wound dressings. The fibres can be spun to form a very tight fabric that still remains breathable and elastic. Rapid recognition “This is a considerable benefit to intensive care medicine,” says Dr Christian Karagiannidis, a Senior Pneumologist at the CologneMerheim Lung Hospital in Germany. “With seriously ill patients, continuous monitoring allows us to optimize mechanical ventilation and to recognize any pathological changes very rapidly.” He has already tested the product in practice. In contrast to the large remote CT scanners that deliver static images of lung structures, the small bedside EIT system with the SensorBelt allows continuous monitoring of the patient’s lung function without negative effects of radiation. Freudenberg Nonwovens contributes its skin-friendly nonwovens to the product, in combination with flexible circuit boards developed by sister company enmech. ©2015 International Newsletters Ltd Flexible “We had to find a material that was flexible and would adapt well to the patient’s body while remaining stable and retaining its shape, even after having been exposed to body fluids and warmth and after 3 February 2015 http://www.technical-textiles.net mechanically ventilated patients in intensive care and during general anaesthesia. Users of its products include intensive care specialists, anaesthetists and nursing personnel. In contrast to conventional tomography methods, the images of Swisstom systems are generated by EIT. Contact: Indira Sadikovic, Freudenberg Corporate Communications North America. Tel: +1 (734) 354-5505. [email protected]; http://www.freudenberg.us Wearable Technologies New route to reading the body opening and closing it for several times,” explains Katja Herbrand, European Medical Sales Manager at Freudenberg Nonwovens. enmech meanwhile, is able to produce flexible circuit boards with a length of over one metre and to equip them with electronic components such as our EIT Chip. “These circuit boards have to comply with the highest possible quality standards,” says Dr Stephan Bohm, Chief Medical Officer at Swisstom AG. “Different-sized circuit boards are required for different body girths. enmech produces these circuit boards and also equips them with the electronic components required. This reduces electrical interfaces and eliminates the need for complex electrode cabling.” The quality of brazed joints is ensured by 100% automatic optical inspection (AOI). An individually adapted electric end-of-line (EOL) test ensures that the electronic systems function properly. The most stringent hygiene requirements apply to the integration of the flexible circuit board with the electrodes into the nonwoven fabric. The EIT system with the SensorBelt may prove to be a life-saver for many patients. “The system has already been tested at various hospitals throughout the world and the feedback has been extremely positive,” says Bohm. The Swisstom system provides measured data and images of unprecedented quality, without any side effects or negative impact on the patient. “A world population that is both ageing and increasing will have considerable impact on the health market,” says Dr Mohsen Sohi of Freudenberg Group’s board. “We can play a key contribution in this field with our materials competence and product solutions.” Swisstom AG, headquartered in Landquart, Switzerland, develops and manufactures medical devices to monitor the lung function of Human sweat carries a significant amount of valuable information about the state of the body and scientists at several laboratories are currently working to develop flexible wireless sensors that are sensitive enough to detect a biomolecule found in sweat within 9.5 million litres (2.5 million) gallons of water. “We are developing small wireless sensors for measuring biological markers in sweat that affect our stress and energy levels,” says Scott Miller, Lab Manager for Nanostructures and Surfaces at GE Global Research. “We can do it with a blood test, but we’d like to detect the early signs of stress and fatigue non-invasively from sweat. The faster we can spot it, the earlier we can deal with it.” Miller and his team are working with the University of Massachusetts Amherst and the University of Cincinnati in Ohio, USA, on the project, which is partially funded by the Nano-Bio Manufacturing Consortium (NBMC) and the US Air Force. The body has two types of sweat glands—eccrine and appocrine. It is the appocrine glands, which are located in areas such as the armpits and the groin, that are active during stressful situations and produce thicker, oil-like perspiration. Body odour comes from bacteria feasting on this kind of sweat. “Nanotechnology can manipulate matter on the level of atoms and molecules and that’s why our receptors are so sensitive,” says Materials Scientist Azar Alizadeh, who is on Miller’s team. Receptors The receptors inside the sensors attract the biomarkers and convert them into electrical signals. The signals then travel wirelessly to a database for storage and analysis. “We are actually utilizing expertise in microfluidics that we typically apply to manipulate and improve the airflow and efficiency of our aircraft engines to direct the sweat over the sensor ever so precisely,” explains Alizadeh. “We create pathways and valves in the sensor itself to control where the sweat goes, so that we can get the most accurate measurement.” The target biomarkers include Orexin-A, which is a naturally occurring neuropeptide hormone released by the hypothalamus in the brain. It plays a crucial role in the stability of arousal and alertness. Another target is the stress hormone cortisol. Cortisol level changes during the day, but with the device, Miller’s team can get a dynamic reading and see in real time how a body responds to stress. 4 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net A patch developed at the University of Cincinnati uses paper microfluidics to wick sweat from the skin through a membrane that selects for a specific ion, such as sodium. Onboard circuitry calculates the ion concentration and sends the data to a smartphone. The electronics within the patch are externally powered, as in an RFID chip. The advanced wearable device is lightweight and can be worn during the day while active, and at night while sleeping. It has been cleared by the US Food and Drug Administration (FDA) for treatment of chronic pain without a prescription and users also have the option of using a smartphone to automatically track and personalize their pain therapy. The company expects Quell to be available for purchase by consumers in the second quarter of 2015. “Recent studies have shown that chronic nerve pain dramatically reduces the quality of life of people with diabetes,” said NeuroMetrix Chief Executive Officer (CEO) Shai N. Gozani. “We believe that Quell may help many of these people reclaim their lives.” Contact: Shai N. gozani, Chief Executive Officer, NeuroMetrix. Tel: +1 (781) 314-2761. [email protected]; http://www.nuerometrix.com The Air Force is interested in using the sensors to monitor pilots in order to understand and improve their performance, but the technology could have much broader civilian applications. “Physical and mental fatigue are factors for air traffic controllers, fire fighters, heavy-equipment operators, and many other professions,” Miller says. “The tiny sensors could also be useful in healthcare. One day we could be analysing electrolytes, metabolites and other molecular markers correlated with disease. We’re already doing this with patient monitors in the hospital, but this technology will cut the wires.” Contact: Todd Alhart, gE global Research Communications and Public Relations. Tel: +1 (518) 387-7914. [email protected]; http://www.ge.com Wearable Technologies Stretch electronic ink from DuPont Wearable Technologies Relieving pain with Quell DuPont Microcircuit Materials (MCM) has introduced a range of stretchable electronic ink NeuroMetrix, based in Waltham, Massachusetts, materials for use in smart clothing applications and other wearable electronics. USA, demonstrated an over-the-counter The materials provide a manufacturing-ready alternative to many wearable pain relief device called Quell, at the traditional methods of embedding electronics in clothing. The 2015 Consumer Electronics Show (CES) in Las DuPont materials have been used to create thin, form-fitting circuits Vegas, Nevada, USA. that can be seamlessly bonded with many standard fabrics, allowing Quell utilizes the company’s proprietary non-invasive neurostimulation technology to provide relief from chronic pain, such as that caused by diabetes, sciatica, fibromyalgia and degenerative knee conditions. It employs transcutaneous electrical nerve stimulation technology, known as TENS, which is already employed medically, for example to relieve pregnant women in labour. Once the passport-size device is strapped to the back of the calf and enabled, it sends electrical pulses to the nerves that signal the brain to release painrelieving opioids. Opioids released during a Quell session (as with other TENS products) do not come with the addictive euphoric feeling pharmaceuticals often induce, the company asserts, so addiction is unlikely. ©2015 International Newsletters Ltd for comfort and freedom in wearable electronic design. A working model of a biometric shirt that incorporates DuPont electronic inks was on display for the first time during Printed Electronics USA, in Santa Clara, California (19–20 November 2014). “We believe that this new line of DuPont stretchable electronic inks can be used in wearable electronics applications to make clothing more capable and comfortable,” says Michael Burrows, Segment Manager at DuPont MCM. “Imagine how smart athletic wear could help contribute to healthier, more active lifestyles by continuously monitoring vital information such as heart and breathing rates, calories burned and even stress level.” DuPont stretchable electronic inks deliver stable performance despite repeated elongation. A third-party evaluation of fabrics that 5 February 2015 http://www.technical-textiles.net Wearable Technologies Wearable technology: a materials goldmine In 2025 over US$25 billion will be spent on formulations and intermediate materials for wearable technology, according to analyst Dr Peter Harrop of IDTechEx. Companies at this early part of the value chain will enjoy a multiplier over the coming decade, he believes, participating in a rapidly growing market and taking a greater percentage of it as some incorporate these DuPont materials to create thin electronic circuits other parts of the value chain are eliminated. have shown them to be washable, durable and capable of “This is not because e-fibres will be used to create e-textiles from withstanding up to 100 wash cycles. They can also be used in many bandages to apparel,” says Harrop. “That is a longer-term prospect. common manufacturing processes to produce smart clothing, Instead, it is a matter of making today’s devices differently. They including fitness and outerwear, without significant investment. need to be made smaller, flexible, more comfortable, often invisibly DuPont plans to offer a full material range of conductors, hidden in or under clothing or transparent. Other items in the wish encapsulants and sensors for use in wearable electronics list will sometimes include being implantable, disposable and a applications, including: frequent request is that they should never be short of electricity. • DuPont PE872 stretchable conductor with encapsulation, which “Indeed, power running out after a few hours – a common is washable; inadequacy today – can be life-threatening with exoskeletons and • DuPont PE772 a stretchable, washable dielectric encapsulant. medical e-patches, and dangerous with planned glucose-indicating The growing portfolio of DuPont MCM electronic inks is used in contact lenses and wristbands for severe diabetics. many applications, including forming conductive traces, capacitor and resistor elements, and dielectric and encapsulating layers that are Structural materials compatible with many substrate surfaces including polymer, glass In most cases, the only way forward is to abandon the 100-year-old and ceramic. ‘components in a box’ approach of almost all manufacturers of Contact: Noelle Hagen, DuPont MCM. wearable technology today, Harrop asserts in the latest IDTechEx Tel: +1 (919) 248-5062. report, Wearable Technology Materials 2015-2025. [email protected]; Instead, structural electronics will be employed and smart http://www.dupont.com materials are key—which is good news for manufacturers of electronic and electrically functional materials that can be made into structures using those increasingly crucial intermediate materials. The industry needs to prioritize and de-risk its future investments, and the report finds large opportunities for organics, inorganics and composites. It tackles prioritization in different ways. First it looks at which materials are low-risk because they are useful in many different ways. Polyvinylidene difluoride, for example, is a “gymnast of chemicals” electrically. It and its derivatives can be electret microphone, ferroelectric memory, piezoelectric energy harvester and much more besides. Three-dimensional Printing Three-dimensional metals, stone and wood Entirely new forms of composites are likely to arise from the latest developments in materials for three-dimesnional (3D) printing introduced by MakerBot, at the 2015 Consumer Electronics Show (CES) in Las Vegas, Nevada, USA (6–9 January). Formulations IDTechEx also looks at the prevalence of different formulations that are being used in planned integrated devices for the future. For example, there is great interest in lithium, indium and titanium salts across a broad sweep of functions. III-V compounds feature strongly in next-generation products such as flexible displays and photovoltaics for low-light conditions. Carbon allotropes are being very broadly researched for wearables and allied markets but there is not much on C60 buckyballs. Graphene is of more interest for future batteries, supercapacitors, flexible displays etc. There are also many niche opportunities for smaller players such as those specializing in the chemistry of tungsten or tantalum, where many new uses are emerging. Similarly, although fluorocarbons have large potential, there are plenty of niche opportunities for other organics and some of these are very big ones. IDTechEx believes that The company is introducing polylactic acid (PLA) composite filaments made with composites of real metal, stone and wood that provide realistic and highly stabilized materials for the latestgeneration MakerBot Replicator 3D Printers. The new filaments are said to bring 3D printing closer to the look of a finished product, yet retain the non-toxic and ease-of-use properties that make PLA such a popular 3D printing material. The new MakerBot Replicator Smart Extruder has been specifically developed to match these new materials. Contact: Jenifer Howard, MakerBot. Tel: +1 (347) 676-3932. [email protected]; http://www.makerbot.com 6 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net many new morphologies and formats are needed from electronic printing inks to metal feedstock for the new higher-speed, lower-cost 3D printing. These challenges with the new formulations identified reduce competition and open-up opportunities for premium pricing. Contact: Dr Peter Harrop, Chairman, IDTechEx. Tel: +44 (1223) 812300. [email protected]; http://www.IDTechEx.com Smart Fabrics £2.8 million for UK smart fabrics development Researchers from Nottingham Trent University’s Advanced Textiles Research group (ATRg) and University of Southampton’s Electronics and Computer Science (ECS) in the UK are to receive £2.8 million to further develop new manufacturing methods for wearable technology. Printed Electronics The project is one of 10 to receive a slice of a £20 million funding pot from the UK’s Engineering and Physical Sciences Research Council (EPSRC). The project will allow ATRG to continue work on embedding electronics – light-emitting diodes (LEDs), sensors and microcontrollers – directly into yarns that can then be made into any number of products, from clothes to car seats. ATRG plans to improve its product by making the yarns even finer, allowing the production of items such as shirts with built-in, invisible sensors, micro-controllers and communication devices. It can now also develop the machinery it needs to begin a medium-scale manufacturing unit for the fibre electronics. Developer’s kit for three-diemensional electronics launched Functionality “I believe that fibre electronics will initiate a second industrial revolution in textiles,” says Professor Tilak Dias, who heads-up ATRG. “We are confident we have developed the platform technology for future electronic textiles, and this project will build on the results gained to date by ourselves and ECS in order to revolutionize the way that smart and interactive textiles are produced. The end-result will offer a greater level of functionality The company has also partnered with software company Autodesk, that is far beyond the state-of-the-art.” headquartered in San Rafael, California, to develop a new design tool Currently the group works with electronic components in the called Project Wire for creating 3D electronic devices printed on the form of packaged dies. Now, however, it wants to work with a Voxel8 machine. This will enable designers and engineers to create 3D stripped-down bare die that would allow it to make yarns that parts with embedded circuitry for the first time. are 0.2 mm in diameter rather than the current 0.9 mm it can “We are excited to work with companies like Voxel8, because they already produce. It will also mean more complex circuits can be are really pushing the boundaries of what 3D printing is capable of, and made, which will improve the variety of functions the fibres by incorporating conductive inks directly into 3D printing process, we can perform. can start to create things that have function after they are printed,” said A range of partners have identified the huge potential of the work Jeff Kowalski, Chief Technology Officer (CTO) of Autodesk. and are supporting it to the value of a further £430 000. These The Voxel8 developer’s kit will include the desktop 3D include Stretchline, the Defence Science and Technology Laboratory electronics printer, conductive ink cartridges, polylactic acid (PLA) (DSTL), Speedo, BSN Medical, Royal Centre for Defence Medicine, filament, modleling software and software support. The printer International Automotive Components, Plessey Semiconductors, allows dual material capabilities by combining a fused filament Urgo, the Centre for Process Innovation and MediCity. fabrication (FFF) printhead with a conductive silver ink printhead. “Working with academia and industry to support game-changing “Voxel8 builds on over a decade of research, which has led to 17 manufacturing projects like these is at the heart of the government’s patents (10 issued) on functional materials, printheads, and other industrial strategy,” said the UK’s Business Secretary Vince Cable. processes for 3D printing, from my lab,” said Dr Jennifer A. Lewis, “By supporting the jump from the manufacturing lab to the market Voxel8 founder and Wyss Professor of Biologically Inspired Engineering place, we are driving innovation, creating valuable new jobs and at Harvard University. “Our work provides the foundation for Voxel8’s delivering economic growth that will secure the UK's global effort to revolutionize multi-material 3D printing. To realize our vision, leadership for decades to come.” we have recruited a multi-disciplinary team with expertise in the Contact: Professor Tilak Dias, Advanced Textiles Research advanced materials, precision hardware, intelligent software and design.” group, Nottingham Trent University. Contact: Daniel Oliver, Voxel8. Tel: +1 (916) 396-3714. Tel: +44 (1158) 486518. [email protected]; [email protected]; http://www.voxel8.co http://www.ntu.ac.uk Voxel8, based in Somerville, Massachusetts, USA, has created the world’s first multi-material three-dimensional (3D) electronics printer and announced the pre-order availability of an initial developer’s kit priced at US$8999. ©2015 International Newsletters Ltd 7 February 2015 http://www.technical-textiles.net Nanofibres Nanofibre media from PgI Polymer group Inc (PgI) has introduced Everist brand filtration media as a nanofibre-based technology that offers enhanced mechanical efficiency, low pressure drop and excellent dirtholding capacity to companies in heating, ventilation and air conditioning (HVAC) or other industries reliant on highefficiency filtration media. Everist is said to outperform traditional mechanical media in multiple key areas including: • the media provides a higher initial efficiency and the same mechanical efficiency as glass, while providing the same initial efficiency and a higher discharge efficiency compared with synthetics; • the nanofibre technology provides half the pressure drop of glass media and is similar to electrostatically charged synthetics; • Everist doubles the dirt-holding capacity of synthetic composites and has a similar capacity to glass. It pleats on both rotary and blade pleaters and can be sonically welded. It is both more durable than glass and greener than traditional media. The launch of Everist represents the culmination of recent investments at PGI’s plant in Waynesboro, Virginia, USA. Contact: Catherine Fyfe, Marketing Communications, PgI. Tel: +44 (1621) 874273. [email protected]; http://www.polymergroupinc.com Nanocoatings graphene Elicarb graphene expansion New funding for C3Nano C3Nano, based in Hayward, California, USA, has at Thomas Swan raised US$12 million in Series C funding led by The UK’s Thomas Swan has started-up a new integrated pilot line for the manufacture of Elicarb graphene products. Nagase America Corp and a yet-to-be disclosed large-cap global industrial company. C3Nano is the developer of Active-grid, a nano-based, solutioncoatable transparent conductive material marketed as a substitute for indium tin oxide (ITO). ITO is one of the most widely used transparent conducting oxides because of its two chief properties – its electrical conductivity and optical transparency – as well as the ease with which it can be deposited as a thin film. As with all transparent conducting films, however, a compromise must be made between conductivity and transparency, since increasing the thickness and increasing the concentration of charge carriers will increase the material’s conductivity, but decrease its transparency. C3Nano materials have been proven to be more durable, mechanically stronger and more robust than ITO and no sputtering is required. They can be coated onto any substrate including glass, and flexible plastic films. The company’s conductive inks are formulated for high performance and superior mechanical properties for flexible, foldable and even stretchable electronic displays and devices. When coated onto plastic or elastomeric substrates, the films are capable of handling several thousand flexing cycles at greater than 50% strain. Depending on the application and manufacturing requirements, C3Nano’s transparent, conductive materials can be patterned via standard photolithography or printed directly onto a substrate, The plant is capable of producing 1kg per day of high-quality, fewlayer graphene nanoplatelets (GNPs) by the liquid exfoliation of graphite raw materials. It will provide a reliable supply of prototyping materials and further support the development of graphene-based applications for customers. “This is an exciting time for our business as interest in [research and development] R&D quantities of Elicarb has been high,” says Andy Goodwin, Commercial Director of the Thomas Swan Advanced Materials Division.“We now have the ability to provide larger quantities and work more closely with our customers on development of graphene technologies. The line also gives us the opportunity to optimize our unit operations for our next scale-up step, which we are already planning.” Elicarb graphene products are manufactured by a proprietary liquid exfoliation process that was developed in collaboration with Trinity College in Dublin, Ireland, and produces high conductivity, few-layer GNPs with average X-Y dimensions of 1 micron. Currently Elicarb is available as powder or dispersions and additional products will be available in 2015. Contact: Andy goodwin, Commercial Director, Thomas Swan.Tel: +44 (1207) 505131. [email protected]; http://www.thomas-swan.co.uk 8 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net eliminating costly, time-consuming and environmentally unfriendly process steps. The materials can be used with existing roll-coating or other production equipment so there are no capital equipment expenses and barriers to adoption are low. The company plans to use the new funding to expand its manufacturing capacity and also to support research and development (R&D) in relation to several complementary advanced materials and new products. “With Nagase’s leading position in the display and touch panel industry, and the deep background and operations of our undisclosed industrial partner, we see a clear path to expanding our reach into key markets and regions, so we are excited about deepening these relationships with our strategic investors,” said Cliff Morris, C3Nano Chief Executive Officer (CEO). “Their investments demonstrate a great vote of confidence in our technology and our people, and we’re looking forward to working closely with both companies.” Contact: Missy Bindseil, C3Nano. Tel: +1 830-237-9527. [email protected]; http://c3nano.com team. “We would be happy to adapt the fibre exactly to the demands of other applications depending on customer-specific needs. In the past, individual development partnerships have oft-proven very fruitful.” Contact: Matthew North, Commercial Director Kelheim Fibres gmbH. Tel: +49 (9441) 99-368. [email protected]; http://www. kelheim-fibres.com Smart Fabrics Smart Fibres Encapsulated infrared fibre from Kelheim NovaBone promotes new growth Kelheim Fibres, based in Kelheim, germany, has developed a viscose fibre that reflects infrared (IR) radiation. The NovaBone Bioactive Strip is a new bone graft composed of purified fibrillar collagen and resorbable bioactive synthetic morsels being introduced to the market by Novabone Products, based in Jacksonville, Florida, USA. The human body – like any other matter with comparable temperature – releases a large part of its energy via thermal radiation. This radiation is mainly composed of IR light. It leads to a loss of energy and therefore to a cooling of the human body. Kelheim says the newly developed viscose fibre with incorporated IR-reflecting particles can significantly reduce this process because thermal radiation emanating from a body is reflected by the particles incorporated in the fibre and sent back to the body, reducing cooling. In addition to this thermal retention function, the wearer of such a textile also benefits from the typical properties of a viscose fibre such as wearer comfort, softness and skin-friendliness. This is achieved by the intrinsic quality of the treatment – in contrast to a subsequent finish with additives based on titanium oxide, the mineral IR-reflecting particles are incorporated into the fibre’s core, preserving the typical fibre properties. The effect is permanent as the additive cannot be washed out. First test results have already been successfully manufactured on a pilot scale and show significant temperature effects in comparison with a standard viscose fibre. This opens-up a multitude of possible fields of applications. Used in functional underwear, the thermal effect can increase the well-being of the wearer even at low temperatures. In functional sportswear, the new fibre can lead to improved performance and a faster regeneration of the athlete, thanks to improved blood circulation. Together with textiles, different nonwoven applications could benefit from the IR-reflecting fibre, such as warming shoe inserts. “Comfortable feel-good clothes and functional special clothing are just two obvious applications for our new IR fibre,” said Dr Nina Köhne of the Kelheim Fibres’ Research and Development (R&D) ©2015 International Newsletters Ltd Its open structure allows for rapid vascularization and mineralization, and permits complete device absorption and replacement by new bone. The compression-resistant, formable and mouldable bone graft creates a highly osteoconductive matrix for new bone growth. The strip’s optimal composition and pore size is designed to mimic cancellous bone. “Last September, we announced the launch of the MacroFORM packable graft and MacroFORM composite, both designed to be hydrated with bone marrow aspirate and then moulded into a puttytype format as the first of a new bioactive collagen line designed for use in orthopaedic surgeries,” said Art Wotiz, President of NovaBone Products. “We feel the strip will be well-received because of its ability to absorb and retain bone marrow aspirate while being easy to handle and place.” The strip consists of 95% bioglass dispersed in a collagen matrix in a preformed shape that is cross-linked using a proprietary process avoiding the use of aldehydes, alleviating any concern of residual aldehyde contamination. After hydration with bone marrow aspirate, the device retains its shape even after manipulation. NovaBone Products was established in 2002 with a focus on developing bone graft substitutes based on advancements in biomedical engineering that would meet the specialized needs of orthopaedic and dental surgeons. It has developed numerous formulations and delivery systems of its patented, bioactive technology platform that result in accelerated bone growth. In total, its bone graft substitute has been used for the 9 February 2015 http://www.technical-textiles.net applications we’re thinking of involve manufacturing robots that lift large glass panels or liquid-crystal displays. We’re also working on a project with NASA’s Jet Propulsion Laboratory to apply these to the robotic arms of spacecraft that could gently latch on to orbital space debris, such as fuel tanks and solar panels, and move it to an orbital graveyard or pitch it towards Earth to burn up.” Previous work on synthetic and gecko adhesives showed that adhesive strength decreased as the size increased. In contrast, the engineers have shown that the special springs in their device make it possible to maintain the same adhesive strength at all sizes from a square millimetre to the size of a human hand. The current version of the device can support about 90 kg (200 pounds), and theoretically its size and effectiveness could be increased ten-fold. Contact: Mark R. Cutkosky, Fletcher Jones II Professor, Department of Mechanical Engineering, Stanford University. Tel: +1 (650) 450-0589 [email protected]; http://www.stanford.edu repair of osseous defects throughout the skeletal system for over a decade and used in over a million clinical applications. Contact: Dennis McBride, Vice President of Sales and Marketing, NovaBone. Tel: +1 (908) 287-2284. [email protected]; http://www.novabone.com Smart Materials Climbing the walls at Stanford The extraordinary ability of the gecko to form a strong bond with smooth surfaces with its toes and then release them with minimal effort is well known, but the downside of gecko-inspired adhesives to date has been that making them on a larger scale reduces their effectiveness. Smart Fabrics Researchers at Stanford University believe they are on the way to overcoming this problem in the development of a new synthetic adhesive that can share large loads very evenly and can create sufficient adhesion to allow a person wearing ‘gecko gloves’ to climb a glass wall. The adhesive climbing devices have been developed by researchers at Mark Cutkosky’s Biomimetics and Dextrous Manipulation Lab. Each hand-held gecko pad is covered with 24 adhesive tiles covered with sawtooth-shaped polymer structures each 100 µm in length. The pads are connected to special degressive springs, which become less stiff the further they are stretched. This characteristic means that when the springs are pulled upon, they apply an identical force to each adhesive tile and cause the sawtooth-like structures to flatten. “When the pad first touches the surface, only the tips touch, so it’s not sticky,” says Eric Eason, a graduate student in applied physics working on the development. “But when the load is applied, and the wedges turn over and come into contact with the surface, that creates the adhesion force. As with actual geckos, the adhesives can be turned on and off. You simply release the load tension, and the pad loses its stickiness. It can attach and detach with very little wasted energy.” “The ability of the device to scale-up controllable adhesion to support large loads makes it attractive for several applications beyond human climbing,” adds Mark Cutkosky. “Some of the Funding for advanced Ebola suit An advanced protective suit for healthcare workers incorporating technology originally developed for cooling patients in cardiac arrest has been developed by a research team at Johns Hopkins University and non-profit health organization Jhpiego. It has been selected for federal funding by the US Agency for International Development (USAID) through its new programme, Fighting Ebola: A Grand Challenge for Development. The suit is designed to do a better job than current garments in keeping healthcare workers from coming in contact with the contagious body fluids of Ebola patients, both during treatment and while removing a soiled suit. In addition, it is expected to keep the wearer cooler – an important benefit in hot, humid regions such as West Africa. Enhancements include a large clear visor in the hood, which is integrated into the suit, air vents in the hood, a rear zip to reduce infection risks while removing the garment, a cocoon-style doffing process that requires far fewer steps than existing garments and a small battery-powered, dry air source to cool the user by blowing air into the hood. “The funding from USAID will support moving our concepts into fully functional prototypes,” said Youseph Yazdi, Executive Director of the university’s Centre for Bioengineering Innovation and Design (CBID). “This will allow the team to do more detailed evaluations of our concepts, and quickly move to evaluations in the field. By the end of the funded timeline, we will have a product design that is ready to be taken-up by a major manufacturer, or several, for largescale production and distribution. Our goal is to follow the fastest path to get these concepts into the field and having an impact.” Contact: Phil Sneiderman, John Hopkins University. Tel: +1 (443) 997-9907. [email protected]; http://www.jhu.edu 10 ©2015 International Newsletters Ltd February 2015 http://www.technical-textiles.net Diary of Events FEBRUARY 2015 5–8 February ISPO Munich Munich, Germany. Messe München GmbH. Tel: +49 (89) 949-11388. Fax: +49 (89) 949-11389. [email protected] http://www.ispo.com 11–13 May Smart Fabrics & Wearable Technology San Francisco, California, USA. Stephanie Whitman, Marketing, Smithers Apex. Tel: +1 (207) 781-9616. [email protected] http://www.smartfabricsconference.com JULY 2015 2–4 July ISPO Shanghai Shanghai, China. Corinna Feicht, Messe München. Tel: +49 (89) 949-21477. [email protected] http://www.ispo.com MARCH 2015 4–5 March Nonwovens for High-performance Applications Cannes, France. Jill Gwinnutt, International Newsletters Ltd. Tel: +44 (870) 165-7210. Fax: +44 (870) 165-7212. [email protected] http://www.intnews.com/nhpa 4–11 July Nanotexnology 2015 Thessaloniki, Greece. Aristotle University of Thessaloniki. Tel: +30 (2310) 998091. [email protected] http://www.nanotexnology.com 31 March–1 April Expo Hightex and Advanced Workwear Canada Saint-Hyacinthe, Quebec, Canada. Aldjia Begriche, CTT Group. Tel: +1 (450) 778-1870. Fax: +1 (450) 778-3901. [email protected] http://www.gcttg.com APRIL 2015 9–11 April Technotex 2015 Mumbai, India. Federation of Indian Chambers of Commerce & Industry. Tel: +91 (11) 2348-7579. Fax: +91 (11) 2335-9734. [email protected] http://www.technotexindia.in SEPTEMBER 2015 11–13 September Hightex 2015 Istanbul, Turkey. Teknik Fairs Ltd Co. Tel: +90 (212) 876-7506. Fax: +90 (212) 876-0681. [email protected] http://www.hightex2015.com MAY 2015 4–7 May Techtextil Frankfurt, Germany. Michael Jänecke, Messe Frankfurt GmbH. Tel: +49 (69) 7575-6710. Fax: +49 (69) 7575-6541. [email protected] http://www.messefrankfurt.com 16–18 September Dornbirn Man-Made Fibers Congress Dornbirn, Austria. Austrian Man-Made Fibers Institute. Tel: +43 (1) 319-2909-40. Fax: +43 (1) 319-2909-31. [email protected] http://www.dornbirn-mfc.com Editor: Adrian Wilson Editorial Office Tel: +44 (870) 165-7211 Fax: +44 (870) 165-7212 [email protected] Published by International Newsletters Ltd, 44 Friar Street, Droitwich Spa, WR9 8ED, UK. Smart Textiles and Nanotechnology is published in 12 issues a year and online at http://www.technical-textiles.net ©2015 International Newsletters Ltd Subscription enquiries, orders and payments: International Newsletters Ltd, 44 Friar Street, Droitwich Spa, WR9 8ED, UK. Tel: +44 (870) 165-7210 Fax: +44 (870) 165-7212 [email protected] http://www.technical-textiles.net ©2015 International Newsletters Ltd, UK: No part of this publication may be reproduced, stored in a retrieval system, or transmitted by any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the publishers. Annual Subscription (12 issues) Worldwide Delivery and Online Access: £362/$615 ISSN 1752-2668 Printed by Kopy Kats, Worcestershire, UK 11 February 2015 http://www.technical-textiles.net Electronic Textiles First piezoelectric fabrics Teijin is introducing the world’s first piezoelectric fabrics for wearable devices based on polylactic acid (PLA) and carbon fibres. They have been developed with Professor Yoshiro Tajitsu of the Faculty of Engineering Science at Kansai University and comprise a piezoelectric poly-L-lactic acid (PLLA) and carbon fibre electrode. Plain-, twill- and satin-weave versions serve different applications—the plain weave detects bending, the satin weave twisting and the twill weave three-dimensional (3D) motion, as well as bending and twisting. The sensing function, which can detect arbitrary displacement or directional changes, incorporates Teijin’s weaving and knitting technologies and allows fabric to be applied to the actuator or sensor to detect complicated movements—even in three dimensions. Kansai University and Teijin will continue working on ideal weaves and knits for fabric applications that enable elaborate human actions to be monitored simply via clothing worn. Piezoelectricity is the ability of certain dielectric materials to generate an electric charge in response to mechanical stress. It also has the opposite effect—the application of electric voltage produces mechanical strain in the materials. Both of these effects can be measured, making piezoelectric materials effective for both sensors and actuators. Contact: Nana Saito, Corporate Communications, Teijin. Tel: +81 (3) 3506-4055. [email protected]; http://www.teijin.co.jp 3. CHOOSE HOW TO PAY AND SIGN FORM: ( ) I enclose a cheque payable to International Newsletters Ltd (£ sterling or US dollars only) ORDER FORM ( ) Please invoice me (company purchase order number:__________________________________) 1. PLACE YOUR ORDER: ( ) Please charge my VISA / MasterCard / Amex ( ) £362/$615—subscription for one year/12 issues. (Price includes first-class or airmail delivery worldwide, and free access to the online news service and back issues.) Card number: 2. FILL IN YOUR DETAILS: Cardholder’s name: Expiry date: Today’s date: Please supply cardholder’s address if different from 2. Title: Last name: Job title: Signature: First name/Initials: 4. RETURN YOUR COMPLETED FORM: Organization: Address: Country: Organization VAT number: Telephone: Email: Nature of business: Post/zip code: By fax: +44 (870) 165-7212 By email: [email protected] By post: Subscription Department International Newsletters Ltd, 44 Friar Street, Droitwich Spa,Worcestershire,WR9 8ED, UK Fax: Internet: By telephone: +44 (870) 165-7210 12 ©2015 International Newsletters Ltd

© Copyright 2026