A Performance Monitoring of Gas for Failure Prevention Turbines

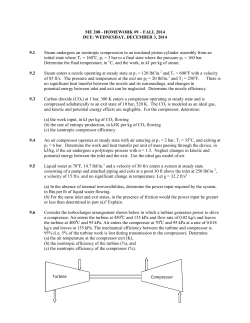

A THE AMERICAN SOCIETY OF MECHANICAL, ENGINEERS 345 E. 47 St., Now York, N.Y. 10017 S +s 92-GT-267 The Society shalt not be responsible for statements or opinions advanced in papers or in dia• cuenion at meatings of the Society or of its Divisions or Sections, or printed in its publications. Discuaslon is printed only If the paper is published In an ASME Journal. Papers are available from ASME forfifteen months after the meeting. Pentad in USA. Copyright © 1992 by ASME Performance Monitoring of Gas Turbines for Failure Prevention ROBERT E. DUNDAS Factory Mutual Engineering & Research Norwood, Massachusetts DANIEL A. SULLIVAN Technical Innovations, Inc. Sandwich, Massachusetts FRANK ABEGG Golden Valley Electric Association, Inc. Fairbanks, Alaska ABSTRACT Special Nomenclature The concept of performance monitoring for prevention of certain serious failures in gas turbines is described. The use of compressor mapping as the key to avoiding surge is developed, and an example is presented showing how the compressor in a steaminjected gas turbine can be much closer to surge in one of two nearly-identical operating points on a steaminjection control envelope than the compressor in the other. The technique of monitoring blade-path temperature spread in the exhaust of a gas turbine is then described, and examples of its value in preventing combustor burnout and turbine blade failures in highfrequency fatigue are given. Next, a concept of diagnosing internal deterioration by recognizing patterns of deviation of operating parameters from baseline data is described, and illustrated for a single-shaft generator-drive gas turbine. Finally, the use of a modern computer-controlled data acquisition system to perform the above monitoring functions in real time is demonstrated. CDP = Compressor Discharge Pressure (P 3 ) EGT = Exhaust Gas Temperature (T6) HR = Heat Rate-(W f /kW in any units) NOMENCLATURE c = specific heat at constant pressure-Btu/lb-°R (kJ/kg- K) h s = enthalpy of injected steam-Btu/lb (kJ/kg) H v = Heating value of fuel-Btu/lb (kJ/kg) N = rotor speed-rpm P = total absolute pressure-psia (kg/m2) P R = compressor pressure ratio Q = generator output at terminals-kW T = total absolute temperature- °R (°K) W a inlet airflow-lb/s (kg/s) Wf = fuel flow-lb/s (kg/s) W s = water or steam flow-lb/s (kg/s) d = pressure correction for compressor inlet flow y = ratio of specific heats n = efficiency n L = assumed mechanical and electrical efficiency of the load e = temperature correction for compressor inlet flow Subscripts c = compressor R = Standard day (reference) conditions It = turbine Numerical subscripts on P, T and c refer to the stations in Figures 1 and 2. Superscript * denotes corrected value. INTRODUCTION The concept of performance monitoring as an essential element of predictive maintenance and failure prevention for gas turbines is rapidly gaining acceptance throughout industry. This acceptance has been accelerated by the adoption of computer-controlled data-acquisition and control systems. These systems permit the on-line acquisition and reduction of a very large amount of performance information, as well as its manipulation for presentation to an operator in any manner considered useful. Performance monitoring has an important role in preventing certain types of failure; these are: compressor surge, compressor and turbine blade failure in high-cycle fatigue, burnout of combustors, and thrust-bearing wiping. This paper concentrates on the use of performance monitoring to prevent these very serious failures, and shows how modern control systems can be programmed to recognize and diagnose performance discrepancies that could result in those types of gasturbine failure. PERFORMANCE MONITORING Performance monitoring consists of using the supervisory instrumentation installed on a gas turbine to Presented at the International Gas Turbine and Aeroengine Congress and Exposition Cologne, Germany June 1-4, 1992 Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms CALCULATION OF ENGINE AIRFLOW--SINGLE-SHAFT GAS TURBINE recognize trends that indicate some internal discrepancy. It does not involve elaborate instrumentation to assess the exact performance of the machine for comparison with manufacturer's guarantees, or for similar purposes. That type of monitoring requires extensive traversing instrumentation to measure temperatures and pressures throughout the flowpath at various axial stations along the machine, as well as, possibly, a system to measure the airflow through the machine at either the inlet or the exhaust. By means of such instrumentation, the average temperatures and pressures at each station can be determined. However, such elaboration is not necessary for trending purposes to enable the operator to recognize and correct deterioration that might lead to surge or component failure, such as high-cycle fatigue of blades, or burnout of the combustor. All the instrumentation required for performance monitoring of a gas turbine for failure prevention purposes is usually in place. Figure 1 shows the stations of a single-shaft industrial gas turbine, indicating the instrumentation required for monitoring. This instrumentation measures static temperature and static pressure at key locations, and it should be installed in the casing at axial locations where the throughflow velocity is lowest--for example, the instrumentation at Station 3 should be installed downstream of the diffuser; in this way, the measured values will approximate the thermodynamic (total) parameters most closely. Fuel flow (and, if appropriate, injected steam or water flow) should also be measured. The following discussion outlines suitable algorithms for calculation of the airflow, as well as the turbine inlet temperature for the unit shown schematically in Figure 1. For simplicity a number of assumptions are required: 1. The injection of steam does not affect the thermodynamic properties of the gas flowing through the turbine significantly. 2. There is a 5 percent pressure drop through the combustor. 3. The thermodynamic properties of the working fluid are constant through the various components, and constant regardless of the operating condition; it is suggested that the values listed in Table 1 be used. Table 1 Assumed Properties of the Working Fluid for Performance Monitoring Station Specific Heat at Constant Pressure Btu/(lb-°R) 0.24 0.25 0.28 0.25 Ratio of Specific Heats kJ/(kg-°K) 1.005 1.047 1.172 1.047 1.40 1.40 1.33 1.33 (ye) (yc) (yt) (yt) The equation for airflow Wa is Stations: Wa= T P T 2 P 2 T 3 P 3 ( HWf + hsWs - ( Cp6Te) (Wf +WS ) ) - KQ /11 z, (1) C16 T6 — Cp2 T2 6 where K = 0.948 for Wa in lb/s, K = 0.239 for Wa in kg/s. 6 and the equation for the turbine inlet temperature T4 is +HvWf +h s Ws T = Cp3T3Wa f +W.) Cp4 (W.+W ° Load a (2) CALCULATION OF ENGINE AIRFLOW--AERODERIVATIVE GAS TURBINES Compressor Combustor Turbine Figure 1. Instrumentation required for performance monitoring on a single-shaft industrial gas turbine. No instrumentation is shown at the turbine inlet (Station 4), because the temperature at that location is such that the durability of the installed instrumentation would be in question. Instead, the exhaust gas temperature, measured by the ring of thermocouples at Station 6, is used to control the turbine inlet temperature to the desired limit. Some control and monitoring systems have algorithms in their software to calculate the turbine inlet temperature, as well as the airflow through the machine. These algorithms vary in complexity; this is of little consequence as long as they are used consistently in a program of performance monitoring. The typical aeroderivative is a two-shaft gas turbine. The following discussion on calculation of engine airflow, therefore, also applies to two-shaft heavy-duty gas turbines. It also applies to aeroderivatives having dual-rotor gas generators; the lowpressure and high-pressure compressors, as well as the low-pressure and high-pressure gas-generator turbines, are treated as a single unit. It must be noted, however, that this statement does not apply to compressor mapping, as will be discussed under that heading. The instrumentation required for an adequate program of performance monitoring of a two-shaft engine is shown in Figure 2. As in the case of a single-shaft machine, the parameters measured by the instrumentation of the figure are used to calculate values for the inlet airflow W a and the turbine inlet temperature T4. The values of Q, W f , and W s are measured. In contrast to the single-shaft gas turbine, the value of the efficiency n L of the load need not be assumed if all the indicated parameters are measured. Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms incidence. Figure 4 is a map of the compressor pressure-ratio/flow characteristics. It consists of a series of lines of constant corrected speed, each showing the pressure-ratio characteristic of the compressor vs corrected flow at that corrected speed. The concepts of corrected speed and corrected flow allow the effects of compressor inlet temperature and pressure to be taken into account, and, in fact, these concepts represent the tangential Mach number at the tips of the first stage blades, and the axial Mach number of the airflow entering the compressor. These parameters will be defined below in the section on compressor mapping for single-shaft gas turbines. Stations 5 7 8 13 T5 T T8 P3 P6 P7 P8 2 2.5 3 12 T3 P3 P 2 4 Figure 2. Instrumentation required for performance monitoring on a two-shaft aeroderivative gas turbine. The assumptions used for the single-shaft calculation are applicable. Table 2 gives the thermodynamic properties at the stations shown in Figure 2. Table 2. Assumed Properties of the Working Fluid for Performance Monitoring Station Specific Heat at Constant Pressure kJ/(kg-°K) Btu/(lb-°R) 1.005 1.047 1.172 1.11 1.089 1.047 0.24 0.25 0.28 0.265 0.26 0.25 2 3 4 5 7 8 Ratio of Specific Heats 1.40 (y c ) 1.40 (y c ) 1.33 (Y t ) 1.33 (Yt) 1.33 (Y t ) 1.33 (Yt) Figure 3. Damage to compressor of a heavy-duty industrial gas turbine due to surge. As corrected flow is reduced along a line of constant corrected speed, the pressure ratio increases until the stall of the blades is imminent. This point is considered the surge point, and the line joining these surge points at all corrected speeds is the surge line. It is the boundary line between surge and aerodynamic stability. Figure 4 also shows a typical curve of the operating points of a compressor in a gas turbine. This operating line is designed to assure a reasonable flow (or pressure- ratio) margin on surge, allowing for possible variations in installation features and engine deterioration or damage, each of which could lower the surge line and reduce the margin. The equation for airflow W a is we- (H3,Wf + h s Ws ) - cp ,T7 (Wf +Ws) (3) cp7 T7 -cp2 T2 The equation for the turbine inlet temperature T4 is T4 cp3 T3 Wa +Hv Wf +h s Ws(4 ) Cp4 (W.+Wf +W.) COMPRESSOR MAPPING Compressor surge is one of the most severe hazards in the operation of a gas turbine. When a compressor goes into "hard stall" or "deep surge," a series of shock waves passing back and forth through it is generated. These shock waves cause the blades to deflect, with two possible types of damage: 1) Clashing, or the deflection of the blades forward into the preceding row of stationary vanes, with possible fracture of blades and/or vanes, and extensive subsequent damage throughout the compressor, and 2) Clanging, or the differential tangential deflection of blades in the same row, with impact at the tips, resulting in bent or cracked tips. Figure 3 shows damage to a compressor in a heavyduty industrial gas turbine as a result of a surge. Compressor surge occurs when the airflow through the compressor is restricted in some fashion, and the compressor blades stall because of the resulting high Surge Line Operating Line d Lines of Constant Corrected Speed Corrected Airflow Figure 4. Compressor map showing surge and operating lines. 3 Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms One of the more important protective functions of the control system for a gas turbine is to avoid surge In single-shaft machines, the control system schedules fuel flow so that, at full throttle, a straight-line relationship between compressor discharge pressure (CDP) and exhaust gas temperature (EGT) is maintained as illustrated in Figure 5. This schedule is designed to keep the turbine inlet temperature (TIT) constant, but, in the absence of internal deterioration, the compressor cannot get into surge as long as this schedule is maintained. Compressor Discharge Pressure--Kg/cm 7 8 9 10 11 12 13 1100 2 14580 U rn 1080 560 0 a) 0 1060 1 1040 0) 1020 540 2 0 0 a- d a- 1000 520 E 980 E N N 960 3 a 500 940 X 920 w 900 130 0 L w 480 140 150 160 170 180 190 200 210 220 Compressor Discharge Pressure--Psia Figure 5. Typical schedule of exhaust gas temperature (EGT) vs compressor discharge pressure (CDP) for a single-shaft gas turbine. As noted above, the compressor of a single-shaft, industrial gas turbine can only get into surge if there has been some internal deterioration; this deterioration may result in moving the operating line toward surge, or it may lower the surge line, reducing the surge margin (Dundas, 1986). Two types of deterioration move the operating line toward surge: fouling of the compressor blades and closing down of the 1st stage turbine nozzles, restricting the airflow through the machine. Erosion of the compressor blades, particularly at the tips, lowers the surge line by lowering the pressure ratio at which the tips will stall, and, consequently, at which generalized stall of the compressor occurs. The rounded leading edges of the blades, and the locally increased clearances, result in poorly-defined incidences at the tips, and this condition degenerates into stall. Clogging or fouling of the inlet filters by dirt, or by icing, if nonuniform, may also trigger local pockets of rotating stall at pressure ratios below the surge line, providing a more ready transition to premature surge. It is well-established that compressors must be washed or cleaned before fouling becomes so severe that the compressor is in danger of surge. The need for washing is signaled by some deterioration of performance, such as an increase in heat-rate, or a reduction in CDP at full throttle. It is expected that washing will restore the performance: sometimes a series of online washings are performed to check and slow the rate of deterioration of the performance parameters, with periodic shutdown for a slow-speed cleaning to bring the performance back up to baseline (Thames, Stegmaier, and Ford, 1989). If this washing and cleaning process is not successful, the cause of the reduced performance must lie elsewhere; later in this paper, a scheme for determining the causes of performance deterioration will be described. Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms It is clear, however, that the performance deterioration that is really being addressed is a movement of the compressor operating line to the left-toward the surge line. It is obvious, then, that a determination of where the compressor is on that map is of more value than a simple review of the heat-rate. Changes in heatrate are caused by other factors, and the possibility of surge, or the proximity thereto, may be masked by other factors. A procedure of locating the operating points of the compressor on a compressor map would provide a much more reliable indication of the need for compressor washing. Water or steam is often injected into the combustors of gas turbines for NOx emission control. Additional steam may also be injected into the compressor discharge section for power augmentation. This additional mass flow may backpressure the compressor (since the first stage turbine nozzles run choked and control the total flow through the engine). Because such backpressure pushes the operating point on the compressor map toward surge, the total quantity of steam injected into the high-pressure airstream (HP steam) must be restricted. This is done by a schedule of HP steam flow as a function of CDP. Therefore, in the case of such engines a more persuasive case for compressor mapping can be made. Aeroderivatives have more parameters that vary with power setting, inlet conditions, steam flow, including, in the case of aeroderivatives with dual-spool gas generators, two variable rotor speeds. It is considerably more difficult to determine whether or not the compressor section needs cleaning, than in the case of the single-shaft constant speed gas turbine. An illustration will clarify this point. Figure 6 shows a plot of CDP vs HP steam flow (steam injection into the high-pressure (HP) section of the gas generator) for an aeroderivative gas turbine. The limiting steam-flow line specified by the manufacturer is shown. A number of operating points taken over a period of a few months are also shown; in particular, two almost identical points (Points 1 and 2) at part power are highlighted. Shortly after the filled-in point (Point 1) was recorded the gas turbine experienced a deep surge. However, there was no surge when Point 2 was taken. Further, the heat rates at the two points were identical. 450 •° a 31 440 430 v C) 30 KPPH = 453.6 kg7i 420 410 29 0' Point 2 400 u 0 390 380 E ♦ HP Steam Flow Limit 26 u ^o a E 360 350 t 0 27 ♦ y 0' 28 Incident (Point 1) 370 E i a' 0 25 30 40 50 60 70 HP Steam Flow—KPPH 80 90 Figure 6. Plot of HP steam flow vs CDP for an aeroderivative gas turbine. Points 1 and 2 are nearly-identical operating points at the steam control limit at part power. The control limit is shown. The operating points shown on Figure 6 were then plotted on a compressor map. The monitoring system used with the gas turbine has an algorithm to calculate an estimated airflow from the supervisory instrumentation readings; this is necessary for compressor mapping. The result of this mapping is shown in Figure 7. Point 1 is clearly to the left of the body of successful operating experience, and, therefore, is at least trending toward surge, while Point 2 is well within the probable stable region. The difference between the points having otherwise identical supervisory parameters was in the gas-generator exhaust temperature: at Point 1, the temperature was up against the limit, while at Point 2, the temperature was 60°F (33°C) lower. The possible effect of this difference on surge margin would not have been detected, however, without mapping the operating points. The pressure ratio is P3 Incident (Point 1)y, 0 rr 28 , 26 T2 ) The value of Y c from Table 1 or 2 may be used in (10). The above parameters of corrected airflow, pressure ratio, corrected speed, and compressor efficiency can be plotted on a compressor map for trending purposes. Figure 8 shows a composite map of efficiency vs corrected flow and pressure ratio vs corrected flow for three values of corrected speed. After a number of operating points are plotted in this fashion, the internal condition of the compressor can be evaluated readily. The figure shows the trends that can be detected. A reduction in airflow through the compressor indicates the need for washing. If washing does not correct the flow restriction, and, in particular, if the efficiency is distinctly lowered, the compressor should be opened, and the blades examined for erosion or other extensive damage. A baseline map should be developed over time to indicate where the compressor can operate successfully. The envelope of successful operating points should then be treated as a surge line. If surge or stall has been experienced, points on the actual installed surge line can be plotted. It can be shown that the corrected flow represents the Mach number of the flow through the compressor and that corrected speed represents the Mach number of the blades as they rotate. In a high-speed machine, such as an axial-flow compressor, these parameters have more significance with respect to performance than axial velocity and rpm. 4 ♦ /^1 d 25 24 T 23 22 260 270 sec = 0.454 k 5r 310 280 290 300 Corrected Airflow—Lb/Sec 320 1 (10) Point 2 • 27 Yc Yc P2 ^ Z o 29 (9) P2 The adiabatic efficiency of the compressor is given by Assumed Surge Line 30 = 3 R 32 31 P P 330 Figure 7. Compressor map for aeroderivative gas turbine showing typical operating points, as well as the two nearly-identical operating points at the steam control limit in Figure 6. An assumed surge line is also shown. COMPRESSOR MAPPING--SINGLE-SHAFT GAS TURBINE Corrected flow and corrected speed are the actual airflow and actual speed multiplied by correction factors that account for variations in actual inlet temperature and pressure. The temperature correction is IE 99 0 T T(5) S I .82 and the pressure correction 6 is given by 81 16 P PZ(6) Ns=107% ,5 N4=100% o is S Nx =97.5% 13 12 where T 2 and P 2 are the actual inlet conditions, and T s and P are the selected standard conditions, such as 21° C 1294 °K) at sea level (14.7 psia or 76 cm Hg). The corrected airflow W* is then given by W4 ° W/ g vi 1, i a ,0 D O Good Com p ra ♦ ■ Im aired Com 6 7 (7) 1 Ib/s = 0.454• k5/s 20 21 22 23 24 25 26 27 Corrected FIow--W 4 Ib/s 28 29 30 and the corrected speed N* is N'— N Figure 8. Performance trending on a compressor map. ,/U (8) - 5 Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms COMPRESSOR MAPPING--AERODERIVATIVE GAS TURBINES It is even more important to include compressor mapping in a program of performance monitoring of aeroderivative gas turbines than it is for single-shaft machines. The former are much more complex aerothermodynamically, especially with the full steam injection systems currently employed, and simple approaches to assessing their health may not detect a compressor operating point that is toward the surge side of previous successful operating experience. The case history of the steam-injected aeroderivative gas turbine is a dramatic example of this possibility. Compressor mapping can be performed as described, using the data obtained from the instrumentation of Figure 2, together with Eqs. 3 and 4. In the case history referred to above, the gas turbine was a dual-spool aeroderivative, but it was not possible to map the LP and HP compressors individually, because P 2was not printed out in the performance logs, even €hough it was sensed. It is clearly important that this parameter be included in any printout of dual-spool aeroderivative parameters, so that any compressor deterioration that might lead to surge can be traced to the appropriate spool. BLADE-PATH TEMPERATURE SPREAD Monitoring the circumferential temperature spread in the plane of the engine or gas-generator exhaust is another important procedure for avoiding serious internal damage. Figure 9 illustrates the principle for a gas turbine having individual combustor baskets. A ring of thermocouples is placed in the exhaust, with a thermocouple in line with each of the baskets. This harness and the associated data reduction hardware may do double duty--measuring and averaging the temperatures to determine the control value of EGT, as well as recording the difference between the minimum and maximum readings (the blade-path temperature spread)-or there may be two harnesses--one for measurement of EGT, and the other for determining the spread. Blade-Path Temperature Spread may signify a problem with the fuel nozzles or with one or more of the combustors. Manufacturers often set operating limits on the spread. Following is a typical set of such limits: If spread is greater than 90°F (50°C), operator alert; If spread is greater than 108°F (60°C), shut down engine; If more than 5 thermocouples have failed, shut down engine; If more than 3 adjacent thermocouples have failed, shut down engine. The use of blade-path spread monitoring helps avoid three main types of internal problem, as discussed in the following sections. FUEL-NOZZLE MALFUNCTION Blade-path spread instrumentation can be used with pressure-measuring instrumentation in the fuel system to detect malfunctioning fuel nozzles. In many heavyduty industrial gas turbines operating on fuel oil, fuel is metered to each fuel nozzle by pressuresensitive valves known as flow-dividers. Pressure sensors can be located downstream of each divider, and upstream of each nozzle. If there is an excessive blade-path spread and a simultaneous fuel-pressure maldistribution, the problem can be traced to an individual fuel nozzle. COMBUSTOR BURNTHROUGH OR STRUCTURAL DAMAGE There are various causes of combustor damage, such as local burnthrough, structural failure, and heat distortion. These modes of damage can result in dangerous hotspots in the basket. These problems can be detected from the blade-path temperature spread, and corrective action may be possible before widespread combustor section damage occurs. The No. 4 combustor basket in a large industrial gas turbine ruptured, with the broken pieces passing into the turbine section and producing extensive impact damage. The blade-path spread had increased from 3040°F (17-22°C) to well over 100°F (55 ° C) during the previous week. The operator's logbook for two weeks was examined, and the individual thermocouple readings were plotted as shown in Figure 10. The plots show that at least one of the combustors must have had severe structural damage for at least a week prior to the incident. There was clearly sufficient warning of this, and the gas turbine should have been shut down at a much earlier stage to replace the damaged basket or baskets. The severe dip in the circumferential temperature pattern in Figure 10 does not correspond to the angular location of the No. 4 combustor. This is because the gas flow develops a circumferential swirl as it expands through the turbine, and the distortion pattern is rotated from the turbine inlet to the turbine exhaust. TURBINE BLADE FAILURE Combustors Temperature in Exhaust Plane Figure 9. Definition of blade-path temperature spread. Figure 9 shows the use of blade-path spread thermocouples for individual combustor baskets. The principle can also be applied to gas turbines having single annular combustors. In such configurations, a harness of from 6 to 18 equally-spaced thermocouples is used. Under ideal conditions, all thermocouples register the same temperature; conditions, however, are never ideal, and a pattern of circumferential temperature distortion exists. The degree of this distortion Control of blade-path temperature spread is also of importance in preventing turbine blade failures due to high-cycle fatigue as a result of resonant vibration. Uneven combustion results in a circumferential distortion of the gas flow into the turbine section. The distortion takes the form of circumferential variations of temperature, and, therefore, of pressure and velocity, with consequent circumferential variations of aerodynamic loading on the turbine blades as they rotate around the flowpath annulus. These distorted patterns of loading are comprised of sine waves, or harmonics, of all orders (numbers of complete sine waves seen by a blade as it passes through one revolution). Normally, the lower orders (1,2,3, and 4) would be strongest in such a pattern of distortion. Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms Thermocouples 1 1020 aa) 980 d 940 900 E 860 820 X w780 2 3 4 5 6 7 89 10 11 12 iiiuiuu 1Ii1iii •UUUhlii 1I•1 UtiáIUI 0 30 60 90 U 540 a) a' U 0 520 Q) E 500 480 460 a) 0 Q E Cr - N 440 0 L x 420 W 2 120 150 180 210 240 270 300 330 360 Figure 10. Deterioration of blade-path temperature spread in ten days prior to a severe combustor failure. 3 4 5 Harmonic Order Polar Angle--deg Figure 11. Relative strength of harmonics in the bladepath temperature spread pattern in an industrial gas turbine. MONITORING OF CYCLE PARAMETERS If a turbine blade has a low-order resonance, it will be excited by the corresponding harmonic. When the spread is low, the strength of the excitation may not be sufficient to initiate a fatigue crack in the blade; however, if the spread is allowed to increase significantly, the strength of the excitation and, therefore, the magnitude of the vibratory stresses in the blade, may result in fatigue failure. The operator of the gas turbine may never know whether such a low-order resonance (which would be a design fault) exists until the blade fails. It is necessary, then, to control the spread to the low level associated with good combustion to avoid such a possibility. This does not guarantee against blade failure, since the strength of the excitation may be excessive even at normal levels of spread (the response of the blade depends on a number of factors, among which is the damping available), but it guards against the possibility of aggravating an existing low level of resonant vibration. A certain model of industrial generator-drive gas turbine experienced a series of fatigue failures of turbine blades. It was determined that the natural frequency of that blade in its 1st bending mode was just about 180 cps, that is, it had a 3rd order resonance almost exactly at the operating speed of 3600 rpm. Operators of the machine were advised to maintain the blade-path temperature spread at a low level, using alarm and trip settings established by the manufacturer, until the appropriate redesign could be effected. A Fourier analysis was made of the temperature spread in one installation, with the spread at a fairly high value. The relative strengths of the low-order harmonics result are shown in Figure 11. The 3rd order, corresponding to the blade resonant order, proved to be the strongest; this indicated that the blade resonance was critical and should have been avoided. The only recourse available to an operator, however, was to monitor the spread and keep it as low as possible. A third technique of performance monitoring for failure prevention involves recognizing the patterns of deviation of the measured parameters from baseline data; this includes evaluation of the percent deviation to determine whether the indicated internal discrepancy has progressed to a dangerous extent. CYCLE PARAMETERS--SINGLE-SHAFT GAS TURBINES (Dundas, 1986) showed how the technique of deviation pattern recognition can be applied to detect internal discrepancies that could lead to surge for a single-shaft generator-drive gas turbine. The reference contained a chart of deviations for four discrepancies: 1. Fouling of the inlet filter or icing of the inlet; 2. Compressor fouling; 3. Compressor damage or erosion; 4. Closing of 1st stage turbine nozzles. Figure 12 expands on that chart to include turbine damage or erosion and opening of the 1st stage turbine nozzles. Each of the internal discrepancies has a distinct and unique pattern of deviation of the indicated parameters that permits it to be recognized. Appropriate maintenance action can then be taken. The data must be taken under conditions consistent with the baseline data. The compressor inlet temperature should be the same (baseline data could be taken at a number of inlet temperatures to provide a database for use at various later inlet temperatures). Data should also be taken at full throttle, i. e., right up against the EGT limit. Thus, the concept of deviation pattern recognition is most suitable for base-loaded gas turbines that generally run at full load. In addition to helping avoid surge, monitoring and correction of internal discrepancies can help avoid compressor and turbine blade failures due to resonant vibration (Dundas, 1982). Internal discrepancies leading to performance deterioration often disrupt the pressure balance across the rotor, and may result in wiping of the thrust bearing, particularly on the inactive face. Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms Operating Parameters P 2P3 13 Output Fuel Flow Heat Rate EDT + + = + 3 + + _ 4 4 + + = _ 4 y + 4 _ = 4 4 + 4 4 4 Fouling of Inlet Filter or Inlet Icing Compressor Fouling Compressor Damage or Erosion Turbine Damage or Erosion = 4 4 4 4., = 4 4 4 4 Opening of 1st Stage Nozzles Closing of 1st Stage Nozzles % CORR T +2 0 -2 +2 % CORR N 0 4 4 4 3, -2 +2 % COR R N -2 +2 Figure 12. Chart of performance-parameter deviation patterns for various internal discrepancies. % CORR P 0 -2 0 100 200 300 400 500 600 700 800 900 1000 Engine CYCLE PARAMETERS--AERODERIVATIVE OR TWO-SHAFT GAS TURBINES Figure 13a. Trends of cycle parameters characteristic of fouled compressors in aeroderivative gas turbines. Figure 12 presented a method for diagnosing internal conditions in a single-shaft gas turbine based on trending of the various parameters read by the supervisory instrumentation. It is very difficult to construct a similar chart for aeroderivative gas turbines, particularly those with dual-rotor gas generators. One of the reasons for this difficulty is the fact that the gas generator speed, or speeds, can vary, depending on the type of deterioration, independently of the power turbine output speed, which may be kept constant, as in a generator-drive application. Manufacturers have, however, compiled curves of the variations of the key parameters for some types of deterioration. Figures 13a, b, and c are typical curves for a dual-spool aeroderivative. The cycle parameters for trending are the corrected gas-generator exit temperature, the corrected gas generator speeds, and the corrected compressor discharge pressure; these parameters are expressed in percentages of maximum values to keep the numbers close to unity for easy comprehension of the trends. All parameters should be recorded at maximum power setting for the inlet temperature at which baseline data was obtained. Referring to Figure 2, and letting the subscript 0 refer to the baseline (undeteriorated) parameters, and with given by (5), the trending parameters are given by the following equations: Percent corrected gas-generator exit temperature (T5), S— T5—T50 T %T Hours +2 j % CORR T 5 j 0 -2 +2 % CORR N 0 -2 +2 % CORR N 0 -2 +2 % CORR P 0 Z 0 100 200 300 400 500 600 700 800 900 1000 Engine Hours Figure 13b. Trends of cycle parameters characteristic of fouled turbines or worn internal seals in aeroderivative gas turbines. - 2% CORR T x100 0 508 _2 (11) +2 0 Percent corrected low-pressure compressor speed (Ni), -2 +2 Percent corrected high-pressure compressor speed (N2), 11 = 0 -2 Nl —N1O x100 +2 7 CORK P 0 ( 12) Ni i -2 -4 0 100 200 300 400 500 600 700 800 900 1000 Engine ( %N • — NZ—NZ 0 N20 (13) Hours Figure 13c. Trends of cycle parameters characteristic of blocked or bowed 1st stage turbine nozzles aeroderivative gas turbines. 8 8 Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms and percent corrected compressor discharge pressure (P3), P3-P30 % ^73 l • P30 X100 (1k) P2 : IMPLEMENTATION OF PERFORMANCE MONITORING FOR FAILURE PREVENTION The techniques of performance monitoring described above can be implemented readily through computercontrolled data acquisition systems. The use of such systems in gas-turbine installations is becoming widespread throughout the utility, cogeneration, pipeline, and other industries. Selected data can be directed, either from the supervisory instrumentation directly or from the engine control hardware, to a separate analysis module. This separate software module can be programmed to perform the indicated calculations and to enter the results into pre-designed graphical formats. When called for by the operator through a workstation, the calculated information can be returned to the host computer and displayed numerically or graphically in real time on the workstation screen. The illustrations in the following sections were prepared using the Powerlog Process Monitoring System, available from Powmat Ltd. of Ballston Lake, New York. The software for performance analysis in this system was written by Dr. Daniel Sullivan, one of the authors of this paper. Off-line performance data from a large heavy-duty single-shaft unit was provided by another author, Frank Abegg. This data was used for the illustrations of compressor mapping and blade-path spread analysis. Since the units from which the data was taken have been on standby in recent years, they were not suitable subjects for deviation pattern analysis. The data was instead based on the model used in (Dundas, 1986). This model was idealized, but it does provide consistent results for illustration of the pattern analysis procedure. e••o, —'- wo Corrected Sp.sd--W 1b/s Real—Tana Operating Point 1 .: sao Assumed Surge Line Figure 14. Compressor map with operating points, as displayed on workstation screen. BLADE-PATH TEMPERATURE SPREAD The depiction of blade-path temperature spread in real-time at an operator workstation is readily effected using the Powerlog software. Figure 15 is an illustration of one possible display for an engine having individual combustor baskets. The distribution of pressures, as well as the pressure spread, to the fuel nozzles is also shown. The diagram of baskets and nozzles can be color-coded to show the angular locations of the highest and lowest readings. A further refinement could be to develop an algorithm to correct the diagram for the swirl effect. COMPRESSOR MAPPING The performance data indicated in Figure 2, taken over a single day was entered into a software module, and the calculations for airflow, corrected flow and pressure ratio (Equations 1,5,6,7,9) were performed for each point. The results were then entered into the Powerlog Graphics module and displayed on a workstation screen, as shown in Figure 14. A wide range of operating conditions is represented in the figure; such a wide range of conditions could be compiled over a longer period of time, and considered as representing the stable operating regime for the compressor. A putative surge line, representing the limit of successful operating points on the compressor map could then be drawn as shown (again using the algebraic and graphing capabilities of the analysis module). This line could be saved permanently in the compressor-map format file. At the request of the operator at a workstation, the compressor map, including an assumed surge line based on previous successful experience, would be displayed on the screen with a real-time point. The operator could then judge whether the compressor was operating too close to the assumed surge line, and take the appropriate action (such as compressor washing) to move the operating point back to the more stable region. Figure 15. Workstation display of blade-path temperature and fuel-nozzle pressure spreads. DEVIATION PATTERNS The results of the parametric calculations performed for the study of (Dundas, 1986) were used to derive the deviation patterns for the various internal discrepancies shown in Figure 12. Figures 16a through e show how these would be displayed on the workstation monitor in real time, using the Powerlog analysis software. The software was programmed to read the indicated parameters for a given operating point (at the EGT limit) and to calculate the percent deviation from the baseline point at the same compressor-inlet Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms (a) (c) (b) (d) Figure 16. Workstation displays of deviation patterns. (a) Compressor fouling; (b) Compressor damage or erosion; (c) Closing of 1st stage turbine nozzles; (d) Opening of 1st stage turbine nozzles; (e) Turbine damage or erosion. 10 Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms temperature. These deviations were then plotted on bar charts having deviation warning limits as shown. The software was programmed also to recognize the patterns of deviation using logic equations, and to show the type of internal discrepancy existing on the display. Depending on the amount of the deviation from baseline, the operator can take the necessary action to correct the indicated internal discrepancy. This may be as straightforward as washing the compressor or cleaning the inlet filter, or it may entail dismantle of the gas turbine to inspect the compressor, combustor, or turbine section. Additional workstation displays can be devised to inform the operator of possible courses of action. Among these might be a check on the compressor operating point or blade-path spread (through the displays described earlier). Various additional monitoring features can readily be devised using a system such as Powerlog. For instance, the control system can be programmed to alarm when a selected parameter exceeds the preset deviation limit; the operator can then activate the deviation pattern display to assess the reason for the alarm and to initiate the indicated action. Maintenance efforts can be directed with maximum efficiency by this means. This study of implementation of deviation pattern analysis was applied to a single-shaft generator drive gas turbine, because a theoretical basis for it was available in the reference. Its application to a twoshaft gas turbine, and especially to an aeroderivative having a dual-rotor gas generator, would be much more complex. As far as is known, there is no existing theoretical basis for such an application, but, of course, one could be derived using the capabilities of current cycle analysis software. The benefits of such an effort would be even greater in terms of early recognition of internal discrepancy and optimization of Downloaded From: http://asmedl.org/ on 03/24/2015 Terms of Use: http://asme.org/terms maintenance efforts because of the number of components and the probable complexity of the deviation patterns. SUMMARY The three most important aspects of performance monitoring of gas turbines for failure prevention are compressor mapping, monitoring of blade-path temperature spread, and analysis of the patterns of deviation of measured cycle parameters. Compressor mapping is essential to determine if the compressor operating point is approaching the surge line because of compressor fouling or warping of the 1st stage turbine nozzles. Blade-path spread can forewarn of serious combustor damage due to faulty combustion for whatever cause. It should also be controlled to guard against the possibility of turbine blade failure in resonant vibration. Modern computer-controlled data acquisition systems are a very powerful tool for analysis of measured performance parameters on a real-time basis to recognize the existence of internal discrepancies rapidly, to diagnose them accurately, and to minimize maintenance and correction time. REFERENCES R. E. Dundas, "A Study of the Effect of Deterioration on Compressor Surge Margin in Constant-Speed, Single-Shaft Gas Turbine Engines," ASME Paper 86 -GT -177, 1986. J. M. Thames, J. W. Stegmaier, and J. J. Ford, Jr., "On-Line Washing Practices and Benefits," ASME Paper 89- GT -91, 1989. R. E. Dundas, "The Use of Performance-Monitoring to Prevent Compressor and Turbine Blade Failures," ASME Paper 82- GT -66, 1982.

© Copyright 2026