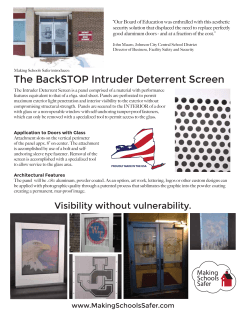

Fabricator Front Cover alt01.qxd