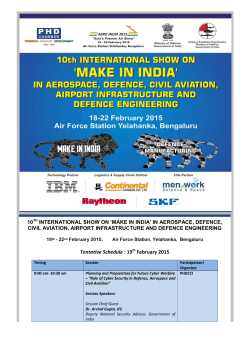

Magazine