Document 85642

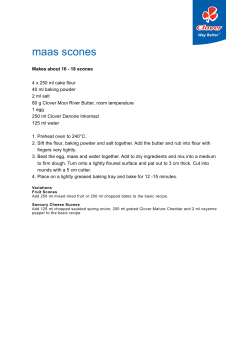

Plant Foods for Human Nutrition 41: 213-223, 1991. 9 1991 Kluwer Academic Publishers. Printed in the Netherlands. 213 Quinoa flour in baked products K. L O R E N Z & L. COULTER Department of Food Science and Human Nutrition, Colorado State University, Fort Collins, CO 80523, USA Received 15 September, 1990; accepted 1 November, 1990 Key words: quinoa, bread, cake, cookies, baking Abstract. The performance of quinoa-wheat flour blends (5/95, 10/90, 20/80, 30/70) were evaluated in breads, cakes and cookies. Breads baked with 5% and 10% quinoa flour were of good quality. Loaf volume decreased, crumb grain became more open and the texture slightly harsh at higher usage levels of quinoa flour. A bitter aftertaste was noted at the 30% level. Cake quality was acceptable with 5% and 10% of quinoa flour. Cake grain became more open and the texture less silky as the level of quinoa substitution increased. Cake taste improved with either 5% or 10% quinoa flour in the blend. Cookie spread and top grain scores decreased with increasing levels of quinoa flour blended with high-spread cookie flour. Flavor improved up to 20% quinoa flour in the blend. Cookie spread and cookie appearance was improved with a quinoa/low-spread flour blend by using 2% lecithin. Introduction Quinoa originates from the highlands of South America. Currently, it is grown for its grain in Argentina, Chile, Bolivia, Peru, Ecuador and Colombia (Carmen, 1984). The grain is resistant to drought and frost. It can be grown on poor soils and at high altitudes. Quinoa has potential agronomic importance elsewhere in the world, because it can adapt to produce high yields under adverse conditions (Wilson, 1985). It has been grown experimentally in other areas of the world where climatic conditions are similar to those of its native South American mountains. In Colorado, the grain grows at high elevations, but is limited by temperature to locations between 2,000 and 3,500m. Only one numbered variety, D407, is available for experimental production in Colorado. It has early maturity, a semi-dwarf growth habit, yellow compact heads and medium-small kernels. In two years of trials, it has produced consistent yields of 12001bs/acre in the San Luis Valley of Colorado (Johnson and Croissant, 1985). The proximate composition of quinoa ranges from 10 to 18% for protein, from 4.5 to 8.75% for crude fat, from 54.1 to 64.2% for carbohydrates, from 214 2.4 to 3.65% for ash and from 2.1 to 4.9% for crude fiber (White et al., 1955; DeBruin, 1984; Lamenca, 1979). The proximate composition of the grain varies with species. In comparison to wheat, quinoa is generally higher in protein, fat, ash and fiber. The amino acid balance of quinoa is better than that of wheat or corn, because the first limiting amino acid, lysine, is present in relatively higher amounts in quinoa seeds (White et al., 1955; VanEtten et al., 1963; Mahoney et al., 1975). Quinoa seeds contain saponins. These bitter compounds are located in the seed coat and make the grain less appealing to birds (Risic and Galwey, 1984). Most varieties contain these compounds, which affect their color and palatability (Johnson and Croissant, 1985). Saponins can be removed by washing the grain vigorously in cold, running water, then drying overnight at 60~ (Mahoney et al., 1975) or by repeated washing of the grain in alkaline water, coupled with pounding and rubbing to remove the pericarp (Simmonds, 1964). The saponins can also be removed by soaking in water overnight in a refrigerator followed by a quick, hot rinse. Saponin content is checked by placing the grain in a tube, adding water and vigorously shaking it for 30 sec. If no foaming occurs, all saponins are assumed to have been removed. The grain must then be dried quickly to prevent germination (Risic and Galwey, 1984). A barley pearling machine modified for on-farm use has been used in Colorado for pericarp and saponin removal of quinoa (Johnson, 1987). Quinoa may be used either as a whole grain or ground into a flour. As a whole grain it may be incorporated into soups or cooked and served in a manner similar to rice (Weber, 1978; Bean and Fellers, 1982). The grain may also be fermented to make a beverage called "chicha" (Simmonds, 1964). A coarse bread "Kispina" has been prepared from quinoa flour (Weber, 1978). Noodles have been made using 40% quinoa flour without adversely affecting the appearance of other characteristics of the final product. A number of quinoa recipes for cookies, chowder, croquettes and casseroles have recently become available (Gorad, 1986). Quinoa was used in a composite flour blend for Bolivia (Bean, 1981; Bean and Fellers, 1982). Levels of 5 and 10% quinoa in a wheat flour-quinoa blend caused a decrease in loaf volume. Potassium bromate added at 20 or 40ppm counteracted this volume decrease and produced breads similar to wheat bread with no dough additives. Though quinoa can be used in various ways, very few scientific reports mention its effects on the sensory, nutritional and functional qualities of breads, cookies or pasta. In this study we report the performance of quinoa flour used in blends with wheat flour to bake breads, cakes and cookies. 215 Materials and methods Sample identification and proximate composition All wheat flours were obtained from a commercial source. The quinoa flour was ground from variety D407, grown in the San Luis Valley of Colorado, using a Udy cyclone mill. Before milling, a barley pearling machine, modified for on-farm use, was utilized for pericarp and saponin removal of the quinoa as described by Johnson (1987). Standard AACC (1969) methods were used to determine moisture, fat, ash and nitrogen. All values, expressed on a dry weight basis, are shown in Table 1. The quinoa flour for cake experiments was chlorinated to three different pH levels: 6.2, 5.7 and 5.1. The original sample had a pH value of 6.5. Samples were treated with measured volumes of chlorine gas from a gas cylinder. The gas was applied to the quinoa flour in a wood reactor box with a tumbling action. Baking experiments Breads. Pup loaves were baked by the straight dough procedure from four blends of wheat and quinoa flours. Quinoa flour replaced 5, 10, 20 and 30% of the bread flour. The bread formulation was: 100% wheat flour or blend of wheat flour and quinoa flours, 6% sugar, 3% shortening, 2.5% yeast, 2% salt, 0.5% yeast food, 0.3% calcium propionate, and 10ppm potassium bromate. Fermentation time was 1.5 hr at 30 ~ and 85% RH. The loaves were scaled at 200 g each. They were mechanically molded, proofed to height at 35 ~ and 95% RH, and baked at 208 ~ for 18 min. Specific loaf volume was measured by rapeseed displacement. To score the breads, a maximum number of points was given to each bread characteristic, crust color, 7: Table 1. Proximate composition of floursa Bread flour Cake flour High-spread cookie flour Low-spread cookie flour Quinoa flour a All value on dry weight basis. b Protein = N • 6.25. Ash Ether extract Proteinb (%) (%) (%) 0.61 0.51 0.55 0.48 3.11 1.49 0.93 1.39 0.99 6.10 14.0 9.6 10.5 9.4 18.9 216 Table 2. High-ratio yellow cake formulation" Ingredient Proportion (% of flour weight) Flour Sugar High-ratioBaki powderCake ng shortening 100 120 [ 754~ A Salt Milkb Milkb Whole eggs 2.5 ) 55.5 B 40 ~ C 75 J a Procedure: the dry components (A) are mixed alone (45 sec) in a Hobart N-50 mixer, then mixed with milk (B, 5 min), and finally mixed with egg and more milk (C, 5 min). Portions of batter (400g) were baked at 375 ~ for 23 min. b One-part nonfat dry milk and 10 parts water. symmetry, 7: break and shred, 6: crumb color, 10; volume, 15; flavor, 15; grain, 20; and texture, 20. Bread crumb color was also measured with a Hunter color difference meter. The standard was L = 94.65, a = - 0 . 6 , and b = 0.1. Duplicate bakes were made. Cakes. Performance of the flours milled from quinoa and chlorinated to different pH levels were evaluated in a high-ratio yellow cake formulation, shown in Table 2. Quinoa flour replaced 5, 10, 20 and 30% of the cake flour. Duplicate bakes were made and the cakes were evaluated 3 h after baking. Cake volume was measured with a volume meter developed by the Pillsbury Co. The cakes were scored as follows: for volume, 15: crust color, 5; symmetry, 10; crust character, 5; grain, 15; crumb color, 10; aroma, 10; taste, 20; and texture 10 - the maximum number of possible points being indicated after each cake characteristic. Cookies. Performance was measured using the AACC (1969) cookie spread factor test. A high- and a low-spread cookie flour were used for wheat flour-quinoa flour blends. Quinoa flour replaced 5, 10, 20 and 30% of the wheat flour. Cookies were also baked with low-spread cookie flour - quinoa flour blends with 2% lecithin. Top grain characteristics of the cookies were scored and crust color was measured using the Hunter Color Difference meter. Cookie spread factors were calculated. The quality of the cookies was evaluated by a panel, as described by Badi and Hoseney (1976). 217 Results and discussion Proximate compositions Proximate compositions of wheat flours and the quinoa flour are shown in Table 1. Values for ash, fat and protein are typical of those for bread, cake and cookie flours. The quinoa flour had much higher ash, fat and protein contents compared to the wheat flours which agrees with previous reports in the literature (DeBruin, 1964; Risic and Galwey, 1984; Johnson and Croissant, 1985). Quinoa also has a much better essential amino acid composition that wheat (DeBriun, 1964; Quiros-Perez and Elvehjem, 1957; Coulter, 1989). Bread baking data Bread baking data of blends of wheat flour and quinoa flour are given in Table 3. Replacing 5% of the bread flour with quinoa flour resulted in a volume increase, which was probably due to rather high e-amylase activity in the quinoa flour. High e-amylase activity in quinoa D407 has been reported by Lorenz and Nyanzi (1989). Increased bread volume as the result of slightly higher amylase activity has been shown by Lorenz et al. (1983). Higher e-amylase activity increases the amount of fermentable sugars produced from starch. This reaction causes increased gas production and slightly higher load volume. Loaf volume decreased with quinoa replacement levels of 10% and higher. This has previously been reported by Bean and Fellers (1982). Quinoa flour does not have a gluten-forming protein as wheat flour does and the reduction in loaf volume is due to a gluten dilution effect. Breads baked with 5% and 10% quinoa were judged quite acceptable considering all external and internal bread characteristics. At higher levels of wheat flour substitution, the grain of the breads became more open and the texture slightly harsh. At the 30% level of substitution, the bread had an undesirable aftertaste. The crumb color of the breads became darker with ' higher levels of quinoa flour in the blend as indicated by lower Hunter color L values. The breads are shown in Fig. 1. Cake baking data There is good chemical evidence indicating that starch is altered at the low levels of chlorine used in flour chlorination and that these alterations affect its physical properties (Varriano-Marston, 1985). This is the reason why we 218 e~ tt~ 0 Ca ..= ca +1 +1 +1 +1 +1 ~8 Jl "~,4 O ..= ,-q "8 H H 219 Fig. 1. Breads baked with 5, 10, 20 and 30% of quinoa flour. chlorinate the quinoa flour. The commercial soft wheat flour used was chlorinated. Substitution of soft wheat flour with up to 30% of quinoa flour chlorinated to different p H levels had no effect on batter specific gravity as shown in Table 4. Use of unchlorinated quinoa flour (pH 6.5) up to 20% had no effect on cake volume. At the 30% level of substitution cake volume decreased. Chlorination of the quinoa flour was not beneficial as was hoped. Cake volume remained unchanged with 5% and 10% of quinoa flour chlorinated to pH levels of 6.2, 5.7 and 5.1 in the blend. Higher levels of chlorinated quinoa flour caused volume reduction. Chlorination to pH 5.1 had the most detrimental effects on cake volume. Cakes containing 5% of quinoa flour chlorinated to different p H levels received slightly higher scores for grain compared to the soft wheat flour control cakes. The grains of cakes became more open as the level of quinoa substitution increased regardless of the quinoa flour pH. Texture of the cakes became less silky with quinoa flour substitution beyond the 5% level. This was observed with all quinoa flours tested. Quinoa flour substituted at 220 0 r~ zZ~ r~ 0 e-, H t,.y~ r,.) ,4 o-~ 221 5% and 10% improved the taste of cakes, however. The taste was described as very pleasant and nutty in comparison with the flavor of the control cakes which was considered to be too sweet. Use of 20% or 30% of quinoa flour in the flour blend produced slightly bitter aftertastes, which, however, was less pronounced with quinoa flours which had been chlorinated to pH values of 5.7 and 5.1. Cake crumb colour became slightly darker with increasing levels of quinoa flour in the formulation as indicated by lower Hunter color L values (Table 4). This was observed with each of the different quinoa flours used in the cake baking experiments. Total scores, which include scores of all external and internal cake characteristics, indicate that cake quality was quite acceptable with 5% or 10% of quinoa flour, unchlorinated or chlorinated to pH levels of 6.2 or 5.7, in the formulation. Cookie baking data Baking data of blends of a high- and a low-spread cookie flour and 5, 10, 20 or 30% of quinoa flour (no chlorination) are given in Table 5. There was no quality improvement using quinoa flour in blends with a high-spread cookie flour. Cookie spread and top grain scores decreased with increasing levels of quinoa in the blend. Cookie top color became darker as indicated by lower Hunter color L values. Overall cookie appearance became less satisfactory. Only flavor improved with quinoa flour substitutions up to 20%. The flavor was described as nutty. At the 30% level of quinoa in the blend with the high-spread cookie flour a bitter aftertaste was noted, however. Quinoa flour caused only a slight decrease in cookie spread when used in blends with a low-spread flour. Grain scores actually improved with 5 % and 10% of quinoa flour in the blend, probably due to slightly higher levels of fat contributed to the formulation by the quinoa flour. Cookie top colors became darker with increasing levels of quinoa flour. Cookie appearance and texture were essentially unaffected using quinoa flour with a low-spread cookie flour. Flavor improved somewhat up to 20% of quinoa in the flour blend. A bitter aftertaste was again noted at a level of 30% of quinoa flour in the formulation. Both spread and top grain of cookies have been shown to be improved by increased emulsification (Kissell and Lorenz, 1976). We, therefore, also used 2% lecithin with low-spread cookie flour-quinoa flour blends. As shown in Table 5, cookie spread improved and cookie appearance scores were higher with additional emulsification. Even at the 20% level of quinoa substitution, cookie spread was higher than that of the control cookies made with the low-spread flour but without added emulsifier. 222 Table 5. Quinoa flour in cookies Percent in blend 0 5 10 20 30 High-spread cookie flour Cookie spread (W/T)" Grain score (9 pts max) Top color (L) b Appearancec Texture c Flavoff 7.26 8 73.4 4 4 2.5 5.98 8 72.8 5 4 3 6.05 7 72.8 4 4 3.5 5.40 5 71.6 3 4 3.5 4.93 4 70.4 2.5 4 1.5 Low-spread cookie flour Cookie spread (W/T) a Grain score (9 pts max) Top color (L) b Appearancer Texture c Flavoff 4.79 2 74.0 2 4 2.5 4.77 4 74.5 3 4 3 4.64 3 73.7 2 4 3 4.60 2 70.7 2 4 3 4.57 2 69.5 2 3.5 1.5 Low-spread flour plus 2% lecithin Cookie spread (W/T) a Grain score (9 pts max) Top color (L) b Appearancec Textirec Flavoff 5.25 4 76.2 3 4 3 5.07 3 73.8 3 4 4 5.05 2 70.2 3 4 3 - - W/T = width/thickness ratio. b L = value from Hunter Color Difference Meter; Standard: L = 94.6; a = - 0 . 6 ; b = 0.1. c Scale for judging appearance, texture, flavor: 1 = poor, 5 = excellent. Acknowledgments We thank Dr. D. Johnson, Department of Agronomy, Colorado State University for supplying the sample of quinoa and Mr. P. Ranum and Mr. R. Erickson, Pennwalt Corp, Buffalo, N.Y. for chlorinating the quinoa flour. References AACC (1969) AACC Approved Methods. American Association of Cereal Chemists, St. Paul, M N Badi SM, Hoseney RC (1976) Use o f sorghum and pearl millet flours in cookies, Cereal Chem 53:733-738 Bean M M (1981) Composite flours for bread making in Bolivia: technical aspects. Appendix B-18 of final report: improving the nutritional value of wheat foods. Agency for International Development, 231-11-76. U S D A Western Regional Research Center, Albany, CA 223 Bean MM (1981) Composite flours for bread making in Bolivia: technical aspects. Appendix B-18 of final report: improving the nutritional value of wheat foods. Agency for International Development, 231-11-76. USDA Western Regional Research Center, Albany, CA Bean MM, Fellers DA (1982) Composite flour breads in Bolivia: technical aspects. Proceedings of the 7th World Cereal and Bread Congress, Prague, pp. 859-864 Carmen ML (1984) Acclimatization of quinoa (Chenopodium Quinoa, Willd.) and cafiihua (Chenopodiurn pallidicaule, Aellen) to Finland. Annales Agric. Fenn 23:135-144 Coulter LA (1989) Extrusion of corn grits - quinoa blends, M.S. Thesis, Colorado State University, Fort Collins, CO DeBruin A (1964) Investigation of the food value of quinoa and cafiihua seed. J Food Sci 29: 872-876 Gorad SL (1986) Quinoa - Ancient Harvest: Recipes. Quinoa Corporation, Boulder, CO Johnson DL (1987) Release of (CO 407) Quinoa germplasm. National Seed Storage Laboratory, Fort Collins, CO Johnson DL, Croissant RL (1985) Quinoa production in Colorado. Service-In-Action No. 112. Colorado State University Cooperative Extension Kissell LT, Lorenz K (1976) Performance of triticale flours in tests for soft wheat quality. Cereal Chem 53:233-241 Lamenca MB (1979) Composicion de la quinoa cultivada en el altiplano de Puno, Peru. Turrialba 29:219-221 Lorenz K, Nyanzi F (1989) Enzyme activities in quinoa (Chenopodium quinoa). Int J Food Sci Technol 24:543-551 Lorenz K, Roewe-Smith P, Kulp K, Bates L (1983) Preharvest sprouting of winter wheat. II. Amino acid composition and functionality of flour and flour fractions. Cereal Chem 60:360-366 Mahoney AW, Lopez JG, Hendricks DG (1975) An' evaluation of the protein quality of quinoa. J Agric Food Chem 23:190-193 Quiros-Perez F, Elvehjem CA (1957) Nutritive value of quinoa proteins. J Agric Food Chem 5:538-541 Risic J, Galwey NW (1984) The chenopodium grains of the Andes: Inca crops for modern agriculture. Adv Appl Biol 10:145-216 Simmonds NW (1964) The grain chenopods of the tropical American highlands. Econ Bot 19: 223-235 VanEtten CH, Miller RW, Wolff IA (1963) Amino acid composition of seeds form 200 angiosperm plant species. J Agric Food Chem 11:399-410 Varriano-Marston E (1985) Flour chlorination: new thoughts on an old topic. Cereal Foods World 30:339-343 Weber EJ (1978) The Inca's answer to food shortage. Nature 272:486 White PL, Alvistur E, Dias C, Vinas E, White HS, Collazos C (1955) Nutrient content and protein quality of quinoa and cafiihua, edible seed products of the Andes mountains. J Agric Food Chem 3:531-534 Wilson HD (1985) Chenopodium quinoa, Willd.: Variation and relationships in southern South America. National Geographical Society Research Reports 19:711-721

© Copyright 2026