Is this the world’s best microwave-mix cake?

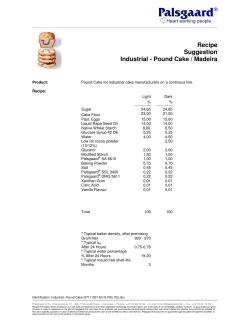

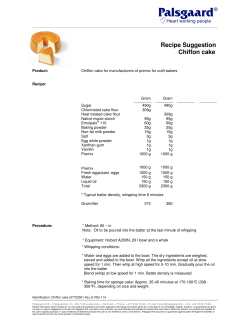

Is this the world’s best microwave-mix cake? Microwave cake mixes don’t always deliver the pleasurable, convenient experience consumers hope for. Now, food manufacturers can take advantage of ingredients producer Palsgaard’s latest research results to develop an entirely new level of cake quality with comparatively few ingredients. Interview with Lasse Kolding Sørensen, Application Technologist, Palsgaard A/S NEW INTEREST IN MICROWAVE BAKING If you’re in touch with consumer cake markets, you’ve probably noticed that the use of microwave ovens to produce cakes and similar food in a convenient format is finally gaining a foothold. While just-add-water or similarly simplified cake mixes for both conventional and microwave ovens have had their ups and downs for decades, it now seems that the microwave is being viewed with less scepticism than before. In fact, recent trends such as “mugging” or “cake-in-a-mug” – preparing various ingredients in a single-serve coffee mug then placing it in a microwave oven – are hot topics among cake lovers, who avidly swap recipes on their favourite social media sites. Even El Bulli, the Michelin 3-star restaurant voted the world’s best no fewer than five times, has served a 30-second microwave sponge cake for its guests. BUT IS IT A CAKE? Encouraged by these developments, cake mix manufacturers are climbing on the band wagon with ranges designed to exploit this new market potential. But, while microwave cakes based on “real” ingredients can often produce something that closely resembles an oven-baked product, few of the mix products have the same degree of success. In fact, consumers experimenting with the new mixes are all too often disappointed by the result. Typically, it seems, they’re rewarded with something that lacks the consistency of oven-based cakes and which quickly dries out. It’s just, well, not a cake. MICROWAVES ON A MISSION Danish-based ingredients manufacturer Palsgaard has been aware of the problem for some years. But, with numerous ingredient development projects on the go at any one time, it wasn’t until 2013 that the company turned its attention to helping its cake-manufacturing customers to lift the quality of their microwave mix recipes. Given that food and ingredient manufacturers have been experimenting with microwave cake mixes since the 1980s, Palsgaard realised that solving the problem was going to take a concentrated, sustained effort. At the same time, a more holistic approach was required rather than focusing on finetuning or replacing individual ingredients. Special resources were allocated in the company’s labs, with a mandate to work in near isolation from other projects until a solution was discovered. The project was headed by application technologist Lasse Kolding Sørensen. “When talking to cake manufacturers, we only had to mention dryness or complicated ingredient mixes and they would start nodding vigorously. So we knew which problems were key to address.” The Palsgaard team suspected that the difficulty of getting microwave cake mix recipes right – and the potential brand damage from disappointed consumers – was holding many manufacturers back. So they set out to deliver a compelling solution that would simplify mix recipes and provide an end result that, in the hands of consumers, closely resembled an ovenbased cake, more of the time. “We wanted to come up with some recipes that could give the industry the confidence to work further on their microwave products,” says Lasse. “Luckily, I was given all the resources I needed to really throw everything up in the air and start again from scratch, working with as many recipes and running as many tests as I needed to. And that made all the difference.” THE CHALLENGE Microwave ovens don’t provide the perfect setting for producing cakes. Far from it, in fact. One of the problems is that the changes in, and interactions among major ingredients, which would normally occur over a lengthy baking period in a conventional system, can’t be completed during the short baking period of a microwave system. The reason for this is that micro- While developing the two recipe suggestions Palsgaard also ensured that they would work if consumers were to try try to personalise the cakes - e.g. by adding a toffee-filled chocolate, or by adding fresh fruit to the coconut cake. wave radiation interacts with water to create a boiling rather than baking effect. To make matters worse, cake mixes are demanding applications, with all ingredients added at once and, especially with microwave products, with an extremely short stirring and baking time. None of these challenges, however, could stand in the way of a concentrated effort in Palsgaard’s labs. And after months of work, and more than a few frustrating moments, a convincing solution finally emerged. DYNAMIC DUO The results are impressive, to say the least. Two distinct recipes were created, one for a rich chocolate cake, the other for a coconut-flavoured product. When cooked in a microwave oven at 1,000 W for 50 seconds, both recipes produced remarkably appealing cakes that feature genuine cake-style consistency and don’t quickly dry out. Adding to their appeal, the two recipe suggestions can easily be personalised by the consumer to fit his or her own tastes and creative urges. For example, a toffeefilled chocolate added to the stirred chocolate cake batter will result in a delicious lava cake that’s a real treat when served warm with a scoop of ice cream. And freshly chopped pineapple or raspberries can add a fresh, fruity touch to the coconut cake. There’s yet another advantage, too, with the Palsgaard recipes: consumers who like their indulgent treats to be as convenient as possible will be pleased to find that removing the finished cake is as simple as turning the container upside down on a plate. The cake won’t stick to the container’s sides or appear damaged after removal. Much of the recipes’ success, it turns out, lies in the fact that both are based on a balanced mix of raw materials whose crucial ingredient is an emulsifier system well-suited for a tough job: fast dispersion and hydration using al- most no energy. Put another way, that means gently stirring the mix in a mug of water, then exposing it to microwave treatment with a pleasing cake structure as a result. The system, named “Emulpals®” is highly tolerant of other ingredients that may be added, and provides long shelf life for the cake mix, too. This unique system is based on only a few selected emulsifiers, which have been activated on a native rice starch. So, aside from superior functionality, it provides a label-friendly approach, too. YOU’RE INVITED! Despite the success of the two recipes, Lasse emphasizes that they are primarily designed as inspiration for the industry – and that Palsgaard’s role is to help food manufacturers to improve existing products or develop new ones. He offers to throw open his lab to manufacturers who would like to explore these recipes together with Palsgaard’s knowhow to craft exactly the right recipe for their region and their target markets. “We’ve got well-equipped pilot labs around the world that can now work with customers to refine their recipes – or create new microwave mixes that can address new markets,” says Lasse. “As an ingredients supplier, we have created a new product development springboard, and we’re keen to follow it through to products that really sell in the marketplace.” The Palsgaard technologist points to the fact that, over the years, consumers have demonstrated a willingness to try out both ovenbased and microwave-based mixes as evidence that the right recipe can open up the market’s true potential, both with younger and older segments. For example, microwave-based cake mixes make it possible for children to safely enter the baking world, while senior citizens can finally serve up a cake that lives up to their guests’ expectations with far less effort. There are other markets, too, that may be of interest, such as cafés looking to provide tasty, attractive cakes with a minimum of fuss and bother. we solve those issues? It may be market opportunities or production difficulties. Shouldn’t we solve those problems together? With this particular project, I think, we’ve achieved what everyone wants in a cake mix today: quality, ease, convenience, and most important of all, the ability to get the taste just right.” “I think one of the visitors to our stand at FIE in Frankfurt said it best. He just squeezed it, took a bite and said: ‘That’s just like a cake!’ It was the best thing he could have said to me.” “We’re here to solve problems related to food ingredients,” explains Lasse. “What are our customers having difficulty with and how can Palsgaard’s pilot plants and product development support teams in Denmark, Mexico and Singapore can provide manufacturers with dedicated assistance based on awareness of regional markets, regulations and requirements. Trials – from small to industrial-scale – can be conducted in advanced facilities equipped with mixers, aerators, depositors and ovens, providing a complete recipe development and testing environment for optimal results.

© Copyright 2026