GOVT. OF PUDUCHERRY DEPARTMENT OF AGRICULTURE O/O

GOVT. OF PUDUCHERRY

DEPARTMENT OF AGRICULTURE

O/O HYDROGEOLOGIST-II

THATTANCHAVADY

PUDUCHERRY

****

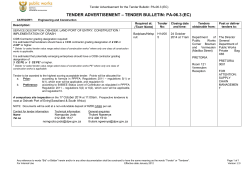

NOTICE INVITING E-TENDER

Online Tenders are invited through the Government e-Procurement website of U.T

Puducherry https://pudutenders.gov.in

Tender for the supply of

:

Power Rig

Tender Fee

EMD

:

:

Availability of Tender online

:

Last date for bid submission online

Bid Opening date / time

:

:

Rs. 2,600/Rs.5,00,000/From Date/Time:

To Date/Time:

Date/Time:

Date/Time:

20-02-2015 / 05.00 PM

16-03-2015 / 04.00 PM

16-03-2015 / 04.00 PM

17-03-2015 / 11.00 AM

The tender schedule may be downloaded from the website

1. https://pudutenders.gov.in

2. http://py.gov.in and

3. http://agri.puducherry.gov.in

Bids will be accepted only through online.

(Dr. A. RAMAMOURTI)

DIRECTOR OF AGRICULTURE

TENDER NOTICE INVITING

e-TENDER FOR THE SUPPLY OF

DIRECT MUD CIRCULATION ROTORY

DRILLING RIG WITH OPERATING

TOOLS & ACCESSORIES

1

GOVERNMENT OF PUDUCHERRY

DEPARTMENT OF AGRICULTURE

O/o The HYDROGEOLOGIST – II

STATE GROUND WATER UNIT & SOIL CONSERVATION

THATTANCHAVADY- PUDUCHERRY- 605 009

-*-*-*-*-*-

No.07/SGWU&SC/DD (AE)-I/RKVY/PUR-RIG/2013-14

Puducherry, Dt.

NOTICE INVITING e-TENDER FOR THE SUPPLY OF

HEAVY DUTY TRUCK MOUNTED DIRECT CIRCULATION ROTARY KELLY DRIVE

WATER WELL DRILLING RIG MACHINE

“e-Tenders” are invited on behalf of the President of India by the Chairman, Committee for

centralized purchase of Heavy duty truck mounted direct mud circulation Rotary Kelly drive

water well drilling rig machine along with Operating tools, Fishing tools & Accessories for

use in the O/o the Hydrogeologist-II, State Ground Water Unit & Soil Conservation, Department of

Agriculture, Thattanchavady, Puducherry – 605 009 during the year 2014-15.

1. The Tenderers for supply of above item must be either the manufacturer or authorized Stockist and

who hold valid Manufacturing Licence or such other document / Dealership certificate / Sales tax

registration certificate with the Government. Detailed information must be enclosed along with the tender.

2. The Tenderers must have a minimum of five years experience in this field and whose average annual

sales turnover during last five years was not less than ` 1.5 crores and who have supplied and

commissioned Rotary Drilling Rig machine having capacity of drilling holes of 300mts. depth or higher

capacity during last five years as on tender opening date to Central Government / State Government /

Public Sector Units/ Private Firms in India are only eligible.

4.

Bidders

should

submit

their

tender

through

online

at

the

Government

website

https://pudutenders.gov.in with proof of payment of Tender Fee ` 1040 /- inclusive of sales Tax 4%

as Demand draft in favour of Drawing and Disbursing Officer, O/o Hydrogeologist-II, State Ground

Water Unit & Soil Conservation, Thattanchavady, Puducherry-605 009 from any Nationalized Bank

payable at Puducherry. This amount is not refundable.

5. The Tender details, and ‘Terms and Conditions’ may also be downloaded from the Department

website http://agri.puducherry.gov.in for reference only. Tenders will be processed online only. Hence

hardcopy submission will not be accepted.

6. The technical tender and other documents will be evaluated only on receipt of Tender fee of ` 1040/and EMD of ` 5,00,000/-, as demand draft as specified in the tender document in a separate, sealed

cover superscribed as “Tender fee for Supply of Direct Circulatory Rotary Drill” & “EMD for for Supply of

Direct Circulatory Rotary Drill”, on or before 4.00p.m on 16.03.2015 at the O/o the Hydrogeologist-II,

State Ground Water Unit & Soil Conservation, Thattanchavady, Puducherry, 605 009.

7. Tenderers are requested to stick on to the date and time specified strictly. Tenders will be accepted

only if submitted in the prescribed manner. Tenderers are requested to read the instructions help for

2

contractors, information about Digital Signature Certificate, resources required and bidder’s manual kit at

the home page of the website https://pudutenders.gov.in before submission of tender through online.

8.

Training on submission of e-tender is also provided in the e-Procurement cell, Chief Secretariat,

Puducherry-1. Help desk No.0413-2220225

Tender Fee

Sl.

No.

1.

Tender description

Supply,

Installation

and

Tende

r I.D

Tender

Reference

Fee in

`

Sales

Tax

in `

EMD in

`

2,500

100

5,00,000

Successful

Commissioning and Testing of Heavy duty

truck mounted direct circulation Rotary Kelly

Drive Water well Drilling Rig unit complete,

as per the following:a) Specifications

in ANNEXURES- “1” & “2”.

b) Standard tools & accessories and Spares

for proper maintenance / operation of Rig

as per ANNEXURE “3”

c)Training of Technical Personnel of State

Ground Water Unit & Soil Conservation.

The Rig will be mounted on a heavy duty

truck chassis complete with driver’s built-up

cabin made of Galvanised sheets and truck

will be complete with all the vehicular out-fits.

TENDER TIME TABLE

Sl.

No.

Subject

Date and time

*

05-03-2015 at

11.00 AM

1.

Date of pre-bid meeting for the bidders

2.

Starting date and time of Bid submission of

e - Tender

05.03.2015 at

1.00PM

3.

Last date and time of bid Submission of

e - Tender

16.03.2015 at

4.00 PM

4.

Date and time for opening of technical bid online by the Committee

17.03.2015 at

11.00 AM

*[If these days happen to be a holiday, the next working day will be considered]

Phone No.

Fax No.

Helpdesk@eprocurement

Toll free

: 0413 - 2250482

: 0413 - 2250357

: 0413 – 2220225

: 1800 - 2337315

Any clarification in Technical specification /

Technical Data of the machineries

: 0413-2248245

: +91-9443075527

: +91-9245797327

: +91-9443860

For free training and technical support

on e- Procurement

DIRECTOR

DEPARTMENT OF AGRI

3

PUDUCHERRY

GOVERNMENT OF PUDUCHERRY

DEPARTMENT OF AGRICULTURE

O/o The HYDROGEOLOGIST – II

STATE GROUND WATER UNIT & SOIL CONSERVATION

THATTANCHAVADY- PUDUCHERRY- 605 009

-*-*-*-*-*-

TENDER CONDITIONS :1.GENERAL:-

1.1 The rates should be quoted in whole rupee only and must be expressed in figures and in words

(English). In cases of discrepancy between the prices quoted in figure and in words, lower of the two

shall be considered and binding. The rate for each item should be independent of other items.

1.2. The rates should be inclusive of all Excise duty and exclusive of Sales-Tax, Surcharge, Local

Taxes, etc. (Excise duty components included in the rate, to be shown separately for reference only

as per the schedule enclosed) and for free delivery inclusive of all incidental charges such as

loading, unloading, packing, forwarding, Insurance and stocking charges etc., at the O/o. The

HYDROGEOLOGIST-II, State Ground Water Unit & Soil Conservation, Thattanchavady,

Puducherry-605 009. The supply should be made at the suppliers own risk.

1.3. Damages and breakages, if any, found in transit, the articles thereof, should be replaced.

Otherwise the corresponding cost will be deducted from the bill.

1.4. The rates should be typed in the space provided ONLY in the pricelist format ONLINE.

1.5. No column in the price list shall be left blank. Tenderer should quote the rate for all the

machineries and materials, failing which, the tender would be disqualified.

1.6. The rates quoted should be only as per the packing unit printed in the schedule and should be

valid for a period of six months from the date fixed for signing the agreement..

1.7. If artificially low rates are tendered, Government will not consider any subsequent claim for

compensation. The tenderers are advised to satisfy themselves that the rates tendered by them are

for the items, for which tenders have been invited and shall quote only for the readily available items

/ Items that could be supplied within the delivery schedule.

1.8. No representation towards upward revision of rates will be allowed. Ex-godown rates offered by

the firm are not acceptable and such tenders will be summarily rejected. The rates should be quoted

for free delivery as specified by the O/o. The HYDROGEOLOGIST-II, State Ground Water Unit & Soil

Conservation, Thattanchavady, Puducherry-605 009.

1.9. The price quoted online by the tenderer shall not in any case exceed the controlled price, if a

Government controlled price be in force on the date of acceptance of tender or the reasonable price

(in the absence of a controlled price) which is permissible for the tenderer to charge a willing private

purchase in bulk in the open market for the same class of description of goods.

1.10. In the case of imported goods, when the price accepted is the existing price, quoted by the

tenderer, benefit of any reduction in the Cost, Insurance and Freight price should accrue, to the

purchasing Department of the Government.

1.11. The rate should be quoted online in Indian currency for the units specified against the items

and payment will be made in Indian currency only. In respect of imported goods, the rates should be

quoted in foreign currency as well as equivalent Indian currency duly mentioning the exchange rate.

1.12. The successful tenderers himself shall procure permits, licence etc., that may be required in

fulfilling the contract.

1.13. All offers should be for supplies, from ready stock in original packing of the manufacturers.

1.14. After the due date, no addition or deletion or alteration in the tender will be allowed.

1.15. The bill of cost of the articles supplied should be sent to the consignee immediately after

delivery of goods.

4

1.16. If the Government introduces any fresh taxes or increases the present rates of taxes, no

change in the rates can be claimed.

2.ELIGIBILITY CRITERIA:-

2.1 Only those suppliers / manufacturers, whose average annual sales turnover during last five

years was not less than ` 1.5 crores and who should have supplied and commissioned Rotary

Drilling Rig of 300mts. or higher capacity, last five years as on tender opening date to Central

Government / State Government / Public Sector Units/ Private Firms in India are only eligible.

Tenderers shall submit photocopy(s) of order(s) and end user performance certificate (s) to

establish their claim for satisfactory past performance.

2.2 The authorised sale & service dealers for diesel engines attached to drilling rig should be

present in Pondicherry or within 150 Kms. from Pondicherry. The tender should mentioned clearly in

the tender the Make & Model of diesel engines attached to drilling rig and whether authorised

dealers for the same is present in Pondicherry or within 150 Kms. from Pondicherry..

2.3. Acceptance of tender for the supply of equipment will be subject to tenderer certifying that they

have adequate servicing and spares facilities in respect of the equipment tendered for by them or

that they shall arrange to provide such facilities simultaneously with the supply of the equipment.

3. TENDER DOCUMENTS:-

3.1. The Tender shall be submitted only if the Tenderer is agreeable to all the terms and conditions

of this Tender, which includes the Description and Specifications of the items mentioned therein.

3.2. The Tenders are invited in two-bid system. (i) The technical bid and (ii) The financial bid

(i)

The technical bid shall contain all documents except the price bid. The Technical bid will be

opened on the day fixed for opening Tenders. The bidders will be shortlisted based on the

documents submitted in the Technical bid. Only the Financial bid of shortlisted - bidders will

be evaluated subsequently on the date / time specified in the Tender schedule. Incomplete

documents, if any in the technical bid will result in the automatic rejection of the entire

Tender and the financial bid will not be opened. The Technical Bid shall contain the

Documents listed hereunder and the Tenderers are requested to upload the papers

according to a sequence as given below:

(a) The scanned copy of Tender Fee including sales tax for ` 1040/- and the scanned

copy of a Demand draft towards Earnest Money Deposit for ` 5,00,000/- separate

Demand drafts in favour of Drawing and Disbursing Officer, O/o the

Hydrogeologist-II, State Ground Water Unit & Soil Conservation, Thattanchavady,

Puducherry-9.

(b) Income tax certificate for the past three years, latest Income-Tax verification /

clearance certificate from Income Tax Authority. Permanent Account Number of

Income Tax should be quoted in the offer without fail.

(c) Annual Turn over Statement from Chartered Accountant for the past five years.

(d) Documents supporting that they are the manufacturer / Authorised Dealer.

(e) Technical tender details for Rotary Drilling Rig is as per Annexure – A, 1, 2 & 3

(f) Declaration as in para. 16.

(ii) The financial bid shall contain only price list. The Tenderers shall quote the rates in the

financial bid (BOQ) only after downloading it from the website. Any discrepancy in this

regard will cause the rejection of Price list. The Financial Bid (BOQ) shall contain the

following:(a) Tender offer form (BOQ) - Basic price, excise duties, sales tax, packing and

forwarding charges, freight charges, unloading charges, insurance, etc. for each

item shall be entered by the tenderer in the prescribed column of the excel sheet.

5

(b)Tenderers are requested to submit the break up of prices viz. cost of manufacture,

labour cost, overhead etc., and the margin of profits. Documentary evidence in

support of break up may be furnished.

(c) In case if the machinery is found to be covered under DGS&D rate contract or in

the quoting of the Government of India / Government of India undertaking firms,

such items will not be considered through this tender.

3.3. Only the terms and conditions specified in this tender by the Department shall be binding on the

Tenderer and the tendering authority, irrespective of the terms and conditions that may have been

specified by the Tenderer,

3.4. In the event of any discrepancy in respect to the rates quoted, the “Committee” reserves the

right to accept or reject the tender.

3.5. Copies of any document produced with tender including photo copies, should be clear and

legible, otherwise it will not be considered. If the required certificates are in a language other than

English, attested copy of English version should be furnished for verification and record.

3.6. Entry to participate in the Tender Opening Committee Meeting is restricted only to bona-fide

Tenderers or one of their Authorized Representatives.

3.7. The Tenderers or their Authorized Representative who are present shall produce the

authorization letter and sign in the Attendance Register evidencing their presence during the

opening of tenders.

3.8. The Tenderer or their authorized Representatives who are present at the time of opening of

Tenders shall not bring Mobile Phones to the Venue.

3.9. In the event of the date of submission or opening of tender, being declared as a holiday for the

office of the tendering authority, the due date for submission of tender and opening of tender will be

the following working day at the same time.

3.10. The verification of documents in the technical bid and samples, the decision to open financial

bid to readout the rates quoted by the tenderer, by the tender opening committee is only provisional,

subject to further verification.

3.11. The Tenderer shall bear all costs associated with the preparation and submission of his tender

and the O/o The Hydrogeologist-II, State Ground Water Unit & Soil Conservation, Thattanchavady,

Puducherry will in no case be responsible or liable for these costs, regardless of the conduct

outcome of the Tendering process.

3.12. The Tenderers are responsible to furnish all the required particulars along with the tender. No

correspondence will be made on this account from this office/ department.

3.13. Tenders submitted in forms other than the one prescribed and /or without the payment of the

prescribed fee will be rejected.

4. QUANTITIES OF REQUIRED ITEMS :

The quantities of stores indicated in the schedule are only tentative and approximate. O/o the

Hydrogeologist-II, State Ground Water Unit & Soil Conservation, Thattanchavady, Puducherry-9 has

the right to increase or decrease the quantity.

5. EARNEST MONEY DEPOSIT:

Such of those tenderers who submit tenders in forms downloaded from Web-site shall pay

` 1,040/- towards the cost of the Tender Schedule inclusive of VAT by Demand Draft in addition to

the Earnest Money Deposit to the value of `5,00,000/- by drawing a crossed demand draft

drawn in favour of "The Drawing and Disbursing Officer, O/o The Hydrogeologist-II, State Ground

Water Unit & Soil Conservation, Thattanchavady, Puducherry " from any Nationalized Bank,

payable at Puducherry. Separate Demand drafts should be drawn for EMD and Separate

Demand drafts for cost of Tender Schedule. The copies of the Demand Drafts should be

furnished in a separate, sealed cover in the “Technical Bid” along with the samples. The tenders

5.1

6

without payment of cost of tenders will be rejected, unless they are otherwise entitled for free tender

documents.

5.2

No cheque will be accepted for Earnest Money Deposit payable. Similarly no fixed deposit

or short deposit etc. will be accepted for Earnest Money Deposit. Also no request for adjustment of

previous year's outstanding money of Earnest Money Deposit/Security Deposit or any other dues

payable by the O/o. The Hydrogeologist-II, State Ground Water Unit & Soil Conservation,

Thattanchavady, Puducherry to the firms, will be accepted for Earnest Money Deposit. No interest

will be paid on the Earnest Money Deposit. The tenders submitted without requisite Earnest Money

Deposit will be summarily rejected.

5.3.

The firms permanently registered as Industrial Co-operative Society/Small Scale Industry

with the Government of Puducherry / National Small Industries Corporation / D.G.S.&D. for the

supply of particular Stores of items proposed to be purchased, shall be exempted from the payment

of Earnest Money Deposit up to the monetary limit to which they are registered. Such exemptions

will not be granted to the small scale units during the currency of "Provisional Registration".

5.4

Earnest Money Deposit of unsuccessful tenderer will be refunded after opening the Financial

Tender and selection of items within 15 days.

6. AGREEMENT:

The successful tenderer shall be required to execute an agreement stipulating all the

conditions mentioned herein within 30 days from the date of communication of the approval of rate

by the Director of Agriculture, after furnishing the required amount of Security Deposit, EMD will be

returned

6.1

6.2

Failure to sign the agreement within the period specified in the pre-para above shall amount

to withdrawal of the approval of rates and will lead to forfeiture of amount of Earnest Money Deposit

paid in respect of that particular item. Director of Agriculture is free to take further necessary action

for entering into an agreement with other tenderers and the excess amount that the Director of

Agriculture has to incur in effecting supply of such stores be recovered from the defaulting tenderer.

7. SECURITY DEPOSIT:

Within 30 days of the receipt of notification of award from the Director of Agriculture ,

Puducherry the successful Bidder shall furnish the Performance security equal to 10% of the

contract value of items to be supplied. Performance security Deposit shall be furnished in the form

of demand draft / Fixed Deposit Receipt drawn in favour of "The Drawing and Disbursing Officer,

O/o. The Hydrogeologist-II, State Ground Water Unit & Soil Conservation, Thattanchavady,

Puducherry" payable at Puducherry or by furnishing Bank Guarantee in the specified proforma.

Earnest Money Deposit made will be refunded to the firm which enters into agreement after having

paid adequate amount of Security Deposit. On the specific request of the firm, the Earnest Money

Deposit paid will be adjusted against Security Deposit, which falls short of the adequate amount.

7.1

7.2

The firms permanently registered as Industrial Co-operative Society/Small Scale Industry

with Government of Puducherry / NSIC / DGS & D for the supply of particular store item proposed to

be purchased shall be exempted from the payment of Security Deposit upto the monetary limit to

which they are registered. No exemption is granted to such firms during the currency of "Provisional

Registration". No interest shall be payable on Security Deposit.

7.3

The Performance Security Deposit will be refunded only after a period of two years from the

date of successful commissioning and testing of the Rig and the faithful and complete discharge of

all the Terms and Conditions of the contract by the contractor and to the fullest satisfaction of the

Drawing and Disbursing Officer, O/o. The Hydrogeologist-II, State Ground Water Unit & Soil

Conservation, Thattanchavady, Puducherry-9

8. DELIVERY:

8.1

The Drilling Rig along with Operating tools, Fishing tools & Accessories complete, as per

supply order should be delivered free within a period of three months from the date of receiving

supply order to the O/o. the Hydrogeologist-II, State Ground Water Unit & Soil Conservation, (Stores

7

Section), Thattanchavady, Puducherry-9.Tenderer should bear the loading, unloading & handling

charges.

8.2

The supplier will be responsible for the supplied material and specification and defective

material if found will be rejected and will be returned to supplier at his risk and cost.

8.3

In case if successful tenderer fails to supply the Drilling Rig unit complete with standard tools,

accessories and spares etc. within stipulated time the security money deposited by the tenderer/

bidder shall be forfeited.

.

9. TERMS OF PAYMENT:

No advance will be paid for effecting the supply. The tenderer shall supply machineries

complete, with standard tools, accessories and spares as per supply order at consignee’s site. The

tenderer shall produce the Bill in triplicate along with an advance stamped receipt. First stage 80%

payment will be made after receiving all the items in good condition including completion of R.T.O

registration and balance 20% after successful commissioning and testing of the equipment and

accessories to their rated capacity and training of rig crew . Minimum one well should be

successfully constructed for testing the rig to its capacity and for training.

10. GUARANTEE/WARRANTY:

The Rig equipment quoted must be covered with guarantee / Warrantee for a period of

minimum two years from the date of completion of successful commissioning against

manufacturing defect or faulty workmanship / design. The driver cabin of the Rig should have

warranty for minimum 3 years and drill Pipes for 5000mts depth or 2 years which ever is earlier.

During the Guarantee / Warrantee period all defective parts should be repaired or replaced at free

of cost.

11. TEST CERTIFICATES:

Providing of test certificates for load testing for the following equipment from reputed,

Government recognized testing house.

(i)

Water Swivel, Hoisting Plug, Triple sheave travelling block and single sheave

travelling block, supporting calculations for load testing shall be provided.

(ii)

Test certificate for mast testing, mud pump and power-take-off shall be provided.

Calculation for pull down capacity, single line pull of hoisting drum/sand-reel drum

shall be furnished. All the above certificates will be provided at the time of inspection.

12. IMPORT DOCUMENTS:

All the import documents for drill pipes and Kelly have to be furnished during inspection and

copies of certificates for drill pipes and Kelly earlier supplied.

13. INSTALLATION, COMMISSIONING AND TESTING:

The supplier should arrange for pre- inspection of materials used fabrication of driver

cabin, mast, Hydraulic pumps. The supplier will arrange assembling, commissioning and testing of

the equipment and accessories to their rated capacity at consignee’s site at least for one well.

Materials for constructing tubewell will be supplied by Agriculture department, Puducherry

14. TRAINING:

The supplier shall arrange practical training in operation, maintenance, repairs and up keep of the

equipment/machinery and accessories to the purchaser’s officers and technical personnel at the

time of commissioning and testing at consignee’s site. Training should be on site during exploratory

drilling of at least one well of 300m. in the presence of qualified experts from the manufacturer.

8

15. OTHER CONDITIONS:

15.1 Upon signing the agreement of the contract of supply with the Director of Agriculture,

Puducherry, the firm shall supply those items for which the contract is signed. Supply of materials

with substandard quality will be summarily rejected.

15.2 The Director of Agriculture, Puducherry is vested with powers to cancel or to revoke the

contract without assigning any reason therefore, if the contractor fails to effect the supply in

conformity with the contracted terms and conditions The Director of Agriculture reserves right to

evaluate the performance, quality, durability of rig & after promptness in sales service by Rig

manufacturer and the manufacturer should arrange for inspection and evaluation of their rotary rig

working in field conditions. In case the manufacturer could not able arrange for evaluation of their rig

in working condition or in case during evaluation if it is found that the rig performance, durability,

after sales service is not adequate , the Director of Agriculture reserves the right to reject the bid

out rightly.

15.3 In case of non supply or failure of supply as per the terms and conditions by the firm with in

the delivery schedule the Director of Agriculture, Puducherry shall be entitled to appoint a new firm

to effect supply and the excess amount that the Director of Agriculture, Puducherry has to incur

shall be recovered from such defaulting supplier.

15.4 Any dispute under or arising out of the agreement executed for supply of stores shall be

referred to the Secretary to Government in-charge of the Director of Agriculture, Puducherry, the

sole arbitrator under the provisions of Arbitration and Conciliation Act, 1996.

15.5 The Director of Agriculture, Puducherry has the right to recover all or any dues from the

contractor by exercising the provisions of the Puducherry Revenue Recovery Act 1970.

15.6 The Director of Agriculture, Puducherry reserves the right to reject any or all the tenders

without assigning any reason therefore.

15.7 The decision of the Director of Agriculture, Puducherry in all matters relating to this tender

shall be final and conclusive.

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-* *-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

9

16. DECLARATION

A declaration as given below in token of acceptance of all the terms and conditions of

tender shall be furnished by the participating tenderers. Otherwise the tender will be rejected.

"I/We. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Name of the firm (Proprietor)]

the undersigned hereby solemnly declare that the terms and conditions of tender schedule for

supply of “Heavy duty truck mounted direct mud circulation Rotary Kelly drive water well

drilling rig machine along with Operating tools, Fishing tools & Accessories” are accepted

and that in the event of selection of my/our rates, the agreement in the prescribed proforma will be

executed".

SIGNATURE OF THE TENDERER

DIRECTOR

DIRECTORATE OF AGRICULTURE,

PUDUCHERRY

10

ANNEXURE – ‘A’

TECHNICAL TENDER

1.

Name of the machine

:

2.

Manufacturer’s name

:

3.

Make / brand name

:

4.

Detailed specification

:

5.

Technical details

:

6.

Literature / pamphlets of the machine

:

7.

List of parties to whom such machinery

has been supplied

:

8.

Other references

:

9.

Warranty period

:

10.

Service backup

:

11.

Other related information

:

12.

Special features of the machine

:

13.

Training facilities to be offered

:

Signature of the tenderer

11

ANNEXURE– 1

TECHNICAL SPECIFICATIONS OF POWER RIG

1. CAPACITY

Heavy Duty Truck mounted direct mud circulation Rotary Kelly drive water well drilling

Rig machine, suitable for fast drilling with mud circulation method in normal drilling condition in

hard abrasive alluvial soil, thick layer of hard clay mixed with kankar, sand stone, gravel, shell

etc. formations. Rig machine will have the capacity as under.

(a) 215.9 mm (8.5”)

dia pilot holes up to 457m. (1500 ft.) depth.

(b) 311.0 mm (12.25”) dia bore holes up to 420m ( 1377ft.) depth by reaming

(c) 406.0 mm (16”)

dia.bore holes up to 400m (1310 ft.) depth by reaming

(d) 444.5 mm (17 ½”) dia bore holes up to 250m ( 820 ft.) depth by reaming

The specification of rig vehicle carrier and technical specification abstract of rig components

are furnished in ANNEXURE “2”

2. ROTARY DRIVE / DRILL HEAD

The rig machine will be provided with hydraulically retractable drill head with twin cylinder

(Hydraulic) pull down arrangement. Drill Head complete with spirally cut standard heat treated

gears and pinion fully immersed in oil bath type. Gear case ensuring proper lubrication, long life

and noiseless operation provided with suitable seals.

The power transmission is through torque tube and the drill Head is Hydraulically retractable

having maximum retraction of 533mm (21”)to accommodate up to 18” dia casing pipe and to

handle drill strings. A Heavy duty Hexagonal spindle suitable for 104.8 mm (4.1/8”) OD three

fluted round Kelly is provided.

The drill head will be made of cast Alloy steel and will be provided with Kelly drive bushing,

bevel gears, pinion, bearings, oil seals and pins etc. The speed reduction from pinion shaft to

Kelly is indicated in the offer. An independent clutch is provided for imparting rotary movement

as and when required. Construction of drill head will generally conform to para 3.3.4 of IS : 7206

( Part -1 ) 1986.

3. PULL DOWN

Drill Head should be with two Nos. hydraulic pull down cylinders sufficient to give required

pressure of 8690kgs (18000 lbs) on drill string and having a stroke length of approximately

762mm (30”). Maximum pull down force and maximum pull up force is indicated in offer. The

system will be equipped with “micro feed” arrangement for ensuring optimum loading on the bit

during drilling. The pull down will generally conform to para 3.3.7 of IS: 7206(Part-1) 1986.

4. KELLY & KELLY DRIVE BUSHING

Heavy duty imported single piece three fluted round\Square Kelly of size 104.8 mm (4.1/8”) OD

x 8.5 meters (28 ft.) long should be provided. The Kelly will be provided with Kelly drive bushing

and pins with appropriate API threads at both ends. Kelly saver shall be provided with Kelly to

protect the threads. The Kelly must be suitable for use with 88.90 mm (3.1/2”) OD drill pipes.

Kelly should be made from alloy steel seamless mechanical tubing having the following physical

properties.

(a) Minimum Yield Strength

(b) MininmumTensile Strength

(c) Elongation percent

(d) Impact value

(e)Hardness

: 686 N/mm2 (Min.)

: 882 N/mm2 (Min.)

: 11 % (Min)

: 35 J, Hardness

: 255 BHN (Min)

The Kelly will be built with extreme accuracy to ensure strength and balance. Thread portion of

the Kelly will be phosphate, to prevent corrosion and galling. Import document including “Test

Certificate” should be provided at the time of delivery / inspection.

12

5. DRAW WORK

The rig will be provided with heavy duty enclosed draw works consisting of two drums, one main

line hoisting drum and another sand reel drum. Both the drums will be provided with equalized

double brake bands and replaceable brake drums flanges. Brake control will be conveniently

positioned at driller’s station for ease of operation. The drum will be chain driven with

mechanical clutches and will be complete with adequate length of 19/22 mm non-spinning

tested wire rope with safety clevis assembly. Both drums will have a single line pull of not less

than 6.8 M.T. Main hoisting drum will be able to operate at different hoisting speeds as and

when required according to load conditions. Suitable traveling block with triple pulley and swivel

hook shall be provided with machine. A shaft mounted cathead suitable to handle 25mm manila

rope will be provided with draw works, complete with cat line roller. Tong line and counter weight

assembly. The draw works will generally conform to IS: 7206 (Part-1) 1986 para 3.3.3.

6 TRANSMISSION GEAR BOX

For obtaining different rotational speeds at the rated power from the prime mover to operate the

drill head as well as the hoisting drums according to the load conditions. A sturdy gear box with

four to five forward and one reverse gear, with required gear reduction ratio will be provided.

This unit is coupled to the power unit through a main clutch. Individual clutch is provided for all

the sub-units. The gear box will be simple design and gear will be of sturdy nature to withstand

sudden loads. The TRANSMMISION gear box will generally conform to IS : 7206(Part-1)-1986

para 3.3.5.

7. HYDRAULIC PUMP/SYSTEM

The rig will be provided with a reputed make Chain driven or directly coupled to PTO Hydraulic

pump of adequate capacity to meet following operations.

a) Mast rising and lowering

b) Twin pull down cylinders

c) 1 No. brake out cylinder

d) Retraction of draw works

e) 4 Nos. of hydraulic jacks for rig levelling.

Hydraulic system will be provided with hydraulic oil tank of adequate capacity, control valves for

various operations, pressure relief (release) valves, pressure gauges, filters and piping etc. The

hydraulic system will conform to IS specifications 7206 (Part-I) – 1986 para 3.3.10

8 MAST

The mast provided will be of minimum 12.8m(42’). high and fabricated from heavy duty

seamless steel tubes with sufficient cross members for uniform distributing load and of open

face construction in two sections. It will be provided with 2 Nos. of mast extension legs and jack

screw foot. The mast will be designed for maximum gross load capacity of 31818 Kgs ( 70000

lbs) and minimum working load capacity of 19958.27 Kgs (44000 lbs). The mast will be

equipped with minimum 5 wire line sheaves and 1 cat line sheaves all mounted on roller

bearings. The mast will be raised and lowered by two double acting hydraulic cylinders with

controls conveniently located for efficient operation.

The heavy duty steel tubes used for construction of mast will be conforming to IS: 1161–1979 of

steel tubes for structural purpose. The mast structure will be capable of handling maximum load

without any distortion and for a factor of safety of 3 times of working load. The mast must be

designed to take maximum load of drill pipes or casing pipes and with stand heavy wind load.

The traveling block, water swivel and the hook provided between them will be capable to handle

with safety the total weight of drill string or casting weights, etc. and for a factor of safety of two.

The mast is suitable to accommodate rotary table, Triple sheave travelling block, single sheave

traveling block, swivel hook, water swivel and wire ropes and other drilling accessories. The

mast should be designed to have sufficient height and width to handle with ease the changing

of drilling bits, lowering and raising of drill pipes and casing pipes etc.

The mast will be wired for electric lighting for night shift operation. Other specifications of the

mast will generally confirm to IS:7206–(Part-I) 1986 para 3.3.2

13

9. LEVELLING JACKS:

The rig will be equipped with 4 Nos. of Hydraulic levelling jacks of adequate capacity with

“Reverse flow restricted valves” to ensure safe operation. Two jacks are mounted at rear of the

Rig and controlled by two separate valves and two jacks mounted at the front portion of the Drill

Rig and controlled by a single valve. The machine will be provided with a spirit level located at

drilling point to facilitate the levelling of the rig.

Cylinder Bore (Mini.Dia.) 125 mm

Stroke

610 mm

4.93 inches

24.00 inches

10 MUD PUMP:

The rig will be equipped with heavy duty one duplex double acting reciprocating mud pump

having 203.2mm(8.00 inches) stroke and fitted with 152.4mm (6”) liners capable of delivering

905 LPM in Normal and Maximum 1435 LPM at approximately 19.97 Kg/cm 2pressure. The mud

pump shall have a facility for replacing the liners of 150mm(6’’),125mm(5”), 114mm

(4.1/2’),100mm (4”) and 87.5mm (3.1/2”) with same stroke. The pump will be capable of

handling high viscous drilling mud. The pistons, their rubber cups, valves, valve – seats etc. will

be of replaceable type and of proper quality and material to withstand abrasion.

The pump will be driven by a truck engine through a suitable P.T.O. system and will be driven

through a multiple roller chain running in an oil bath or through ‘V’ Belt / Pulley system through

suitable friction clutch. The mud pump controls are conveniently located at control panel situated

at driller’s point for the independent control of pump.

The pump should be with suction and discharge fittings, suction strainer, flow line consisting of

air vessel / surge chamber, pressure relief valve, safety valve, over-flow pipe, pressure gauge,

strainer and suitable fitting for connecting discharge hose and suction hose.

The pump should be supplied with necessary suitable tools such as liner puller, valve seat

puller and necessary pipe fittings, tools, etc. A mud mixing hose will also be supplied with pump.

The high pressure delivery hose and a suction hose should be supplied. The pump will be

generally conforming to IS: 7206 – (Part -I) -1986.

11. POWER SOURCE OF RIG MACHINE (PRIME MOVER) :

All the components of drilling rig including mud pump will be driven by the engine of truck

chassis through a P.T.O. device.

The diesel engine will be continuous rated and conform to IS: 10002 – 1981 and will be easily

accessible for ease of repairs and maintenance. The engine will be developing an output of

more than 10% excess of rated output for at least a period of two hours in a cycle of 24 hours.

Power unit shall generally confirm to IS 7206-(Part-I)-1986 para 3.3.9.2.

12. MOUNITNG:

The complete drilling rig including 1 No. of mud pump and one welding set will be mounted on

Ashok Leyland /TATA 1616 4 x 2 drive full forward control truck chassis with power steering.

The truck mounted with rig should be compatible to RTO rules and BS IV(Euro IV) pollution

norms, The truck will be complete with driver’s cabin having one long back seat besides one

driver and cleaner seat as per the norms of transport authority. It will generally confirm to IS :

7206 – ( Part – I ) – 1986 para 3.3.13. The driver cabin should be fabricated using 16G\18G

Galvanized sheets and heavy duty angle\pipe frame structure. Tools box should be provided

underneath backseat. Two focus light (tilt able type) should be provided on the rear top of driver

cabin with power source from vehicle battery. The driver cabin should have warranty for 3

years. The Battery should be located outside cabin with locking facility

13. WELDING SET:

A new generation welding set, high frequency, brushless, with winding-less, commutator-less,

slipring-less . Arc welding set of 400 Amp capacity with open circuit voltage of 45 to 100 volts

approx. will be supplied duly mounted on the drilling rig. Welding set will be complete with two

numbers of copper welding cable of 95 sq. mm cross section area of copper wire of 50 mtrs.

14

length with BIS standard and other standard accessories. A welding set will be driven by the

P.T.O. system\hydraulic system of rig and by truck engine through a separate clutch. The

complete welding set will be covered with M.S. sheet and locking arrangement.

14. LIGHTING SYSTEM:

The rig will be provided with a lighting system to facilitate drilling at night. The lighting points will

be provided on the mast and at other strategical points of the rig. The lighting will be shock and

vibration proof and adequately sealed to protect from dirt and water.

15. HYDRAULIC BREAK OUT SYSYEM:

A hydraulic breakout system will be provided on the drilling rig at a convenient location of the rig

for breaking and opening of tool joints. The break-out system should be complete with a suitable

hydraulic cylinder, chain tong, counter weight along with wire rope, etc.

16. CONTROLS:

All the controls will be grouped together at the left side of the driller and located near the rotary

table / drilling point. The gauges for mud pump pressure, hydraulic pressure, voltmeter,

Ammeter, etc. will also be provided at control panel.

17. TEST CERTIFICATES:

Test Certificates should be providing for load testing for the following equipment from reputed Govt.

recognised testing house:Water Swivel, Hoisting Plug, Single & Triple Sheave Travelling Blocks, Mast, Mud Pump

18. GUARANTEE / WARRANTY

The equipment quoted must be covered Guarantee / Warrantee for a period of 24 months

from the date of completion of successful commissioning against manufacturing defect or faulty

workmanship / design. During the Guarantee / Warrantee period all defective parts should be

repaired or replaced at free of cost the driver cabin of the Rig should have warranty for 3 years.

Drill Pipes for 5000mts depth.

19. TRAINING

The supplier shall arrange practical training free of charge in operation, maintenance, repairs

and up keep of the equipment/machinery and accessories to the purchaser’s officers and

technical personnel at the time of commissioning and testing at consignee’s site. Training should

be on site during exploratory drilling of at least two wells to the rated capacity of the Rig in

presence of experts from the manufacturer.

20. PARTS CATLOGUE / MANUALS:

Two sets of Catalogue and Service manuals for rig, rig truck, hydraulic pumps, motors, with

sectional diagrams of all components of rig, Spares part catalogue of rig, engine catalogue, mud

pump catalogue etc in English need to be provided.

21. Tools and accessories

Standard Tools and accessories for day to day maintenance of the rig, Set of special tools for

mud pump and fishing tools should be supplied with the Rig in a suitable Tool Box. Any

tools\accessories required for any kind of operation in rig for completion of well though not

mentioned in the Annexure I”C” will need to be supplied by the firm without additional cost.

Note: Accessories as per manufacturer’s own specification, design to meet item

requirements shall also be acceptable. The manufacturer/supplier of the rig

should indicate details of accessories quantities, rates and full name & address

of the manufacturer of the particular accessory / component

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-

15

ANNEXURE – 2

TECHNICAL DATA OF POWER RIG FOR WATER WELL CONSTRUCTION

1. CARRIER / MOUNTING

a) Make

Permissible axle Loads

Front Axle

Rear Axle

: Ashok Leyland / TATA

: 6000 Kgs.

: 10200 Kgs.

Actual axle Loads(approx.)

Front Axle

Rear Axle

: 4900 Kgs.

: 9300 Kgs.

b) Total Load

: 16200 Kgs.

c) Size of the tyre

: 10.00-20.00 (6 Nos.)

2. HOISTING DRUM/Sand reel Drum details

a) Brake Size

: 100mm width x 470mm dia

b) Type of driven system

: Mechanical, Chain driven with friction clutch

c) Hoisting and sand line speeds in various gears in RPM:

1st

2nd 3rd 4th

5th

25

41 72 116 177

3. TRANSMISSION

1st

2nd

3rd

4th

5th

a Gear Ratio

7.20 4.22 2.44 1.52 1:1

b RPM in various gears

250 426 738 1184 1800

c Torque available in various gears 342 201 116 72

47

4. MAST

a) Gross Load, Capacity

: 70000 lbs / 31820 Kgs.

b) Hook Load with single sheave block

: 12500 Kg.

c) Double sheave block

: 20000 Kg.

d) Triple sheave block

: 30000 Kg

e) Safety Factor

: 3.0

f) Length of rods/casings which can be handled : 20 Ft.

g) Height of mast when raised.

: 42 (12.8 Mt.)

h) Number of Hydraulic cylinder.

: 2 Nos.

i) Overhanging of Mast in resting position.

: 3 Mt. (Approx)

5. LEVELING JACKS (HYDRAULIC)

Cylinder Bore (Dia.)

Stroke

6. MUD PUMP

a) Type of pump

b) Size of pump.

c) Working pressure in Kg./cm2

: 4 Nos.

:125 mm

: 610 mm

4.93 inches

24.00 inches

: Duplex double acting reciprocating

: 152.4mm (6”) Bore x 203mm (8”) Stroke.

: 19.97 Kg./cm2

16

d) Capacity in LPM

e) Power requirement at fullcapacity.

: 1435 LPM Maximum

905 LPM Normal

: 47.2 H.P.

7. PULL DOWN

a) Type

b) Stroke Length

c) Piston dia

d) Minimum pull down Force

: Twin Hyd. Cylinders

: 762mm / 30”

: 60mm

: 8690kgs (18000 Lbs)

8. HYDRAULIC BREAK OUT

a) Details

b) Minimum Breakout Force

: Double acting Hyd. Cylinder.

: 10000 Kgs.

9. KELLY Single piece Three fluted

a)Size

b) Material composition.

Kelly should be made from alloy steel

seamless mechanical tubing having the

following physical properties.

(a) Yield Strength

(b) Tensile Strength

(c) Elongation percent

(d) Impact value

(e)Hardness

: 104.8 mm(4.1/8”) X 8.5 mts. (28 ft) long

suitable for 88.90 mm (3.1/2”) OD drill pipes.

: EN -19 Steel / AISI- 4140

: 686 N/mm2 ( Min.)

: 882 N/mm2( Min.)

: 11 % ( Min )

: 35 J, Hardness

: 255 BHN ( Min )

c) Source of procurement /manufacturing

of Kelly with documentary proof whether

local or imported.

: Procured Imported.

10. DRILL PIPE - 88.90 mm ( 3.1/2”), 6.096m(20ft) long External Upset

a) Type of base pipe.

: Seamless Steel Tube confirming to API 5 DP

Grade – “E-75 ”

b) Wall thickness.

: 9.35 mm

c) Weight per meter.

: 18.34 Kg./ Mt. Approx

d) Type of tool joints.

: API 88.90 mm (3.1/2”) IF Box & Pin Connection

NC – 38 API – Spe - 7

11. WELDING SET

a) Type

::

:Brushless,windingless,commutatorless,

slipringless arc welding set

b) Length of copper wire cable

: 50 Mts.

c) Open circuit voltage.

: 80 / 90 Volt. – 400 Amp

12. HYDRAULIC PUMP

Fixed Displacement Vane Type Pump

: 80 LPM (21 – US GPM)

: 70 Kgs./Sq.cm (1000 PSI)

13. MISCELLANEOUS

a) Capacity of Center latch elevator

b) Capacity of Hoisting plug

c) Capacity of Casing elevators

d) Material of subs.

: 25000 Kgs.

: 10000 Kgs.

: 20000 Kgs.

: EN -19 Steel

17

e) Material of drill collars

: EN - 8 Steel

f) Material of Fishing tools

: EN - 353 Steel Case Hardened.

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

18

ANNEXURE – 3

OPERATING TOOLS AND ACCESSORIES & SPARES OF POWER RIG

Sl.

No.

Description

Qty.

Unit

2

Nos.

2

1

Nos.

No.

1

No.

1

No.

1

No.

2

Nos.

1

100mm x7.6m (4’’ x 25’) Suction Hose complete with fittings and strainer.

2

7

50mm x7.6m (2’’ x 25’) high pressure double steel wire braided swivel hose

suitable for working pressure upto 100 psi complete with heavy duty fittings.

30 Tons capacity triple sheave traveling block with the sheave grooved for

wire rope.

12.5 Tons capacity, Single sheave traveling block with sheave grooved for

wire rope.

Heavy duty bail type water swivel of 25 tons capacity having 50mm (2’’)

water course with heavy duty connections for swivel hose.

104.8mm (4.1/8’’) x 28 ft. long Kelly with drive bushing with top plate and

pins.

Sub water swivel to Kelly. 104.8mm (4.1/8’’)

8

Sub – Kelly to drill pipe size 88.90mm (3 ½”)

2

Nos.

9

Sub - Drill pipe {Size 88.90 (3 ½”) to

88.9mm ( 3 ½” ”) API – REG Box

2

Nos.

10

Sub - Drill pipe {Size 88.90 (3 ½”) to 193.67mm (7 5/8”) API – REG Box

2

Nos.

11

Sub - Drill pipe {Size 88.90 (3 ½”) to 168.00mm (6 5/8”) API – REG Box

2

Nos.

12

Sub - Drill pipe {Size 88.90 (3 ½”) to 114.00mm (4 ½””) API – REG Box

2

Nos.

13

88.9 mm (3.1/2’’) O.D. x 6.10m (20’) long external upset drill pipe confirming

to API 5DP, Grade-‘E-75’ manufactured from hot drawn seamless Steel tube

having wall thickness of 9.35mm and the normal weight of tube

approximately 18.34 Kg/m with screwed on Type counter bore welded

120.65mm(4 ¾”_ alloy steel heat treated IF tool joint having surface

hardness of minimum 285 BHN provided with API RH connection complete

with thread protectors. With warranty for 5000m or 2years

75

Nos.

4

Nos.

3

4

5

6

14

88.9 mm (3.1/2’’) O.D. x 3.0 m (10’) long external upset drill pipe confirming

to API 5DP, Grade-‘E-75’ manufactured from hot drawn seamless Steel tube

having wall thickness of 9.35mm and the normal weight of tube

approximately 18.34 Kg/m with screwed on Type counter bore welded

120.65mm(4 ¾”_ alloy steel heat treated IF tool joint having surface

hardness of minimum 285 BHN provided with API RH connection complete

with thread protectors. With warranty for 5000m or 2years

15

Heavy Duty Hoisting plug with 88.9 mm (3.1/2”) API pin suitable for lifting drill pipes.

3

Nos

16

Spider base, Spider, Spider bushing and slips for the following sizes of

casing pipes.

(i) 323.9mm (12 ¾”) casing

- 1 No

(ii) 273 mm (10.3/4”) casing

- 1 No.

(iii) 219 mm (8 5/8”) casing

- 1 No.

(iv) 168 mm (6 5/8”) casing

- 1 No.

(v) 114 mm (4 ½”) casing

- 1 No.

(vi) 88.9mm (3 ½”)

Drill pipe

- 1 No.

1

Set

19

Sl.

No.

17

18

19

20

21

22

Description

Qty.

Unit

1

Set

(In

400

Mts.

(In

400

Mts.

Heavy Duty Rigid Imported - Pipe Wrenches. 18”, 24”, 36” & 48”

(i) 18” - 1 No., (ii) 24” - 1 No. (iii) 36” - 1 No. & (iv) 48” - 1 No.

2

Sets

Heavy Duty Rigid Imported - Chain Wrenches. 4”, 6”, 8” & 10”

(i) 4” - 1 No., (ii) 6” - 1 No. (iii) 8” - 1 No. & (iv) 10” - 1 No.

2

Sets

1

Set

Heavy Duty Elevator with Links for the following sizes of casing pipes.

(i) 323.9mm (12 ¾”) casing

- 1 No

(ii) 273 mm (10.3/4”) casing

- 1 No.

(iii) 219 mm (8 5/8”) casing

- 1 No.

(iv) 168 mm (6 5/8”) casing

- 1 No.

(v) 114 mm (4 ½”) casing

- 1 No.

(vi) 88.9mm (3 ½”) Drill pipe

- 1 No.

19/22 mm non-spinning tested wire rope with safety clevis assembly

addition to already existing in rig)

19/22 mm non-spinning tested wire rope with safety clevis assembly

addition to already existing in rig)

Mud Pump Tools:.

(i) Mud Pump Valve seat puller

- 1 No

(ii) Mud Pump Liner Puller

- 1 No.

(iii) Mud Pump Piston Rod Box Spanner - 1 No.

23

24

.

Mud Pump Spares:.

i)

Mud Pump Liner 150 mm (6”)

3

Sets

ii)

Mud Pump Piston Rod assembly

4

Sets

iii) Mud pump Piston cups

50

Nos

iv) Mud pump valve seat guide

2

Sets

v) Mud pump Valve

2

Sets

vi) Mud Pump Valve seat rubber

100

Nos

vii) Mud Pump liner Packing

25

Nos

viii) Mud Pump Gland Packing

100

Nos

ix) Mud Swivel “V” Packing

10

Sets

x) 6m long Heavy duty suction Hose

2

Nos

4

Sets

25

Sets

1

Set

Water Swivel:

(i) Water Swivel Bearing

(ii) Water Swivel seal packing

25

Fishing Tool

i) Overshot

ii) Inner shot

iii) Magnet with 20 Kg pulling load along with wire rope mounted on

manual operated winch drum

20

Sl.

No.

26

Description

Qty.

Unit

1

Set

Standard Tools

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

n)

o)

p)

q)

r)

s)

t)

u)

10” Adjustable Spanner

Grease Gun with nozzle, Capacity 1lbs.

Preassure type lubricating oil cane capacity ½ Lts

Nose Plier 8”

Ball pan hammer Capacity 1 ½ lbs.

12” Mill Standard file with handle – Rough, Medium, & Fine

10” Plier

8” Screw Driver

Padlocks

Double end spanners set 6mm to 32mm

Ring spanners set

6mm to 32mm

Box Spanner set

6mm to 32mm

Allen Keys set

- 3mm to 12mm

6” Chisel

Centre Punch 125mm

Double end spanners

36mm x 41mm

Tommy bar

Out side & Inside Callipers

Steel Engineer Scale – 30 cms & 1 mtr.

Steel Measurement tape – 3 mts & 30 mts

Mechanical Screw Jack - 25 Ton

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

4

No

No

No

No

No

Set

No

No

Nos.

No

No

No

No

No

No

No

No

Set

Set

Set

Nos.

© Copyright 2026