Phased Array Ultrasonic Testing - Anatec-LMT

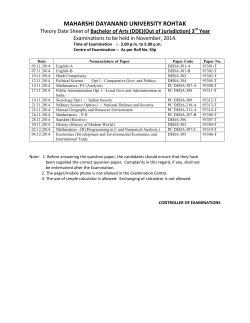

Nuclear Division | LMT LMT Advanced NDE Solutions Phased Array Ultrasonic Testing LMT, a business unit of Curtiss-Wright, has been providing NDE services to the nuclear power industry for over 30 years. Our team of experts develop and deliver the latest technology, procedures, and programs to help ensure continued safe operation, equipment reliability and compliance with industry and regulatory standards. LMT’s PAUT Services: • Fully Encoded Dissimilar Metal Welds & Weld Overlay Repairs • Non-Encoded Similar & Dissimilar Metal Welds and Weld Overlay Repairs • Fully Encoded Alternative NDE in lieu of Radiography (RT) – ASME Section XI Carbon Steel Piping Applications – ASME B31.1 Applications – Socket Welded joints for PLEX applications Fully Encoded Phased Array Ultrasonic Testing provides a cost effective solution for complex examinations. Phased Array Ultrasonic Testing (PAUT) is an advanced method of volumetric examination that can reveal all types of material defects. LMT, a leader in the delivery of PAUT, has developed several “first use” applications that provide customers with innovative solutions for technically challenging and critical situations. LMT performs PAUT services using their team of highly skilled and experienced technicians utilizing LMT customized delivery systems. PAUT: Advanced Volumetric Examination in lieu of Radiography (RT) LMT has extensive experience in the utilization of their innovative PAUT technology to confirm material integrity on modification and replacement projects in lieu of RT. LMT has delivered this PAUT in lieu of radiography in both B31.1 and ASME Code applications. PAUT provides significant improvements by: — Superior flaw discrimination and flaw positioning — Providing superior mapping for defect removal — Performing weld examination concurrent with other work activities — Reducing examination durations — Eliminating RAD Protection support — Eliminating work stoppage to perform testing PAUT: Dissimilar Metal Nozzle Welds LMT delivered “first use” applications for PAUT of PWR Reactor Pressure Vessel (RPV) Dissimilar Metal (DM) nozzle welds and RCS piping nozzle DM welds. LMT first performed RPV nozzle DM weld examinations on Westinghouse RPV nozzles eliminating the need to remove the core barrel. This application significantly reduced the critical path duration while removing the radiological risk. Encoded PAUT has also been delivered for RCS component (SG, RCP, drains, attachment welds) DM welds. LMT delivers the same PAUT techniques for the examination of BWR vessel nozzle welds. All testing meets ASME Code Section XI Appendix VIII. Nuclear Division | LMT Phased Array Ultrasonic Testing Services PAUT: Socket-Welded Joints LMT has developed a “first use” application for PAUT in lieu of RT or destructive testing for socket-welded joint examination. Nuclear power plants require the examination of Socket-Welded Joints as part of their plant life extension (PLEX) programs. By delivering PAUT for this application, LMT provides utilities with improvements in ALARA, schedule duration and cost, all without the schedule impact associated with RT. Large Bore Delivery System LMT is committed to the advancement of PAUT technology by sponsoring and conducting periodic Phased Array UT Workshops. For additional information on PAUT workshops contact Jeff Devers at 501.366.0334 or Todd Blechinger at 218.791.9163 Additional Services • NDE Services: UT, MT, PT, ET, VT • Nuclear PSI & ISI Services • PDI Qualified Procedures, Personnel and Equipment Limitless Applications • NDE and Quality Training Programs — ASME XI, Appendix VI, Visual Examination — ASME XI, Appendix VII, UT — Introduction to Phased Array — Advanced Phased Array — Advanced Phased Array Analysis Small Bore Delivery System — Quality Control — ASME Code Program Development and Review • Quality Control Inspection Services — Mechanical, Civil, Electrical • Quality Assurance and Licensing Support Nuclear Division | LMT | 38 Executive Park, Suite 350, Irvine, CA 92614 949.498.3350 | http://anatec-lmt.cwfc.com

© Copyright 2026