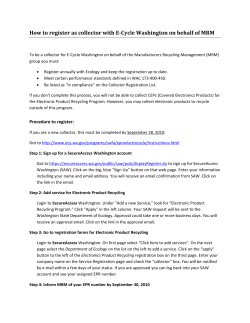

AIIA E-SIG / PSA Interim Industry Standard Collection