jim pattison centre of excellence

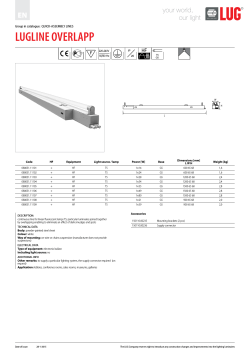

CASE STUDY JIM PATTISON CENTRE OF EXCELLENCE The Jim Pattison Centre of Excellence in Sustainable Building Technologies and Renewable Energy Conservation in Penticton, BC is one of the world’s greenest buildings and one of the largest buildings pursuing the Living Building Challenge. Applied Engineering Solutions provided Electrical Engineering design services for the Centre, which is a teaching and demonstration lab for trades students. Its design allows students to see cutting-edge systems in action and helps them understand how a building can be designed and built in a highly sustainable manner. The building also provides business development, research and development facilities, as well as amenities for students, staff and the community, including a gymnasium and fitness room. PROJECT OBJECTIVES, SOLUTIONS & ACHIEVEMENTS OBJECTIVES The objective of the Jim Pattison Centre of Excellence in Sustainable Building Technologies and Renewable Energy Conservation was to create a building that is highly sustainable, and that will serve as a benchmark for innovative design for students for years to come. The project was funded through Industry Canada’s Knowledge Infrastructure Program (KIP), which helps universities and colleges enhance their current infrastructure. To meet KIP funding requirements, buildings must be designed to meet LEED® Gold certification standards under CaGBC. Okanagan College wanted to exceed this requirement with an objective of the building being designed to reach LEED® Platinum and Living Building Challenge requirements. Okanagan College also wanted to use the building as a teaching and demonstration lab for its trades students. Through its unique design, students can see how its systems work, and how a building can be designed and built in a highly sustainable manner. The ultimate goal is for students to take away what they learn from this building, and apply it to other buildings that they will work on throughout their careers. SOLUTIONS Electrical engineering design was key for this project to meet its sustainability goals. Meeting the client’s objective of a highly sustainable building, while staying within the established project schedule and budget, required creative solutions to reduce the building’s carbon footprint and operating costs. Applied Engineering Solutions (AES) first considered the needs of the other project team members, such as the architectural and mechanical teams, and how their system and design selections would ultimately affect overall energy usage. Working together in an integrated environment, AES proposed the question: “What can be done to lower energy usage?” “Can you put on a sweater instead of turning up the heat?” “Can you work in an environment where lighting levels are slightly lower than if the lights are on?” Looking at the project from this perspective helped find solutions that would meet the criteria for LEED® Platinum and Living Building certification. Through constant communication and discussion, the project team was able to find the balance between energy usage and each discipline’s individual design needs. Energy-saving selections at the start meant fewer electrical system components being required, which in turn left funds available to select other components that would not normally have fit into the project budget. The end result is a building that is highly sustainable, and that was delivered to the client with no additional costs. APPLIED ENGINEERING SOLUTIONS LTD. APPLIEDENGINEERING.CA [email protected] ACHIEVEMENTS Working together with the project team on their system selections resulted in a lower energy load for the building, and the need for fewer electrical systems. This allowed $400,000 from the electrical budget to be transferred to the architectural budget to purchase triple-glazed windows, which allowed for more daylight in the building without affecting energy loss through the windows. This collaboration with the building’s design team has resulted in a building that will be Net-Zero by the end of 2012. The end result is a highly-sustainable building that meets both LEED® Platinum and Living Building certification criteria. It is anticipated to be verified and then further certified in approximately one year. Project management was key to keeping the project on schedule and on budget. KIP funding meant that the project schedule was accelerated, reducing the design process from 18 months down to just 12 months. To meet this timeframe, the project had to be designed in multiple packages; the below-slab package was designed in May 2010, well in advance of the systems inside the building, while the second package contained the remainder of the project design. AES worked in a construction management environment, working with contractors who could advise what materials would be available in time to fit the schedule. The prime consultant’s project schedule and AES’s internal deadlines allowed the project to reach substantial completion by March 31, 2011 as per Ministry requirements. The remainder of the project was completed shortly thereafter, with the building opening for classes in September 2011. APPLIED ENGINEERING SOLUTIONS LTD. APPLIEDENGINEERING.CA [email protected] TECHNICAL EXCELLENCE & INNOVATION In order to meet the client’s requirements for sustainability, AES sought out a number of cutting-edge innovations that are not typically seen in traditional building design. Working with the architect and other team members, AES was able to provide systems that take advantage of natural lighting, lessening the lighting load and energy generation on site. DAYLIGHTING AES installed two different systems that are designed to capture natural lighting and divert it to provide natural light to interior spaces. The first is the Solatube Daylighting System. Installed in every workshop, the Solatube system starts with a domed skylight mounted on the roof of the building. Its smart technology redirects low-angle light in the morning or afternoon hours and rejects overwhelming mid-day sunlight, providing consistent lighting throughout the day. Light is then funnelled through a tube that connects to a dual lens array fixture mounted in the ceiling below, which diffuses light throughout the space, eliminating the need for lighting during daytime hours. WIRELESS SWITCHES The school’s Audio/Visual workshop features two completely glass walls, which posed a challenge for electrical controls. The AES team decided on self-powered, wireless switches for lighting control, which convert kinetic energy from each button press into electricity to power the wireless signal. The advantages of using wireless switches include fewer materials being required because there is no installed conduit or wiring involved, and that there is less embodied energy in the building. And since the technology is brand new, it serves as a showcase component for students who are studying the building. OCCUPANCY AND DAYLIGHT SENSORS Light fixtures in common areas, as well as open and enclosed spaces, have built-in occupancy and daylight sensors. These sensors will automatically turn off lights if there is no one in a room, and will dim lighting if there is enough natural light available to illuminate the space. The second daylighting feature selected by AES is sun-tracking light pipes, which were used to provide daylighting to other areas in the building where Solatube technology could not be used. Light pipe technology can be installed on top of or beside a building, where a solar tracking device collects light and channels it into piping that takes it inside and focuses it by a factor of ten. The main advantage of this technology is that light pipes can be installed on side walls and directed down corridors, reducing the amount of lighting required during daytime hours. APPLIED ENGINEERING SOLUTIONS LTD. APPLIEDENGINEERING.CA [email protected] PHOTOVOLTAIC SYSTEM ALTERNATIVE MATERIALS The photovoltaic system was designed for installation in phases. The first installation of approximately 1,106 modules has been completed at 259.9 kW with an estimated energy output of 293 kWh. Installing the photovoltaic modules flat on the roof has provided a significant advantage over traditional installation. Typically, photovoltaic modules are installed at a 25 to 30 degree angle to capture optimum sunlight in Penticton, but require more space so that no stand casts a shadow over any other modules. Laying the modules flat on the roof, which has a 4% grade, allows more modules to be installed in the same amount of space, and only reduces overall output by 10%. The reduction of space needed allows the addition of up to 40% more modules, thereby capturing more energy than a traditional installation could. Living Building criteria includes a “red list” of materials that are prohibited on projects because of the harm they cause to the environment. AES had to find acceptable materials to replace these banned items that would meet Living Building certification standards, and yet would also meet local Code requirements. AES is monitoring the building’s energy usage and generation from the photovoltaic panels for one year. At that time, the team will evaluate what is needed to make the building Net-Zero, and will amend the number of modules and type of equipment that will best meet that goal. Waiting for one year enables precise observation of how the building is performing, and allows the team to take advantage of lowered costs and advances in technology to bridge the energy gap, if any. APPLIED ENGINEERING SOLUTIONS LTD. One example of this is PVC piping, which is normally used for electrical conduits. After researching a number of different materials, AES decided to use FRE material in place of PVC. Another energy-saving alternative used was the installation of white boards in classrooms instead of traditional blackboards. White boards reflect more light, therefore result in lower lighting requirements for the classroom space. AES was able to use 300 lux lighting for classrooms with white boards, as opposed to the 500 lux lighting that would have been required with blackboards. LED LIGHTING The use of LED lighting in parking lot areas is advantageous in that it uses less energy and has less glare than traditional lighting, thus meeting the client’s sustainability goals. Since LED technology is “instant on” versus HID, it is also more practical to implement control strategies to further reduce energy consumption. APPLIEDENGINEERING.CA [email protected] ENVIRONMENTAL, ECONOMIC, SOCIAL SUSTAINABILITY & AESTHETICS ENVIRONMENTAL The project site was limited by two existing buildings to the west, including a school, and NAV Canada property to the east. The project team had to work with a number of NAV Canada requirements for their property, including minimum distances, clearances, the amount of light that appears on their property, and the amount of EMI they would have. Construction for the low-grade site services occurred during the winter months, which posed a challenge due to the ground being cold or frozen. Furthermore, the school to the west was kept open during construction, so any electrical work had to be completed without interrupting school operations. ECONOMIC The project was funded and approved by Industry Canada’s Knowledge Infrastructure Plan (KIP) in early 2009. SOCIAL SUSTAINABILITY The project team took every opportunity to involve the community in this project. CEI Architecture hosted a 3-day design charrette, which included more than 40 stakeholders consisting of college staff, maintenance workers, local community members who have an interest or who are directly involved in the college, and the local manufacturing and engineering community. The project team’s preference was to use local firms whenever possible. Supplier procurement was done early enough in the design process that suppliers could see the benefit of having their products featured in a building that serves to demonstrate sustainability to students. This included Skyfire Energy, who provided the photovoltaic system. AESTHETIC ASPECTS Great care was taken to ensure that component selections fit in with the architectural vision for the building. Exterior lighting was chosen to match existing structures and the surrounding landscape. Building-mounted lighting was installed so that it is concealed within the wood and concrete piers, and at night appears to glow as part of the wood ceiling. For the light pipe system, AES worked together with the architect and supplier to change typically boxy and industrial looking reflector patterns into attractive and practical lighting styles for each space. The overall effect is that the structure’s lighting is both seamless and aesthetically interesting. APPLIED ENGINEERING SOLUTIONS LTD. APPLIEDENGINEERING.CA [email protected] PROJECT FEATURE HIGHLIGHTS TEACHING AND DEMONSTRATION LAB Right: The building itself has been designed as a teaching and demonstration lab. Sections of the ceiling have been left open, exposing conduit and cabling. This allows students to see how mechanical and electrical systems work, and understand the application of sustainable design. INTEGRAL OCCUPANCY SENSORS Below: Luminaires feature built-in occupancy and daylight sensors, ensuring each individual fixture supplies light as needed and at appropriate levels to supplement day lighting within the space. TRIPLE-GLAZED WINDOWS Below: Collaboration with the design team on system selections resulted in a savings of $400,000 allowing for the purchase of triple-glazed windows in the gym, which enable more daylight without affecting energy loss through the windows. LIGHTING DESIGN Below: Enclosed passage ways feature a unique lighting installation which adds visual interest by creating the illusion of natural rays of light reflected on the wall. PROJECT FEATURE HIGHLIGHTS SOLATUBE DAYLIGHTING SYSTEM & PHOTOVOLTAIC SYSTEM Below: Every workshop is outfitted with the Solatube Daylighting System, eliminating the need for artificial lighting during daytime hours. Above: The Solatube Daylighting System collects light through domed skylights mounted on the roof of the building. Its smart technology redirects low-angle light in the morning or afternoon hours and rejects overwhelming mid-day sunlight, providing consistent lighting throughout the day. Flat installation of solar panels allows for 40% more modules than traditional layout. SUN TRACKING LIGHT PIPES Right: Solar tracking devices collect sunlight and channel into pipes, focusing light by a factor of ten before illuminating interior spaces. Below: Sun-tracking light pipes can be installed on side walls and directed down corridors, reducing the amount of lighting required during daytime hours. PROJECT: JIM PATTISON CENTRE OF EXCELLENCE Electrical Engineer: Project Owner / Client: Architect: Photographer Credit: Applied Engineering Solutions Ltd. Jim Pattison Centre of Excellence CEI Architecture Planning Interiors Ema Peter APPLIED ENGINEERING SOLUTIONS (AES) We offer a full spectrum of electrical engineering services including: • • • • • • • • • Power Distribution Architectural Lighting Life Safety Systems Communication Systems Audio Visual Systems Security Systems Daylight Modeling BIM Acoustic Modeling VANCOUVER 2nd Floor, 1330 Granville Street Vancouver, BC V6Z 1M7 TEL: (604) 569.6500 FAX: (604) 569.6501 VICTORIA 3rd Floor, 1815 Blanshard Street Victoria, BC V8T 5A4 TEL: (250) 381.6121 FAX: (250) 381.6811 appliedengineering.ca @appliedengineering.ca applied-engineering-solutions @ _AES_Electrical appliedengineeringsolutions

© Copyright 2026