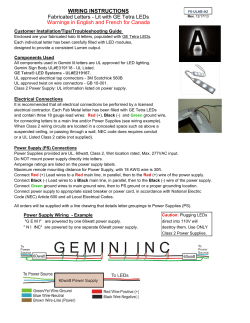

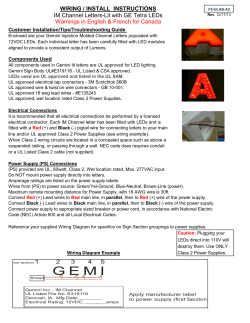

Wire Design Basics Book 2 More Techniques and Designs for