Learn at Home: Sewing 101 Getting to Know Your Machine

Learn at Home: Sewing 101

Getting to Know Your Machine

Anatomy of a Sewing Machine

Stitching Corners, Made easy!

Basic Maintenance and Cleaning

Easy-to-sew ice-breaker projects

for getting to know your new

machine.

Page 18 - 2 1

Click to navigate

Table of Contents

Anatomy of a Sewing Machine . . . . . . . . . . . . . . 3

Sewing Machine Features & Functions . . . . . . . . . . 4

Feature Focus — Feed Dogs . . . . . . . . . . . . . . . 6

Bobbin Winding . . . . . . . . . . . . . . . . . . . . 7

Bobbin Case. . . . . . . . . . . . . . . . . . . . . . 8

Thread Tension. . . . . . . . . . . . . . . . . . . . . 9

Page 6

Tension Extremes. . . . . . . . . . . . . . . . . . . 10

Get to know the doggies!

Starting & Stopping a Stitch Line. . . . . . . . . . . . . 11

There’s more to this dog than meets the eye.

Needle Threader & Needles. . . . . . . . . . . . . . . 12

Stitches & Terms . . . . . . . . . . . . . . . . . . . . 13

Sewing Supply List. . . . . . . . . . . . . . . . . . . 14

Sew Smarter

Presser Feet. . . . . . . . . . . . . . . . . . . . . . 15

Pinning & Pressing . . . . . . . . . . . . . . . . . . . 16

Right from the start

— Your SAH Learn to Sew Guide will

Basic Maintenance . . . . . . . . . . . . . . . . . . . 17

teach you the basics of sewing and have

you making your first project as soon

as you open the box. Be brave

and sew what you love!

Easy First Project. . . . . . . . . . . . . . . . . . . . 18

Appliqué Project. . . . . . . . . . . . . . . . . . . 20

Appliqué Prep and Ideas. . . . . . . . . . . . . . . . 21

Good to Know . . . . . . . . . . . . . . . . . . . . 22

© 2012 Janome Canada Ltd. and Janome Shop at Home; all content

distributed free for personal use only.

Page 2

———————

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

PAGES

Anatomy of a Sewing Machine

Each machine is different

Please consult your owners

manual for specific details

for your SAH machine

< 26

<1

2>

4>

5>

< 22

3>

< 25

28 >

<6

27 >

7>

21 >

8>

< 23

<9

< 29

20 >

19 >

10 >

11 > 12 >

< 17

32 >

30 >

< 18

14 >

33 >

31 >

1. Bobbin winder stopper

12. Feed dogs (below presser foot)

23. Stitch selection panel

2. Bobbin winder spindle

13. Extension table

24. Presser foot

3. Additional spool pin goes here

14. Accessory storage (inside)

25. Needle

4. Spool holder/cap

15. Free arm

26. Needle clamp screw

5. Spool pin

16. Drop feed lever

27. Foot holder

6. Bobbin winder thread guide/ tension

17. Hook cover plate (bobbin cover)

28. Setscrew

7. Thread take up lever

18. Bobbin cover release button

29. Carrying handle

8. Thread tension dial

19. Reverse stitch lever

30. Handwheel

9. Thread tension discs (within thread path)

20. Stitch length dial

31. Power switch and power socket

10. Thread cutter

21. Pattern selector dial

32. Foot lifter

11. Throat plate (stitch or needle plate)

22. Stitch width dial

33. Foot pedal

Sew

Encourage Curiosity — Get acquainted with all of the parts

and operations of your new sewing machine. Don’t be afraid to turn the dials and

push the buttons. The two of you will soon be best friends!

Smarter

———————

< 15

16 >

14 >

13 >

Page 3

< 24

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

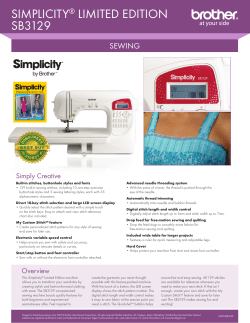

Sewing Machine Features & Functions

Each machine is different — Please consult your owners manual for specific details for your SAH machine

1. Bobbin Winder Stopper — Causes

a filled bobbin to stop winding.

2. Bobbin Winder Spindle — Secures

the bobbin in place for winding.

3. Additional Spool Pin — A second

spool allows for twin needle stitching,

or sewing with two threads

4. Spool Holder/Cap — Secures spool

to stay on pin, guides thread from spool

into thread path.

5. Spool Pin — Either horizontal or

vertical. Holds thread spool.

6. Bobbin Winder Thread Guide

Tension — Maintains even tension on

thread during bobbin winding.

7. Thread Take Up Lever

This lever pulls the thread from the

spool, through the tension and feeds

it through to the needle. It keeps thread

from tangling in thread path. The sewing machine will jam if the take up

lever unthreads.

8. Thread Tension Dial — Adjust the

degree of drag or ‘pinch’ on the upper

thread. Higher number indicates

more tension.

9. Thread Tension Discs (within

thread path) — Keep thread taut in the

thread path and pulling up the bobbin thread just enough for a balanced

stitch. Always thread machine with

tension discs open (presser foot up)

to properly seat thread in thread path.

———————

the side of the machine. To use: raise

presser foot, lift the stitched piece

and drag both the bobbin and upper

thread through the cutter to trim both

threads.

11. Throat Plate — Removable flat

metal or resin plate below the presser

foot through which the feed dogs raise

and the needle passes. A standard

plate has an oval shaped needle

Computerized Conveniences

Achieving Similar Results — Mechanical and computerized sewing

machines achieve similar results in

generally the same manner. Different

features and functions are often

a matter of convenience and

preference. Mechanical machines

will use levers and dials while

computerized machines will often

use digital displays and automatic

function buttons like those seen

on the Juno M1230Q.

1. Speed Control Slider

Page 4

10. Thread Cutter — Mounted along

Learn at Home

—

2. Start/Stop

4>

3>

<1

<2

3. Auto Lock, Reverse

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

4. Needle Up/Down

PAGES

Sewing Machine Features & Functions

25. Needle — Pierces fabric to allow

for joining upper and bobbin threads in

a locked stitch. Different needle sizes

accommodate different threads and

fabrics. The higher the needle number,

the larger the needle. Larger needles

are used with heavier fabrics.

26. Needle Clamp Screw — Secures

the needle in proper position in order

to create a balanced stitch.

opening wide enough for all stitches,

whiles an optional straight stitch plate

is for centre straight stitch only, and can

offer more thread/stitch control.

Push or hold to take several stitches or

continually reverse stitch. Most often

used for locking stitches and securing

seams.

12. Feed Dogs — Feed fabric

20. Stitch Length Dial — To manually

through the sewing path.

13. Extension Table — Flat bed of the

machine for sewing.

14. Accessory Table Storage — Holds

sewing accessories (removable).

15. Free Arm — Created when acces-

sory table is removed. Allows for sewing

in narrow spaces like cuffs or hems.

16. Drop Feed Lever — Lowers feed

dogs so that fabric can be moved freely,

or not moved at all for button sewing.

17. Hook Cover Plate (Bobbin Cover)

— Covers the bobbin and bobbin case.

18. Bobbin Cover Release Button

— Push to release the bobbin cover.

Always use JANOME bobbins : )

19. Reverse Stitch Lever (or button

(or digitally) select the length of a stitch.

A higher number gives a longer stitch.

Common length is 1.8 – 2.2mm.

21. Pattern Selector Dial (or stitch

number key) — To select stitch pattern

or turn through the steps of a four —

step buttonhole.

———————

27. Setscrew — Secures the foot

holder in place. Turn this screw to

attach feet remove the foot holder and

attach the walking or darning foot.

29. Carrying Handle — Retractable

or flip handles are built in to carry

the machine.

30. Handwheel — Used to manually

raise or lower the needle with precision.

Always turn towards you.

22. Stitch Width Dial — To manually

(or digitally) select the width of a zigzag or other stitch. When used with a

straight stitch, the stitch width controls

the NEEDLE POSITION.

— To turn the machine on or off. Always

turn the machine off when changing

needles or presser feet.

23. Stitch Selection Panel — Visual

32. Presser Foot Lifter — Handle

representation of stitch menu.

24. Presser Foot — Presses fabric in

place during stitch formation. Releases

thread tension when raised with presser

foot lifter. Different presser feet support different stitch effects such as a

blind hem or zipper insertion.

on computerized machines)

Page 5

27. Foot Holder (Ankle) — Securely

holds most presser feet by snapping or

sliding in them place. The small lever at

the back of the foot holder is depressed

to release/change feet.

Learn at Home

—

31. Power Switch and Power Socket

behind the needle used to lift or lower

the presser foot. Can sometimes be

lifted higher for extra clearance.

33. Foot Pedal — Used to regulate the

machine speed by pressing down like

a gas pedal. Can be disconnected on

some machines and replaced with the

start/stop button.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Feature Focus

SAH machine feed systems vary

between 3 (back), 4 (center) and

7 piece feed dogs (front). The 7-piece

superior feed provides more points

of contact between the machine and

fabric to make the feeding process all

the more smooth and precise.

Feed Dogs

Teeth to Lift & Pull — After a stitch is locked together, the fabric is fed

the distance of the next stitch. This feeding is accomplished by the action of the

feed dogs. A series of metal teeth along a thin metal bar rise up through the sewing

machine’s needle plate to lift and pull fabric along the stitch path. The drop feed

control keeps the feed dogs lowered and allows for free motion sewing where the

user controls the feeding pace and direction of the fabric. An even-feed or walking foot is an accessory foot which provides a second, upper set of feed dogs that

add even greater control to the fabric movement. This foot is particularly useful for

stitching quilts and other thick or multi-layered projects.

Cleaning Your Feed Dogs — Unscrew the needle plate and give the feed dogs

a thorough brushing (an old toothbrush works well for this). Lift out any fluff balls

rather than blowing them aside as you don’t want debris pushed deeper into the

machine. Replace the needle plate cover, and tighten the screws to hold it in place.

Seam Guide Lines

Accurate & Consistent Stitching — The markings etched in the

needle plate are convenient for stitching accurate and consistent seam lines. The

number indicates the distance from the centre needle position. Centimeter and

fractional inch markings are included.

Page 6

———————

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Bobbin Winding

One of the first steps in beginning to sew is to wind a bobbin.

Whether for a SAH mechanical or computerized machine, the

process is about the same. Wind the bobbin at a moderately fast

and consistent speed, and you will be ready to sew. While you’re at

it, wind several and you can sew the day away!

Winding Bobbins — The setup is the same for horizontal or vertical thread delivery

1. Prepare the machine for bobbin winding by disengaging the clutch (pulling

out the hand wheel) if necessary.

2. Set the spool on the spool pin and

secure it in place with the spool cap.

5. Place the bobbin on the bobbin winder

spindle & push the spindle to the right,

towards the stopper. (On computerized

machine, a code on the screen indicates the bobbin winder is engaged)

3. Wind the thread around the bobbin

winder tension disc in a ‘U-turn,’ not a wrap

around as with some other machines.

8. Press on the foot pedal until the bobbin

is full. It will start to ‘sputter’ and stop as the

fully wound thread contacts the stopper.

6. Hold the bobbin thread securely

between your fingers as you start to wind.

9. Disengage the winder by

pushing the spindle to the left.

10. Cut the thread at the bobbin and

7. After several turns of the bobbin,

4. Bring the thread up through one of the

small holes in the outer rim of either side

of the bobbin, not through the center hole!

Page 7

———————

snip the thread tail so as not to get

it caught in the winding thread.

Learn at Home

—

thread the machine for sewing. Be careful

NOT to keep the upper thread in the

bobbin winder tension. You must remove

the thread from this tension disc and secure

it in the first thread guide of the threading

path. Remaining in the upper bobbin

tension disc will inhibit sewing

and break threads.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Bobbin Case

Front Loading Bobbin Cases

You will quickly get a feel for the placement of a few simple parts

and bobbin winding will be a snap!

3>

<1

<4

<2

1. The Hook Cover

2. The Latch

3. The Horn

4. The Bobin Case

It is perfectly normal to see a few drips of

oil on a new machine. Check the general

bobbin case area. Remove the case and

check inside as well. Swipe it away with

paper towel.

When loading a new bobbin into the case,

be sure that the thread is unwinding away

from you (see image in your manual). Draw

the thread back towards you, into the bobbin case slot, then snap it under the tension

spring and into the delivery eye. [arrows

to spring & eye

2. The tail of the thread makes a ‘P’ shape

when correctly positioned. The image on

the cover is a helpful reminder.

4. Pop the cover back on, drawing the tail

backward, over the needle plate (see image

above). You are now ready to raise the

bobbin thread by holding the upper thread

as you lower and raise the needle. Gently

pull on the upper thread to raise a loop of

bobbin thread.

Top Loading Bobbin Case

Although the two cases look different, they

perform the same function. In the case of

the top-loading bobbin, it is easier to know

when thread is running low. Reloading your

next bobbin is simple.

1. Release the cover with a push of

the release.

Page 8

———————

3. Draw the thread to the left. Feel it

snap into the notch, and then between

the tension blades. Continue to draw it

backward into the notch at about the

“9 o’clock” position.

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Thread Tension

Understanding Tension

The mention of thread tension can scare off many-a-sewing enthusiast,

but once you understand the system, there is little to fear. Balanced

stitches, where threads meet and form a solid stitch within a smooth

flat seam or stitch line, are a result of good tension.

Good tension comes from these components working together to

have the same amount of thread on each side of the stitch:

The Tension Dial — This dial sets the closeness of the tension discs. A higher

Take-Up Lever

numbered setting increases the pressure between the discs, increasing the drag

on the upper thread which in turn pulls the bobbin thread more towards the top

of the fabric. A lower setting reduces drag and allows upper thread to flow more

freely, sometimes allowing the bobbin thread to pull the upper thread to the back

of a project.

Thread Guides — Along the thread path, including the guide on the take-up lever.

These assorted guides cumulatively increase the tension on the thread as well as

add to its proper alignment for a straight stitch.

Improper threading is often the cause of stitch troubles. Before adjusting tension,

double check all threading.

Front Loading

Top Loading

The Tension Discs — Located within the thread path, before the take up lever.

(These are not easily visible.) The presser foot must be lifted to open the tension

discs for proper threading.

Bobbin Case Tension Screw

Heavier threads will fill the tension discs more than normal sewing threads. Tension may need to be reduced when using these. The opposite is true for ultra-fine

threads that may require higher tension.

Bobbin Case Tension Spring — The tension screw controls the bobbin case

tension. Most tension issues can be resolved with upper tension adjustments.

Sew Smarter

smooth stitching

— Balanced tension may not always equal

good tension! Top and bobbin threads

may be staying on their own sides of the

fabric, but seams may still either pucker

or gap. This indicates that adjustments

need to be made to get a smooth,

well-balanced stitch.

Page 9

———————

A second bobbin case allows you to freely adjust bobbin tension, keeping the original case set for everyday sewing. With experience, you can adjust bobbin tension

by turning the screw in small increments (turn right to tighten or left to loosen). A

quarter turn is sufficient to make a change. Work over a soft cloth to catch this tiny

screw if it falls from the bobbin case while adjusting.

As you advance, you may wish to try ‘bobbin sewing’ using ultra-heavy threads in the

bobbin since they are too heavy to pass through a needle. Rather than loosening the

bobbin tension, consider bypassing it all together.

Other Factors — The thread, fabric or stitch selection, as well as the needle plate

or presser foot being used also affect tension.

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Tension Extremes

Try this: Put two different color threads in the top and bobbin.

Crank the tension all the way up to 9 or 10 and stitch a straight

and zigzag stitch. Turn it down to 0 or 1. Stitch through one or two

layers of cotton to see the effects. Over-tightened tension causes

puckering, while loosened tension shows thread loops on the back

side of the stitching.

Keep these tips in mind when evaluating your machine’s

thread tension:

1.Always TEST your stitches with the same threads and fabrics being used in your

project to set your machine up for each individual circumstance.

2.Use compatible threads: extreme variances in weight or content make balancing

a stitch more difficult

3.Loops of bobbin thread at the top suggest that the bobbin is not inserted

correctly.

Sew Smarter

4.Loops of upper thread at the back, or ‘thread nests’ in the bobbin case indicate

that the thread is not in the take up lever (sometimes the thread will ‘jump out’

of the take up if it is not clicked snugly into position). Having the presser foot up

while sewing can cause the machine to jam or thread nesting.

Dust bunnies

— Clean your machine regularly. Dust

bunnies and balls of thread can throw

off tension. Cleaning the bobbin case,

feed dogs and even the upper discs

themselves. This can be done by

‘flossing’ between the discs with

a folded piece of tightly woven

fabric (like a batik).

Page 10

———————

5. Check threading before making tension adjustments. Be sure that every thread

guide is used.

6.Use a fresh needle. Bent or dull needles impede good stitching.

7. Use a proper sized needle for the job. Forcing a heavy thread through a small

Learn at Home

needle can cause thread breaks or puckers.

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Starting & Stopping a Stitch Line

Start and Stop — Methods for solid seam construction

Auto-lock Button — This ‘bulls eye’ but-

Auto–lock Stitch — Available on select

Reverse — Pushing the reverse button or

lever at the beginning and ending of a seam

is a quick and easy method, but can leave

bulky or noticeable areas of excess stitching

Manually Shorten Stitch Length

ton on some SAH machines can be used to

take four locking stitches in place and then

stop. It is also used to complete a decorative

stitch pattern before stopping and locking.

SAH machines, this utility stitch begins with

locking stitches and, at the touch of the

reverse button, ends with locking stitches.

Reverse vs. Auto-lock — Reverse

stitching (top) is quick and easy, but autolock (bottom) secures with less bulk at the

beginning and end of the seam.

— Temporarily adjust stitch length to the

shortest setting, for compact, difficult to

loosen stitches.

Head off sewing frustrations by securing your threads at the beginning

and ending of each seam line.

Starting Tips — Try one or more of these tips for a clean start to your sewing

1. Don’t forget to raise the bobbin thread

up above the stitch plate when using a new

bobbin. Hold the upper thread tail and

either push the needle up/down button

or turn the hand wheel to draw the

bobbin thread up in a loop.

2. Start sewing with the needle in the

down position.

3. Prevent unthreading. Hold thread tails

pinched between the fingers of your left

hand as you start to sew. Release after

a few stitches.

Page 11

———————

4. Draw the bobbin thread up to the top

of the fabric. Similar to raising the bobbin

thread up, in this case, both of the thread

tails will be at the TOP side of the fabric.

This is particularly useful with free-motion

sewing. Do this before locking stitches in

place, by lowering and raising the needle

while holding the upper thread tail to

catch the bobbin tail in the thread loop,

pulling it up through the fabric.

Learn at Home

—

5. Use a Starter Square. When starting

at the leading edge of the fabric, it is not

uncommon to get a thread tangle, as the feed

dogs are not yet propelling the fabric along

the stitch path. The fabric edge could also be

pulled into the zigzag stitch plate. A starter

square (AKA a ‘startie-stoppie’ or ‘stitch

buddy’) 1s a scrap of fabric abutted against

the project fabric to be stitched. It gives the

stitch line a bit of a ‘running start’ before

getting to the leading edge of the project.

(An optional straight stitch plate can also

help with this scenario. You can purchase

this plate from your Janome dealer)

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Needle Threader & Needles

Needle Vari ety

Needle Know How

Your sewing machine needles: petite, but powerful tools that are

responsible for bringing precision and stability to your stitching. It’s

worth getting to know a little bit more about these hard working helpers.

Needle Stash

Needle sizes are marked with both the European (60 – 120) and American (8 – 19)

measurements. A size 60/8 needle is the finest needle for delicate fabrics and a

120/19 is the heaviest for fabrics like upholstery. Size is related to the needles blade

diameter. A size 75 needle has a .75mm blade.

Aside from the blade size, needles also have different types of tips, points, eyes,

scarves and grooves. The groove guides thread down the needle, across the notched

scarf and through the eye. More information can be found on the websites of quality

producers like Schmetz or Klasse.

Needle Storage

As you grow in your sewing skills, you will find that keeping a collection of varied

needles on hand will be a necessity. Changing a needle every eight hours is the

standard rule of thumb, but if you have to change needle type, you can keep track of

your needles with something as easy as a dollar store pincushion. Simply mark each

section with a ‘needle type’ as a holding area for those gently used needles.

Your SAH manual has a comprehensive needle guide on which needle should be

used with what fabric.

Needle threader — An easy-to-use convenience, available on some SAH machines

1. Lower and raise the needle to its highest

position with a turn of the hand wheel or by

pushing the needle up/down button.

2. Pull the needle threader controller down

and swing it forward towards the back of the

needle. This engages the wire threading hook

through the eye of the needle.

<2>

3. With the right hand, gently draw the

thread across the path of the threader,

which positions the thread just under the

wire hook. Hold the threader controller in

place with the left hand as needed.

<3>

<4>

Learn at Home

<5>

TO THE POINT — Signs that it is time to change a damaged or

unsuitable needle: a ‘banging’ noise as you sew, skipped or breaking stitches,

shredding thread, puckering seams or wonky tension.

Smarter

———————

5. Pull on the newly created thread loop

to draw the thread tail through the eye.

Sew

Page 12

4. Keep a light hand on the thread as you

release the controller to go back upwards.

The hook will draw the thread back

through the needle.

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Stitches & Terms

Stitch Categories

Navigate your machine’s menu

to discover some of your favourite ‘go-to’ stitches. Don’t hesitate

to experiment with varying stitch

length, width or varying thread

type to change its look.

Utility Stitches: These are usually at

the beginning of any machine stitch menu

because they are the most frequently used,

but don’t let the utility word throw you off.

You can embellish, couch, stitch with heavy

thread and imagine all sorts of uses for this

humble category. Stitches include: straight,

zigzag, straight stretch, auto-lock stitch and

tricot stitch (triple zigzag).

Sculpture: Sometimes called ‘saddle

stitches.’ The multiple stitch passes of this

stitch make it stand out, and it looks great in

topstitching. Can also be used to create the

hand-look quilt stitch.

Satin Stitches: So named for the ‘satiny

finish’ created by the short stitch length

when stitched in a lustrous thread.

Patchwork: Also known as the feather

stitch. Great for topstitching quilt seams.

Heirloom: These stitches capture the

look of traditional heirloom sewing. They are

often created with a wing needle, which cuts

a larger whole in fabric.

Smocking: While smocking comes and

Seam Finishes: These are often

grouped together in larger stitch menus.

Appliqué: Variations on the most common

appliqué stitch, the blanket stitch. Try different versions for heavier thread appearance

or more distant spaced stitches.

goes in fashion, these stitches never go out

of style.

Decorative: A general term used to describe

most stitches outside of the utility category.

General Sewing Terms — Good to know

Baste: Temporary stitching to hold things

in place. By machine, you baste using your

longest stitch setting. Loosening the tension

makes removal easier.

Bias: The 45 degree thread line in fabric.

When cut on the bias, fabric will have a

more fluid drape and stretch. Bias strips are

great for binding. Bias can be tricky to sew,

so use extra pins.

Hand: The drape and ‘feel’ of fabric.

(Soft, smooth, crisp…)

Raw Edge: The cut edge of fabric which

will often fray if left unfinished. The fraying

bits are sometimes called ‘whiskers.’ Can

also refer to a type of appliqué where the

edges are left to show through stitching

or be unstitched.

Page 13

———————

Seam: Two pieces of fabric sewn together

create a seam. The line of sewing is called

the seam line. The distance between the

cutting edge of a pattern and the seam line

is called the seam allowance (commonly

5/8˝ in garments and 1/4˝ in quilting). Seam

finishes are the assorted techniques used

to ‘clean up’ or hide the raw edge of a seam

(including overcast stitching).

Selvedge: The factory woven edges of

fabric often used to print collection details

and colour registration dots are known as

the selvedge. This part of the fabric behaves

differently than the rest, so it is usually cut

off, and quite often used as a decorative

embellishment.

Topstitching: Your spell checker won’t

like it, but you can use this as one word. This

is the functional or decorative stitching that

Learn at Home

—

shows on the outside of a project. It can be

enhanced with heavy threads or increased

stitch length. It is not limited to the straight

stitch. When used close to the edge of

stitching, this is often called edgestitching.

Warp and Weft: Not often used in your

vocabulary, but good to know: the lengthwise grain, parallel to the selvedge is the

warp fibre and the crosswise grain is the

weft fibre. A good way to remember is weft

goes from weft to right. Shot silks will often

use different colour warp and weft fibres

for an iridescent effect.

WST/RST: You have to know this one as

it is in patterns all the time! Wrong Sides

Together (WST) and Right Sides Together

(RST) are the two most common directions

for aligning fabric together for sewing

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

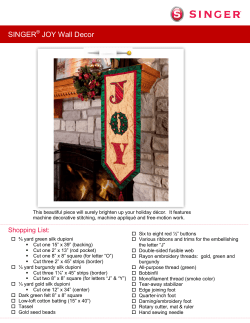

Sewing Supply List

〉〉 Take your time

So you have just purchased your

new sewing machine and you

want to get busy sewing. Every

project has a list of tools and

supplies and your stash may not

be quite there yet. Take your

time. Add to your supplies slowly.

You do not need EVERY tool,

notion, fabric or thread seen

in the magazines.

To get you started, things

you might need

Add-ons — Nice to have

• Your first pattern

• Your machine

• Sewing needles: You have a few with

your machine. You will need specialized

ones for topstitching or fine fabrics.

• A means of cutting: Good scissors will

serve you well

• Fresh sewing thread: Black, neutrals and

your favourite colour will be a good start

• Fabric: A bundle of a few fat quarters will

give you the means to embellish and make

small items (like our coasters!). Pressing, starching and cutting up old clothes

will also give you some good scraps.

• Small trimming scissors for cutting

out appliqué and trimming threads

• Separate, budget priced scissors for

cutting paper and patterns. Leave

your sewing scissors for fabric only

and they will stay sharp longer

• A magnetic pincushion makes holding and

gathering pins much easier. Of course, making a sweet, soft cushion is a good idea too.

• More bobbins (a sewist can never have

too many, and Janome bobbins are very

affordable. PLEASE, Always use Janome

brand bobbins for your machine)

• Slowly add to your fabric and thread stash

• Iron and ironing surface (board,

mini board or mat will do)

• Pins

• A means of measuring (tape measure)

• A hand sewing needle for little details

• Lint brush and small screw driver if

they did not come with your machine

• Fusible webbing and or interfacing.

Depending on what you are sewing, having

a small stash of this will come in handy.

• A good sewing reference book will be

used often. No matter how experienced

you are, there is always something new to

learn! The Sewing Answer Book by Barbara

Weiland Talbert and The Sewing Bible by

Ruth Singer are two excellent resources.

Signs that you are really

enjoying your sewing

• Bobbin keeper box or ring to keep

your collection from unwinding

• Thread storage rack or box

• Fold away cutting table

• A dedicated sewing chair that works

for you to keep your shoulders,

back and neck in good shape.

• Auxiliary thread stand for managing

any size of thread with your machine

(a cup at the back of your machine

will work, but these stands are reasonably priced and do a good job)

• If you are quilting, look at investing in a

rotary cutter, ruler and mat. They make

cutting so much easier. Local sewing

lounges and your dealer will quite often

let you use their classroom supplies

for a small fee. This could help you to

know if the tools are right for you.

• Machine carrying tote or case for

classes and getaway weekends

• Sewing lamp

Page 14

———————

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Presser Feet

Feet First

Various assortments of these feet are found in

your SAH machines. Others can be purchased

through your Janome dealer. Your manual will

help you to select the best foot for each stitch.

The All Purpose Foot (A)

The Zipper Foot (E)

The Adjustable Buttonhole Foot

The Overedge Foot (C)

The Sating Stitch/ Craft Foot (F)

The 1/4˝ Seam Foot (O)

Designed for optimal control of most utility

and straight stitching (Packaged on the

machine when new).

Neatly finish seams and prevent unraveling.

Even Feed Foot (Walking Foot)

Evenly feed quilts, garments or home décor

projects, as well as knits, velvet and velours

through your machine with this extra set

of feed dogs.

Page 15

———————

Install a zipper, but also use to attach

piping and cording.

A beveled channel beneath this foot allows

for smooth delivery of heavier stitches, F2

(in some machines) has an open toe.

Darning Foot for Free Motion

Embroidery A spring loaded foot that

allows you to stipple and thread paint with

a clear view and consistently formed stitch.

Learn at Home

—

Creating perfectly aligned buttonholes.

Sew a perfect quarter inch seam for

consistent quilt block assembly.

The Adjustable Blind Hem Foot (G)

Place folded edge against the adjustable

guide for an invisible blind hem — great

for top stitching.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Pinning & Pressing

1>

Pinning

2>

3>

Pins hold fabric in place until you are ready to sew. They keep fabric

in one area from shifting while you sew another area. They are also

handy to mark an area for altering. You might use two different

types of pins in your sewing: straight pins and safety pins.

4>

Straight pins can vary in length and headtype. Shorter length pins are known as

sequin pins and are designed to hold small

embellishments in place. Dressmaker pins

are the most used, mid length pins, suitable

for most sewing tasks. Quilting pins are

longer and can pass through the thick

layers of a quilt.

6>

5>

7>

1. Glass Head Pin

Cheaper plastic-head pins seem like a

good bargain, but they do not hold up well.

Glass head pins resist bending and do not

melt with ironing. Flat, flower head pins are

useful, especially when laying your rotary

cutting ruler over pinned fabric.

2. Silk Pin

3. Flat Head (Tailor’s) Pin

4. Applique Pin

5. Safety Pin

6. Flower Head Pin

Specialty pins, like silk pins or fork (twoprong) pins are designed for specific tasks.

The fork pin offers more control with slippery fabrics, while the fine silk pins do not

leave visible holes in your fabric.

7. Fork Pin

Insert pins perpendicular to a seam. This will

make it much easier to remove them as you

The bad, the worse

and the headless!

Top 3 faults of plastic head pins: they

bend, they melt & their heads pop off.

———————

Safety Pins (also known as basting pins)

come in a variety of sizes and finishes. Some

can be quite small and difficult to easily

open and close, while others can be so large

that they create a visible hole in your fabric.

Some quilters like to use curved safety pins

for quick basting. Avoid oversized pins.

Remove pins as you sew. Do not sew over

pins. Broken pins or needles in your bobbin

case (and eyes) = bad.

Ironing vs. Pressing

Pressing uses heat, moisture and pressure to

manipulate fabric. While ironing is a means

of removing wrinkles, pressing is a sewing

technique, used to blend stitches into fabric,

tidy up seams (pressing them to one side

or open), set curves or sharpen creases. To

properly press, you don’t need to move the

iron much. Pick the iron up and set it down,

pressing downward with just enough pressure to feel your fabric push into the ironing

pad surface (no need to exert huge force).

Lift and move to the next area. Let the iron,

heat and steam do their work. Rapidly dusting the iron over a large area may remove

a few wrinkles and work out the arms, but

pressing keeps a project on track, properly

shaped and sized.

Page 16

approach the machine needle. Perpendicular pinning also helps to prevent puckering.

Learn at Home

—

Pressing can be more effective when using

steam. Steam can come from the iron’s

water reservoir, a spritz with a spray bottle

or it can be created from pressing through

a damp cloth. Spray starch (traditional and

newer scented products) also eases

wrinkles away and keeps fabric crisp

with a professional finish.

Pressing aids come in different forms. Pressing cloths, made of cotton or silk organza

protect delicate fabrics and prevent ‘iron

shine.’ Teflon sheets protect the iron and the

ironing board from getting gunked up with

residue from fusible webbing or interfacing.

Dressmaker’s hams and seam rolls are also

useful for pressing curves and garments.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Basic Maintenance

A clean machine is a happy machine!

“Low Maintenance” is something we all like to hear, and that is what you get with your SAH

machine. Regular cleaning of the bobbin area and feed dogs is all that you really need

to look after. Of course you will want to change your needles as needed too.

After a year or two, you may want to bring your machine in for a check-up and interior

cleaning to get the dust and fibres out of the spots that you can not reach with a lint brush.

You can talk to your dealer about this.

Cleaning — Front-loading machines

1. Turn off your machine.

Raise the needle to its

highest position, lower

the hook cover and

remove the bobbin case

by lifting its hinged latch.

2. Push aside each of the

hook race ring holders.

3. Remove the hook

cover (shuttle race ring),

noting what the top of

the ring looks like.

4. Remove the shuttle,

lifting it out of its ‘nested’

position inside of the

shuttle race.

5. Brush and wipe out

the inside of the shuttle

race and reassemble

the unit.

Cleaning — Top-loading machines

Knob Stopper

1. Turn off your machine.

Raise the needle to its

highest position and pop

open the bobbin cover.

Page 1 7

2. Unscrew the needle

plate and remove the

bobbin case.

———————

Learn at Home

—

3. Brush away the dusty

bits (ewww…). Clean the

interior of the case with

a soft cloth.

4. Replace the bobbin

case. Be sure that it feels

properly seated in position. You should be able

to gently wiggle the knob

on the case towards the

somewhat bouncy

feeling stopper.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

5. Replace the needle

plate and tighten the

screws to secure it.

Replace the cover by

pushing the two prongs

to the left and then

clicking the cover down

into position.

PAGES

Easy First Project

〉〉 PROJECT MATERIALS

• 4 – approximate 4 to 4.5”

squares of cotton fabric

• 4 squares of felt, same size

as fabric

• Top and bobbin thread in a colour

that contrasts with the fabric

• Hand sewing needle

• All purpose sewing foot (A)

• Your SAH sewing machine,

we used the G1206

Coasters — Blissful Pivots

Pivoting, or turning a corner

with the needle in the down position,

is one of those super simple techniques that you will use whenever

you sew. A little bit of practice will

give you time to get to know your

new sewing machine a little better.

There are TWO versions of

Blissful Pivots: Outside and Inside

Outside — Raw Edge Finish

1. Pin fabric and felt WST (Wrong Sides

2. Place under the needle, top side up,

and lower the needle into the down position,

about 1/4˝ in from both edges.

3. Start sewing. Remember to hold the

thread tails. Reverse to lockstitch and continue sewing. Slow down as you approach

1/4˝ from the next edge.

4. Once near the corner, stop sewing.

If your needle is not in the down position,

turn the hand wheel towards you to pierce

the fabric. If taking one more stitch would

extend your sewing line too far, you can

firmly hold the fabric in place while turning the hand wheel to effectively not move

forward.

Together).

6. Repeat at each corner. You can stop after

completing all sides, but continuing around

the entire square two or three times, with

slightly wonky lines gives an interesting

finish and more practice pivoting.

7. When finished, reverse (or lockstitch)

to secure threads.

OPTION: Mark 1/4˝ corners inside from

each corner with a pencil dot, or just “eye”

the measurement. Perfection is not the goal.

5. With the needle down, lift the presser

foot, turn the corner and lower the presser

foot again.

Page 18

———————

Learn at Home

—

8. Trim loose threads and press.

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Easy First Project

9. Press flat. Be careful to turn under

the edges of the gap and press these

flat as well.

Inside — Turned Edge Finish

The steps here are very similar to the Outside version. The difference is that you are

working with fabrics RST, leaving a gap in the

single stitch line for turning right-side-out,

and hand closing the gap. You may choose

to finish with a top stitch.

5. As you make the final pivot to the first

side, prepare to stitch only about 1/3 of the

way down. This will leave a gap in the centre

of the first side for turning.

6. Finish stitching with a reverse or

locking stitch. Snip threads.

1. Pin fabrics RST (Right Sides Together).

2. Staring about 2/3 of the way down the

first side, lower the needle to begin sewing.

Use the OUTSIDE EDGE of the presser foot

as a guide, aligning the fabric edge with the

edge of the foot.

10. Use a hand needle to close this opening

with a whip stitch. (Basically pull the knotted

thread through the seam near the opening

from the inside to bury the knot within the

seam. Pierce the folded edge of each fabric

with the needle and draw the sides together.

Repeat until the gap is closed. Knot thread

inside the seam and clip.)

7. Clip all four corners, careful not to

cut the stitches. This makes for less bulk

when turning out the corners.

11. TOP STITCH OPTION: Top stitching

adds a nice finish to anything from coasters

to garments. This is a good opportunity to

practice. This stitch line runs close to the

fabric edge.

The goal is to leave a gap when done

3. Stitch as in step 3 of “Outside Pivot”.

Stop about 1/4˝ from the edge and pivot.

The Presser foot edge should align with this

next fabric edge. You may have to play a

bit with the first corner to pivot at the right

time, but this gets easier with practice.

4. Continue around the second, third

8. Turn right-side-out. Gently push out all

corners. You may need to use a pointed

object like a blunt pencil to help with this,

but be gentle. The corner stitching will open

if pushed too much.

and fourth sides.

Page 19

———————

Learn at Home

—

Note: the fabric may need to be coaxed

(pushed) along at the beginning until the

feed dogs can catch the fabric and do their

job. Starting between 1/8 and 1/4˝ from the

edge, take a locking stitch and start sewing.

Continue around all sides as you did above.

Press flat to finish. Fill your glass with

refreshing beverage of choice to celebrate

your first project. Cheers!

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Appliqué Project

〉〉 PROJECT MATERIALS

Background material of choice. We used:

• One 8.5 x 30˝ strip of plain

background fabric

• Two 8.5 x 3.5˝ strips of print fabric

for ends

• Scrap fabrics for houses and hearts

• Small piece of fusible webbing for fusing

hearts (brands like Wonder Under or

Steam a Seam work well)

• Two or more thread colours with

matching bobbins wound

House He{art}: A Moving on Project

Appliqué: the art of stitching

one fabric shape to another, is the

focus for this project. Appliqué

can take many forms, but the most

casual stitched form would be raw

edge appliqué.

You can choose to use a simple straight

stitch, which will be fairly similar in form to

our Blissful Pivots, or you can play with your

machine’s selection of decorative stitches.

We have also added a simple bit of fused

appliqué with the small hearts. While raw

edge appliqué gives a soft and ‘thready’

edge, the fused appliqué has a firmer edge.

A first step is to decide what type of background that you would like your appliqué

practice piece to be on. We stitched a few

fabrics together to create little table scarf

<2>

Page 2 0

(to practice our seams), but you can use

a pillow, tea towel, tote bag, or any other

flat surface.

Our simple house motif is made from rectangles and triangles. You choose the size;

no templates needed!

3. On each long edge of the scarf, fold the

fabric edge over about 1/4˝. Press and then

fold again to encase the raw edge in the

hem. Press and pin in place.

Sew On! Appliqué is an easy embellishment

technique that has many applications. It is

especially fun for customizing kids projects

with names, favourite animals or themes.

Eventually you can try out different forms

of appliqué like faced or turned edge.

4. Stitch the hem in place from the back

side. Use the presser foot edge as a guide.

Repeat steps 3 & 4 on the short edges of

the scarf. When done, all four sides will be

hemmed.

Preparing Your Base fabric

5. Either at this point or after the appliqué

1. Pin together the shorter edge of the plain

and print fabrics at each end of the scarf.

Using the presser foot edge as a guide, stitch

a straight seam line from one outside end to

the other. Remember to lock your stitches at

each end. Repeat for the other end of

the scarf.

<3>

———————

2. Press the seam open and flat from the

back side.

Learn at Home

<4>

—

is added, embellish the joining seem lines

with a decorative or zigzag stitch. This

serves to hold the seam flat. You can follow

the directions for Patchwork seams in the

manuals of most of the SAH machines (1218

and higher.

<5>

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Appliqué Prep and Ideas

Tip: Removing the pin after the first line of

stitching is completed can be helpful with

small patches of fabric. Otherwise, the lift

caused by the pin may cause a bubble or

pucker as you near completing the stitching

of a shape. Smooth your fabric flat as you go

and you should have no problems!

Plan out the number

and placement of

appliqué motifs.

Audition different fabrics to see

how nicely they play together.

Cut out assorted rectangles and

triangles for the house and roof

shapes. Lay these out. When happy

with the layout, pin the pieces in

place. Our houses were stitched

with the G1206 and the J1250.

This house repeats the basic

straight stitch pivot. It shows

a nice contrast between single

and multiple lines of stitching.

The straight stitches of the

heart appliqué are done with

multiple pivots to maintain

a curved shape.

Page 2 1

———————

Adding the hearts to the houses is an easy

final step. A scrap of fusible web is ironed

to red fabric. Hearts are drawn on the web’s

paper backing and then they are cut out.

The backing paper is peeled from the shape

and they are fused (ironed) in place. (Please

follow the manufacturer’s directions for your

specific fusible web product).

This utility stitch house makes

use of zigzag and blind hem

stitches for appliqué. The variation of the height of the humble

blind hem stitch shakes things

up a little. The heart is finished

with a satin style stitch made

with a narrow and short zigzag.

Learn at Home

—

Tip: As you lift your needle and presser foot

to remove the fabric from under the needle,

sometimes threads will seem to be caught in

the bobbin case. This is because the stitch

hasn’t finished forming. Turn the hand wheel

towards you to complete the stitch. If the

stitch cannot be completed, a GENTLE wiggle

of the hand wheel forward and back (about

one tenth to one eighth of a turn) should

release the threads. If not, remove the needle

plate to clear any possible thread jam. This fabric print seemed to suggest a simple stitch. The straight

stitch did most of the work. The

joining stitch was used between

the two shapes (this would be

a tricky stitch to pivot neatly

around a corner). The heart

is tacked with cross-stitch X’s.

Each single stitch is made easily

by using the auto lock button.

The traditional blanket stitch

is used on this house, with a

narrower version used on the

heart. The straight baseline of

the blanket stitch is kept off

of the appliqué fabric, running

alongside its edge, while the

horizontal ‘bite’ pierces the

fabric patch and holds it in

place. The star burst decorative

stitch was used on the roof

base just because!

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Good to Know

We asked our experts what they wished they had

known when they started to sew and what they would

tell their beginner selves. Sometimes the answer

was a simple sewing trick. Sometimes it was

something more. Either way, we hope that you

find something helpful for YOU.

I wish I knew when I started to sew…

that — You don’t have to follow the rules – Ok. Maybe just use them

as general guidelines… sometimes.

that — I would be doing this for the next 40 plus years… I would have

organized my sewing room better and sewn up my fabrics as I bought them!

that — My sewing did not have to be perfect to be shown in public.

Too many lovely pieces were hidden away.

“

“

that — There are NO “Quilting Police! There might have been a few

at one time but I am sure their “jobs” were made redundant.

Mistakes are your

one-of-a-kind

“design features.”

And there’s a lot

to be learned from

what our mistakes

teach us.

”

We can learn a lot from an easy project but we can get discouraged with

one that is too complicated.

Certain fabric types are recommended for certain projects. (My first big project,

in grade seven, was a thick wale, corduroy skirt with an elastic waist. It was

so stiff that it stood up by itself.)

Its worth learning how to put in an invisible zipper. They are not that scary,

and they look great.

I was about the

‘destination’ not

the journey.

I changed that.

Page 2 2

Pass It On…

”

———————

Recycling. Fabulous doesn’t have to cost a fortune. I love to go to thrift stores

now and look at the fabrics that inspire me to create something new.

Have more than one project on the go. When one is not making you happy

or coming together as you like, move on to the other one.

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

PAGES

Good to Know

Always prewash dry and iron before starting a new project to avoid a bad fit.

Don’t wind one thread over another on a bobbin. The result will be a bad tension

for seemingly no reason. And, always use Janome bobbins because they are the

proper width and height for your machine.

For better control of fabric and building confidence using your machine, use a

heavier fabric for your first project.

Turn the machine and iron on at the same time. Press every seam and your work

will look good.

Better quality needles, threads and fabric are worth the investment to

avoid breakage and frustration.

Take the time to learn how to find your “happy creative space” to relax,

let go of all the stresses and worries of daily life. Let creativity take over. Even if only for ten minutes.

“

“

Get to know, embrace and develop your sewing style. Understand that it may

not be the same as your decorating or clothing style. Colour palettes, textures

and forms that appeal to your sewing self may be similar or different from

your shopping self. Go with it!

You can sew for

the sake of creating.

Sewing can transform

a wardrobe, a room

or a life.

”

You will be your biggest critic. You might see the imperfections but most others

will not. They will praise you for being so creative and you should feel

awfully proud of your sewing and quilting projects.

Challenge yourself; whatever that may be. Don’t be afraid to keep learning.

Feed your passion.

Take a class, borrow

a book, visit a

museum or show.

Look at the wide

world of design and

ask how it influences

your sewing.

Page 2 3

Accuracy is important for many (not all) quilting projects so that your finished blocks

look good but there is no need to get terribly stressed about 1/4˝ inch seams. So

long as you remain consistent throughout your project, the end result will be lovely.

”

———————

Make time to organize your space and supplies. Its not all about cleaning,

its about being familiar with the fabrics and threads that you love.

Playing with them inspires new ideas.

Babies do not walk at 3 weeks old, nor at even 6 months, and so it is with folks

who start sewing or quilting. Allow yourself the luxury of time to take baby steps.

It is a very natural progression. Enjoy the learning. You are already on your way:

you have a new JANOME sewing machine and lots of access

to information to help you every step of the way!

Learn at Home

—

S e w i n g 1 0 1 : G e t t i n g t o K n o w Y o u r M a c h i n e ———————

© Copyright 2026