Effects of Isolation Methods and Conditions on the Properties of

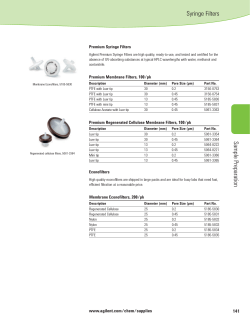

Effects of Isolation Methods and Conditions on the Properties of Cellulose Nanocrystals Mi Lia,d,*, Patrick Bassb, Alexander Haywoodc, Maobing Tua a Forest Products Lab and Center for Bioenergy and Bioproducts, School of Forestry and Wildlife Science b Materials Research and Education Center, Samuel Ginn College of Engineering c Department of Chemical Engineering, Samuel Ginn College of Engineering d Current affiliation: Oak Ridge National Laboratory, Oak Ridge, TN 37831 * [email protected] Introduction Results Cellulose, an almost inexhaustible biopolymeric raw material in the world, exhibits fascinating structure and properties such as semi-crystallinity, sustainability, biodegradability, and modifying capacity. The amorphous regions of cellulose are readily hydrolyzed by acids whereas the crystalline regions are left as rod-like intact cellulose – cellulose nanocrystals(CNCs) – which are “the most dominant fundamental building block of the biosphere” (Fig. 1). A variety of advanced nanoscale materials with important properties inherited from cellulose can be developed from CNCs. The wide application of CNCs based materials, inexpensive, green, and renewable, would establish a platform for environment friendly high-tech devices generation. However, the physiochemical properties of CNCs vary highly on the isolation techniques and cellulosic sources. 1. Aqueous dispersion of CNCs. Acid hydrolysis b c HO OH Sample Average length Elemental analysis (%) Zeta potential C H N S (mV) 100 µma 43.49 6.82 0.08 0.29 ND 2 µma 42.25 5.84 0.02 0.12 ND HCl-CNCs 496 nm 42.60 6.64 0 0.26 ND H2SO4-CNCs-50 335 nm 39.58 6.56 0 0.89 -28.77±0.23 H2SO4-CNCs-100 118 nm 41.28 6.72 0 1.21 -62.13±1.10 H2SO4-CNCs-FP 220 nm 41.73 6.51 0 0.95 -30.73±0.78 Avicel Avicel sonicated Fig. 2 Aqueous dispersion o f unhydrolyzed cellulose (a), H2SO4 hydrolyzed cellulose (b), and biphasic form of CNCs liquid crystals (c). Transvers cutting OH a Table 1. Elemental analysis and zeta potential of Avicel and CNCs. HO OH O OH OH OH O O O O HO HO HO HO 2. SEM images of CNCs. HO OH O crystalline amorphous Cellulose elementary fibril CNCs Fig. 1 Schematic illustration of CNCs production from cellulose by acid hydrolysis. Materials and methods Two cellulose, ashless filter paper and Avicel PH101, were used to prepare CNCs with different acids – HCl and H2SO4. The Avicel and filter paper were hydrolyzed by 64% H2SO4 at 45ºC for 50 min. Additional 50 min was extended on Avicel hydrolysis. The CNCs were isolated by successive centrifugation and wash, followed by dialysis and sonification and were designated as H2SO4-CNCs and H2SO4-CNCs-FP, respectively. The HCl-CNCs were prepared by hydrolyzing Avicel through 4 M HCl at 80ºC for 5 h. The isolation process was the same as that for H2SO4-CNCs. Fig. 3 SEM images of H2SO4-CNCs (left) and HCl-CNCs (right) from Avicel. 3. TGA analysis. The physiochemical properties of CNCs, such as aqueous dispensibility, surface charges and zeta potential, elemental composition, geometrical dimensions, thermostability, and lyotropic phase behavior were characterized by Zetasizer, CHNS/O analyzer, SEM, TGA, and polarized optical microscopy. Objectives CNCs were prepared from Avicel and filter paper with HCl or H2SO4 in order to investigate the effects of cellulose source and reaction conditions on the physical and chemical properties. Conclusions 1. CNCs were prepared from different acid, HCl or H2SO4 , showed different dispersibility. The better dispersion of H2SO4–CNCs in water was due to the introduction of the negatively charged sulphate groups. The presence of -OSO3- groups on surface of H2SO4–CNCs was confirmed by negative values of zeta potential and the increased content of sulfur. Fig 4 TGA curves of Avicel, HCl-CNCs, H2SO4CNCs, and H2SO4-CNCs-FP). Fig 5 Polarized optical micrograph of 6.7 wt% H2SO4-CNCs-100 (the picture was taken 15 min in equilibrium after the drop casting). 4. Lyotropic phase behavior. 6% 10% 15% 5% 9% 15% 2. HCl-CNCs and H2SO4–CNCs prepared from Avicel possessed different dimension inducing higher aspect ration for H2SO4–CNCs. 3. However, H2SO4–CNCs compromised its thermal stability with the presence of -OSO3groups whereas the HCl-CNCs retained the decomposition property of cellulose. 4. Lastly, the H2SO4–CNCs produced from Avicel showed different lyotropic phase behavior from that produced from filter paper. Acknowledgments Authors are grateful to USDA-NIFA for financial supports. Authors are indebted to all the supports from Department of Mechanical Engineering and Chemical Engineering, SFWS. Fig. 6 Polarized light microscopy images of H2SO4-CNCs-100 (top) H2SO4-CNCs-FP (bottom) suspensions with different weight percentage at 25ºC.

© Copyright 2026