BlueOcean`s Algae Production System

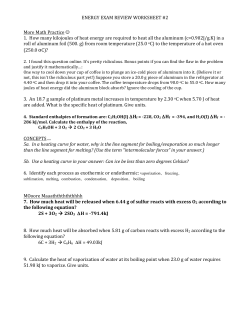

120 Adelaide Street West, Suite 2400, Toronto, Ontario, Canada, M5H 1T1 -‐ Tel: 416-‐859-‐0909 or 613-‐661-‐6788 -‐ Email: [email protected] -‐ www.blueoceannutra.ca BlueOcean’s Algae Production System BlueOcean NutraSciences (TSXV:BOC) has developed a proprietary algae production system to economically produce high value algae products targeted at the rapidly growing nutraceutical health and wellness markets. CO2 Infusion Technology The core technology in BOC’s algae production system is its patented CO2 infusion technology. The technology infuses CO2 into water at a molecular level by displacing other molecules in the water such as oxygen and nitrogen, and replacing them with carbon dioxide (CO2). The CO2 is infused and completely dissolved into the water in a bubble-‐less solution to levels up to 1 gram of CO2 per liter of water (maximum CO2 saturation is 1.5 g/L) and can be adjusted to the required CO2 level by the strain. Bubble-‐less CO2 Benefits The bubble-‐less CO2 further stays in solution as they are not in bubbles which rise and gas-‐off. The bubble-‐less nature of the CO2 in solution, the high levels of dissolved CO2 in solution, and with the CO2 remaining in solution, makes the CO2 more bio-‐ available to organisms such as microalgae that require CO2 as a nutrient. Since the high amounts of CO2 causes the media pH to drop, a buffer can be added to raise the pH to whatever level is required for the respective strain being grown, yet this adjustment of pH upwards does not result in CO2 off-‐gas so both the high CO2 levels and optimum pH levels can be achieved. These high levels of CO2 also make it unfriendly for bacteria and other contaminants that require oxygen to survive, thus preventing contamination. The CO2 infused media has been proven to enhance algae production yields by 2 to 3 times by Canada’s National Research Council, Community College of New Brunswick and St. Cloud State University. Multiple CO2 Sources The CO2 can be sourced from a variety of sources including pure bottled CO2, ethanol CO2 emissions, brewery CO2 emissions and anaerobic digester biogas emissions (biogas typically contains 40% CO2 and 60% methane). If the CO2 source is bottled then the CO2 can be delivered directly into the PBR via the mini infusers. If the CO2 source is from biogas, or other large emissions, then the CO2 infusion can be done on the front end by the large scale infusion system and that CO2 infused media can be delivered to the PBR or raceway pond, with mini infusers lodged in the PBR or pond to provide top up CO2 if required. The large CO2 infusion system has been proven to infuse CO2 from biogas and the CO2 infused media delivered to BOC’s former 10,000 gallon PBR design. While enhanced algae production rates were achieved, BOC has decided to move away from the 10,000 gallon design to improve the capital and operational economics of the algae production system. See the YouTube video of the large CO2 infusion system and 10,000 gallon PBR: https://www.youtube.com/watch?v=nb4uKS-‐mmGw Photo-‐Bio Reactor BOC has further developed the core CO2 infusion technology into a complete algae production system. The system is comprised of the CO2 infusion system which infuses the CO2 into the media in a photo bio-‐reactor (PBR). The PBR is a re-‐purposed 250 gallon tote where the infuser is lodged in. The light nutrient is provided by LED lights from the top of the PBR and is delivered deep into and throughout the PBR through PVC tubes. The system also has a CO2 probe and light meter which is connected to the CO2 infuser and LED lights to provide the culture with the optimum CO2 levels and light intensity in order to achieve maximum growth yields. The entire system is automatically controlled by an automated PLC system. Each strain requires an appropriate harvesting and extraction technique which are integrated based on the strain produced and required end product. BlueOcean is developing its own high EPA omega-‐3 algal oil product with AZCATI (Arizona Centre for Algae Technology and Innovation) and is also offering its complete algae production system or just the CO2 infusion technology to other algae companies that are interested in enhancing their algae production yields, on a license or joint venture basis. 250 gallon PBR design with smaller CO2 infuser when sourcing bottled CO2 Large scale CO2 infusion system when sourcing CO2 from emissions Intellectual Property BlueOcean’s microalgae growth patent portfolio now includes: US Patent 6,209,855 US Patent 6,436,290 US Patent 7,537,200 Canadian Patent 2,271,170 European Patent 1,173,271 Australian Patent 778,289

© Copyright 2026